Cement Available in Local Markets in Bangladesh”, was completed under the guidance of JM Raisul Islam Shohag, Department of Civil Engineering, Daffodil International University, Dhaka, Bangladesh. To the best of our knowledge, the centerpiece does not contain any previously published or written works by others, unless appropriate citation is given in the actual centerpiece. This confirms the thesis on “Assessment of mechanical properties of concrete using different types of cement available in local markets of Bangladesh”.

Bodruzzoha; ID for the partial fulfillment of the requirement for the degree of Bachelor of Science in Civil Engineering from Daffodil International University. The thesis titled “Assessment of Mechanical Properties of Concrete Using Different Types of Cement Available in Local Markets in Bangladesh”. We are very grateful to our respected parents and respected teachers of Daffodil International University and our friends who completed this research within a limited time.

In conclusion, it can be said that if this research of ours is of little use to the people of the country in the light of the actual situation, then we feel that this tireless work and effort was worth it. And we all know that a large part of the material for building this structure is concrete, and the main component of these concrete materials is cement. We know that there are different types of cement available in the current market with different qualities, so to get high strength cement, we need to have an idea of which cement to use for building structures.

By comparing the results obtained at seven days we found out which cement gives more strength to the concrete, just as by comparing the results from 14 days we found out which cement gives the highest strength.

- BASIC CONCEPT

- BACKGROUND OF STUDY

- SCOPE OF THIS STUDY

- OBJECTIVE

The availability of concrete materials and concrete can be easily cast into various shapes and is strong, durable and has high pressure resistance, the use of concrete is increasing day by day in today's world. Cement is an important component of concrete, it acts as an admixture of concrete, the strength of concrete is highly dependent on the quality of cement. The main focus is to find out the compressive strength of concrete using three types of cement in the local market in Bangladesh.

- INTRODUCTION

- LITERATURE REVIEW

- CONCRETE

- CEMENT

- TYPES OF CEMENT COMPANIES

The compressive strength of cement and, consequently, its physical properties can vary due to variations in the raw materials, as well as in manufacturing conditions. Therefore, an experimental study was investigated herein by investigating the mechanical and physical properties of concrete samples using four different types of Ordinary Portland cements namely Black Bull, Lucky, Pak Land and DG obtained from the market of Sindh Pakistan. Concrete mixes were prepared so that mass cement, water cement factory and granulometric composition were varied.

Values of the coefficient ma/mc in experimental research varied between 7.20 in concrete mixes mixed with 250 kg of cement to 3.60 in concrete mixes mixed with 500 kg per 1m3. Concrete made from a combination of cement, coarse aggregate, aggregate and water is called cement concrete and is known as ordinary concrete. This type of concrete has high pressure resistance, so it is used where concrete must withstand high pressure.

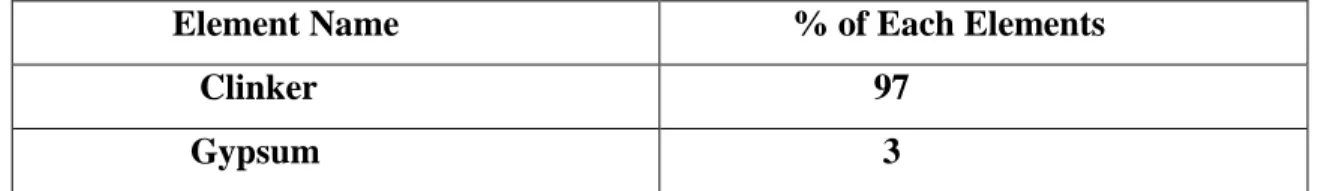

There are four types of concrete, namely lime concrete, cement concrete, reinforced cement concrete and prestressed concrete. Cement is the common name for a powdery substance that, when mixed with water or another liquid, forms a pliable, mud-like substance, which sets over a period of time to form a solid of varying strengths. The required cement is available according to the type and quality of the job, it is easy to work with, and the job is durable.

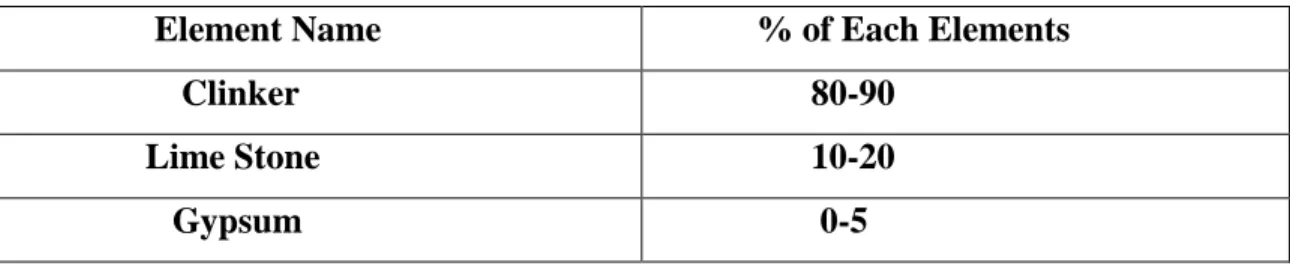

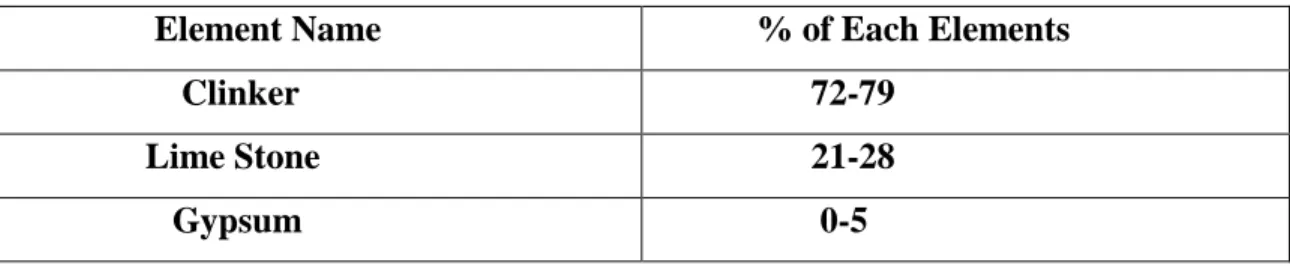

1.Shah Cement: Shah Cement is a product of Shah Cement Industries, a sister group of Abul Khair Group, a well-known and recognized company in Bangladesh. Shah cement is available in Bangladesh market since 2000 For the last 22 years, Shah Cement has maintained its position in the cement market of this country with its reputation. It is indeed a source of great pride to deliver the world's most technologically advanced cement products to every Bangladeshi's doorstep. 2.Premier cement: Premier Cement is one of the most famous cement brands in Bangladesh. Several advertisements for Premier Cement gained popularity in the country Premier Cement Industries Limited is the manufacturer and supplier of Premier Cement Premier Cement located in Munshiganj, Dhaka was first marketed in 2004.

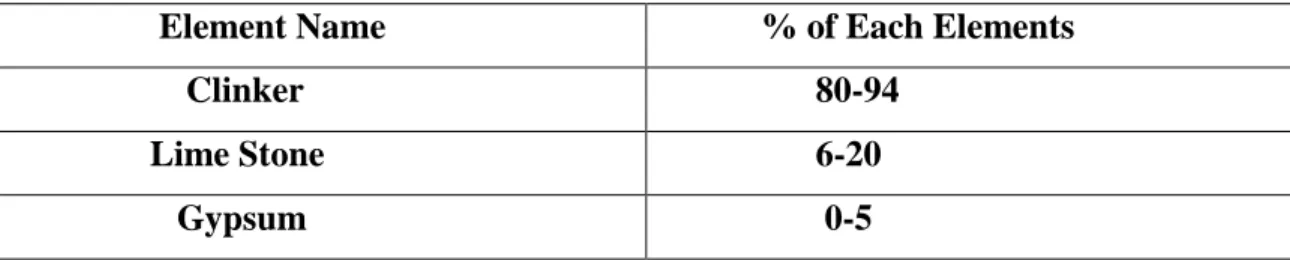

During my three-month internship at Premier Cement Mills Ltd. I had the opportunity to see and learn new things about how a cement company in Bangladesh operates. Akij Cement: Akij Group is a renowned company in Bangladesh. Akij has expanded its activities in several countries. sectors Their presence in the market of Bangladesh since 2002 for making cement Akij has a huge factory in narayanganj. Dhaka Akij Cement is the first company in Bangladesh to produce cement using vertical rolling machines and export cement abroad. Akij Group, the largest local taxpayer in 2009, paid 390 million euros in taxes, representing about 2% of the country's total budget.

- INTRODUCTION

- WHAT IS THE GRADE OF CONCRETE M10

- WHAT IS THE GRADE OF CONCRETE M15

- WATER

- CEMENT

- AGGREGATE

- COMPRESSION TEST

- SLUMP TEST

- COMPRESSIVE STRENGTH TEST

The pH range of ideal water for concrete mixing should be (7.2 to 7.6), and the amount of water for this concrete mix is calculated from the water cement ratio, and this amount of water affects the strength of concrete. We have already discussed that in this project we have used cement from three types of companies available in the market. We have used Premier Cement, Shah Cement and Akiz Cement as cement in this project.

Fine Aggregate: According to the ACI Code, aggregate less than 10 mm in diameter is called fine aggregate. Good quality sand should be used as fine aggregate and the fineness modulus of this fine aggregate should be from 2.3 to 3. Course Aggregate: According to ACI Code, aggregate with diameter greater than 10 mm is called flow aggregate .

And the main goal of our project is to check the compressive strength of this concrete. Freshly mixed concrete must be such that it can easily move and form between the formwork. The cylinder samples used to test the compressive strength of concrete have a diameter of 102 mm and a length of 204 mm.

And this size cylinder is used in both M10 grade concrete and M15 grade concrete. A total of 27 molds were made for M10, with nine for Premier Cement, nine for Shah Cement, and a total of nine molds for Akiz Cement. Similarly, a total of 27 molds for M15 were made for Premier Cement, Shah Cement and Akiz Cement.

And each mold was opened from the cylinder after 24 hours of casting and cured for 7 days, 14 days and 28 days respectively, then these curing molds were tested higher on Universal Testing Machine (UTM) and the load was noted.

- INRODUCTION

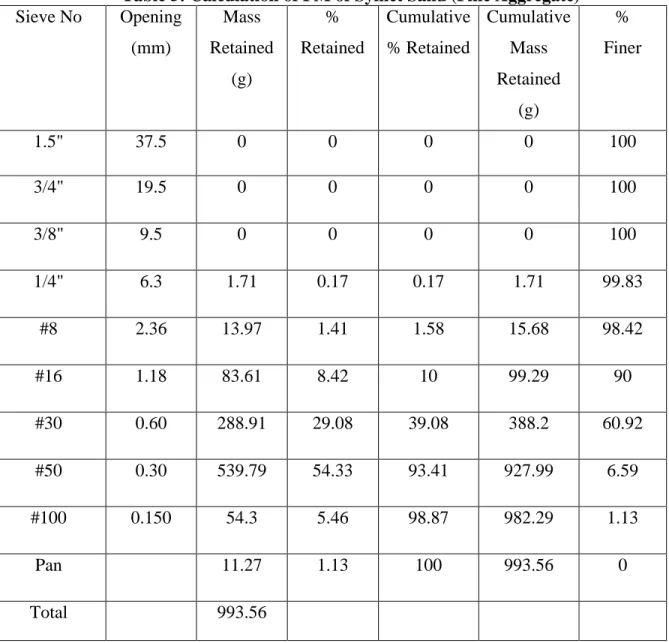

- CALCULATION OF FM OF SYLHET (FIND AGGREGATE)

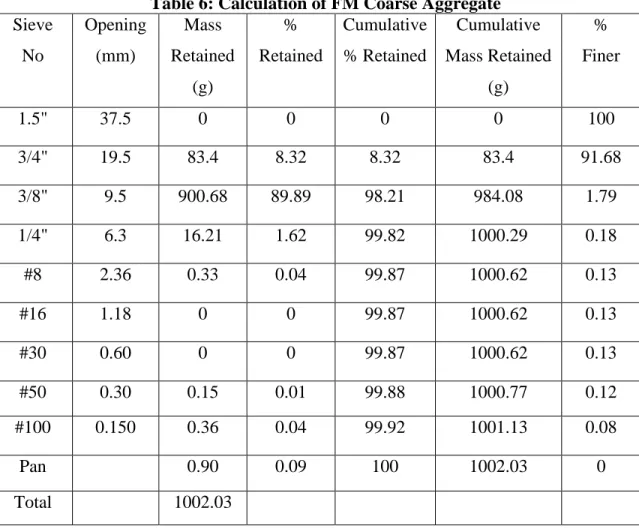

- CALCULATION OF FM COURSE AGGREGATE

- DISCUSSIONS

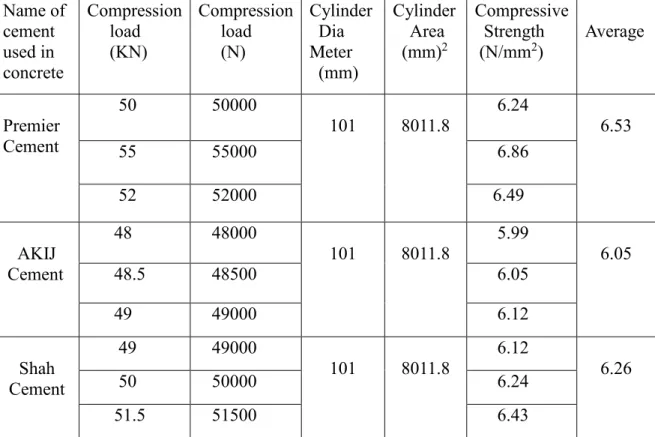

Seven day average compressive strength of concrete made with Premier, Akij and Shah Cement for M10 are 6.53 MPa, 6.05 MPa and 6.26 MPa respectively. If you observe here, it can be seen that the highest comprehensive strength was obtained from Premier cement, then from Shah cement and then from Akij cement, so it can be said that Premier cement is comparatively more effective for concrete. Fourteen day average compressive strength of concrete made with Premier, Akij and Shah Cement for M10 is 9.47 MPa, 9.09 MPa and 9.21 MPa respectively.

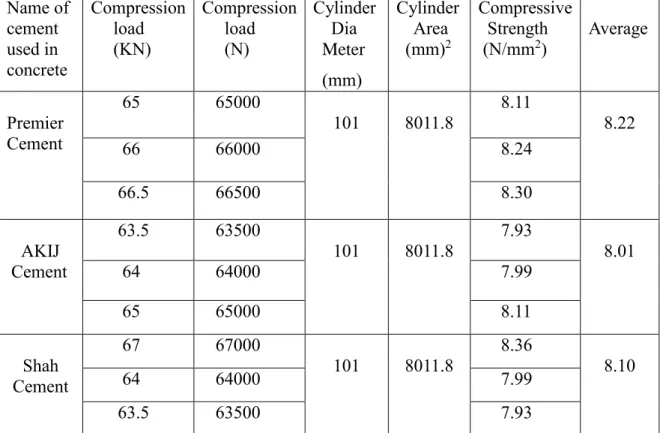

From Table 9: Concrete compressive strength result for 3 different cement companies after 28 days after M10. The twenty-eight-day average compressive strength of concrete made with Premier, Akij and Shah cement for M10 is 12.59 MPa, 12.33 MPa and 12.58 MPa, respectively. The seven-day average compressive strength of concrete made with Premier, Akij and Shah cement for M15 is 8.22 MPa, 8.01 MPa and 8.10 MPa, respectively. The 14-day average compressive strength of concrete made with Premier, Akij and Shah cement for M15 is 11.51 MPa, 11.63 MPa and 11.26 MPa respectively.

If you observe here, it can be seen that the highest comprehensive strength was obtained from Akij cement, then from Premier cement and then from Shah cement, so it can be said that comparatively Akij cement is more effective for concrete. Twenty eight day average compressive strength of concrete made with Premier, Akij and Shah Cement for M15 are 14.85 MPa, 14.46 MPa and 14.54 MPa respectively.

INTRODUCTION

CONCLUSION

RECOMMENDATION

-The eight day average compressive strength of concrete made with Premier, Akij and Shah Cement for M15 is 14.85 MPa, 14.46 MPa and 14.54 MPa respectively. Asal Soltani, Salim Khoso, Manthar Ali Keerio, Antonio Formisano, 2019), Assessment of physical and mechanical properties of concrete produced from different Portland cement brands, Open Journal of Composite Materials, DOI:. Asal Soltani, Salim Khoso, Manthar Ali Keerio, Antonio Formisano, 2019), Assessment of physical and mechanical properties of concrete produced from different Portland cement brands, Open Journal of Composite Materials, 2019 issue, 9, section 327-337.

10 (Development and assessment of cement and concrete made from burning quinary as a product, 2021), Development and assessment of cement and concrete made from burning dilemma as a product, development and assessment of cement and concrete made from burning dilemma , issue 2021:15, volume pages 3708-3721. N S Ghadzali,M H W Ibrahim,M S H Mohd Sani,N Jamaludin,M S M Desa,Z Misri, 2018), Properties of concrete containing different types of waste materials as aggregate replacement exposed to elevated temperatures, IOP Conf.