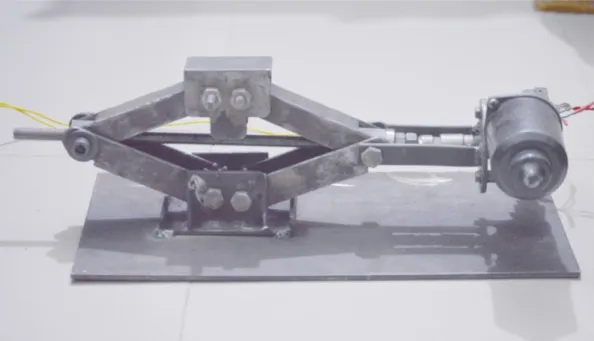

A Scissor Jack is a mechanical device used to easily lift a vehicle off the ground, access sections under vehicles or change the wheel. This thesis concerns the design modification of a crank-operated scissor jack typically used for lifting light motor vehicles (L.M.V) during maintenance. A scissor jack is a device constructed with a hatched mechanism, such as scissors, to lift a vehicle for repair.

The power screw design of a regular scissor jack reduces the amount of force required by the user to operate the mechanism. A scissor jack is simply operated by turning a small crank that is inserted into one end of the scissor jack. The end fits into a ring hole mounted on the end of the screw, which is the object of force on the scissor jack.

Just by turning this screw thread, the scissor jack can lift a vehicle costing several thousand pounds.

Bottle (Cylinder) Jack

When it is closed, the arms spread back apart and the jack locks or flattens out again. Because the gears of the propeller push the arms up, the amount of force applied is multiplied. The car's gravitational weight is not enough to prevent the jack from opening or to stop the propeller from turning, since it does not exert force directly on it.

If a person applies pressure directly to the car's crank, or rests his weight on the maneuver, the person will not be able to turn it, even though his weight is a small percentage of the cars. When the plunger is pulled, it draws oil from the reservoir through a suction check valve in the pump chamber. The ball of the suction valve is inside the chamber and opens with each pull of the plunger.

For lifting structures such as houses, the hydraulic interconnection of multiple vertical jacks through valves enables the even distribution of forces while allowing precise control of the lifter [6].

Objectives

There is evidence of the use of screws in the ancient Roman world, but it was the great Leonardo da Vinci in the late 15th century who first demonstrated the use of a screw jack to lift loads. People weren't sure of the intended use of his invention, but it seems to have been relegated to the history books along with the helicopter and the tank for nearly four centuries. It is not until the end of the 19th century that people have evidence that the product has been further developed [3].

With the Industrial Revolution in the late 18th and 19th centuries came the first use of screws in machine tools, via English inventors such as John Wilkinson and Henry Maudsley. Like Da Vinci's jack, it was a technological innovation because it was based on the principle of the ball bearing for supporting a load and transferring a rotary motion, through a gear transmission and a screw, to a linear motion for moving of the burden. Over the next 30 years, the Duff Manufacturing Company became the largest manufacturer of lifting jacks in the world, developing many new types of jacks for different applications, including its own version of the ball bearing jack.

Using the relatively new portable compressor technology, users could now move and position loads without manual effort.

Construction

Required Components

- Applications

- Advantages

- Disadvantages

- Forms of Threads

- Designation of Threads

- Multiple Threaded Power Screws

- Terminology of Power Screw

- Self Locking Screw

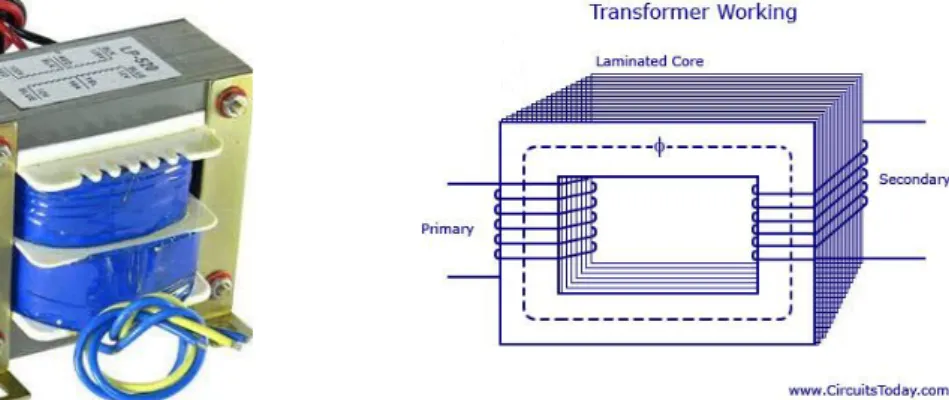

- Transformer

- DC Motor

- Relay

- IR Sensor

- Rectifier

There are three essential parts of a power screw, ie. screw, nut and a part to hold either the screw or the nut in place. In other applications, the nut is held stationary and the screw moves in the axial direction. A load of 15kN can be raised by applying an effort as small as 400N. Therefore, most of the power screws used in various applications such as vices, clamps, valves and vices are usually manually operated.

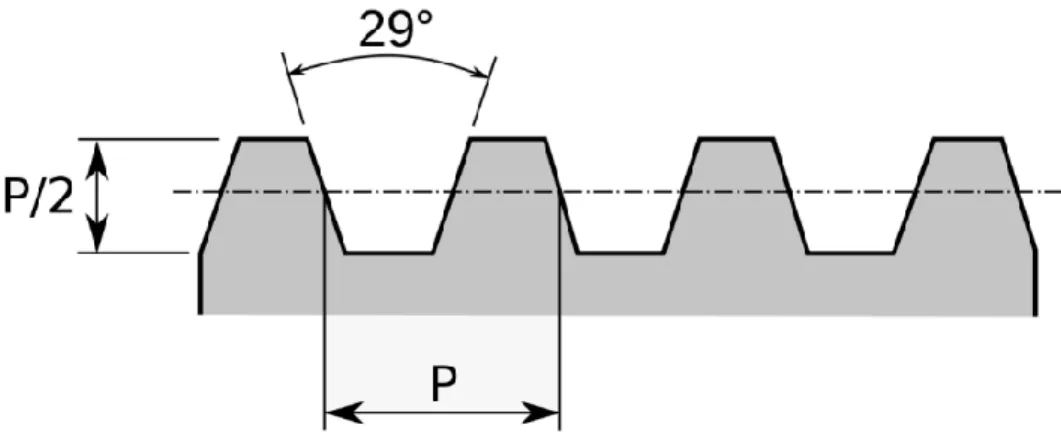

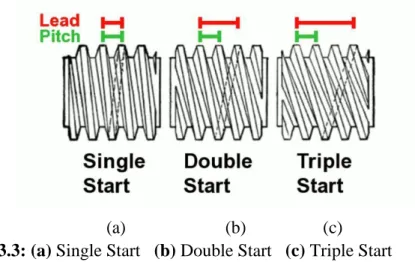

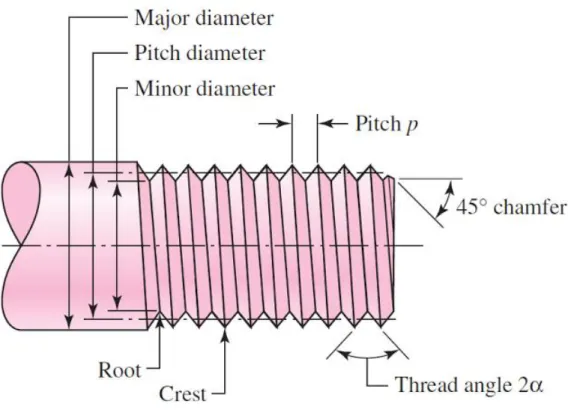

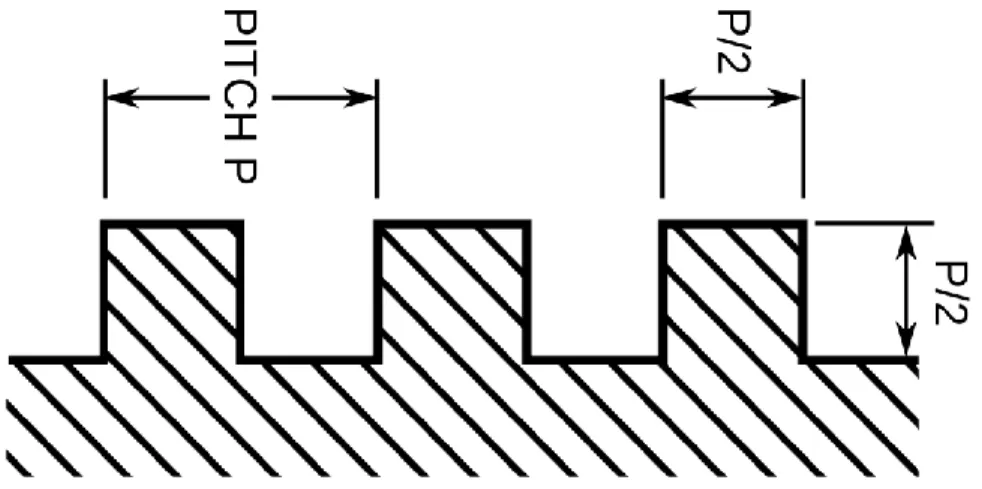

Power screws have very poor efficiency; down to 40%. Therefore, it is not used in continuous power transmission in machine tools, with the exception of the lead screw. The pitch is defined as the distance, measured parallel to the axis of the screw, from a point on one thread to the corresponding point on the adjacent thread. The lead is defined as the distance, measured parallel to the axis of the screw, that the nut will advance in one revolution of the screw.

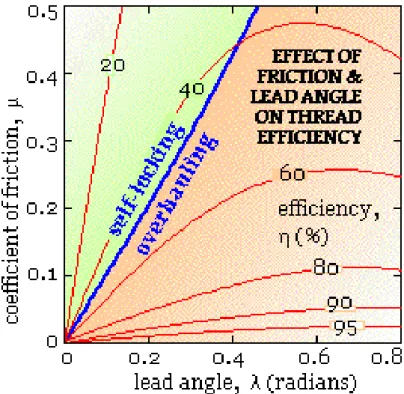

For a single-threaded screw, the lead is the same as the pitch, for a double-threaded screw, the lead is twice the pitch, and so on. It is defined as the angle made by the helix of the thread with a plane perpendicular to the axis of the screw. It can be seen that when , the torque required to reduce the load is negative.

The rule for self-locking screw is as follows: "A screw will be self-locking if the coefficient of friction is equal to or greater than the tangent of the helix angle". The coefficient of friction between the surfaces of the screw and the nut is reduced by lubrication. For double lead screw, lead is twice of the pitch and for triple thread, three times of pitch.

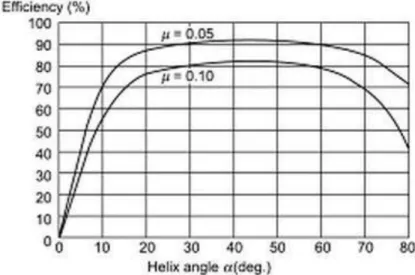

From the above equation, it can be seen that the efficiency of a square thread screw depends on the helix angle α and the friction angle . The following figure shows the variation of the efficiency of a square-thread screw with helix angle for different values of the coefficient of friction. A varying current in any one coil of a transformer induces a varying magnetic flux, which then induces a varying electromotive force in all the other coils wound around the same core. Since the invention of the first constant potential transformer in 1885, transformers have become essential for the transmission, distribution and use of alternating current electricity.

Almost all types of DC motors have some internal mechanism, either electromechanical or electronic; to periodically change the direction of current in a part of the motor.

Various Developments in Lifting Devices

Levers

NC (Normally Closed): the normally closed configuration is used when you want the relay to be closed by default, which means that current flows unless you send a signal from the Arduino to the relay module to open the circuit and stop the current. NO (Normally Open): the normally open configuration works in reverse: the relay is always open, so the circuit breaks unless you send a signal from the Arduino to close the circuit. If you just want to turn on a light bulb occasionally, it's best to use a normally open circuit configuration.

IR detectors are small microchips with a photocell that are set to listen for infrared light. They are almost always used to detect the remote control - every TV and DVD player has one of these on the front to listen for the IR signal from the clicker. Inside the remote control is a matching IR LED that emits IR pulses to tell the TV to turn on, turn off, or change channels.

IR light is not visible to the human eye, which means it takes a bit more work to test a setup. A rectifier is an electrical device that converts alternating current, which periodically reverses direction, to direct current, which only flows in one direction.

Screw thread

Gears

Necessity of Jack

Car jacks should be easy to use for women or those who have had a flat tire in the middle of nowhere. In light of such inherent drawbacks, commercial car repair shops and garages are usually equipped with large and high-tech car lifts, such lifts being raised and lowered via electrically powered systems. However, due to their size and the high cost of purchasing and maintaining electric powered car lifts, these lifts are not available to the average car owner.

Such electrically powered portable jacks not only eliminate the tedious task of lifting a car via manually operated jacks, but further reduce the time required to repair the car. Such a feature can be particularly advantageous when it is necessary to repair a car on the side of a roadway or in other dangerous conditions. Rankine has expressed concern about the dangers associated with the use of a jack that does not carry the weight it is promoted to hold.

Tests have shown that the jack has the ability to tighten well below the weight it is promoted to withstand, and it does not meet the labeling or performance requirements of the Australian Standard for vehicle jacks. Maintain low surface contact pressure Increasing the screw size and nut size will reduce thread contact pressure for the same working load. Keep the mating surfaces well lubricated. The better the lubrication, the longer the service life.

Grease fittings or other means of lubrication shall be provided for the power screw and nut. Keep the mating surfaces clean, dirt can easily get into the soft nut material. The soft material of the nut is removed during contact, allowing the hard dirt particles to remove the material of the mating screw.

When the mating surfaces warm up, they become much softer and wear away more easily. Means of removing the heat, such as limited duty cycles or heat sinks, must be provided to avoid rapid wear of overheated material.

Power Screw

Since the maximum stresses t max and max are within the safe limits, the single-start square screw design is satisfactory.

Trunnion

Top Arm

Bottom Arm

Top Plate

Bottom Plate

Drawing of a Scissors Jack

The round bar was turned to the required dimensions on the lathe, and then the lathe was adjusted to obtain external square threads, thus obtaining external square threads of the required dimensions, as shown in fig.

Top Arms and Bottom Arms

Trunnions

Top and Bottom Plates

Circuit Diagram

Working Process

It is the ratio of the distance (y) moved by the insert to the distance (x) moved by the load. In a lifting machine it is measured by the product of the effort and the distance it has moved (ie P.y). In a lifting machine, it is measured by the product of the weight lifted and the distance it has been lifted, i.e. (W.x).

Calculations

Experimental Data

Results

Conclusion

Scope for future work