The RMOA discusses the need for further regulatory management of the concerns associated with the use of PFAS in firefighting foam. It is therefore concluded that a restriction on the placing on the market (and possibly the use) of PFAS-containing firefighting foams at EU level appears to be an appropriate option.

Introduction

This report

Scope of work

Substance identification - input for the scope of a possible measure

Market analysis

Assessment of the emissions and hazard of fluorine-free foams

Assessment of the remediation costs

Summary of the information in the form of a risk management option analysis (pre-RMOA) Summarise all the information following the structure of a RMOA (“pre-RMOA) to allow the Commission to

Pre-Annex XV dossier”

Analysis of alternatives to PFAS-containing fire-fighting foams Analyse the alternatives in terms of

Tank cleaning (subject to a practical concentration limit, i.e. residual PFAS concentrations that can be achieved at reasonable cost).

Assessment of the socio-economic impacts of substituting PFAS-containing fire-fighting foams

Supporting the organisation of a stakeholders’ workshop

Structure of this report

An overview of the approach and the results of the market analysis (Task 2) are presented in Section 4. The emission and risk assessment of PFAS substances and their alternatives (Task 3) is presented in Section 5; and.

Joint consultation 2. Joint consultation

- Introduction

- Approach

- Consultation questionnaire results

- Consultation workshop

- Additional consultation and resources

Identify where the key data gaps were in relation to the objectives of the project(s); and. Identify other key stakeholders in this sector to target in the next stages of the consultation.

DG ENV STUDY

Task 1. Substance identification

- Introduction

- Approach

- Final results

More details about the specific search terms applied and the specific documents screened are provided with the results in the following subsections. A matrix was created to collect all potentially relevant information from the literature review, but the identified information is summarized in the following.

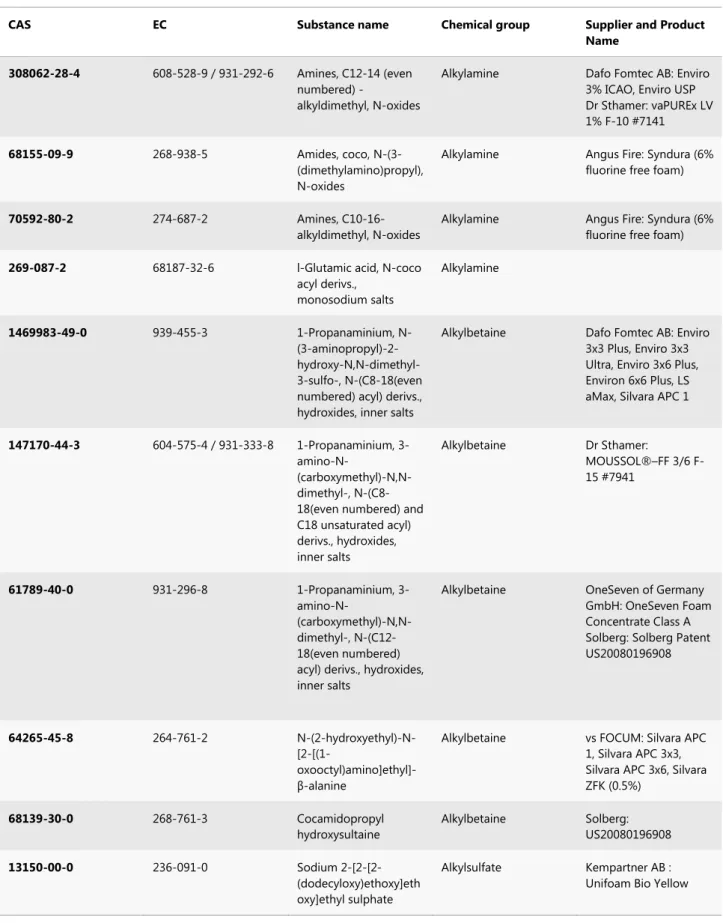

Substance identification non-PFAS fluorinated alternatives

SDS/supplier information, monitoring data, EPAs, NGOs, case studies, and legislation were also screened for information on non-PFAS fluorinated substances (concurrently with the screens for information on the substance identity of PFAS and fluorine-free chemicals, discussed below). In conclusion, the analysis suggests that no fluorinated non-PFAS alternatives exist in firefighting foam.

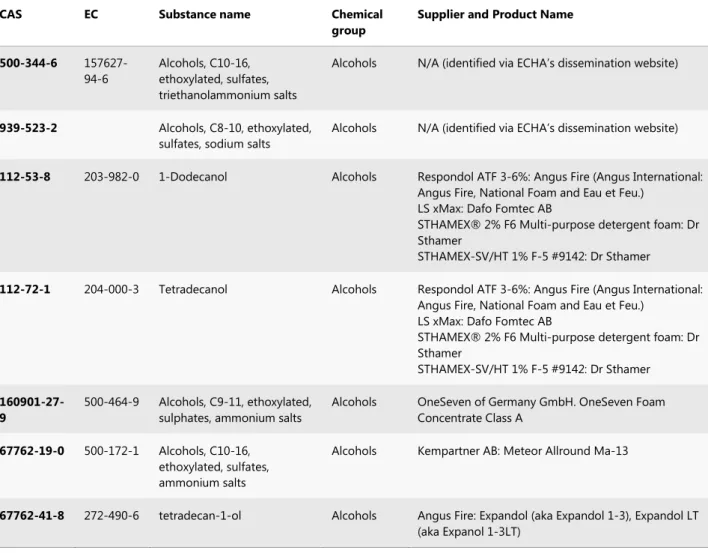

Substance identification - FFF (fluorine-free foams)

A limited number of siloxanes have been identified in this task, possibly because the use of this group of substances is still in the development phase. This information is shown in the table below, where the chemical structure is also shown.

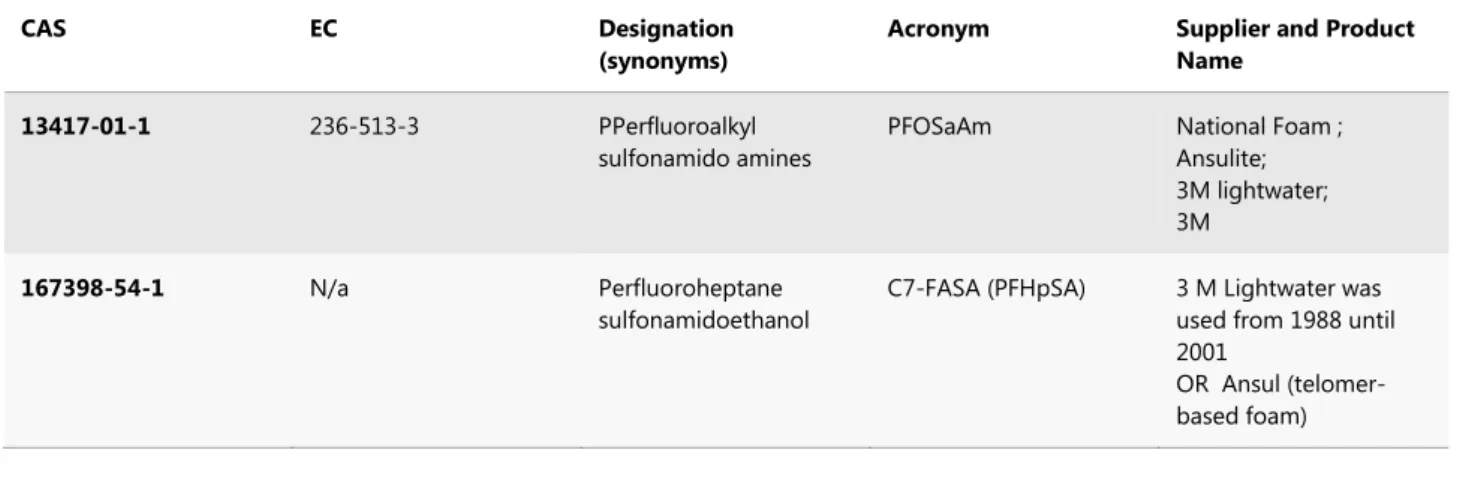

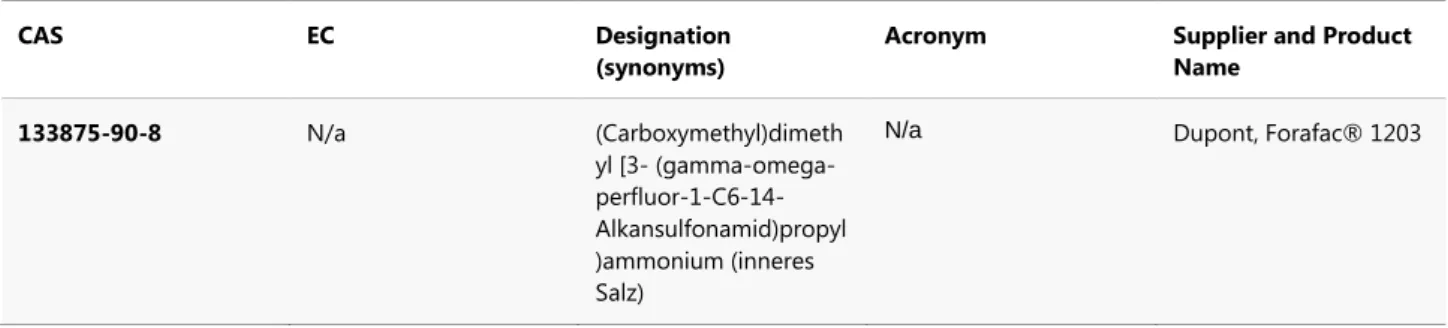

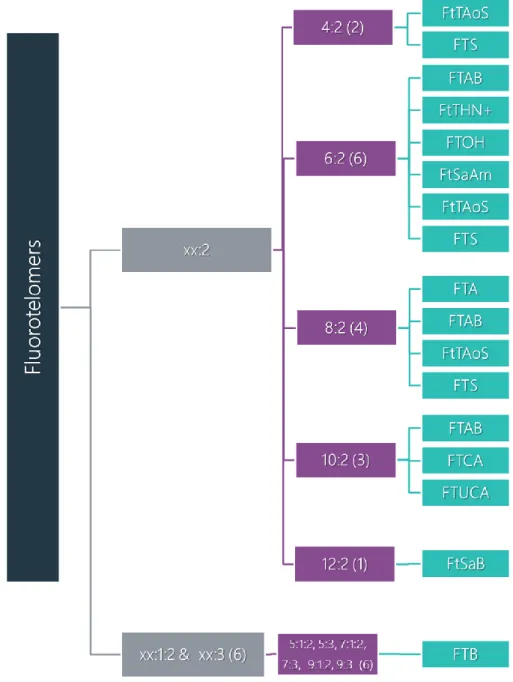

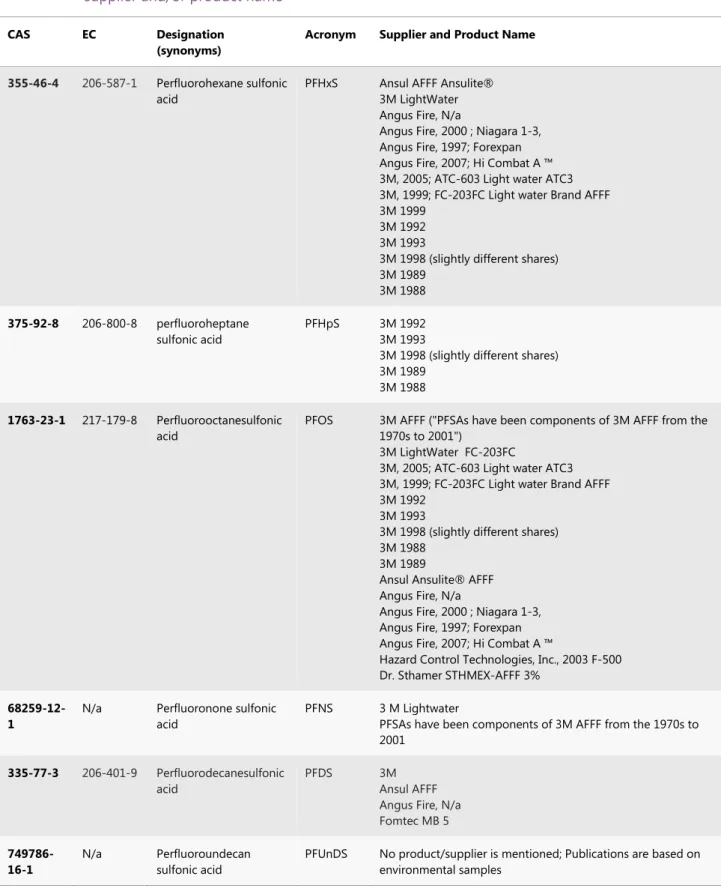

Substance identification - PFAS

In the case of the xx:1:2 substances, an additional fluorinated carbon is inserted between the perfluorinated alkyl chain and the non-fluorinated spacer. In the case of the PFCAs, chemically defined as CnF2n+1-COOH, the substances identified in this task, AFFF-related PFAS substances, will be covered.

Bibliography for Section 3

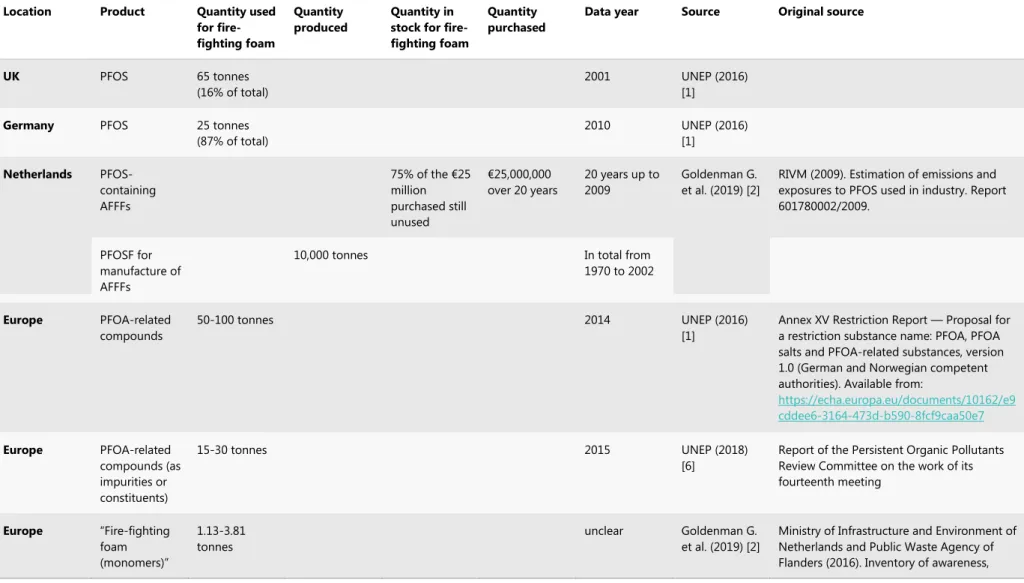

Task 2. Market analysis

- Introduction

- Approach

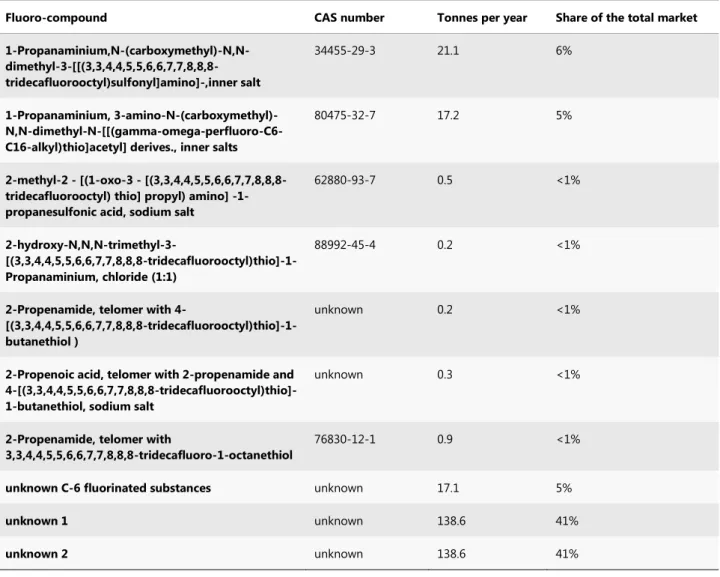

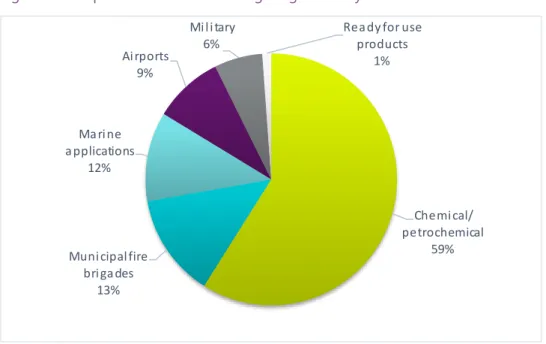

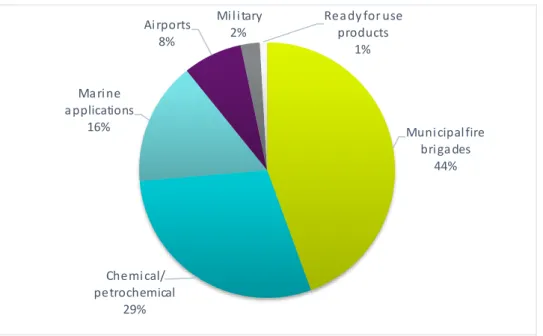

- Results: PFAS in fire-fighting foams

- Fluorine-free fire-fighting foams

- Summary of results

Respondents reported prices for PFAS-based firefighting foams in the range of €2 to €30 per liter for concentrates. No information on tonnage and values of fluorine-free firefighting foam was identified in the literature review.

Task 3. Assessment of the emissions and hazard of fluorine-free foams

- Introduction

- Approach

- Results and analysis

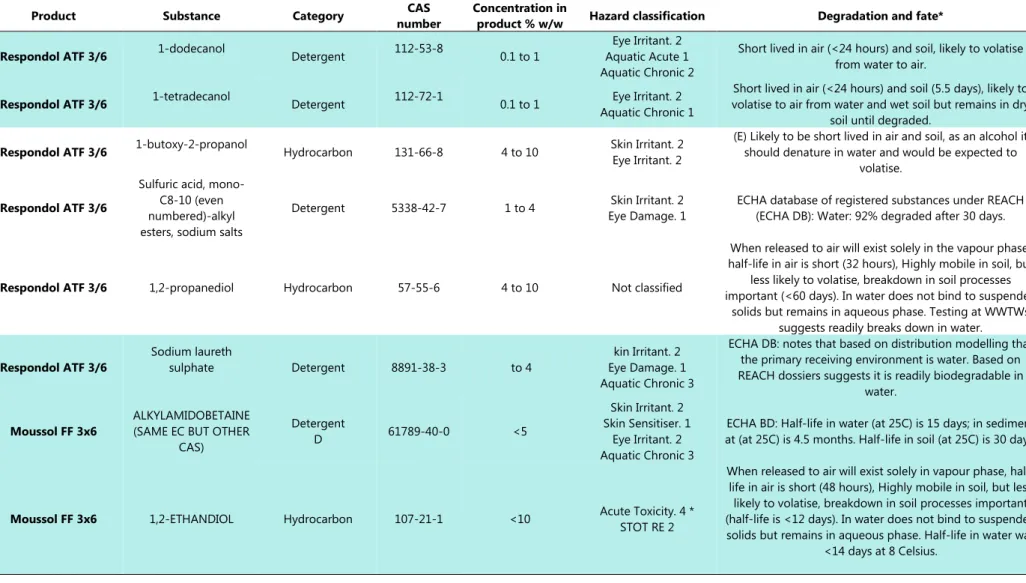

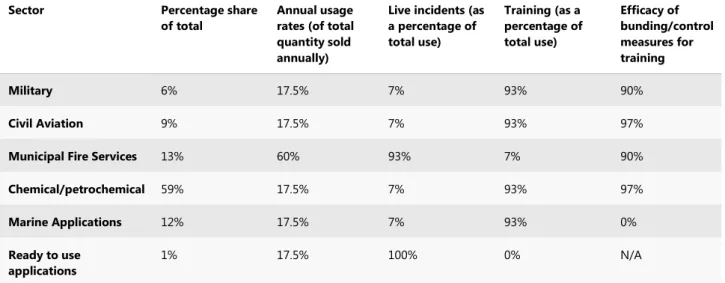

The output of the emissions model highlighted this as the main use of firefighting foam. Further review of the non-fluorinated alternatives highlighted a number of compounds (see Table 5.8) that also have very low PNEC values for water and soil (although higher than their fluorinated counterparts). The emission model also highlighted that the effectiveness of the non-fluorinated substances as surfactants is typically weaker than fluorinated substances and thus greater concentrations are required within the firefighting foam concentrate.

Task 4 – Remediation costs and technologies

- Introduction

- Approach

- Results

Stakeholders provided input on site cleanup and remediation related to PFAS as summarized by the. Cleanup after a live event should occur as soon as possible after the incident, specifically when PFAS foam has been used. Some stakeholders suggest that cleaning and complex treatment is not always necessary after the use of fluorine-free foam, although due to the presence of contaminants from the fire, including liquid fuel and accidental materials and compounds affected or released during the fire, it are often required after live incidents, regardless of the foam used.

What is what: Definition of “remediation” versus “clean-up”

The number of PFAS compounds currently "driving the market" is small compared to the number of potential PFAS compounds known and likely to be present at a cleanup site. As a result, the number of PFAS compounds that have been studied for their toxicology, fate and transport in the environment, and effects on human health and the environment is relatively small. In many European countries, only a few PFAS compounds are regulated in terms of their permitted concentrations in drinking water, groundwater, surface water and soil65.

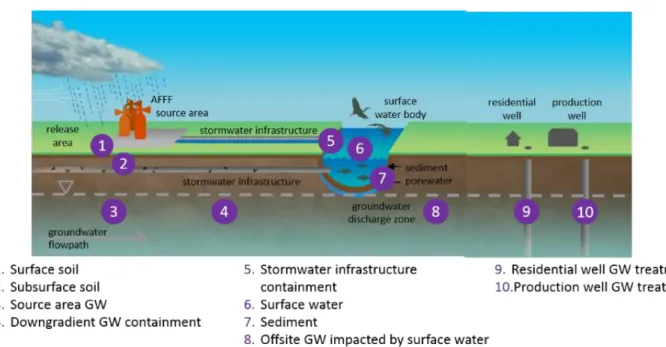

Contamination scenarios: PFAS-containing foams and fluorine-free foams

At the location of the active firefighting activity, PFAS-laden water enters the subsoil leading to PFAS-infected soils – the source area (No. 1). Precipitation supports leaching of PFAS compounds in the unsaturated soil column to greater depth (no. 2) in the soil column which eventually reaches groundwater which is then the starting point of a PFAS plume in groundwater (no. 3). The point of treatment may also be based on protecting a sensitive receptor such as a drinking water (domestic no. 9, . commercial, or public no. 10).

Drivers for active measures – why is clean-up / remediation required?

The foam used during training exercises at the site was frequently dumped without monitoring, dissolving into the soil and rainwater. Schiphol Airport, Netherlands In July 2008, a fault in the sprinkler system at a pilot released 10,000 liters of AFFF, containing 143 kg of PFOS, into the surrounding environment. Firefighting activities in close proximity to open bodies of water (such as oceans or lakes) make it nearly impossible to recover firefighting water spilled into the ocean or lake.

Treatment technologies and treatment scenarios – soil and water

Trial testing or pilot testing is required to confirm the desired performance parameters of the products. Ideally, trial testing and/or pilot testing would be conducted to determine the optimal GAC for adsorbing a mixture of PFAS present in water for a specific project. A relevant factor in efficient and successful RO treatment is described as the pore size of the membrane used in the filtration process81.

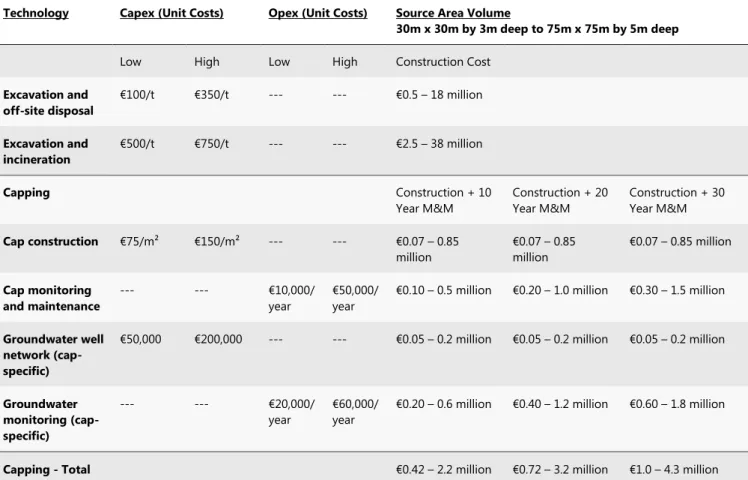

Cost of remediation / treatment: soil and water

Typical costs of transporting PFAS-contaminated excavated soil to a landfill or incinerator are included in the unit cost. System flow rates are affected by the width and depth of the plume to be treated and the hydrologic permeability to groundwater. The well field must be connected to the treatment unit and to the discharge point after treatment for disposal of treated water.

ECHA STUDY

- Task 1: Analysis of alternatives to PFAS- containing fire-fighting foams

- Introduction

- Approach

- Initial screening and consultation results

PBT (Persistent, Bioaccumulative and Toxic) or vBvP (very Bioaccumulative and very Persistent) - information taken from safety data sheets for the products. Two of the example products described in more detail in this section have been evaluated using the Greenscreen® standard. A mixture of substances is typically used in place of PFAS in different percentage combinations for each of the fluorine-free foam alternatives (including solvents and surfactants) to achieve the required foaming/film-forming functions of the product.

Literature review on fluorine-free products

As shown in the examples below, alternatives are available with the A1 class for both Part 3 and Part 4.

Consultation of stakeholders

- Preparation of example list of alternative fluorine-free products

A small number of manufacturers and users reported the volumes of some specific products produced, sold or purchased in the EU, as well as the approximate value of these sales/purchases. It is not possible to comment on any broad observations from this small number of responses. Regarding the economic feasibility of alternatives, a small number of responses were received detailing costs of the alternative foam products, and their required loading, but very limited data was received on costs of replacing equipment.

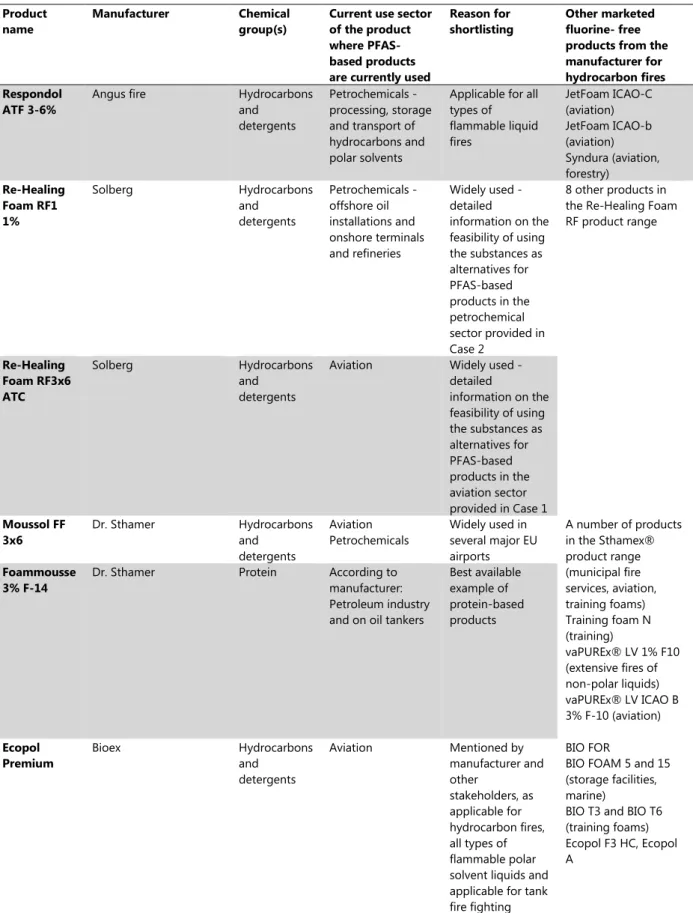

Preparation of shortlist of alternatives

- Properties of shortlisted products

Use - Several stakeholders reported product use, ensuring that the analyzed products are commonly used in the EU as an alternative to foams containing PFAS;. For each of the manufacturers, one or two products in the range were selected for a more detailed assessment. No information on these products was submitted for stakeholder consultation, but one product from the Foamousse® range was subsequently added to the list of examples in the table below.

Additional information gathering and assessment of shortlisted alternatives

- Representative case studies where fluorine-free alternatives are already in use in the EU

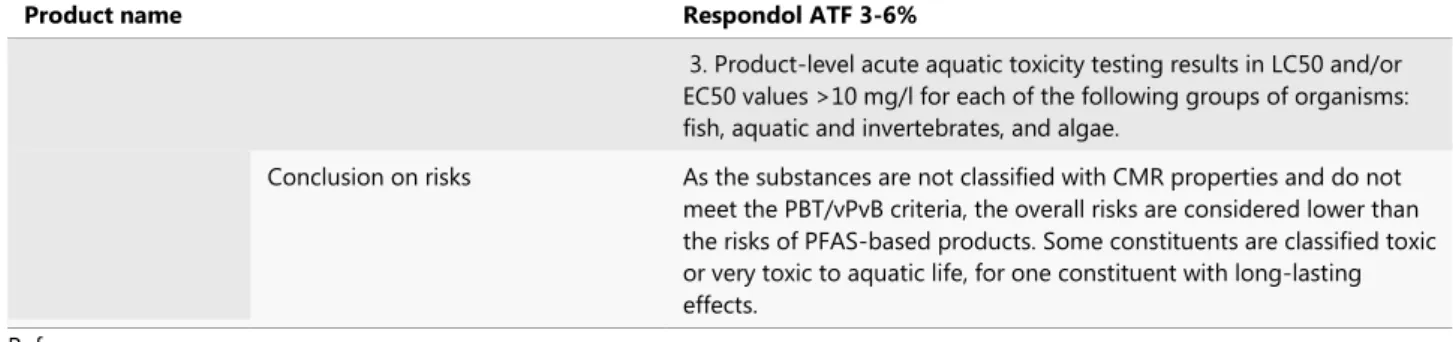

Risks: CMR properties Substances in the product do not meet the CMR criteria. Other potential human health. Risks: CMR properties Substances in the product do not meet the PBT/vPvB criteria. Other potential human health. The product is particularly applied in the marine sector, where volumes used for training are discharged directly to the sea.

Assessment of illustrative cases

Due to lack of information, it cannot be concluded whether the components meet the PBT and vPvB criteria.

Aviation sector - Copenhagen Airport in Denmark 94

Also, the different viscosity of the PFAS-free foam caused some initial challenges, which were later resolved by adjusting equipment; and. Some of the old trucks continued to be in use, and although the tanks were thoroughly cleaned, initially there was contamination of the PFAS-free foam with PFAS. When implementing the new fluorine-free alternative, testing and training required ~5,000 liters of foam/year.

Petrochemical sector - Offshore production in Norway 96

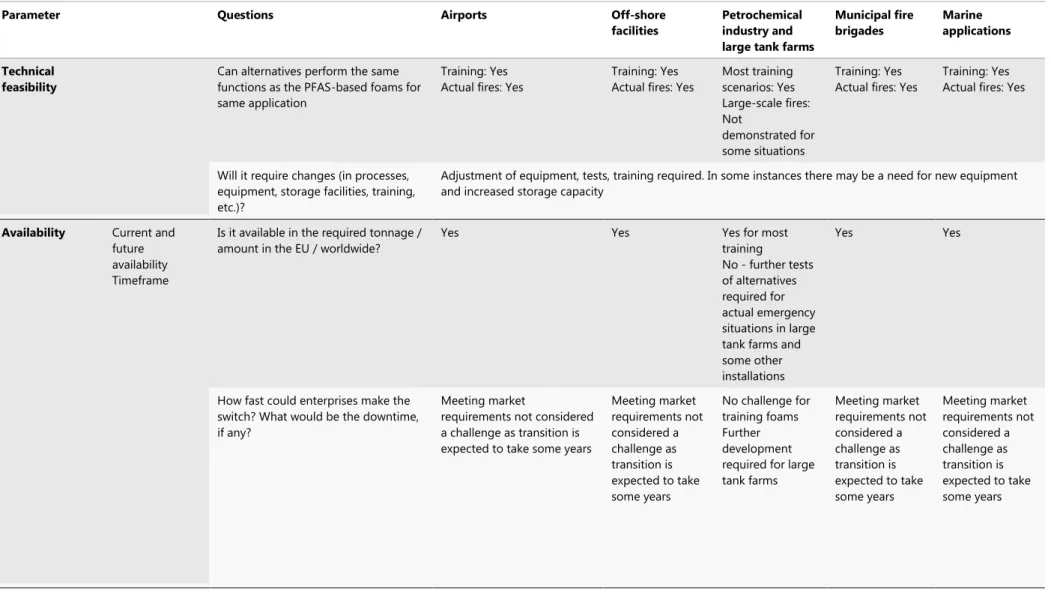

- Overall analysis of alternatives

The driver for the switch was concern over the environmental consequences of firefighting foam containing PFAS released into the sea. During extensive testing with the RF1, a foam dispenser failure occurred, which was initially attributed to corrosion associated with the use of the RF1 foam. The cost of the new foams compared to the PFAS-based foams previously used ranged from +5% to +30% depending on the type/purpose of the foam.

Final summary

- Task 2: The socio-economic impacts of

For the shortlisted products, none of the components included in the Safety Data Sheets are classified with CMR properties. These costs are usually covered by the manufacturers of foam and reflected in the price of the alternative foam. The cost of destroying the PFAS-based foams is likely to be incurred anyway when the foams expire (exceeding their shelf life).

Aims and scope of the SEA

The shelf life of PFAS-based foams is reported to be typically between 10 and 20 years (and up to a maximum of 30 years)103. BiPRO 2010 suggests that the average lifespan of firefighting foam is 15 years, which seems consistent with the above information104; and. Given that between 14,000 and 29,000 tonnes of PFAS-based foams have historically been replaced per year, and assuming an average lifetime of foams of 15 years, this suggests that the existing European stock of PFAS-based foams is between 210,000 and 435 0500 tons can be.

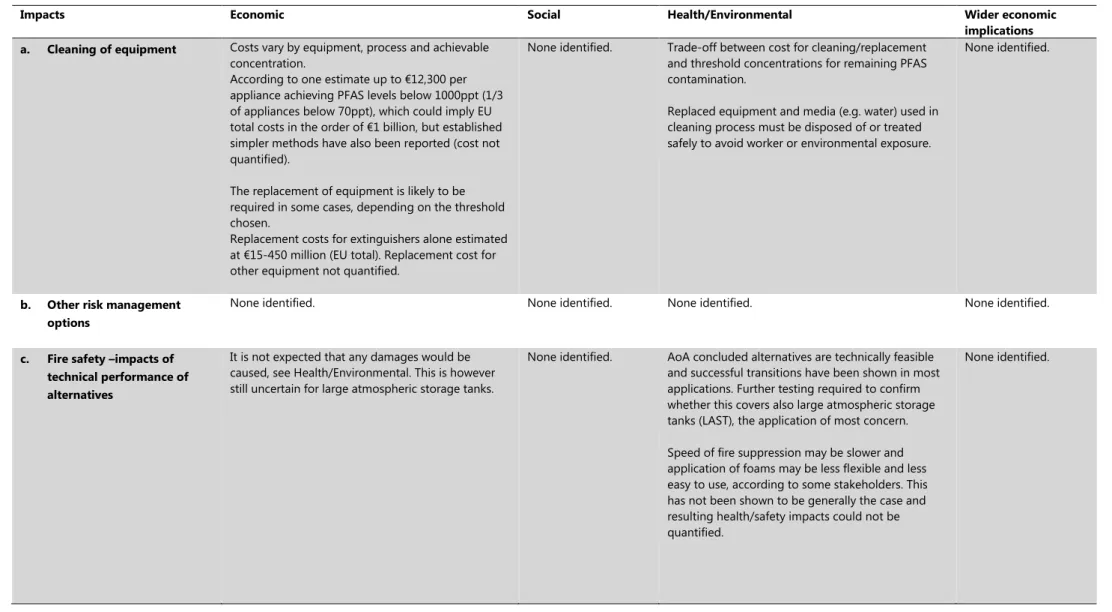

Analysis of the impacts

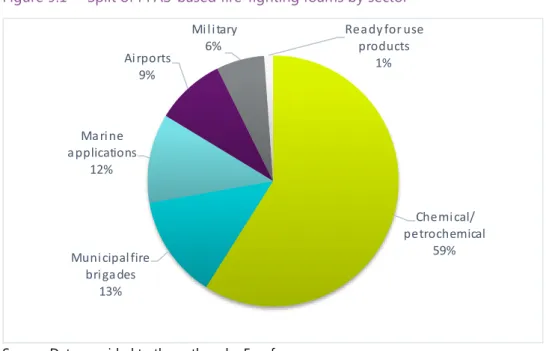

As discussed in the market analysis, the primary application for PFAS-based firefighting foams is Class B fires (flammable liquids and gases). Firefighting foam containing PFAS and PFAS-free foam cannot be combined in the same system. The low level of foam containing PFAS left in the container will have to be discarded.

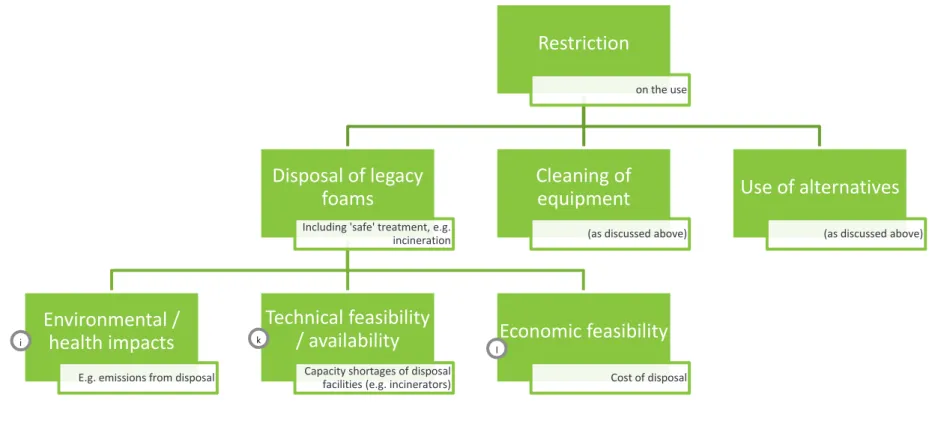

Conclusions

For these foams, a restriction on the use of PFAS-based fire-fighting foams would only bring their burning forward and therefore the cost of burning the fire-fighting foams that would have expired is not additional to the baseline, i.e. repair and cleanup The potential risk of PFAS contamination can be eliminated, which could save up to €100 million in remediation costs per site. Trade-off between combustion temperature (with lower capacity and higher costs) and PFAS destruction effectiveness.

Restriction on the placing on the market of PFAS-containing fire-fighting foams Scenario 1 would allow users to continue using their stocks of foams, but once they are depleted, users

However, only a small proportion of places using fire-fighting foam would release sufficient quantities and without adequate control and prompt clean-up to require large-scale remediation. It has been reported that, at least in some cases, effluents may be sent to wastewater treatment when fluorine-free foams are used, while they may have to be incinerated when PFAS-based foams are used. 144 As discussed in sections 5 and 7, fluorine-free alternatives are generally less stable than PFAS-based foams.

Restriction on the placing on the market and the use of PFAS-based fire-fighting foams

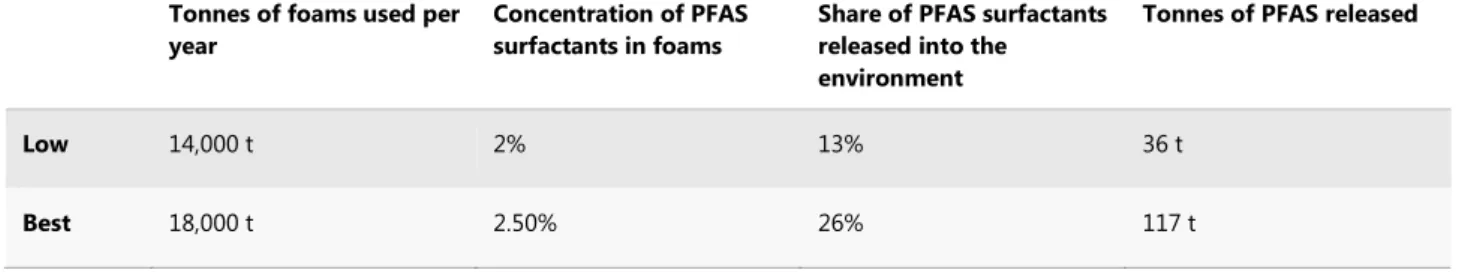

Several tonnes of PFAS-based firefighting foams are used annually in the EU (the best estimate used in the EIA is around 18,000 tonnes) and market analysis suggested that they contain an average. It should be noted that this cost-effectiveness analysis only considers the reduction of PFAS emissions. The environmental/health benefits of reducing PFAS emissions could not be quantified, mainly due to a lack of knowledge about the risks of PFAS.

- Task 5. Regulatory management option analysis (pre-RMOA)

- Introduction

- Hazard information

- Information on tonnage, uses and exposure

- Overview of current measures

- Need for (further) regulatory management

- Identification and assessment of regulatory management options

- Conclusions on the most appropriate (combination of) regulatory management options

This should put the hazards discussed in the previous section into context and allow an assessment of the concerns arising from the use of PFAS-based firefighting foams and fluorine-free alternatives. Effective July 1, 2020, Washington prohibits the sale and use of PFAS-based firefighting foams for training purposes (except for oil refineries, chemical plants, and uses required by federal law, such as aircraft rescue)166; and. Continued use of PFAS-based firefighting foams and subsequent releases into the environment; and.

Consultation questionnaire

Questionnaire: Consultation on polyfluoroalkyl and perfluoroalkyl substances (PFAS) in firefighting foams