WAXES, POLICOSANOLS AND ALDEHYDES IN SUGARCANE (Saccharum officinarum L.) AND OKINAWAN BROWN SUGAR

(KOKUTO)

YONATHAN ASIKIN

GRADUATE SCHOOL

BOGOR AGRICULTURAL UNIVERSITY BOGOR

I hereby declare that this thesis is my own work and to the best of my knowledge

it contains no material previously published or written by another person, nor

materials which to a substantial extent has been accepted for the award of any

degree or diploma at any university, except where due acknowledgement has been

made.

Bogor, August 2008

Yonathan Asikin

YONATHAN ASIKIN. Waxes, Policosanols and Aldehydes in Sugarcane (Saccharum officinarum L.) and Okinawan Brown Sugar (Kokuto). Under direction of RIZAL SYARIEF and HANIFAH NURYANI LIOE.

Waxes, long chain alcohols and aldehydes were found in several variants of sugarcane (Saccharum officinarum L.) and Kokuto, a non-centrifuged Okinawan cane brown sugar. Long chain alcohols, policosanols, have been reported to have beneficial effect to human health. The composition of wax in sugarcane was analyzed using HPLC with an evaporative light scattering detector. Sugarcane wax composed of 55–60% aldehydes, sterol esters and wax esters, 32–40% alcohols, and small amounts of triacylglycerols, acids and sterols. Extraction of policosanols performed effectively with hexane and methanol (20:1 v/v), while that of long chain aldehydes was with chloroform and methanol (2:1 v/v). Their composition was determined using GC with a flame ionization detector, whereas their compounds were identified using GC-MS. Sugarcane rinds contained up to 500 mg policosanols and 600 mg aldehydes per 100 g sample of Ni 22 cultivar. The content of policosanol and long chain aldehyde in Kokuto was influenced by its production systems. Compositional analysis of the end product confirmed the presence of policosanols and aldehydes up to 85 mg and 8 mg respectively per 100 g sample of Kokuto A, a product of brown sugar manufacture with open pan heating system. Octacosanol and octacosanal were found to be the major wax

components in both sugarcane and Kokuto samples. This study revealed

YONATHAN ASIKIN. Wax, Polikosanol dan Aldehida pada Tebu (Saccharum officinarum L.) dan Gula Coklat Okinawa (Kokuto). Dibimbing oleh RIZAL SYARIEF dan HANIFAH NURYANI LIOE.

Wax tebu (Saccharum officinarum L.) telah menjadi perhatian bagi banyak orang, karena aplikasinya pada berbagai bidang industri dan sifat fungsional dari salah satu senyawa yang terkandung di dalamnya, yaitu alkohol rantai panjang. Senyawa alkohol rantai panjang (C20–C30) atau polikosanol telah banyak diteliti dan dilaporkan terkait dengan dampak positifnya bagi kesehatan manusia seperti menurunkan agregasi platelet, menurunkan kadar LDL dalam darah, dan menghambat sintesis kolesterol. Dalam penelitian ini kandungan dan komposisi kimiawi wax, polikosanol dan aldehida rantai panjang diteliti dari beberapa varietas tebu dan Kokuto, gula coklat non-sentrifugasi dari Okinawa, Jepang.

Tujuan penelitian ini adalah untuk mengetahui komposisi wax, polikosanol dan aldehida rantai panjang dengan analisis TLC, HPLC-ELSD, FID dan GC-MS. Secara khusus, analisis ditujukan untuk mengetahui pengaruh metode dan waktu ekstraksi; pengaruh bagian-bagian batang tebu, varietas dan umur panen tebu; serta pengaruh cara produksi dan jenis Kokuto terhadap kandungan wax, polikosanol dan aldehida rantai panjang pada tebu dan Kokuto.

Sampel yang digunakan dalam penelitian ini adalah bagian-bagian batang tebu varietas Ni 15, bagian kulit dari tujuh varietas tebu (Ni 13, Ni 17, Ni 22, NiF 8, NCo 310, F 161 dan F 177), serta tujuh jenis Kokuto (tipe A–G). Komposisi wax tebu dianalisis secara kualitatif dengan teknik TLC dan dikuantifikasi dengan

HPLC yang dilengkapi detektor evaporative light scattering. Kandungan dan

komposisi senyawa polikosanol dan aldehida rantai panjang dianalisis oleh GC dengan detektor flame ionization, sedangkan struktur senyawanya diidentifikasi oleh GC-MS. Pengaruh setiap percobaan dianalisis secara statistik dengan rancangan acak lengkap satu faktor.

Studi ini memberikan informasi mengenai senyawa fungsional polikosanol yang terkandung pada tebu dan gula coklat. Polikosanol dapat diekstrak secara efektif dengan pelarut heksana dan metanol (20:1 v/v), sedangkan aldehida rantai panjang dengan pelarut kloroform dan metanol (2:1 v/v). Identifikasi senyawa polikosanol dengan GC-MS terlihat pada pola fragmen massa trimetilsilil-eter dari ion target, sedangkan senyawa aldehida rantai panjang teridentifikasi dari pecahan fragmen spesifik dari senyawa aldehida. Oktakosanol dan oktakosanal merupakan komponen penyusun utama dari wax tebu dan Kokuto.

Studi ini mengungkapkan bahwa bagian-bagian tebu, varietas dan umur panen tebu berpengaruh nyata terhadap komposisi dan kandungan wax, polikosanol dan aldehida rantai panjang pada tebu. Komposisi wax tebu yang dianalisis dengan HPLC-ELSD adalah 55–60% campuran senyawa aldehida, sterol ester dan wax ester, 32–40% alkohol, dan sejumlah kecil triasilgliserol, asam dan sterol.

Senyawa polikosanol dan aldehida rantai panjang pada bagian kulit tebu

yang dipisahkan dengan Cane Separation System ditemukan lebih banyak

sampel.

Pengupasan kulit tebu secara manual membuat wax epidermis masih melekat pada sampel, sehingga total polikosanol dan aldehida yang terkandung di dalamnya mencapai 500 mg dan 600 mg per 100 g sampel tebu varietas Ni 22. Total kandungan wax pada kulit tebu tersebut dipengaruhi oleh jenis varietas tebu, kondisi pertumbuhan dan umur tanaman tersebut. Kandungan senyawa aldehida pada kulit tebu meningkat lebih besar dibandingkan dengan senyawa polikosanol sejalan dengan meningkatnya umur tanaman terebut.

Pada gula coklat Kokuto, kandungan polikosanol dan aldehida rantai

© Copyright of this thesis belongs to Bogor Agricultural University (Institut Pertanian Bogor), Indonesia and University of the Ryukyus, Japan, 2008.

All rights reserved.

1. Due acknowledgement must always be made of the use of any material

contained in, or derived from, this thesis.

a. Any person, may however, use content of the thesis for the purposes of

education, private study, research, scientific report or review.

b. The use of any material contained in, or derived from, this thesis must not

make negative effect for the University.

2. The written permission from the University is required before any part of the

WAXES, POLICOSANOLS AND ALDEHYDES IN SUGARCANE (Saccharum officinarum L.) AND OKINAWAN BROWN SUGAR

(KOKUTO)

YONATHAN ASIKIN

Thesis

as partial fulfillment of the requirements for the degree of Master of Science

in the Department of Food Science and Technology

GRADUATE SCHOOL

BOGOR AGRICULTURAL UNIVERSITY BOGOR

Student ID : F251050111

Approved by

Advisory Committee

Prof. Dr. Ir. Rizal Syarief, DESS

Chair Member

Dr. Ir. Hanifah Nuryani Lioe, M.Si.

Acknowledged by

Head of Food Science Dean of Graduate School Study Program

Dr. Ir. Ratih Dewanti, M.Sc. Prof. Dr. Ir. Khairil Anwar Notodiputro, M.S.

I would like to thank God, Lord Jesus Christ, for his mercy and spirit

throughout my study and thesis work in Graduate School of Bogor Agricultural

University, Indonesia. He always helps and protects me. I can do everything

through Christ who strengthens me.

This thesis owes its existence to the help, support and inspiration of many

people. Firstly, I would like to express my sincere appreciation to Prof. Dr. Rizal

Syarief as Chair of Advisory Committee for his support and encouragement

during my study in Bogor Agricultural University. I am very grateful to Dr.

Hanifah Nuryani Lioe as Member of Advisory Committee for her advice and

supervision during the thesis work. I am also indebted to Dr. Feri Kusnandar as

Non-committee Examiner for his constructive comments on this thesis.

I would like to thank University of the Ryukyus, Japan for the Short Term

Regular Program (STRP) and for giving me the opportunity to conduct my

research in Laboratory of Food Chemistry, Department of Bioscience and

Biotechnology, Faculty of Agriculture, University of the Ryukyus; and the Japan

Student Service Organization (JASSO) for the scholarship.

I would like to express my sincere appreciation to my supervisor during

STRP period, Prof. Dr. Koji Wada, Head of Laboratory of Food Chemistry,

Faculty of Agriculture, University of the Ryukyus for his advice and support

throughout the research. I gratefully thank Dr. Kensaku Takara for valuable

discussions during my research work. I also would like thank Okinawa Prefectural

Agricultural Research Center, Japan for providing sugarcane and Kokuto samples.

I wish to thank all lecturers and colleagues, especially IPN 2005, at the

Food Science Study Program of Graduate School of Bogor Agricultural

University. It has been a pleasure to work with you.

Last but not least, many thanks to my parents, brother and sisters for their

true and endless love, for never-failing patience and encouragement.

Bogor, August 2008

Yonathan Asikin was born in Karawang, West Java Province, Republic of

Indonesia, on November 24, 1981. After graduating from Karawang State Senior

High School (SMUN 1 Karawang) in 1999, he entered Bogor Agricultural

University, Indonesia, from 1999 to 2003 where he obtained a Bachelor (Sarjana)

of Agricultural Technology degree in Food Technology in 2003.

He entered Graduate School of Bogor Agricultural University, majoring

food science (Master Program), in 2005. During school he attended Short Term

Regular Program (STRP) in University of the Ryukyus, Japan, from April 2007 to

March 2008 as research student. He conducted his thesis research in Laboratory

of Food Chemistry, Department of Bioscience and Biotechnology, Faculty of

x

Page

LIST OF TABLES ... xi

LIST OF FIGURES ... xii

LIST OF APPENDIX ... xiv

LIST OF ABBREVIATIONS ... xv

INTRODUCTION... 1

LITERATURE REVIEW ... 4

Sugarcane (Saccharum officinarum L.) ... 4

Brown Sugar ... 7

Plant Wax ... 8

Wax Compositional Analysis... 10

Policosanol in Human Health ... 14

MATERIALS AND METHODS ... 17

Materials... 17

Methods ... 19

Wax compositional analysis by TLC and HPLC-ELSD ... 21

Policosanol and long chain aldehyde analysis by GC-FID ... 24

Policosanol and long chain aldehyde identification by GC-MS ... 27

Statistical analysis ... 28

RESULTS AND DISCUSSION ... 30

Sugarcane Wax Composition ... 30

GC Chromatogram and Mass Spectrum of Policosanols and Long Chain Aldehydes... 38

Policosanols and Long Chain Aldehydes in Sugarcane Rind ... 43

Policosanols and Long Chain Aldehydes in Kokuto ... 50

CONCLUSION ... 57

REFERENCES ... 59

xi

Page

1 Scientific classification of sugarcane ... 4

2 Sugarcane producer countries in 2005 ... 5

3 Mixture composition of aliphatic alcohols (policosanols) ... 12

4 Content and composition of policosanols in some materials ... 13

5 Wax compositions of rind part of Okinawan sugarcane cultivars, obtained by HPLC-ELSD ... 34

6 Mass fragmentation pattern of policosanols and long chain aldehydes ... 42

7 Policosanol and long chain aldehyde contents of rind part of Okinawan sugarcane cultivars ... 45

xii

Page

1 Kokuto, Okinawan brown sugar ... 8

2 Rind (a) and (b) pith parts of sugarcane separated by CSS ... 17

3 Cane Separation System (CSS) ... 18

4 Experimental designs of sugarcane wax, policosanol and long chain aldehyde analysis ... 19

5 Production lines of Kokuto ... 20

6 Experimental designs of policosanol and long chain aldehyde analysis in Kokuto ... 21

7 Thin layer chromatography of waxes of several sugarcane cultivars ... 30

8 HPLC chromatogram of sugarcane rind of Ni 15 cultivar ... 32

9 Standard curve of triacylglycerol ... 32

10 HLPC chromatograms of wax composition standards ... 33

11 Policosanol and long chain aldehyde contents in sugarcane Ni 15 cultivar, obtained by GC-FID... 36

12 Typical gas chromatogram of (a) policosanol and long chain aldehyde standards, (b) Kokuto A, (c) sugarcane rind of Ni 15 cultivar ... 39

13 Standard curve of octacosanol ... 40

14 Mass spectrum of trimethylsilyl ether of C28 of standard ... 41

15 Mass spectrum of trimethylsilyl ether of C28 of Kokuto ... 41

16 Mass spectrum of C28 aldehyde of sugarcane rind of standard ... 42

17 Mass spectrum of C28 aldehyde of sugarcane rind of Ni 15 cultivar ... 42

18 Influence ofsoxhlettimes on policosanol and long chain aldehyde extraction of sugarcane rind of Ni 15 cultivar ... 43

xiii 21 Product derivates from sugarcane ... 49

22 Influence of methods and solvent types on policosanol and long chain aldehyde extraction of Kokuto A ... 51

23 Influence ofsoxhlettimes on policosanol and long chain aldehyde extraction of Kokuto A ... 52

24 Composition of (a) policosanols and (b) long chain aldehydes in Kokuto A . 53

xiv

Page

1 Mass spectrum of trimethylsilyl derivates of policosanols ... 66

2 Mass spectrum of long chain aldehydes ... 69

xv

Abbreviation Term

CSS Cane Separation System

ELSD Evaporative Light Scattering Detector

HPLC High Performance Liquid Chromatography

GC Gas Chromatography

GC-FID Gas Chromatography Flame Ionization Detector

GC-MS Gas Chromatography Mass Spectra

LDL Low Density Lipoprotein

MSTFA N-Methyl-N-(trimethylsilyl) trifluoroacetamide

MTBE Methyl tert-butyl ether

Sugarcane (Saccharum officinarum L.) wax has been a matter of interest,

due to its industry application and functionality of one of its compound, long

chain alcohols. The surfaces of plants, including sugarcane, are coated with

several layers of lipophilic material, the outermost being the epicuticular wax. It

serves many purposes, for example to limit the diffusion of water and solutes,

while permitting a controlled release of volatiles that may deter pests or attract

pollinating insects. It also provides protection from diseases and insects, and

helps the plants resist drought.

Long chain alcohols, which is well-known as policosanols, is a group of

long chain (C20–C30) aliphatic primary alcohols which is of a great interest due

to their health beneficial effect for human health, such as reducing platelet

aggregation, reducing low-density lipoprotein levels in blood, inhibiting

cholesterol synthesis, and ergogenic properties (Castano et al. 2003; Singh et al.

2006; Taylor et al. 2003). Long chain aldehydes as well as alcohols are one of

main component of natural wax extracted from plant (Adhikari et al. 2006).

Straight chain aldehyde also was known as one of lipid biomarker in leaves and

roots of plant (Jansen et al. 2006).

Recently, research in policosanol analysis with several kinds of materials

and techniques have been well reported (Adhikari et al. 2006; Wang et al. 2007;

Wu et al. 2007). Sugarcane and its wax have been reported contain a number of

policosanols used as major source in commercial product of policosanol (Irmak et

al. 2006; Morrison et al. 2006; Nuissier et al. 2002). However, only a few

sugarcane and its products.

Kokuto, a unique brown cane sugar, has been traditionally produced in

Okinawa, Japan from sugarcane by non-centrifugal method, without molasses

removing process. This product has been reported to contain some antioxidants

and phenolic compounds (Takara et al. 2002, 2003). It is then expected that

Kokuto as one of cane food product contain much wax components, including

policosanol which has beneficial health effect as described above.

Indonesian sugar industry, back to the seventeenth century, was known as

one of the oldest and biggest sugar industry in the world. It reached its zenith in

the early-thirties when 179 factories produced nearly 3 million MT of sugar

annually. Following several up and down conditions in many periods of times,

yet, since 1967, Indonesia has reverted to a net sugar importer position and since

the mid-eighties imports have continued to rise. The present average cane yields

are thus about 7.5% (Hadisaputro et al. 2008). Thus this study would explored

information of functional compounds potentially contained in sugarcane and

brown sugar. Sugarcane might be potent sources for high value added products

of sugarcane derivates, such as cane wax and policosanol.

The main purpose of this study is to determine wax, policosanol and

aldehyde compositions in sugarcane and Kokuto, Okinawan brown sugar, with

TLC, HPLC-ELSD, GC-FID and GC-MS. Some specific aims were applied in

this study, i.e.:

a. to determine the effect of extraction methods and times on the policosanol

and long chain aldehyde contents of sugarcane rinds and Kokuto,

b. to determine the effect of sugarcane cultivars on wax, policosanol and long

c. to determine policosanol and long chain aldehyde contents in different parts

of sugarcane,

d. to determine the effect of sugarcane harvesting time on the policosanol and

long chain aldehyde contents of the sugarcane rinds,

e. to determine the effect of Kokuto types on the policosanol and long chain

aldehyde contents of the Kokuto, and

f. to determine the effect of Kokuto production types on the policosanol and

A. Sugarcane (Saccharum officinarum L.)

Sugarcane is an important crop due to the economic value of its

products. Sugarcane is a tall thick perennial that belongs to the grass

family (Poaceae). It has stout, jointed, fibrous stalk that are rich in sugar.

The genus Saccharum comprises some different species, such as S.

officinarum, S. barberi, S. sinense, S. edule, S. robustum and S. spontaneumi

(Table 1). Saccharum officinarum and S. spontaneum are thought to be the

ancestors of cultivated sugarcane. Saccharum officinarum was

domesticated in Southeast Asia and originally derived from S. robustum.

All of those species interbreed, and the major commercia

complexet al. 1987).

Table 1 Scientific classification of sugarcane

Kingdom Plantae

Division Magnoliophyta Class Liliopsida Order Poales Family Poaceae

Genus Saccharum L.

Species S. officinarum, S. arundinaceum, S. bengalense, S. edule, S. procerum, S. ravennae, S. Robustum

Sugarcane is a highly productive crop that has high photosynthetic

ability as C4 plant. It requires strong sunlight and abundant water for

months. Sugarcane stalk can grow to heights range 3.05–7.9 m and

measuring 2.54–5.08 cm in diameter. Colors range from white, yellow,

and green to purple.

Sugarcane is mainly cultivated in tropical and subtropical regions.

Indonesia harvested about 436 847 ha and produced 77 MT/ha of cane for

centrifugal sugar (Hadisaputro et al. 2008), of which almost three-quarters

is on Java. Most of the remainder comes from Sumatra, Kalimantan and

Sulawesi. The remainder is cultivated on sugar factory plantations, both

in Java as well as on other islands where the dominant form of sugarcane

cultivation is plantation-style. About 70 percents of the sugarcane areas

are cultivated by farmers, mostly on small to medium sized holdings.

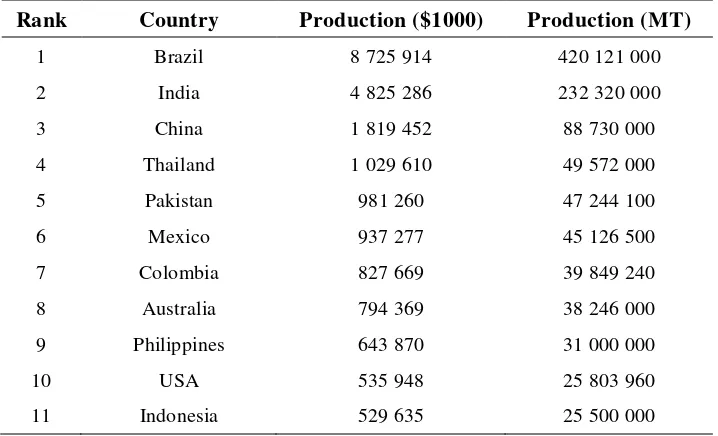

FAO data (2005) mentioned Indonesia in rank 11th of sugarcane producer with 25 500 000 MT or equal to $ 529 635 000 (Table 2).

Table 2 Sugarcane producer countries in 2005

Rank Country Production ($1000) Production (MT)

1 Brazil 8 725 914 420 121 000

2 India 4 825 286 232 320 000

3 China 1 819 452 88 730 000

4 Thailand 1 029 610 49 572 000

5 Pakistan 981 260 47 244 100

6 Mexico 937 277 45 126 500

7 Colombia 827 669 39 849 240

8 Australia 794 369 38 246 000

9 Philippines 643 870 31 000 000

10 USA 535 948 25 803 960

The sugarcane production areas in Japan are limited to the

Southwestern islands, which are located between Taiwan and Kyushu

Island, Japan. The cultivation areas of sugarcane are 20 970 ha in Okinawa

Prefecture and 12 172 ha in Kagoshima Prefecture. Sugarcane occupies

about 50% of agriculture area in Okinawa Prefecture and 60% in

Tanegashima and Amami Oshima regions of Kagoshima Prefecture, and the

crop is considered a key commodity in the region (Takagi et al. 2005).

Sugar is made by some plants to store energy that they do not need

straight away, rather like animals make fat. Scientifically, sugar refers to

any monosaccharide, also called simple sugar, i.e. glucose, fructose and

galactose; or disaccharide, i.e. sucrose (saccharose), maltose and lactose

(Belitz & Grosch 1999). In non-scientific use, the term sugar is used as a

synonym for sucrose, also called table sugar, a white crystalline solid

disaccharide. Many plants produce table sugar although only two are used

commercially and these are commonly known as sugar-cane (Saccharum

officinarum) and sugar-beet (Beta vulgaris). Manufacturing and preparing

food may involve other sugars, including palm sugar and fructose, generally

obtained from fruit.

Typical sugar content for mature cane would be 10% by weight but

the figure depends on the variety and varies from season to season and

location to location. Equally, the yield of cane from the field varies

considerably but a rough and ready overall value to use in estimating sugar

production is 100 MT of cane per hectare or 10 MT of sugar per hectare

B. Brown Sugar

Brown sugar is a sucrose sugar product with a distinctive brown color

due to the presence of molasses resulted from caramelization of sucrose. It

is made up of sucrose with greater amounts of ash, invert sugar and

compounds derived from the process that give the sugar its characteristic

flavor and color. Brown sugar is used in several confections such as

caramels, toffees and butterscotch (Potter & Hotchkiss 1995). In Asia,

Africa and South America non-centrifugal sugars are made for direct

consumption and are known by a range of names: Kokuto in Japan, Gur in

India and Bangladesh, Desi in Pakistan, Jaggery in Africa, and Panela in

South America.

There are two categories of brown sugar: those produced directly

from the cane juice at the place of origin and those that are produced during

the refining of raw sugar. The first type includes a variety of molasses and

syrups. The second type is coated brown or soft sugars and a variety of

refinery molasses and golden syrups. The brown sugar types can be

further divided into those where the crystals are separated (centrifuged) and

those that are not separated (non-centrifuged) from the molasses.

Brown sugar is known to contain antioxidant compounds that have

radical-scavenging activity and related functions such as anticancer effects

and regulation of blood pressure. Takara et al.(2002, 2003) reported that

Kokuto, Okinawan brown sugar (Figure 1) have antioxidative phenolic

glycosides. They are expected to be effective in the prevention of many

polyphenol content and volatile composition in seven cane brown sugars

(four from La Réunion, two from Mauritius and one from France), and the

relation to their unique free radical scavenging capacity.

Figure 1 Kokuto, Okinawan brown sugar.

C. Plant Wax

The term wax is derived from the Anglo-Saxon word weax which was

used to describe the material in the honeycomb of bees. Wax generally

refers to all waxlike solids and liquids found in nature and to those

individual organic substances that crystallize on cooling and melt on heating.

The nature of lipid constituents can vary greatly with the source of the waxy

material, such as hydrocarbons, sterol esters, aliphatic aldehydes, primary

and secondary alcohols, wax esters, diols, ketones, β-diketones,

triacylglycerols, and so on (Dominguez & Heredia 1998).

The surfaces of plants are covered by several layers of lipophilic

hydrophobic barrier of the plant surface, and as such they function primarily

to shed water and prevent nonstomatal water loss (Koch et al. 2006). In

addition, they provide a first line of defense against bacterial and fungal

pathogens and against abiotic stresses such as drought and UV damage

(Reisige et al. 2006). Epicuticular waxes also play a role in plant-insect

communication, by either attracting or deterring insects. This superficial

material is synthesized by specialized cells in the outermost layers of the

plant tissue. The amount of plant cuticular waxes produced is dependent on

growth conditions, whilst chemical composition is less influenced by

environmental factors. In general, wax yield from leaves and fruits of

many species is ranging between 20 and 600 µ g/cm2

Sugarcane wax is the whitish to dark yellowish powdery deposit on the

surface of the stalks of Saccharum officinarum L. During the milling of the

cane, a large portion of this powdery substance is detached and mixed with

the expressed juice. Sugarcane wax has been chemically defined as a

complex and variable mixture of long-chain alkanes, hydrocarbons, fatty

acids, ketones, aldehydes, alcohols, and esters (Nuissier et al. 2002; Purcell

et al. 2005), and steroids such as β-sitosterol, stigmasterol, ketosteroids and

hydroxyketosteroids (Goerges et al. 2006).

(Dominguez & Heredia

1998).

All compounds of plant wax have their own unique roles. However,

only few researches have been investigated wax components functions in

plant and their metabolism to date. Rutherford and Staden (1996) reported

a correlation of high ratio of alcohol to aldehyde and shorter carbon chain

saccharina Walker. Morris et al. (2000) described 1-octacosanal

(C28-aldehyde) as the major component of wheat epicuticular wax that

stimulates oviposition of the Hessian fly, Mayetiola destructor.

Comparison of the activity of five straight-chain primary aldehydes with

chain lengths from C22 to C30 revealed a relationship between chain length

and the number of eggs laid by female Hessian flies, with 1-hexacosanal and

1-heptacosanal the most active of the aldehydes tested.

Wax is valuable source for many industries such as cosmetic, food

ingredient, lubricant, printing and many other applications. Wax esters,

oxo esters of long-chain fatty acids esterified with long-chain alcohols, can

be used as high pressure lubricants, as replacements for hydraulic oil, and in

the pharmaceuticals, leather, and food industries, as well as in candles and

polishes. Long chain alkanals are known as favorable cosurfactants of

liquids containing charged micelles (Meziani et al. 1997). Lately, long

chain aliphatic alcohols of sugarcane wax have been used as

cholesterol-lowering products (Taylor et al. 2000; Castano et al. 2003).

D. Wax Compositional Analysis

Wax content and composition, including long chain alcohols and

aldehydes, can be analyzed with many techniques and instruments. The

determination of wax composition often requires extensive sample extraction

and preparation prior to instrumental analysis. Cuticular wax from potato

leaf was extracted by dipping and shaking the leaves in dichloromethane

spermaceti, carnauba, candellila and Japan waxes (Regert et al. 2005).

Sorghum wax was extracted from grain sorghum using hot hexane and

precipitating it in a -18°C (Hwang et al. 2002; Adhikari et al. 2006).

Similar extraction concept was applied by Kanya et al. (2007), where

sunflower seed wax was purified from oil refineries through extraction using

solvents and precipitation with chilled acetone. Liquid-liquid extractions

were successfully applied in beeswax, sugarcane and wheat (Irmak &

Dunford 2005; Irmak et al. 2006).

Recently, non conventional methods for wax extraction have been

developed with many techniques. Super critical carbon dioxide extractions

were reported to have higher waxes yields than solvent extractions, i.e.

cuticular wax from flax processing waste (Morrison et al. 2006), beeswax

(Jackson & Eller 2006), and sugarcane crude wax (Lucas et al. 2007).

Solvent-free extraction with high-intensity ultrasound treatment was studied

in rice bran wax. Under sonochemical conditions bran wax could also be

hydrolyzed yielding long chain alcohols (Cravotto et al. 2004). Molecular

distillation was used to increase the purity of octacosanol (C28-alcohol)

extracts from transesterified rice bran wax (Chen et al. 2005, 2007).

Compositional analysis of wax can be conducted with some

instruments, whether qualitative or quantitative analysis. Thin layer

chromatography was widely used to separate wax components (Hwang et al.

2002; Adhikari et al. 2006). Analytical methods of wax quantification

were applied with high performance liquid chromatography (Hwang et al.

2002; 2005). Wax compounds were identified and confirmed by gas

2003; Kanya et al. 2007) and liquid chromatography-mass spectrometry with

atmospheric pressure chemical ionization (Rezanka & Sigler 2006).

Main components of plant waxes were composed of fatty aldehydes,

fatty alcohols, fatty acids, hydrocarbons, wax esters, sterol esters and

triacylglycerols (Hwang et al. 2002; Adhikari et al. 2006), based on HPLC

data. Recently, mixture of long chain aliphatic primary alcohols,

policosanols, has been well investigated with gas chromatography technique

(Cravotto et al. 2004; Irmak & Dunford 2005; Irmak et al. 2006; Wang et al.

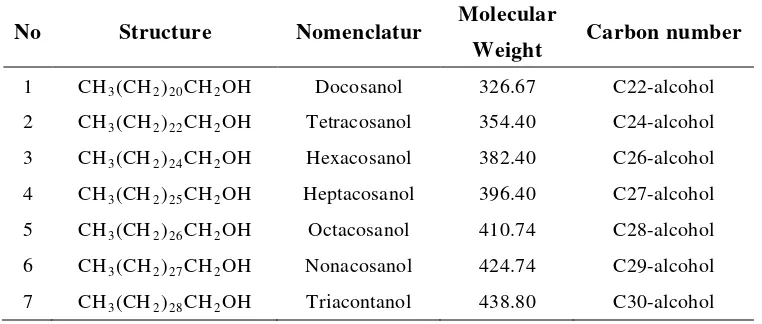

2007). The mixture contains mainly docosanol (C22), tetracosanol (C24),

hexacosanol (C26), octacosanol (C28), and triacontanol (C30), listed in

Table 3.

Table 3 Mixture composition of aliphatic alcohols (policosanols)

No Structure Nomenclatur Molecular

Weight Carbon number

1 CH3(CH2)20CH2OH Docosanol 326.67 C22-alcohol

2 CH3(CH2)22CH2OH Tetracosanol 354.40 C24-alcohol

3 CH3(CH2)24CH2OH Hexacosanol 382.40 C26-alcohol

4 CH3(CH2)25CH2OH Heptacosanol 396.40 C27-alcohol

5 CH3(CH2)26CH2OH Octacosanol 410.74 C28-alcohol

6 CH3(CH2)27CH2OH Nonacosanol 424.74 C29-alcohol

7 CH3(CH2)28CH2OH Triacontanol 438.80 C30-alcohol

Sugarcane is the major source for the production of commercial

policosanol products. Irmak et al. (2006) reported that sugarcane peel

contained the highest amount of total policosanols, about 270 mg/kg. The

total policosanol contents of sugarcane leaves (181 mg/kg) were quite

compositions of sugarcane plant parts varied significantly, C28 (about 81%)

was the main component in all the sugarcane samples (Table 4).

Policosanols in the perilla seeds were composed of 67–68 % octacosanol,

16–17% hexacosanol, and 6–9% triacontanol. The analysis of

commercially milled wheat grain fractions, germ, bran, shorts, and flour

showed that policosanols where concentrated in the bran. Wheat germ

contained a significant amount of policosanols (10.1 mg/kg). These results

were expected since policosanols are associated with lipids and wax in plant

tissues. About 36% of the total policosanols in the wheat bran fraction was

[image:30.595.134.515.411.632.2]constituted of tetracosanol.

Table 4 Content and composition of policosanols in some materials

No Material Policosanol content (mg/kg)

C24 C26 C28 C30

1 Whole sugarcane a 1.68 ± 0.08 0.9 ± 0.2 10 ± 0.2 1.0 ± 0.2

2 Sugarcane peel a 7.7 ± 0.2 2.3 ± 2 219 ± 3 16 ± 2

3 Sugarcane leaves a 29.4 ± 0.5 22.4 ± 0.8 84 ± 4 26.6 ± 0.6

4 Beeswax (brown) a 2.6 ± 0.1 1.7 ± 0.1 2.0 ± 0.1 5.7 ± 0.5

5 Beeswax (yellow) a 1.11 ± 0.06 0.86 ± 0.07 0.90 ± 0.03 2.3 ± 0.4

6 Perilla Seed (Korea) b 1.6 ± 0.13 17.6 ± 0.01 68.4 ± 1.44 6.8 ± 1.42

7 Perilla Seed (China) b 1.5 ± 0.06 16.6 ± 0.43 67.4 ± 0.07 9.1 ± 0.17

8 Wheat germ c 1.4 ± 0.2 n.d. 2.9 ± 0.3 2.5 ± 0.3

9 Wheat bran c 10.68 ± 0.01 4.87 ± 0.03 4.39 ± 0.02 n.d.

10 Wheat shorts c 0.82 ± 0.01 0.45 ± 0.03 0.39 ± 0.01 0.22 ± 0.03

Note: n.d. = not detected

a

Irmak et al. (2006)

b

Adhikari et al. (2006)

c

E. Policosanol in Human Health

Much research has been done on the potential of policosanols in

lowering blood cholesterol and reducing the development of atherosclerotic

plaques (Rodriguez et al. 1997; Arruzazabala et al. 2002). Studies have

involved a wide range of subjects including experimental animals, healthy

volunteers, and elderly patients with hypercholesterolemia. Several studies

also have reported cardiovascular benefits of policosanols and its major

component octacosanol, without major adverse effects.

Policosanols may decrease the risk of atheroma formation by reducing

lipid levels, platelet aggregation, endothelial damage, and the development of

foam cells. Octacosanol may decrease cholesterol synthesis in the liver

before the generation of mevalonate. Octacosanol may down regulate the

cellular expression of 3-hydroxy-3-methylglutaryl coenzyme A (HMG-CoA)

reductase. Treatment with octacosanoic acid isolated and purified from

sugarcane wax suppressed HMG-CoA reductase production in cultured

fibroblasts, and this finding suggests a possible depression of de novo

synthesis of the enzyme and cholesterol (Menendez et al. 2001).

Furthermore, Singh et al. (2006) described that policosanol inhibits

cholesterol synthesis in hepatoma cells by activation of AMP-kinase and is

well established to suppress HMG-CoA reductase activity.

Research indicates that octacosanol at a dose of 5 mg/day may

reduce LDL and total cholesterol in patients with borderline to mildly

elevated serum triacylglycerol levels (Castano et al. 2003) and in

Combination treatment policosanol (10 mg/day) and omega-3 fatty acid (1

g/day) has been associated with significant inhibition of platelet

aggregation in rabbits compared with either drug alone (Castano et al.

2006).

Absorption and metabolism of nonesterified policosanol have been

studied by many researchers. Hargrove et al. (2003) mentioned that the

liver may be converting octacosanol to long chain fatty acids, which were

subsequently taken up by muscle. The study identified that the administered

octacosanol was found in sterols and triacylglycerol, which indicated

conversion to fatty acids and esterification. Policosanol metabolism is

linked to fatty acid metabolism via β-oxidation. Menendez et al. (2005)

demonstrated that octacosanoic acid was formed after incubation of fibroblast

cultures with 3H-octacosanol and after oral dosing with policosanol to rats.

In addition, shortened saturated (myristic, palmitic and stearic) and

unsaturated (oleic, palmitoleic) fatty acid were also formed after oral dosing

with policosanol to monkeys.

More rapid onset of effects suggests that oxidation of policosanols to

very long-chain fatty acids may be necessary for their hypocholesterolemic

actions and enhance the breakdown of LDL particles (McCarty 2005). In

another study, dietary octacosanol was thought to increase lipid catabolism

to generate more energy for improvement of motor endurance; and this

action may contribute in reductions of plasma triglyceride levels.

Octacosanol is already recognized as an ergogenic product used to enhance

In an effort to identify the potential mechanism for the

antiatherogenic effects of policosanols, Ng et al. (2005) investigated the

effects of these natural compounds on LDL oxidation and bile acid

excretion. Policosanols showed no antioxidant activity in human LDL

particles but increased bile acid secretion in hamsters.

However, other research groups using policosanol from alternative

sources have failed to reproduce the efficacy of these alcohols observed in

earlier studies. Lin et al. (2004) reported that wheat germ policosanol 20

mg/day had no beneficial effects on blood lipid profiles in subjects with

normal to mildly elevated cholesterol concentrations. Kassis et al. (2007)

mentioned that sugarcane policosanol treatment at a dose of 275 mg/kg diet

had any significant cholesterol-lowering effect on plasma lipid levels in

A. Materials

1. Samples

Whole parts of sugarcane stalk of Ni 15 cultivar, rind parts of seven

varieties of sugarcane (Ni 13, Ni 17, Ni 22, NiF 8, NCo 310, F 161 and F

177 cultivars), seven types of Kokuto (type A–G) and two non-Japan

brown sugars (type P from Thailand and type Q from Bolivia) were used

as materials. Rind and pith parts of sugarcane stalk (Figure 2) were

separated by cane separator, known as CSS (Cane Separation System),

from Mitsubishi Engineering Co. Ltd., Japan (Figure 3) and by hand

peeling. Kokuto samples were available products from 2007 to 2008

production year of Kokuto manufacturers in Okinawa Prefecture, Japan.

Cane juice and end product from Kokuto production line were also used in

[image:34.595.169.490.544.686.2]this study.

Figure 2 Rind (a) and (b) pith parts of sugarcane separated by CSS.

Figure 3 Cane Separation System (CSS).

2. Materials and Reagents

The policosanol standards used consist of docosanol (C22),

tetracosanol (C24), hexacosanol (C26), octacosanol (C28), and

triacontanol (C30). They were purchased from Sigma (Sigma Chemical,

St. Louis, MO). Derivatization reagent N-Methyl-N-(trimethylsilyl)

trifluoroacetamide (MSTFA) was purchased from GL Science (Japan).

Pyridinium chlorochromate, from Sigma (Sigma Chemical, St. Louis, MO),

was used for synthesis of long chain aldehyde standards.

Several chemicals were used as standards in analysis of wax

composition. They were triacontane, octacosanol, cholesteryl oleate,

lignoceric acid, methyl palmitate and stigmasterol from Sigma (Sigma

Chemical, St. Louis, MO), synthesized aldehyde (octacosanal), and triolein

(Nakarai Chemicals Ltd., Japan). HPLC grade hexane (Wako Pure

Chemical Industries Ltd., Japan) and methyl tert-butyl ether (Kanto

Chemicals Co. Inc., Japan) were used as mobile phases in HPLC analysis.

All reagents and chemicals were of analytical and HPLC grade, unless

B. Methods

Samples (sugarcane and Kokuto) were prepared and kept dry before

use. Sugarcane and cane juice samples were freeze-dried for 24 h. Then

all samples were crushed and ground with dry blender. Parts of sugarcane

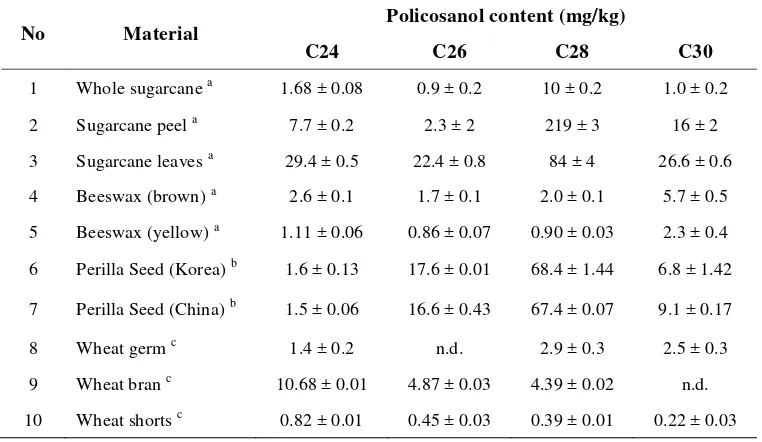

samples were separated by CSS and hand peeling. Those sugarcane samples

were extracted for their wax, policosanol and long chain aldehyde compounds,

and analyzed as shown in experimental design below (Figure 4). Wax

composition of extracted samples were qualitatively separated by thin-layer

chromatography (TLC) and quantified by HPLC-ELSD. Policosanol and

long chain aldehyde contents and compositions were analyzed with GC-FID

and its compounds were identified with GC-MS. All listed quantification

runs were analyzed statistically ANOVA with completely randomized design.

Figure 4 Experimental designs of sugarcane wax, policosanol and long chain aldehyde analysis.

Sugarcane

CSS separation

Ni 15 cultivar

Whole, pith and rind

Policosanol and long chain aldehyde

analysis

Rind

Extration times variation

Policosanol and long chain aldehyde

analysis

Rinds of 8 cultivars

Policosanol and long chain aldehyde

analysis Hand peeling separation (rinds) Mature cane (12 months) Wax compositional analysis Harvesting times (9 and 12 months)

Policosanol and long chain aldehyde

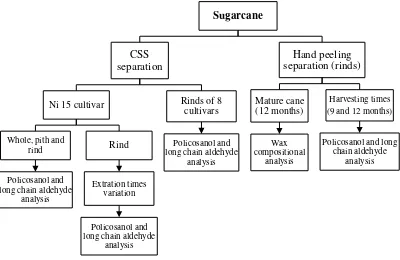

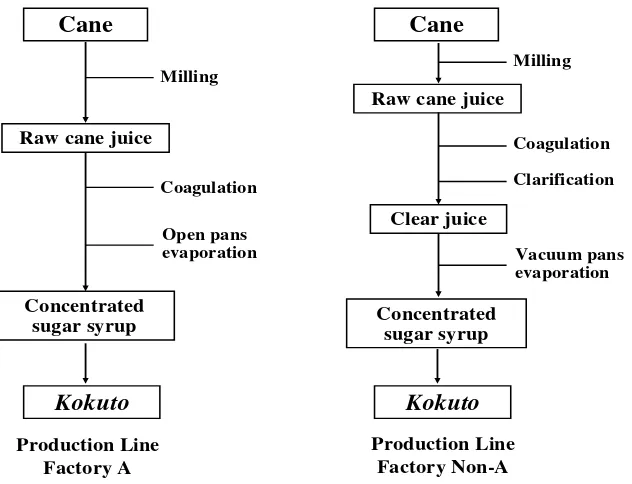

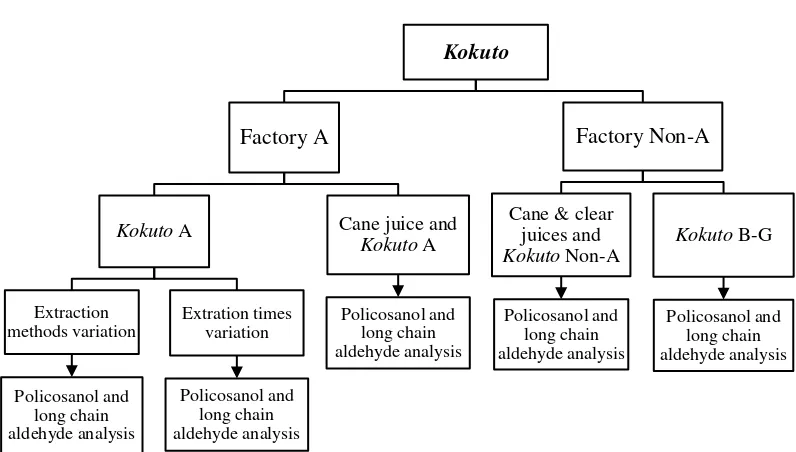

[image:36.595.125.525.434.694.2]Kokuto samples were obtained from two types Kokuto factories

(Figure 5); there were the traditional factory with open pan method (Kokuto A)

and the modern factory with vacuum pan technology (Kokuto Non-A). Raw

cane juice, clear juice and end product of both production lines were compared

to investigate the effect of Kokuto production types on policosanol and long

chain aldehyde contents. Several extraction methods and times were tried as

shown in the experimental design (Figure 6). Samples of Kokuto B–G were

collected from the modern factories (Kokuto Non-A type). Policosanol and

long chain aldehyde contents and compositions were analyzed with GC-FID

and its compounds were identified with GC-MS. All listed runs were

analyzed statistically ANOVA with completely randomized design.

Production Line Factory Non-A Milling

Open pans evaporation

Kokuto

Production Line Factory A Raw cane juice

Cane

Coagulation

Clear juice

Concentrated sugar syrup

Milling

Vacuum pans evaporation

Kokuto Raw cane juice

Cane

Coagulation

Concentrated sugar syrup

Clarification

[image:37.595.161.477.427.669.2]

Figure 6 Experimental designs of policosanol and long chain aldehyde analysis in Kokuto.

1. Wax compositional analysis by TLC and HPLC-ELSD

a. Standard preparation

Several compounds were used as standards of wax components:

triacontane (for hydrocarbon), synthesized octacosanal (aldehyde),

cholesteryl oleate (sterol ester), octacosanol (alcohol), triolein

(triacylglycerol), lignoceric acid (acid), methyl palmitate (methyl ester)

and stigma sterol (sterol). Those standards were prepared in toluene for

TLC analysis and in chloroform with different concentrations (0.05–0.50

mg/ml) covering the levels of sample components for quantification of

each wax component by HPLC analysis.

Kokuto

Factory A

Kokuto A

Extraction methods variation

Policosanol and long chain aldehyde analysis

Extration times variation

Policosanol and long chain aldehyde analysis

Cane juice and

Kokuto A

Policosanol and long chain aldehyde analysis

Factory Non-A

Cane & clear juices and

KokutoNon-A

Policosanol and long chain aldehyde analysis

KokutoB-G

b. Sugarcane wax extraction

Briefly, 10 g of freeze-dried rind of sugarcane were placed in

Advantec No. 84 thimble filter and extracted using soxhlet for 4 h with

about 150 ml of hexane, methanol (20:1 v/v). The solvent solution was

removed from the extract with rotary-evaporator under vacuum condition

at 40°C. The amount of dry wax extract was weighed and diluted with

toluene for TLC analysis and with chloroform down to 1–2 mg/ml to the

reach detection level of ELSD used in HPLC analysis.

c. TLC Analysis

Thin-layer chromatography (TLC) of waxy materials extracted

from sugarcane rind samples using a silica gel 60, 20 cm × 10 cm × 250

µm TLC plate. Cholesteryl oleate, methyl palmitate, synthesized

octacosanal, triolein, lignoceric acid, octacosanol and stigma sterol were

used as standards. Samples and standards were eluted with two steps of

developing solvents. The first solvent mixture, comprising hexane,

diethyl ether, acetic acid (95:5:1 v/v/v), was allowed to travel 10 cm

before the plate was removed and the solvent allowed to evaporate.

Once dried, the plate was redeveloped in hexane, diethyl ether, acetic

acid (80:20:1 v/v/v) to the top of the plate. Developed bands were

visualized by spraying the plate with 10% cupric sulfate solution

containing 8% phosphoric acid. Then the TLC plate was dried in heater

d. HPLC-ELSD analysis

Wax components were separated and determined as previously

reported by Adhikari et al. (2006), using HPLC equipped with a Luna

silica column (250 mm × 4.6 mm i.d. × 5 µm film thickness) connected

to a guard column (4 × 3 mm i.d.) supplied by Phenomenex (Torrance,

CA). Two Shimadzu LC-10AD-VP pumps were operated in

combination with a Shimadzu SCL-10A-VP gradient controller. The

column and guard column temperature were kept constant at 40°C by a

Shimadzu CTO-10AC-VP. Shimadzu model LT evaporative light

scattering detector was operated at 50°C with nitrogen pressure 350 kPa.

Mobile phases consisted of a gradient of hexane (solvent A) and methyl

tert-butyl ether containing 0.2% acetic acid (solvent B), with the

following profile: 0–2 min, 100% A; 3–10 min, 95% A; 14 min, 55% A;

23–26 min, 0% A; then 27–40 min, 100% A. Flow rate of mobile phase

was 1 ml/min. Injection volume of samples and standard were 5 µl.

The detection limit of this analysis was 0.01 mg/ml.

Several compounds were used as standards, i.e. triacontane,

cholesteryl oleate, synthesized octacosanal, triolein, lignoceric acid,

octacosanol and stigma sterol. Wax component contents in analyzed

samples were determined based on the relation between peak area and

calibration curve of each standards. Wax contents were calculated in

percentage (%, w/w) and concentration (mg/100 g sample, wet weight

basis) by following equations:

Component A (%) =Peak area of component A

Concentration (mg/100g) =

Content�mgml�∗× Volume of extract (ml) × 100

Sample weight (g)

where content (*) was calculated by calibration curve of its standard.

2. Policosanol and long chain aldehyde analysis by GC-FID

a. Standard preparation

Mixed policosanol standards for policosanol compounds

quantification were prepared in toluene. Aldehyde standards were

synthesized from their alcohols form by oxidation with pyridinium

chlorochromate, as described by Pérez-Camino et al. (2003). Each 1

mM corresponding alcohols standards (19.14 mg hexacosanol, 20.54 mg

octacosanol, 21.94 mg triacontanol) and 9 mM pyridinium

chlorochromate (97.5 mg) were stirred in 50 ml dichloromethane for 1.5

h at room temperature. The reaction mixture was eluted with

dichloromethane through a short column (6 × 2 cm I.D.), packed with

silica gel 60. Then the reaction product was dried by N2 gas and diluted

in toluene. The synthesized long chain aldehyde standards were

checked with GC-FID analysis.

b. Sample extraction

Kokuto A samples were extracted with two extraction methods in

order to investigate the optimum extraction method; they were

liquid-liquid extraction (LLE) by the method of Irmak et al. (2006) and

method was applied to policosanol and long chain aldehyde contents

analysis in sugarcane and other Kokuto samples.

Liquid-liquid extraction (LLE) method. Briefly, 6 g of Kokuto

sample was mixed with 50 ml of 1.0 N NaOH and 50 ml of methanol and

subsequently hydrolyzed by refluxing in a heater for 30 min. After

cooling, the mixture was filtered through Advantec No. 5A filter paper

under vacuum condition. Then Millipore water was added to the filtrate.

The solution was extracted three times with 50 ml diethyl ether.

Combined diethyl ether phases from three extractions were neutralized

with Millipore water until pH of water phase reached 7. The extract

was dried over 50 g of anhydrous sodium sulfate by storing at 4°C for

one night. Then the solvent was removed from the extract with

rotary-evaporator under vacuum condition. The dry extract was diluted

in toluene or chloroform and made up to 2 ml prior to analysis.

Solid-liquid extraction (SLE) method. Briefly, 10 g of

freeze-dried sugarcane or 6 g of Kokuto were placed in Advantec No. 84

thimble filter and extracted using soxhlet with about 150 ml of several

systems of organic solvent. The solvent systems were Soxhlet A

(chloroform, methanol (2:1 v/v)); Soxhlet B (hexane, methanol (10:1

v/v)); Soxhlet C (hexane, methanol (20:1 v/v)); Soxhlet D (hexane,

methanol (30:1 v/v)); and Soxhlet E (hexane). Several extraction times

were also attempted in order to investigate the heat stability and optimum

extraction condition of policosanol and long chain aldehyde compounds

in sugarcane and Kokuto samples. The solvent solution was removed

Then the dry extract was diluted in toluene and made up to 2 ml for

GC-FID analysis, whereas for GC-MS analysis, the extract was diluted in

chloroform.

c. Gas chromatography analysis (GC-FID)

Shimadzu GC 17-A equipped with a fused capillary column (DB

5, 0.25 mm i.d. × 30 m × 0.25 µm film thickness) from J&W Scientific

(Folsom, CA) and a flame ionization detector were used for policosanol

and long chain aldehyde quantitative analysis. The GC injector was set

at 350°C and the flame ionized detector 350°C. The samples (1 µl)

were injected with split ratio of 1:10. The carrier gas was helium with a

flow rate of 1 ml/min. The oven temperature was programmed at

150°C as initial temperature, raised to 320°C at 4°C/min and maintained

at 320°C for 15 min.

By injecting mixture standards of policosanol and aldehyde with

different concentrations covering the levels of sample extracts, relation

between concentration and peak height was plotted for calibration.

Concentrations of standard solutions for the standard curve were

0.05–0.50 mg/ml. The detection limit of this analysis was 0.01 mg/ml.

Policosanol and long chain aldehyde concentrations were calculated as

mg/100 g sample (wet weight basis for sugarcane) by this following

equation:

Concentration (mg/100g) =

Content�mg ml�

∗

× Volume of extract (ml) × 100

Sample weight (g)

3. Policosanol and long chain aldehyde identification by GC-MS

The silylated derivatization was used for mass spectrum analysis of

policosanol, however mass spectrum of aldehyde was analyzed without

silylation. In this case, policosanol was identified as its trimethylsilyl

derivates. N-Methyl-N-(trimethylsilyl) trifluoroacetamide (MSTFA) was

used as silylation reagent. The derivatization solution was made by mixing

0.5 ml of sample in chloroform with 250 µl MSTFA. The solution was

heated at 50°C for 15 min. The volume of the mixed solution was made up

to 1 ml with chloroform for GC-MS analysis. Derivatization was also

applied for policosanol standard solution at concentration of 0.1 mg/ml.

The analysis was performed using Shimadzu GC-MS QP-2010 with

a fused capillary column DB-5 MS (0.25 mm i.d. × 30 m × 0.25 µm film

thickness) from J&W Scientific (Folsom, CA) under the same GC

conditions. The samples (0.3 µl) were injected with split ratio of 1:10.

For MS detection, the electron impact (EI) ion source and transfer line

temperature were set at 200°C and 280°C. The ionization energy was

mode at 70 eV. The mass acquisition scan range and rate were 30–500

amu and 2 scans/s. Identification of each policosanol or aldehyde was

conducted by comparing its retention time and mass spectrum directly to

those of its respective standard. The mass spectrums were also confirmed

with NIST 2005 Mass Spectral Library by GCMSsolution software

4. Statistical analysis

All extraction runs and analysis were carried out in triplicate and

analyzed statistically using ANOVA with completely randomized design.

The mean values of analysis results were reported. The data were analyzed

by SPSS Version 13.0 for Windows (SPSS Inc., USA, 2003). Univariate

comparisons of the various means were carried out by post hoc test of

Duncan at p = 0.05. Nine experimental designs were attempted with

statistical analysis, there were:

a. The effect of rind parts of sugarcane cultivars on wax composition (3

samples, i.e. NiF 8, Ni 15 and Ni 22 cultivars).

b. The effect of different parts of sugarcane of Ni 15 cultivar on the

policosanol and long chain aldehyde contents (3 samples, i.e. rind, pith

and whole stalk).

c. The effect of extraction times of rind part of Ni 15 cultivar on the

policosanol and long chain aldehyde contents (5 extraction times, i.e. 2, 4,

8, 16 and 24 h).

d. The effect of sugarcane cultivars on the policosanol and long chain

aldehyde contents of the sugarcane rinds (7 samples, i.e. Ni 13, Ni 15, Ni

17, NiF 8, NCo 310, F 161 and F 177 cultivars).

e. The effect of sugarcane harvesting time on the increasing of total

policosanol and long chain aldehyde contents of the sugarcane rinds (5

samples, i.e. NCo 310, Ni 15, Ni 17, NiF 8 and Ni 22).

f. The effect of extraction methods of Kokuto A on the policosanol and

long chain aldehyde contents (6 extraction methods, i.e. a liquid-liquid

g. The effect of extraction times of Kokuto A on the policosanol and long

chain aldehyde contents (5 extraction times, i.e. 4, 8, 16, 24 and 32 h).

h. The effect of Kokuto types on the policosanol and long chain aldehyde

contents of the Kokuto (9 samples, i.e. type A–G, P and Q).

i. The effect of Kokuto production types on the policosanol and long chain

aldehyde contents (5 samples, i.e. raw juice and end product of Kokuto

factory A; and raw juice, clear juice and end product of Kokuto factory

A. Sugarcane Wax Composition

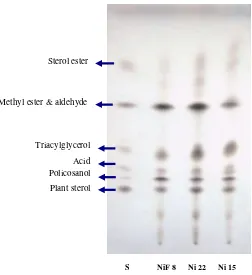

The qualitative separation of most of the major classes of aliphatic

[image:47.595.174.426.407.682.2]wax components could be achieved by silica gel of thin layer chromatography

(Figure 7). Compositions of the waxy materials from sugarcane cultivars

were all similar. They were composed of sterol, alcohol, acid,

triacylglycerol, methyl ester, aldehyde and sterol ester. Thin layer

chromatography had been widely used for qualitative analysis in waxy

materials (Hwang et al. 2002; Adhikari et al. 2006; Webster et al. 2006).

Figure 7 Thin layer chromatography of waxes of several sugarcane cultivars. S: Standard.

S NiF 8 Ni 22 Ni 15

Plant sterol Policosanol Acid Triacylglycerol Sterol ester

Wax components of sugarcane on TLC plate could finally be

visualized by cupric sulfate charring. Each component of waxy materials

was well charred and separated, except for sterol ester which split into two

smear bands. These two separated bands were identified by Adhikari et al.

(2006) as wax ester and sterol ester. Besides this, methyl ester and aldehyde

were appeared as a single spot, while acid and policosanol as closed dense

spots.

Separation of cane wax components by high performance liquid

chromatography (HPLC) were further quantified with evaporative

light-scattering detector (ELSD). Five peaks in HPLC chromatogram were

identified as groups of aldehyde, sterol ester, triacylglycerol, acid, alcohol,

and sterol (Figure 8). Wax component contents in analyzed samples were

determined based on the relation between peak area and calibration curve of

each standards. An example of standard curve of triacylglycerol is shown in

Figure 9, it has a linear equation of y = 1E+07x – 52429. These standards

(Figure 10) had different concentrations covering the levels of components in

samples, i.e. 0.05–0.50 mg/ml.

This result confirmed the same result obtained by TLC. Every peak

represented one group of wax components, except for peak 1 which was a

mixture of aldehyde and sterol ester. However, Hwang et al. (2002) and

Adhikari et al. (2006) identified this peak as mixture of aldehyde, sterol ester

and also wax ester. A very weak respond of hydrocarbon compound

somewhat was detected (after 3 minutes retention), but it was not enough for

Figure 8 HPLC chromatogram of sugarcane rind of Ni 15 cultivar. The chromatogram was obtained by HPLC-ELSD method.

Peak 1 : Aldehyde, sterol ester Peak 4 : Alcohol

Peak 2 : Triacylglycerol Peak 5 : Sterol

[image:49.595.137.497.111.330.2]Peak 3 : Acid

Figure 9 Standard curve of triacylglycerol. y = 1E+07x - 524294

R² = 0.9987

0 1,000,000 2,000,000 3,000,000 4,000,000 5,000,000 6,000,000

0.00 0.10 0.20 0.30 0.40 0.50 0.60

P

ea

k

A

rea

Concentration (mg/ml)

0.0 5.0 10.0 15.0 20.0 25.0 30.0

0.2 0.4 0.6 0.8 1.0

0.0

1

2 3 4

5

[image:49.595.164.490.350.682.2]Figure 10 HLPC chromatograms of wax composition standards. (a) aldehyde, (b) sterol ester, (c) triacylglycerol, (d) acid, (e) alcohol, (f) sterol. Standards concentrations were 0.5 mg/ml (a-d) and 0.4 mg/ml (e-f). The chromatograms were obtained by HPLC-ELSD method.

(a) (b)

(c) (d)

Wax components in sugarcane rind were composed of mixture of

aldehydes and sterol esters (55.1–60.4%), alcohols (31.8–39.8%),

triacylglycerols (2.3–4.6%), acids (2.0–2.7%), and sterols (0.5–0.9%),

respectively (Table 5, Figure 8). Significant differences (p < 0.05) were

observed in all wax composition of Okinawan sugarcane cultivars. The

highest content of wax component was found in sugarcane rind of Ni 22

cultivar with about 1 g of mixture of aldehydes and sterol esters per 100 g

sample (wet weight basis). Followed with mixture of aldehydes and sterol

esters of NiF 8 and Ni 15 cultivars, i.e. 751.0 and 594.6 mg/100 g. The

alcohol group, policosanols, of Ni 22 cultivar sample was 462.9 mg/100 g;

while sterol group was less abundant and its response became too small for

making a detectable peak.

Table 5 Wax compositions of rind part of Okinawan sugarcane cultivars, obtained by HPLC-ELSD.

Cultivar Aldehyde,

sterol ester* Triacylgycerol Acid Alcohol Sterol

% (w/w)

NiF 8 55.1 ± 1.1 b 3.7 ± 0.4 b 2.7 ± 0.1 a 39.8 ± 4.0 a 0.5 ± 0.03

Ni 15

b

60.5 ± 3.0 a 4.6 ± 0.6 a 2.4 ± 0.4 ab 31.8 ± 2.1 b 0.9 ± 0.2

Ni 22

a

58.5 ± 1.8 ab 2.3 ± 0.2 c 2.0 ± 0.2 b 37.3 ± 1.9 ab n.d.

mg/100 g

‡c

NiF 8 751.0 ± 29.4 q 101.7 ± 10.7 p 62.0 ± 1.6 p 367.5 ± 8.1 q 33.3 ± 0.01

Ni 15

p

594.6 ± 32.6 r 80.2 ± 6.0 q 39.0 ± 1.4 q 216.4 ± 14.7 r 25.3 ± 0.2

Ni 22

q

1027.1 ± 66.5 p 97.0 ± 6.9 p 63.2 ± 3.1 p 462.9 ± 7.6 p n.d.r

*Calculated as aldehyde group.

‡

Not detected.

a

Data are means ±S.D. (n = 3). Means in the same column with the same letter are not

[image:51.595.135.512.485.664.2]Similar separation method and stationary phase of wax component of

plant waxes were applied in grain sorghum (Hwang et al. 2002), perilla and

sesame seeds (Adhikari et al. 2006), potato leaves (Szafranek & Synak 2006),

and calanoid copepod Calanus finmarchicus (Webster et al. 2006). The

amounts and compositions of these waxes were markedly different depended

on their genetics, bio-functions, plant growth conditions, and environments.

Another HPLC technique of wax components separation was using alumina

as stationary phase (Nordback & Lundberg 1999).

Plant waxes are a complex heterogeneous mixture of very long chain

(C20–C34) fatty acids and their derivatives. During wax biosynthesis very

long chain fatty acids are further modified to aldehydes, alkanes, ketones, and

so on. Grain sorghum and carnauba waxes compositions were well

investigated by Hwang et al. (2002). Grain shorghum wax was composed of

46.3% (w/w) fatty aldehydes, 7.5% fatty acids, 41.0% fatty alcohols, 0.7%

hydrocarbons, 1.4% wax esters and sterol esters, and 0.9% triacylglycerols.

Carnauba wax contained of 34.3% wax esters, 5.1% fatty acids, undetermined

amount of fatty alcohols, and 3.0% triacylglycerols, determined by HPLC.

Major components of the waxy materials from Korean and Chinese

perilla seeds were alcohols (25.5 and 34.8%), hydrocarbons (18.8 and 10.5%),

wax esters, steryl esters and aldehydes (53.0 and 49.8%), acids (1.7 and

2.1%), and triacylglycerols (1.0 and 2.9%), based on HPLC data were

reported by Adhikari et al. (2006). The principal components of leaf

cuticular waxes from potato varieties were very long chain n-alkanes,

2-methylalkanes and 3-methylalkanes (3.1–4.6 µg cm-2), primary alcohols

cm-2

In general, sugarcane stalk was composed of sugars 12–16%, water

70–74%, pith fiber 7%, rind fiber 7%, and epidermis 0.1%. Wax would

abundantly found in rind part as epicuticular wax. Figure 11 shows the

comparison of policosanol and long chain aldehyde contents as wax

components in sugarcane stalk. Rind and pith samples were separated by

CSS (Cane Separation System). This study discovered that policosanol and

long chain aldehyde compositions of sugarcane parts varied significantly.

Policosanol and aldehyde compounds in the rind part of sugarcane were

found much abundant than in pith.

), analyzed by GC-FID (Szafranek & Synak 2006). Methyl ketones,

sterols, β-amyrin, benzoic acid esters and fatty acid methyl, ethyl, isopropyl

and phenylethyl esters were found in potato waxes. A new group of

cuticular wax constituents consisting of free 2-alkanols with odd and even

numbers of carbon atoms ranging from C25 to C30 was also identified.

Figure 11 Policosanol and long chain aldehyde contents in sugarcane Ni 15 cultivar, obtained by GC-FID analysis.

Means in the same group with the same letter are not significantly different (p > 0.05).

0 20 40 60 80 100

Rind Pith Whole stalk

A

m

ou

n

t (

m

g/

100 g)

Policosanol

Aldehyde a

p

c r

b

[image:53.595.172.471.503.661.2]The whole stalk of sugarcane Ni 15 cultivar contained 35 mg

policosanols and 24 mg aldehydes per 100 g of wet weight basis. The

policosanol and aldehyde contents in pith part were negligible (about 1

mg/100 g), however, policosanols and adehydes of rind part was found in

high concentration, i.e. 80 mg/100 g. This result is associated with surface

wax present in rind of cane. The surface waxes protect plants from water

lost and environmental stress (Koch et al. 2006; Dominguez & Herdia 1996).

Separation with CSS would make loosing an amount of epicuticular waxes in

rind, while either it separated to epidermis wax chamber or attached in rolls

and blades of CSS. In this way the hand peeled rind samples were also

investigated.

Rutherford and Staden (1996) reported a suggestion of sugarcane

surface wax component towards resistance to borer Eldana saccharina

Walker. In their investigation, a high ratio of alcohol to aldehyde and

shorter chain length appeared to be associated with cane resistance.

Furthermore, Purcell et al. (2005) described epicuticular wax as a potential

genetic marker and predictor of desirable plant traits. According to that a

comprehensive study of wax compositional analysis and eco-geochemistry of

B. GC Chromatogram and Mass Spectrum of Policosanols and Long Chain Aldehydes

Figure 12 shows the typical chromatogram of standard mixture and

sample extracts. All compounds of standard mixture were completely

separated to every single peak (Figure 12a). The retention time of three

synthesized aldehyde compounds (hexacosanal, octacosanal, and triacontanal)

were detected 1 minute faster than their corresponding alcohol compounds.

Quantification of each policosanol and aldehyde compounds in extracted

samples was determined base on the retention time and peak height of each

referred standard.

Derivatization is primarily performed to modify an analyte’s

functionality in order to enable chromatographic separations. The formation

of chemical derivatives to facilitate meaningful analysis has long been a

common practice in gas chromatography. The use of MSTFA as silylation

reagent for derivatization has been reported in policosanol determination

using GC-FID by some researchers (Adhikari et al. 2006; Morrison et al.

2006), however, the use of MSTFA in the pre-study was found in less

effective for policosanol determination comparing to direct analysis.

Besides this, the use of internal standard (i.e. octacosanoic acid) was avoided

due to a number of closed peaks in interest area of chromatogram of samples

(Figure 12b and 12c).

Policosanol and long chain aldehyde contents in analyzed samples

were determined based on the relation between peak height and calibration

curve of each standards. An example of standard curve of octacosanol is

Figure 12 Typical gas chromatogram of (a) policosanol and long chain aldehyde standards, (b) Kokuto A, (c) sugarcane rind of Ni 15 cultivar. The chromatograms were obtained by GC-FID.

Peak 1 : C22-OH Peak 2 : C24-OH

Peak 3 : C26-OH Peak 3a

Peak 4 : C28-OH Peak 4

: C26-CHO

a

Peak 5 : C30-OH Peak 5

: C28-CHO

a

: C30-CHO

0.0 10.0 20.0 30.0 40.0 50.0 (min)

(b) 4 5a 5 3 3a 2 1 4a

0.0 10.0 20.0 30.0 40.0

4a 4 5a 5 (min) 3 3a 2 1 (a)

0.0 10.0 20.0 30.0 40.0 50.0 (min)

(c)

4 5a

[image:56.595.137.526.75.529.2]Figure 13 Standard curve of octacosanol.

Figures 14 and 16 show the mass spectrum of trimethylsilyl ether of

C28, derivate of octacosanol, and C28 aldehyde (octacosanal) as standards.

The policosanol and aldehyde compounds of the samples (Figures 15 and 17)

were identified by direct comparison of their chromatographic retention times