The report submitted to the Department of Mechanical Engineering, Sonargaon University, Bangladesh partially fulfilled the requirements for the award of the degree. This project has been carried out as per the instructions of your supervision and as per the requirements of Sonargaon University. We further undertake to indemnify the University against any loss or damage arising from a breach of the above obligation.

Mostof Hossain, Head of the Department of Mechanical Engineering and all respected teachers of the Department of Mechanical Engineering for their cooperation and important help in the successful completion of the thesis. A refrigerator is a common household appliance that consists of a thermally insulated compartment and which, during operation, transfers heat from the interior of the compartment to the outside environment. The circulating refrigerant enters the compressor in a thermodynamic state known as saturated vapor and is compressed to a higher pressure, resulting in a higher temperature.

This pressure reduction results in the rapid adiabatic evaporation of some of the liquid refrigerant. The design parameters of the main components in a vapor compression refrigeration system are also responsible for their energy consumption, exegetical efficiency and energy destruction (irreversibility) in the system. Various researchers have worked on the replacement of R600a as a substitute for R134a in the refrigeration system [1-8] The solutions provide adjustment of the system components such as the length of the capillary tube and the condenser.

9–12] Their works looked at the components responsible for energy loss and provided tools to minimize energy loss and improve the energy efficiency of the cooling system.

Refrigeration System

Some researchers have worked on experimental and theoretical energy performance analysis of vapor compression refrigeration system.

Objectives

Structure of the Project

LITERATURE REVIEW

Introduction

Literature Review

The theoretical and experimental performance analysis, cooling capacity and overall heat transfer coefficient of evaporators studied and predicted in this article. This article does not give any idea about the design and analysis of vertical roller evaporator. A distributed parameter model for predicting the transient performance of an evaporator is presented in the paper by S.Porkhial, et.al [4].

The model is capable of predicting coolant temperature distribution, pipe wall temperature, coolant quality, coolant inventory mass as a function of position and time. An efficient two-level iteration method is proposed to obtain the numerical solution of the model without solving a large set of nonlinear equations simultaneously. The results show that the theoretical model provides a reasonable prediction of the dynamic response compared to the experimental data.

Transient behavior of temperature, pressure, mass flow rate, mass of liquid and refrigerant vapor, quality, heat transfer in domestic refrigerators has been presented. Extensive investigation of theoretical and experimental results shows that with a controllable compressor, power consumption can be reduced. This model predicts the transient behavior of temperature, pressure, mass flow rate, mass of liquid and refrigerant vapor, quality, heat transfer in domestic refrigerators.

A set of equations, which can be used to predict the performance parameters of an evaporator, when there is an oblique angle between the inlet air velocity and the front of the evaporator, was studied by Nan Chen, et.al [5]. In order to calculate the performance, a simulation model for predicting the performance of a plate-fin tube evaporator, on which frost formation occurs, was presented. This model adopts different numerical algorithms according to different flow conditions, including laminar, transitional and turbulent flow patterns.

After correction, the numerical program based on this model is used to predict the relationship between the oblique angle of the intake air velocity and performance.

Summary

HARDWARE ANALYSIS

Hardware

Compressor

Often, the second stage is physically smaller than the primary stage, to accommodate the already compressed gas without reducing its pressure. Each stage further compresses the gas and increases its pressure and also its temperature (unless inter-stage cooling is used). Mathematically, the work done by the reciprocating compressor is equal to the work done by the compressor during compression and discharge minus the work done during suction.

Use of Compressor

Use and Application

Other applications include, but are not limited to

R600a Refrigerant

As a refrigerant, isobutane poses a fire and explosion risk in addition to the hazards associated with non-flammable CFC refrigerants. Substitution of this refrigerant for motor vehicle air conditioning systems not originally designed for isobutane is generally prohibited or discouraged. Vendors and proponents of hydrocarbon refrigerants argue against such bans on the grounds that there have been very few such incidents relative to the number of vehicle air conditioning systems filled with hydrocarbons.

Characteristics And Application

Evaporators

Working Principle of Evaporator and its Types

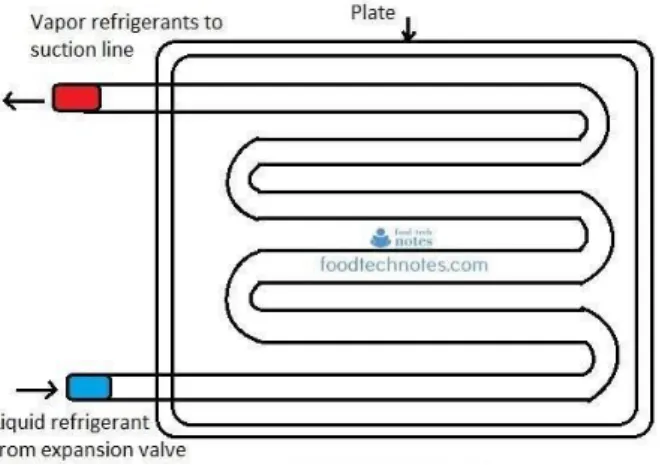

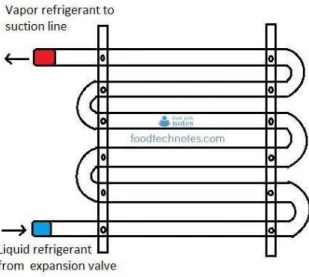

The evaporator consists of several turns of tubes and is usually used for liquid cooling. In blast cooling and freezing operations, atmospheric air flows over bare tube evaporator and the cooled air leaving it is used for cooling purposes. Plate Evaporators: In plate type evaporators the coil is usually made of copper or aluminum embedded in the plate to form a flat surface.

Externally, the plate type evaporator looks like a single plate, but inside there are several turns of the metal tube through which the refrigerant flows. The advantage of plate type evaporator is that they are more rigid as the external plate offers a lot of safety. The external plate also helps to increase heat transfer from metal tubes to the substance to be cooled. They can be converted into box shape, partitions or shelves as required for different purposes.

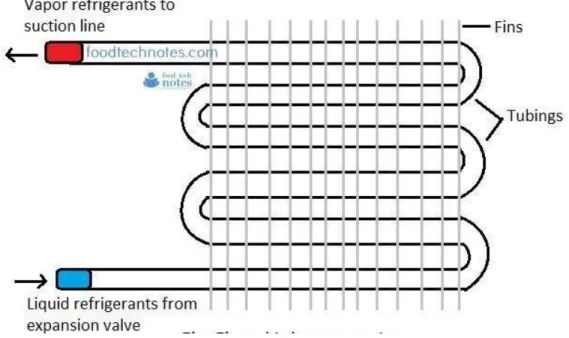

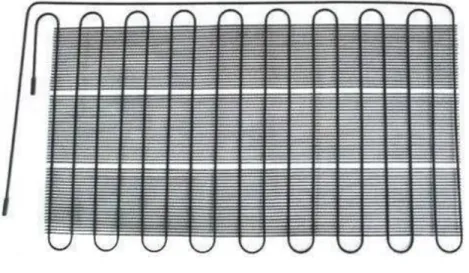

Due to the various advantages and flexibility offered by the plate type evaporator, they are widely used. When the liquid (air or water) to be cooled flows over the bare tube evaporator, much of the cooling effect from the refrigerant is lost as there is less surface area for heat transfer from the liquid to the refrigerant. The fins in the finned tube evaporator increase the contact surface and increase the heat transfer rate.

For fins to be effective, it is very important that there is good contact between coil and the fins. In some cases fins are soldered directly to the surface of the coil and in other cases the fins are just slid over the surface of tubes or coils. The fast evaporators are mostly used in the air conditioners of almost all types such as window, split, packaged and central air conditioning.

To increase the efficiency of heat transfer from evaporator, the tubes are also given internal fins. These fins are made by forming different internal cross-sectional shapes at the time of manufacturing the tube.

Condenser

Principle of Operation

The temperature of the working fluid remains relatively constant during condensation, maximizing the temperature difference between the working fluid and the secondary fluid.

Digital Thermometer

Some of the principles of the thermometer were known to Greek philosophers two thousand years ago. As Henry Carrington Bolton (1900) noted, the thermometer's "evolution from a crude toy to an instrument of precision occupied more than a century, and its early history is marred with erroneous statements which have been repeated with such dogmatism that they have received the fake stamp of authority." The Italian physician Santorio Santorio (Sanctorius is commonly credited with the invention of the first thermometer, but its standardization was completed throughout the 17th and 18th centuries.

In the first decades of the 18th century, Daniel Gabriel Fahrenheit made two revolutionary breakthroughs in the history of thermometry in the Dutch Republic. He invented the mercury-in-glass thermometer (first widely used, accurate, practical thermometer) and the Fahrenheit scale (first standardized temperature scale in widespread use).

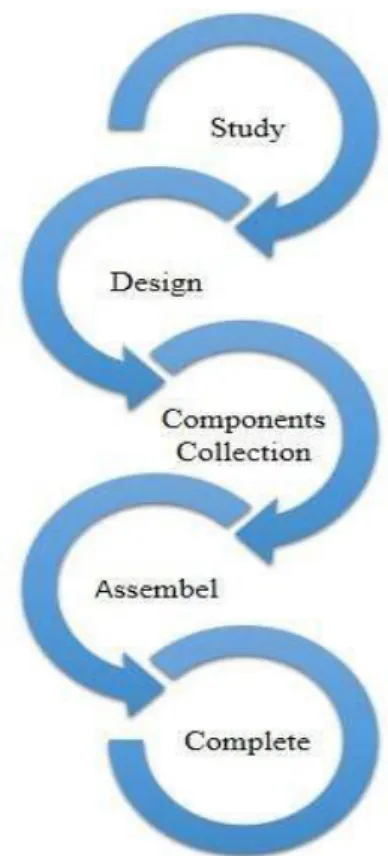

Our methodologies for the project

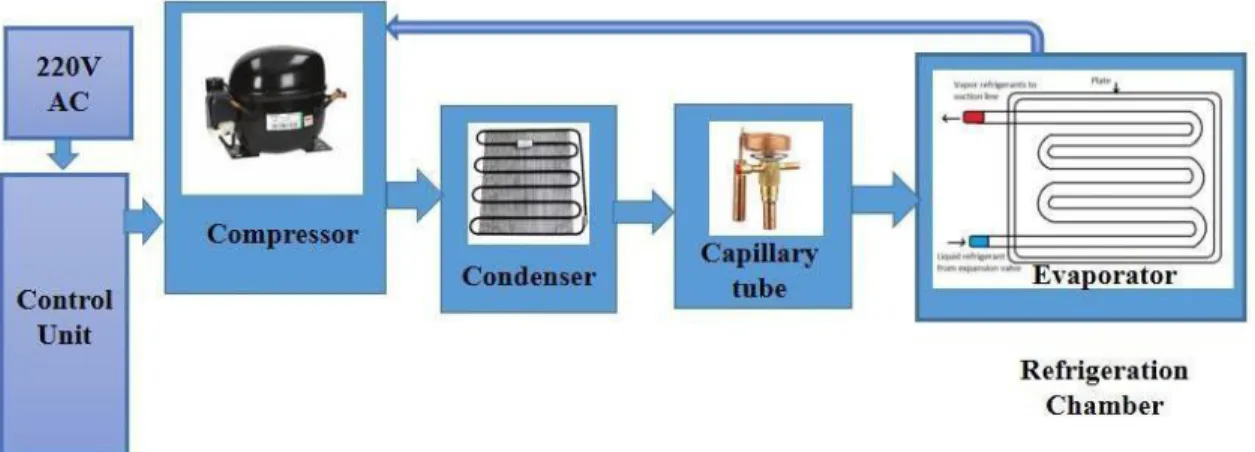

Block Diagram

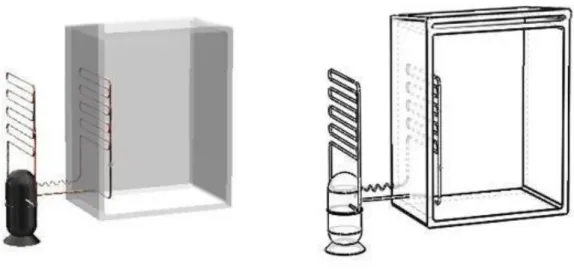

Basic Structural Design

Working Principle

Our Final System View

RESULT AND DISCUSSION

Discussion

Result

Advantage

Application

CONCLUSION

Conclusion

Future Scope