-Page 1 -

PT. Intertek Utama Services

PRE-SHIPMENT INSPECTION

REPORT

JOB NO. : PO130333PS

CLIENT:

PT. AKAR MAS INTERNATIONAL

POMALAA

INDONESIA

-Page 2 -

PRE-SHIPMENT INSPECTION REPORT

NICKEL ORE

AT

STOCK PILE

of

PT. AKAR MAS INTERNATIONAL

REPORT NO

: PO130333PS

ORDER NUMBER

: Email Order on 22-July-2013

CLIENT

:

PT. AKAR MAS INTERNATIONAL

PLACE OF INSPECTION

: STOCK PILE of PT. SSB AND STOCKPILE OF

PT. AKAR MAS INTERNATIONAL IN POMALAA,

SOUTHEAST SULAWESI - INDONESIA

DATE OF INSPECTION

: 30-MAY-2013 UP TO 02 AUGUST 2013

COMMODITY

: SAID TO BE NICKEL ORE

-Page 3 -

TABLE OF CONTENTS:

1.

GENERAL INFORMATION

2.

SAMPLING ACTIVITIES

3.

SAMPLE ANALYSIS

4.

CLOSING

-Page 4 -

PRE-SHIPMENT INSPECTION REPORT

THIS IS TO REPORT, that the Surveyors of PT. Intertek Utama Services, did, at the

request of

PT. AKAR MAS INTERNATIONAL

attended and conducted a pre-shipment

inspection sampling at the stockpile of

PT. SSB and Stockpile of PT. Akar Mas International,

which located in Pomalaa, Southeast Sulawesi, Indonesia.

1. GENERAL INFORMATION

Location of Stockpile

: PT. SSB and PT. Akar Mas International, which located in

Pomalaa, Southeast Sulawesi, Indonesia.

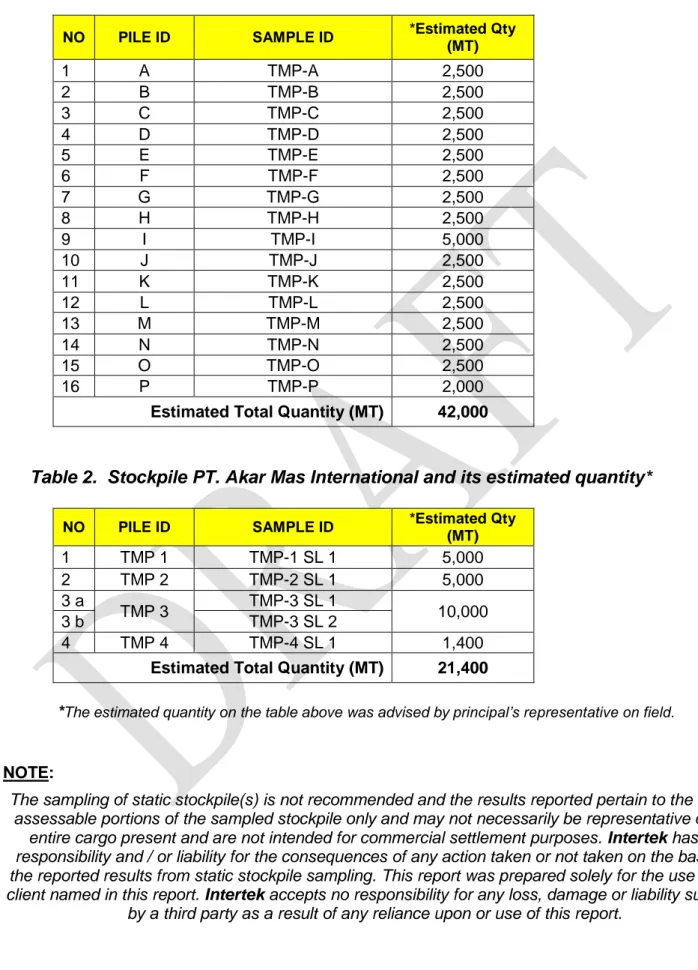

Quantity advised

: Sampling was performed at PT. SSB on estimated total quantity

42,00 MT which consist of 16 piles and at stockpile of PT. Akar

Mas International with estimated total Quantity 21,400 MT which

consist of 8 piles. Quantity of stockpile is based on advice from

cargo owner representative at the site.

2. SAMPLING ACTIVITIES

Sampling at stockpile of PT. SSB was carried out on 30-July-2013 at 11:30 local time and

finished on 31-July-2013at 16:45 local time. The second sampling at stockpile of PT.

Akar Mas International was carried out on 1-August-2013 at 13.05 local time and finished

on 02-August-2013 at 11.30 local time.

Final Preparation was conducted at Intertek Preparation Facility in Pomalaa.

Samples were collected with following details:

There are 16 separated piles at stockpile PT. SSB and 8 separated piles at

stockpile PT. Akar Mas International which inspected by Intertek and as per

advised by cargo owner representative.

The quantity of each pile was not determined but written in the report as per advice

by cargo owner representative (see Table 1 for details).

Sampling was performed using JIS Scoop 125.

Excavator was provided by the cargo owner to open the piles on certain depth.

Based on estimated quantity per pile as per advised by cargo owner representative

on site, amount of grab samples per pile were defined (pile quantity dependant).

Sampling is the random sampling which after dig out the pile on 100 – 300 cm

depth using the excavator, the sample was extracted with the JIS standard scoop

125D on 30-40 cm depth and the grab sample were collected with weight on 20-25

kg per grab sample.

-Page 5 -

Every grab samples which defined for its stock sample will be reduced using

“standard grab samples reduction” to represent each stock sample per pile.

Sampling implement :

1. Sampling scoop 125D (JIS standard)

2. Excavator

3. Sampling Hoe

4. Sampling plastic bag

5. Intertek Security Seal

6. Hammer, etc

Number of Piles

: Total 24 piles

Grab Sample size

: 1 scoopful of ore, weight 20-25 kg approximately

Grab Sample

: Each stock consist about 10 up to 50 grab samples

(Stock quantity dependant)

-Page 6 -

Table 1. Stockpile PT. SSB and its estimated quantity*

NO PILE ID SAMPLE ID *Estimated Qty (MT)

1

A

TMP-A

2,500

2

B

TMP-B

2,500

3

C

TMP-C

2,500

4

D

TMP-D

2,500

5

E

TMP-E

2,500

6

F

TMP-F

2,500

7

G

TMP-G

2,500

8

H

TMP-H

2,500

9

I

TMP-I

5,000

10

J

TMP-J

2,500

11

K

TMP-K

2,500

12

L

TMP-L

2,500

13

M

TMP-M

2,500

14

N

TMP-N

2,500

15

O

TMP-O

2,500

16

P

TMP-P

2,000

Estimated Total Quantity (MT)

42,000

Table 2. Stockpile PT. Akar Mas International and its estimated quantity*

NO PILE ID SAMPLE ID *Estimated Qty (MT)

1

TMP 1

TMP-1 SL 1

5,000

2

TMP 2

TMP-2 SL 1

5,000

3 a

TMP 3

TMP-3 SL 1

10,000

3 b

TMP-3 SL 2

4

TMP 4

TMP-4 SL 1

1,400

Estimated Total Quantity (MT)

21,400

*

The estimated quantity on the table above was advised by principal’s representative on field.NOTE:

The sampling of static stockpile(s) is not recommended and the results reported pertain to the safely

assessable portions of the sampled stockpile only and may not necessarily be representative of the

entire cargo present and are not intended for commercial settlement purposes. Intertek has no

responsibility and / or liability for the consequences of any action taken or not taken on the basis of

the reported results from static stockpile sampling. This report was prepared solely for the use of the

client named in this report. Intertek accepts no responsibility for any loss, damage or liability suffered

-Page 7 -

3. SAMPLE ANALYSIS

Sample analysis was performed at the laboratory of PT. Intertek Utama Services in

Jakarta using XRF method with Laboratory Report No. SS130074 and SS130078.

The detail of analysis result can be seen in the Annex 1.

Our Ref: SS130078

Your Ref: 927376

IDENT Ni Co Al2O3 CaO Fe MgO SiO2 TiO2 LOI UNITS % % % % % % % % % DET.LIM 0.005 0.001 0.01 0.01 0.01 0.01 0.01 0.01 0.1 SCHEME XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 TMP A 1.61 0.03 2.47 0.89 14.02 18.99 45.18 0.03 9.4 TMP B 1.84 0.031 2.51 1.22 14.63 19.45 42.4 0.03 9.4 TMP C 1.78 0.028 2.41 0.82 13.46 19.44 45.62 0.02 9.4 TMP D 1.64 0.031 2.6 0.85 14.83 18.13 44.7 0.03 9.3 TMP E 2.04 0.035 2.68 0.71 15.73 17.98 42.94 0.03 9.5 TMP F 1.92 0.032 2.54 0.81 15.26 18.19 43.2 0.03 9.5 TMP G 2.03 0.036 2.68 0.74 15.88 18.97 41.8 0.03 9.6 TMP H 2.09 0.034 2.64 0.74 15.86 18.85 41.35 0.03 10 TMP I 1.8 0.034 2.71 0.75 14.82 16.35 46.76 0.03 9.1 TMP J 1.94 0.051 3.15 0.67 17.01 13.8 44.23 0.05 9.2 TMP K 1.75 0.036 2.56 0.96 15.22 16.27 46.62 0.02 8.6 TMP L 1.94 0.027 2.27 0.82 12.53 20.54 45.63 0.03 9.8 TMP M 1.92 0.026 2.22 0.91 11.92 20.55 46.61 0.03 9.6 TMP N 1.89 0.026 2.23 0.84 12.43 20.13 46.14 0.03 9.7 TMP O 1.56 0.036 2.93 1.23 15.95 17.05 43.41 0.04 9 TMP P 2.2 0.028 2.33 0.48 13.78 14.09 51.22 0.02 8.6 TMP 1 SL 1 1.77 0.027 2.29 1.45 13.33 20.4 44.36 0.03 8.5 TMP 2 SL 1 1.64 0.03 2.5 1.34 14.33 21.34 41.82 0.03 8.6 TMP 3 SL 1 1.53 0.039 2.68 1.12 16.27 17.02 43.39 0.03 8.7 TMP 3 SL 2 1.53 0.041 2.8 1.21 16.91 16.66 42.52 0.03 8.6 TMP 4 SL 1 2.04 0.03 2.3 1.1 14.41 18.75 44.23 0.02 8.9

-Page 8 -

4. CLOSING

The pre-shipment inspection confirmed the presence of 15 piles where the grab samples of

each pile were prepared such way to represent those piles. The material was said to be

Nickel ore that was visually confirmed to be present at stockpile at the time of the inspection.

This report reflects our findings at the time and place of the inspection and does not refer to

any other matter. The report is issued without prejudice and on the understanding that it does

not relieve parties from their contractual obligations. All inspections covered in this report

have been carried out to the best of our knowledge and ability and in accordance with

practice and standards generally accepted in trade. All work is performed in accordance with

the Intertek Minerals Standard Terms and Conditions of work and is available on

request. http://www.intertek.com/terms/

Jakarta, August 26, 2013

_______________________

Authorized Manager

Note:

Please note that electronic reports are not signed, therefore not considered a final report

document. To ensure the integrity of the analytical data we request that the results be

referenced to the hard copy report

-Page 9 -

PT. Intertek Utama Services

ANNEX 1

Analytical Methods:

Chemical Analysis: Borate fusion X-Ray Fluorescence (XRF) and Loss of Ignition (LOI) gravimetric, determination at 1000

oC. All results reported on a dry basis.

Detail XRF Result

Our Ref: SS130078

Your Ref: 927376

IDENT Ni Co Al2O3 CaO Cr2O3 Fe2O3 Fe K2O MgO MnO Na2O P2O5 P SiO2 TiO2 LOI Total UNITS % % % % % % % % % % % % % % % % % DET.LIM 0.005 0.001 0.01 0.01 0.005 0.01 0.01 0.01 0.01 0.005 0.01 0.001 0.001 0.01 0.01 0.1 0 SCHEME XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 TMP A 1.61 0.03 2.47 0.89 1 20.05 14.02 0.01 18.99 0.354 <0.01 <0.001 <0.001 45.18 0.03 9.4 99.81 TMP B 1.84 0.031 2.51 1.22 1.13 20.92 14.63 <0.01 19.45 0.33 0.06 0.006 0.002 42.4 0.03 9.4 99.23 TMP C 1.78 0.028 2.41 0.82 0.879 19.25 13.46 <0.01 19.44 0.341 0.02 0.005 0.002 45.62 0.02 9.4 99.84 TMP D 1.64 0.031 2.6 0.85 1.05 21.2 14.83 0.01 18.13 0.367 0.04 0.005 0.002 44.7 0.03 9.3 99.77 TMP E 2.04 0.035 2.68 0.71 1.12 22.49 15.73 <0.01 17.98 0.368 0.07 0.005 0.002 42.94 0.03 9.5 99.84 TMP F 1.92 0.032 2.54 0.81 1.12 21.82 15.26 <0.01 18.19 0.356 0.02 0.005 0.002 43.2 0.03 9.5 99.42 TMP G 2.03 0.036 2.68 0.74 1.13 22.7 15.88 <0.01 18.97 0.375 0.07 0.006 0.003 41.8 0.03 9.6 99.97 TMP H 2.09 0.034 2.64 0.74 1.17 22.68 15.86 <0.01 18.85 0.399 0.08 0.006 0.003 41.35 0.03 10 99.88 TMP I 1.8 0.034 2.71 0.75 0.982 21.19 14.82 <0.01 16.35 0.486 0.05 0.005 0.002 46.76 0.03 9.1 99.96 TMP J 1.94 0.051 3.15 0.67 1.21 24.32 17.01 <0.01 13.8 0.951 0.09 0.005 0.002 44.23 0.05 9.2 99.52 TMP K 1.75 0.036 2.56 0.96 1.25 21.76 15.22 <0.01 16.27 0.334 0.02 0.006 0.002 46.62 0.02 8.6 99.69 TMP L 1.94 0.027 2.27 0.82 0.9 17.92 12.53 <0.01 20.54 0.293 0.1 0.007 0.003 45.63 0.03 9.8 99.97 TMP M 1.92 0.026 2.22 0.91 0.857 17.05 11.92 <0.01 20.55 0.269 0.1 0.006 0.002 46.61 0.03 9.6 99.8 TMP N 1.89 0.026 2.23 0.84 0.901 17.77 12.43 <0.01 20.13 0.296 0.08 0.006 0.002 46.14 0.03 9.7 99.68 TMP O 1.56 0.036 2.93 1.23 1.23 22.81 15.95 0.01 17.05 0.352 0.08 0.007 0.003 43.41 0.04 9 99.72 TMP P 2.2 0.028 2.33 0.48 0.955 19.71 13.78 <0.01 14.09 0.345 <0.01 0.003 0.001 51.22 0.02 8.6 99.98

-Page 10 -

Continued

IDENT Ni Co Al2O3 CaO Cr2O3 Fe2O3 Fe K2O MgO MnO Na2O P2O5 P SiO2 TiO2 LOI Total UNITS % % % % % % % % % % % % % % % % % DET.LIM 0.005 0.001 0.01 0.01 0.005 0.01 0.01 0.01 0.01 0.005 0.01 0.001 0.001 0.01 0.01 0.1 0 SCHEME XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 XR81 TMP 1 SL 1 1.77 0.027 2.29 1.45 1.18 19.07 13.33 <0.01 20.4 0.279 0.02 <0.001 <0.001 44.36 0.03 8.5 99.37 TMP 2 SL 1 1.64 0.03 2.5 1.34 1.16 20.5 14.33 <0.01 21.34 0.311 <0.01 0.001 <0.001 41.82 0.03 8.6 99.25 TMP 3 SL 1 1.53 0.039 2.68 1.12 1.31 23.27 16.27 <0.01 17.02 0.378 0.04 <0.001 <0.001 43.39 0.03 8.7 99.45 TMP 3 SL 2 1.53 0.041 2.8 1.21 1.41 24.17 16.91 <0.01 16.66 0.392 <0.01 <0.001 <0.001 42.52 0.03 8.6 99.43 TMP 4 SL 1 2.04 0.03 2.3 1.1 1.16 20.61 14.41 <0.01 18.75 0.304 0.05 <0.001 <0.001 44.23 0.02 8.9 99.46

-Page 11 -

PT. Intertek Utama Services

Annex 2

Photo

Photo 1. Stockpile on point of view_1

-Page 12 -

continued

Photo 3. Sampling Process (1)

-Page 13 -

Continued

Photo 5. Excavator used to assist the sampling (1)

-Page 14 -

Continued

-Page 15 -