Summary

- Purpose of Document

- Management Plan Summary

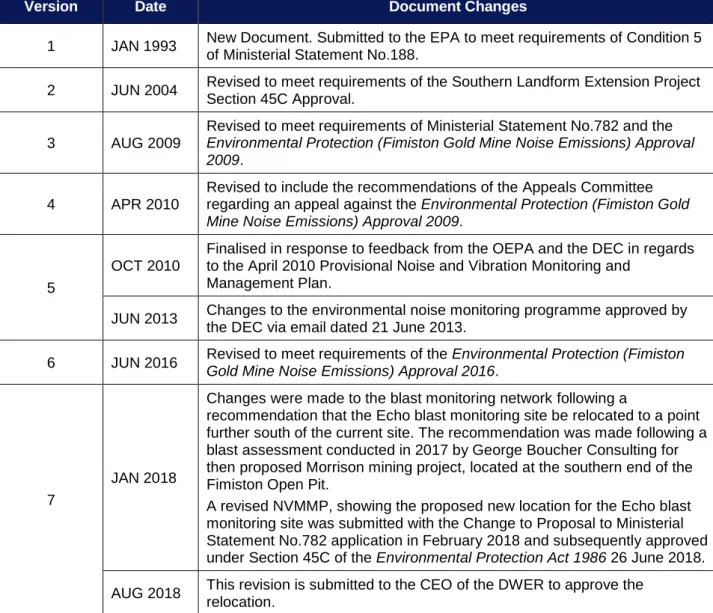

- Document History

- Corporate Endorsement

Revised to incorporate the recommendations of the Appeals Committee regarding an appeal against the 2009 Fimiston Gold Mine Noise Emissions Approval. 6 JUN 2016 Revised to meet the requirements of the Fimiston Gold Mine Noise Emissions Approval ) 2016. AUGUST 2018 This revision is submitted to the CEO of the DWER to approve the move.

Context, Scope and Rationale

- Overview of the Fimiston Operations

- History of Fimiston Noise Approvals

- Key Environmental Factors

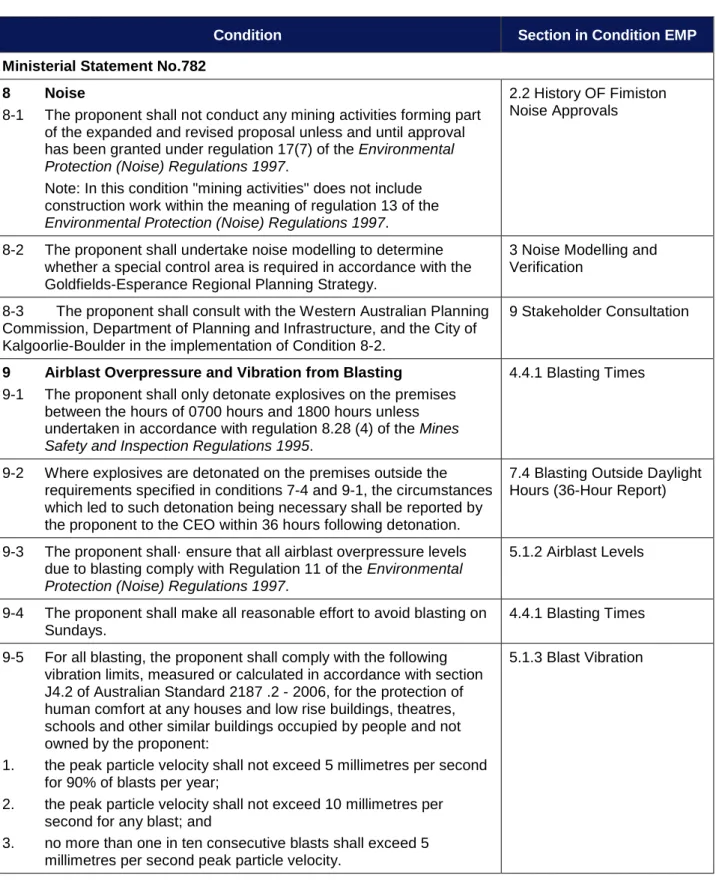

- Requirements of the Condition

In order to allow Fimiston operations to continue, Environmental Protection Authority (EPA) approval has been sought for the expansion of Fimiston Gold Mine operations (Phase 3) and mine closure planning; commonly referred to as the Golden Pike project, which extends the life of the Fimiston open pit until 2019. It has been identified that the existing Fimiston operations may not comply with the noise levels allocated at night under the noise regulations, even if controls are in place (e.g. . environmental noise). In February 2007, the KCGM applied to the Minister for the Environment, in accordance with Regulation 17 of the Noise Regulations, for consent to allow noise emissions to deviate from the prescribed levels.

Noise Modelling and Verification

Section of the condition in the EMP condition 9-6 Within six months of the issuance of the decision notice-. A description of the monitoring equipment and evidence that the equipment complies with the requirements of Schedule 4 of the Environmental Protection (Noise) Regulations 1997 and Section J3.2.l of the Australian Standard. Program in accordance with the requirements of the Minister for the Environment on the advice of the Ministry of the Environment and Conservation.

Management Approach

- Management of Mining Activities

- Environmental Noise Bund

- Surface Activities

- Reversing Alarms

- Mt Charlotte Waste Rock Conveyor

- Management of Haul Truck Noise

- UWA Research Project

- Management of Resource Definition Drilling

- Management of Blast Vibration and Airblast

- Blasting Times

- Blast Design and Modelling

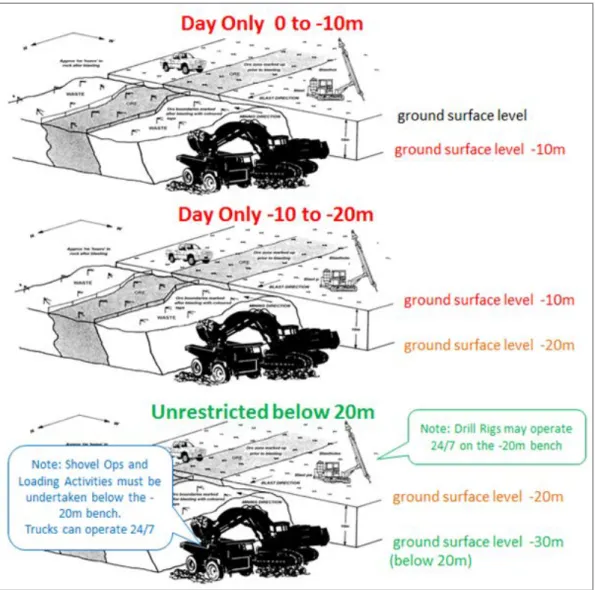

Construction of environmental noise dumps and waste rock dumps occurring in close proximity to residential areas is managed using predictive noise modeling to determine potential noise impacts, and construction activities are restricted to daytime only when necessary. Ensuring that all involved employees and contractors are aware of potential environmental impacts on the community and the importance of noise control measures. The results of an environmental noise study conducted in 1991 identified reversing signals as the main source of noise emissions.

However, the use of the conveyor introduced new noise emission sources, such as creaking rollers and noise from stones falling from the belt and at designated transfer points. KCGM continues to manage noise emissions from the Mt Charlotte Waste Rock Conveyor via routine inspections and maintenance of the conveyor belt, rollers and associated infrastructure. In June 2002, a detailed noise management plan was developed by Herring Storer Acoustics for a drilling program on the west side of the Fimiston Open Pit, which was close to residential areas and noise sensitive premises.

KCGM continued to implement the noise abatement principles and practices described in the 2002 Noise Management Plan, including the use of the acoustic screens, to manage potential noise impacts for drilling programs near residential areas. Noise modeling was carried out by Herring Storer Acoustics (2011) with the sea containers in place, which indicated that the sea containers provided a significant improvement in noise reduction compared to the use of the acoustic screens. Since the inception of the Fimiston Open Pit in 1989, KCGM has achieved a high blasting success rate within approved regulatory levels and has therefore minimized the effects of vibration and air blasting on the community.

The blowout modeling also takes into account the location of the blowout within the pit (i.e. the distance of the blowout from the monitoring sites).

Condition EMP Provisions

Environmental Criteria

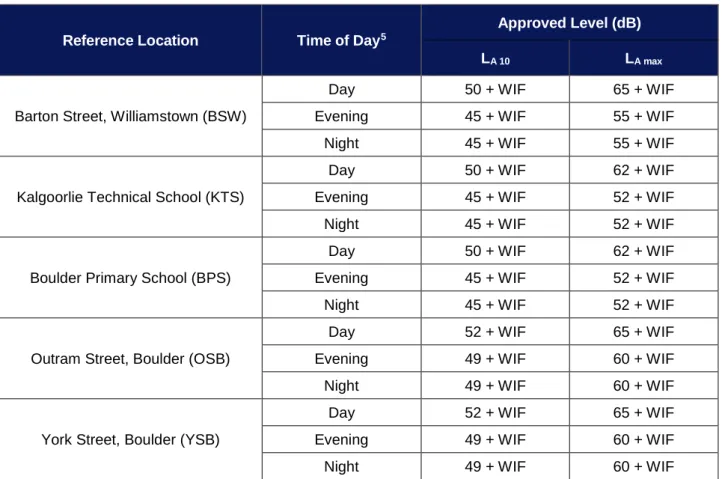

- Environmental Noise Levels

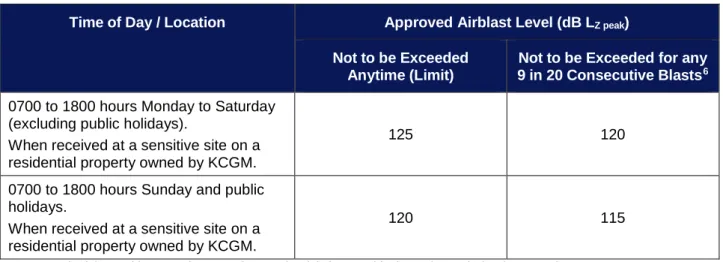

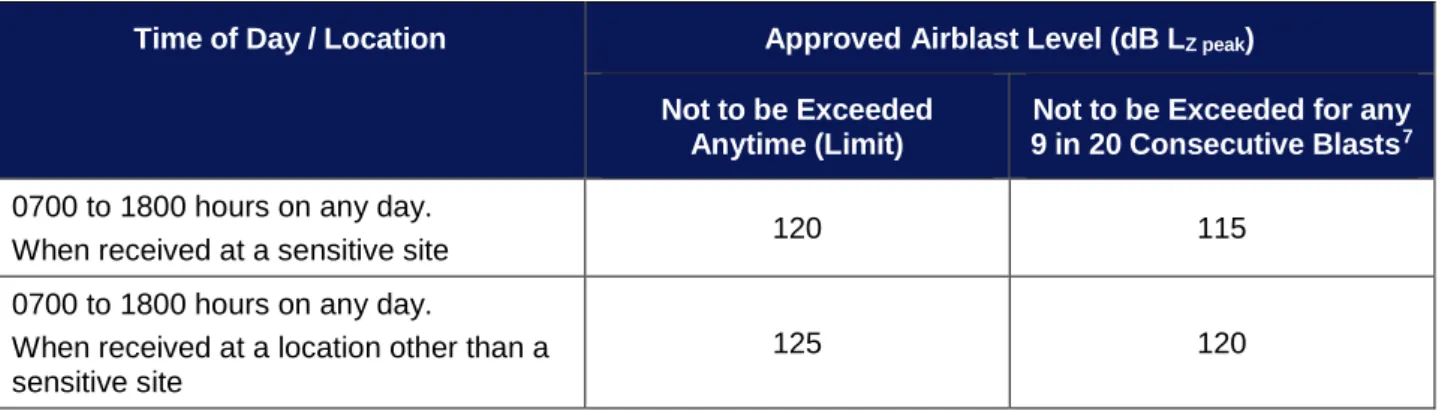

- Airblast Levels

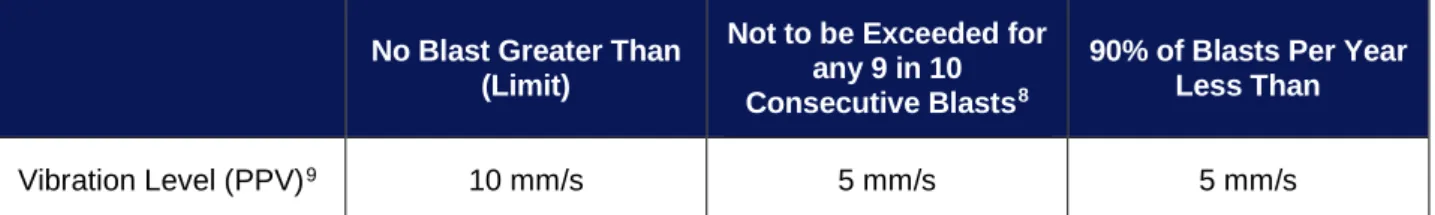

- Blast Vibration Levels

Monitoring Programmes

- Continuous Environmental Noise Monitoring

- Compliance Environmental Noise Monitoring

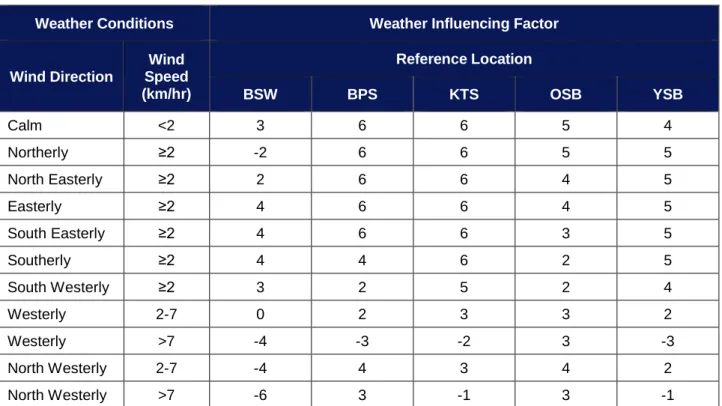

- Weather Monitoring

- Real Time Noise Monitoring

- Blast Vibration and Airblast Monitoring

Complaint Management

Reporting Provisions

Quarterly Noise and Blast Monitoring Report

Since 1993 (in accordance with the Noise Level Standards for Operations at Kalgoorlie set by the Minister in 1992), a Quarterly Noise and Explosion Monitoring Report has been submitted.

Annual Noise Monitoring Report

Publishing of Noise Monitoring Results

Blasting Outside Daylight Hours (24 Hour Report)

Note: In this condition "mining activities" does not include construction work within the meaning of regulation 13 of the Environmental Protection (Noise) Regulations 1997. Locations of the air burst overpressure and ground vibration monitors and demonstration that these locations meet the requirements of regulation 21 of the Environmental Protection (Noise) Regulations 1997 and Section J3.2.2 of the Australian Standard. Calibration by an approved calibration laboratory and field checks of the monitoring equipment in accordance with Schedule 4 of the Environmental Protection (Noise) Regulations 1997 and the manufacturer's specifications and Section J3.l.2 of the Australian Standard or subsequent amendments) and record of the calibration ;.

KCGM Website

Reporting on Exceedance of Environmental Criteria

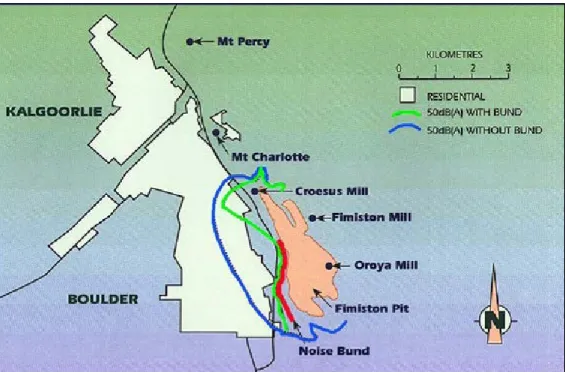

Since the early 1990s, KCGM has consulted with noise consultants Herring Storer Acoustics to undertake noise modeling and assessments of the Fimiston operations. Supplementary noise modeling was undertaken by Herring Storer Acoustics in relation to the proposed Environmental Noise Bond in June 1992, which indicated that significant noise reduction could be achieved by constructing a 20m high bore extending the full length of the Fimiston operations (Figure 1). . For example, in 2005, noise modeling was conducted to determine the impact of the Golden Pike Cutback.

This modeling was reviewed as part of the PER carried out for the Golden Pike project, where it was determined that Fimiston's existing operations may not be compliant with nightly allocated noise levels under the Noise Regulations, even with controls in place (ie ). A daily blast notification is sent to a list of recipients (which includes community organizations) informing them of the scheduled time and location of the blast. Air blast levels for KCGM Fimiston Operations are set out in Condition 4 of the 2016 Fimiston Noise Approval.

Trigger surveys are reviewed on an as-needed basis, usually in response to a noise complaint, to identify whether the source of the noise is attributable to the Fimiston operations. In accordance with Condition 8(2) of the 2016 Fimiston noise approval, KCGM is required to record levels of noise received at each reference location. Weather data recorded at the time of the monitoring (refer to Section 5.2.3) is used to determine the WIF (Table 4) for the calculation of the approved noise level (Table 3).

It means any place within the boundaries of the premises known as Kalgoorlie Technical School at 13. Pursuant to condition 8(3) of the Fimiston Noise Approval 2016 and conditions 9-5 and 9-6 of 782:M, KCGM must record air blast levels and vibrations. ETMs are NATA calibrated annually in accordance with Schedule 4 of the Noise Regulations, Manufacturer's Specifications and Section J3.1.2 of AS2187.2-2006.

The assessment report recommended that the echo blast monitoring site be moved to a point further south of the existing site. Each interaction is logged in the database and categorized based on the nature and topic of the interaction.

Adaptive Management and Review of the Condition EMP

Stakeholder Communication

- Social Impact Assessments

- Goldfields-Esperance Regional Planning Strategy

- Heritage Council of Western Australia

- DWER

- Noise Working Group

- Community Reference Group

Since 1991 when the 188:M was issued by the Minister, KCGM has continuously consulted with the DWER, including EPA Services and Noise Services regarding the development of the NVMMP, including confirmation and approval of noise measurement sites and instruments, and inclusion of additional information in the NVMMP when requested. January 19, 2011, KCGM sent a letter to the OEPA and the DEC to inform them of the new format for advertising the quarterly noise results. July 14, 2011 KCGM sent a letter to DEC (Gas Regulation Branch) seeking approval for the location of the Real Time Noise Monitoring Sites.

September 21, 2011 DEC (Department of Noise Regulation) emailed feedback on site approval for real-time noise monitoring. On June 19, 2013, KCGM emailed the DEC (Department of Noise Regulation) requesting approval to deviate from the October 2010 NVMMP regarding the assessment of noise triggers and field calibration frequency. On June 21, 2013, the DEC (Department of Noise Regulation) provided comments via email regarding the KCGM's intent to differ from the October 2010 NVMMP.

Based on the location of the proposed projects and the results of the environmental noise assessments, there were no concerns about potential noise impacts and the relocation of Echo was to be achieved through an amended NVMMP. During the program review, the function of the Noise Working Group was evaluated and a decision was made to include discussions of the Noise Abatement Program and the Real Time Noise Monitoring Program on the agenda of the monthly CRG meetings, rather than coordinating a separate forum. Details are documented in KCGM's Quarterly Noise Monitoring and Explosion Reports and Annual Noise Monitoring and Management Report.

The group meets monthly to discuss current KCGM planning, operational activities and community feedback.

Supporting Technical Information

Blast Monitoring Sites

Blast Monitoring Equipment

- Vibration Monitoring

- Airblast Monitoring

Blast Monitoring Records

As part of the ongoing life of mine planning process, KCGM undertakes additional modeling to evaluate any proposed changes to mining activities. This project was deemed to meet the intent of the Appeals Panel's recommendation to benefit the community most affected by noise from KCGM's Fimiton Operations (ie, haulage truck noise) and to be over and above the commitments KCGM has already made to other community projects related to noise improvement. An equipment performance check is automatically performed daily and a copy of the performance report is sent to drill and blast personnel.

Approval from DWER was obtained prior to relocation through amendment of the NVMMP in October 2010. 12 This version of the NVMMP has been amended to reflect the proposed relocation of the echo-blast monitoring site following an assessment of blast-induced ground vibration and air blast associated with the proposed Morrison Mine Project (George Boucher Consulting, 2017). Face survey information indicating the proximity of the nearest blast holes to any free faces within the blast.

Glossary of Terms

Means any place within the boundary of the premises known as Kalgoorlie Technical School at 13 Davidson Street, South Kalgoorlie. Leq: The sound pressure level in dB, corresponding to the total sound energy over a given period. Specifications with sound measuring equipment complying with the requirements of Schedule 4 of the Environmental Protection (Noise) Regulations 1997.

Measured: In relation to the measurement of a noise emission, means measured and adjusted in accordance with the Environmental Protection (Noise) Regulations 1997. Noise Sensitive Premises: has the meaning given in Schedule 1 Part C of the Environmental Protection (Noise) Regulations 1997 Peak component particle velocity (ppv): The peak level of the particle velocity for an individual component.

Reference location: A location specified in terms of the Environmental Protection (Approval of Noise Emissions from Fimiston Gold Mines) 2009 for the assessment of noise emissions. Contribute significantly to: A noise emission is considered to "contribute significantly to" a noise level if the noise emission exceeds a value that is 5dB below the specified level at the receiving point. Sound Level Meter: A measuring device that measures sound level and can give dBL, dBA or dBC values.

Vector Peak Particle Velocity: The peak level of the particle velocity calculated from the vector formed by the magnitude of the three orthogonal components of the particle velocity over their measured time history.