Zahid Hasan, Mehedi Hasan, Tawhid Ali at Department of Mechanical Engineering, Sonargaon University, Bangladesh. This thesis entitled 'INDUSTRIAL PRODUCT DISTINGUSHER WITH MODERN CONTROL SYSTEM' was prepared and submitted in partial fulfillment of the requirements for the degree of B. Mainol Hasan, Lecturer, Department of Mechanical Engineering, Sonargaon University, who despite a tight and busy schedule found time to complete our work continued guidance and has given valuable suggestions, encouragement, careful supervision, wisdom, positive criticism and valuable advice during the course of this study and in the fulfillment of the work.

We would like to thank Mostofa Hossain Sir, Head, Department of Mechanical Engineering, Sonargaon University for granting permission to use the available laboratory and workshop facilities. Color recognition machine is mainly a device that can sense the different color of the object and distinguish them in the right place.

Introduction

Executive Summary

The same design is done for the acrylic board which is placed on the lead screw of the base. Most electronic projects can be done quite well from other boards available in the market making the Arduino Mega. It can be taken from the board's Vin or USB cable or another regulated 5V voltage supply.

First, select “Arduino Uno from the Tools menu, Board (depending on the microcontroller on your board). The IC used as an ATmega328 on the Arduino Uno is pre-written with a bootloader that allows you to load new code into it without using an external hardware programmer Escid, et al., “A 0.35mm CMOS Optical Sensor for Integrated Transimpedance circuit”, International Journal on Smart.

Objectives of the thesis

Significance of the project

Our industrial automation systems enable companies to achieve shorter cycle times, greater efficiency and repeatability. Industrial automation not only simplifies labor-intensive tasks and thus significantly reduces labor costs, but also shortens production hours. When manufacturers use industrial automation, they eliminate quality control problems associated with human error.

With industrial automation, processes can be carefully regulated and controlled so that the quality of the final product is not only reliable, it is often greatly improved. So whether the company is a manufacturer that wants to create accurate, consistent welds every time, or a pharmaceutical company that requires hygienic, clean room results every time, industrial automation delivers consistent, reliable results.

Literature Review

The Early Years of Automation

There are 54 digital I/O pins and 16 analog pins incorporated on the board that make this device unique and stand out from the rest. This board comes with the USB cable port that is used to connect and transfer the code from the computer to the board. The DC power jack is connected to the board used to power the board.

Arduino software called Arduino IDE is used to program the board, which is a common software used for all boards belonging to the Arduino family. However, the output voltage through this pin to the board will automatically be set to 5V.

Advancement of Automation in the 20 th cenmtury

The current state of industrial automation in the manufacturing industry

Current industrial robots feature high-quality computing capabilities, improved operational degrees of freedom, and vision systems. Furthermore, they are quite inflexible and too specialized for use in small and medium-sized industries, so industrial automation is usually better suited to large manufacturers and long production runs. Automation in the manufacturing industry relies on computer and software capabilities to automate, integrate and optimize various components of manufacturing systems.

Thanks to the initiation and evolution of industrial automation in manufacturing industries, the world enjoys high quality products and better utilization of energy, resources and raw materials. Contrary to what most people believe, the manufacturing industry is set to create more jobs with the use of robots, which will continue to drive operations and benefit from industrial automation.

Methodology

- Working Process

- List of Necessary Components with Price

- Development of the Mechanical Structure

- Development of the Electrical Structure

- Block Diagram

- Electrical Drawing

- Working Principle

- Stepper Motor 4 Wire

- Servo Motor S8503

- SMPS Power Supply………………………………................................................... 21-22

- A4988 Stepper Motor Driver

A wooden block (plastic board) was first chosen as the basis of the project. When the color sensor detects the color of the product, it sends a signal to the Arduino, and then the Arduino sends a signal to the stepper motor driver. When the item stays on the unloading box, the color sensor detects the color of the item, because the input devices will send a signal to the microcontroller, where Arduino as a microcontroller will give the command to the stepper motor to move to the right place, and then the Arduino will give the command to the servo motor to unload the product .

Arduino Boards have revitalized the automation industry with their easy-to-use platform where anyone with little or no technical background can start learning basic skills to program and operate the board. Availability of Atmega16 on the board makes it different from Arduino Pro Mini which uses USB to serial converter to program the board. You can either use a USB cable to power the board and transfer code to the board or you can power it up with Vin from the board or through Power jack or batter.

Last two sources to power the board are needed once you have already built and compiled code into the board via USB cable. This board comes with a resettable polyfused which prevents the USB port of your computer from overheating in the presence of high current flowing through the board. There are 5 ground pins available on the board which makes it useful when more than one ground pins are required for the project.

On Rev1 boards: Solder jumper connection on the back of the board (near Italy map) and then 8U2 reset. On Rev2 or newer boards: There is a resistor that pulls the 8U2/16U2 HWB line to ground, making it easier to put into DFU mode. The ATmega16U2 on the board channels this serial communication over USB and appears as a virtual com port to the software on the PC. The RX and TX LEDs on the board will flash when data is being transferred via the USB-serial chip and the USB connection to the computer (but not for serial communication on pins 0 and 1).

The 3D Viewer module allows the developing board to be viewed in 3D along with a semi-transparent height plane representing the board enclosure. The STEP output can then be used to transfer to mechanical CAD software such as Solid works or Autodesk for precise table assembly and positioning.

Software Analysis

Proteus

Proteus Design Suite is a proprietary software toolkit primarily used for electronic design automation. The software is mainly used by electronic design engineers and technicians to create schematics and electronic prints for the production of printed circuit boards. The first version of what is now the Proteus Design Suite was called PC-B and was written by the company's chairman, John Jameson, for DOS in 1988.

Mixed mode SPICE Simulation was first integrated into Proteus in 1996, and microcontroller simulation then arrived in Proteus in 1998. Shape-based automatic routing was added in 2002, and 2006 saw another major product update with 3D Board Visualization. More recently, a dedicated IDE for simulation was added in 2011, and MCAD import/export was included in 2015.

Support for high-speed design was added in 2017. Feature-led product releases are typically biannual, while maintenance-based service packs are released as needed.

Microcontroller Simulation

PCB Design

Results

Today in highly competitive industrial manufacturing, managing the integrity of a product's supply from raw material to finished product through quality manufacturing is crucial. Bickman, et al [13] described in the article on automatic color sorting using optical technology that evolved from early designs intended to remove ceramic contamination. So, this project of automatic color sorting is an excellent one because of its working principle and wide implementation [15].

By applying the idea of this project, an industry can easily distinguish the desired product based on its color. Although it has some limitations, but by making some changes, this concept can be implemented in a wide range of applications. Frank, Nobert Kaiser, Wolfgang Buss, Ramona Eberhardt, "High speed industrial color and position sensors", Electronic.

Frisby, Danny Diamond, King Tong Lau, Alan Farrell, Brid Quilty, Dermot Diamond, “Development of intelligent packaging for monitoring fish spoilage”, Food Chem, vol 102, p. 12] Norfazlinda Binti Daud, “Application of Color sensor in an automated system”, Technical University Malaysia, May 2007. Servo servoTop; // create a servo object to control a servo servo servoBottom; // create a servo object to control a servo // Variables.

Discussion& Conclusion

Application

Future Scope

Conclusion

Large & Small acrylic board for X & Y axis movement

Electrical Drawing

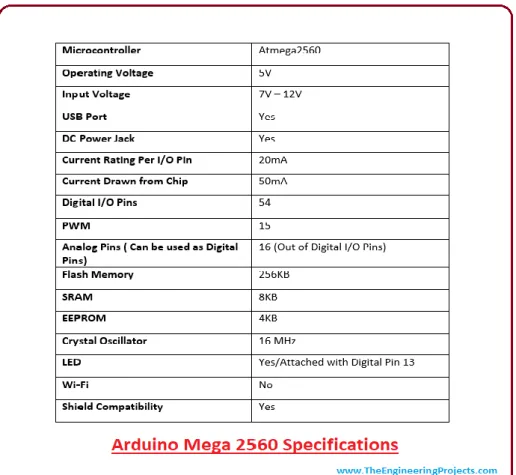

Arduino mega 2560

This board comes with 54 pins and 16 analog pins with more memory to store the code. I will try to cover everything related to Arduino Mega 2560, what is it about, its main features, working, technical specifications and everything you need to know. It comes with more memory space and I/O pins compared to other cards available in the market.

ICSP header is a remarkable addition to Arduino Mega that is used for programming the Arduino and uploading the code from the computer. There is not much difference between Arduino Uno and Arduino Mega except that later has more memory space, bigger size and more I/O pins. Arduino Mega is specially designed for the projects that require complex circuits and more memory space.

However, there are some projects that are handled exclusively by Arduino Mega, such as creating 3D printers or controlling more than one motor, due to its ability to store more instructions in the code memory and some digital and analog I/O -pins. It is important to note that all of these analog pins can be used as digital I/O pins. This module can be used for creating color sorting robots, reading test strips, color matching tests etc.

A smart microcontroller unit called Arduino Uno can be programmed using Arduino software.

Arduino mega specification

Arduino mega pin out 2560

Stepper Motor

Servo motor S8503

SMPS Power Supply

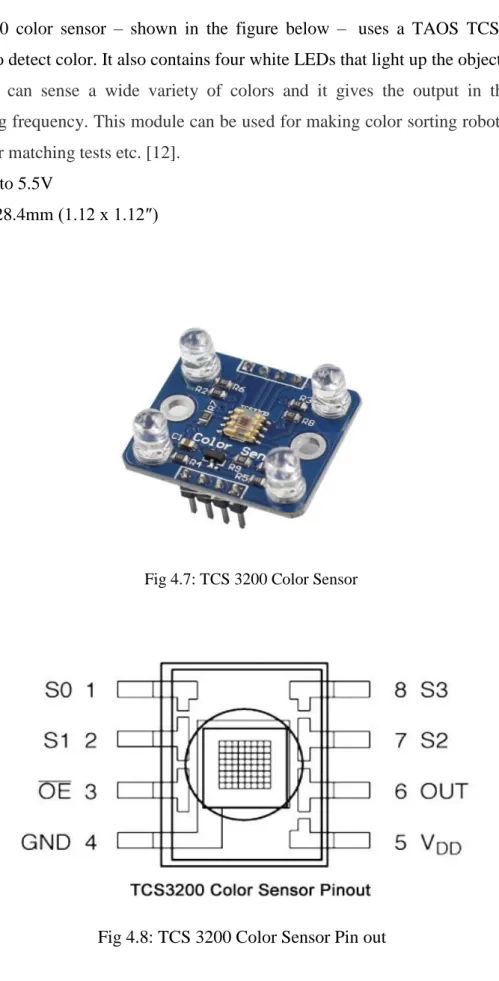

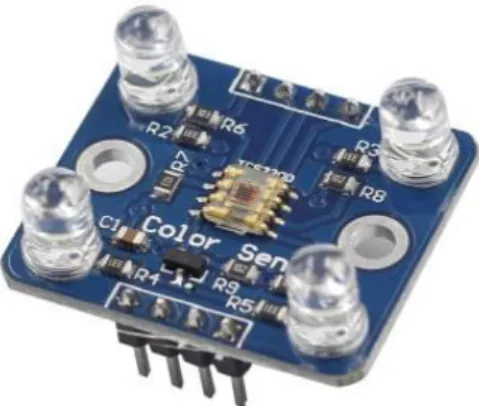

TCS Color Sensor

TCS Color Sensor pin Out

A4988 Motor Driver

Arduino Software Interface IDE

We can also bypass the bootloader and program the microcontroller via the ICSP (In Circuit Serial Programming) header.