The project work has been carried out as per the requirements of Sonargaon University of Bangladesh. Abu Tarek and Abdul Kuddus on the partial fulfillment of the requirements for the degree of B.Sc.

BASIC PRINCIPLES OF EQUALIZATION TANK

EQUALIZATION

- THE MAIN ADVANTAGES OF HAVING AN EQUALIZATION TANK

- EQUALIZATION TANK OPERATION

- EQUALIZATION TANK MAINTENAMCE

- CONSTRUCTION OF COARSE BUBBLE DIFFUSERS IN

Make sure the air flow/mixing is uniform across the entire floor of the tank. Therefore, only coarse bubblers should be used in the equalization tank in wastewater treatment.

OBJECTIVES OF EQUALIZATION

As keeps said in suspension and prevents set of said in the tank, thereby reducing the frequency. If membrane diffusers are used, they will fail frequently, due to the repeated cycles of expansion and contraction caused by fluctuating water levels in the equalization tank.

ORGANIZATION OF THE THESIS

IN-PLANT CONTROL

BACKGROUND OF THE STUDY

Bangladesh is an agriculture-centric country, but now a days the industrial sector plays a vital role in the development process of the country [1]. The main source of this pollution of the water bodies is the industries established nearby.

OBJECTIVES

To support these garment industries, hundreds of large-scale textile industries have been established in the last few years and many more will be established in a short time. Recently, the textile industry, which has water bodies close to its location, has been heavily polluting the water.

MAIN ACTIVITIES OF EQUALIZATION TANK

SCOPE OF THE THESIS

The primary interest in flow equalization alone is understandable: Flow equalization has generally only been tested on plants operated at short sludge ages (< 3 days). Specific advantages resulting from flow equalization in the operation of activated sludge treatment plants have been identified by a number of authors (La Grega and Keenan, 1974; Wallace, 1968; Spiegel, 1974;.

REQUIREMENTS FOR CONTROL

With the advent of low-cost microcomputers, it appeared feasible to design an on-line control strategy that would (1) minimize daily deviations in flow and load rates from their respective mean values within the volume limitations of a given system on a continuous basis and (2) overcome the problems associated with operating leveling devices by man. Solving this problem requires the use of a balancing algorithm in a suitable control strategy.

EQUALIZATION ALGORITHM …

The combined effect of the leveling error and the penalty error for the volumetric limits caused a further problem: "spikes" in the 24-hour tank discharge profile could develop when the tank was nearly full or empty, especially for tank residence times of less than 3 hours ( relative to the average inflow). This problem in the optimization procedure was solved by including a second penalty error E, s to limit the rate of change of the reservoir discharge rate. This punishment has an additional benefit; rapid changes in the outflow velocity profile that are not adequately reflected in the offset error are damped.

Optimal equalization requires a tank with an average retention time in the range of 4 to 6 hours; little scavenging efficiency is gained at retention times greater than 6 hours.

CONTROL STRATEGY

DESIGN METHODS FOR EQUALIZATION

In the literature, consideration has generally been limited to determining volume requirements; the other factors listed above have been largely neglected. When it comes to calculating equalization volume requirements, there have traditionally been two approaches: (1) for constant volume equalization and (2) for variable volume equalization. Ref:file:///C:/Users/88019/AppData/Local/Temp/Temp3_Flow_Equalization_and_Neutralization.zip/thesis _ebe_1982_dold_pl.pdf).

EVALUATION OF FLOW EQUALIZATION EXPERIENCE

In all cases, the inferences (regarding reservoir size, configuration, etc.) drawn under fixed daily input patterns were found to hold under real-time inputs. Ref:file:///C:/Users/88019/AppData/Local/Temp/Temp3_Flow_Equalization_and_Neutralization.zip/thesis _ebe_1982_dold_pl.pdf).

METHODS FOR IMPLEMENTING EQUALIZATION

With flow equalization, the hold-up provided in the equalization tank necessarily induces some damping of the variations in the input load. Nevertheless, flow balancing with its associated degree of load balancing should have significant advantages over plant. It appears from the above list that flow equalization can only have positive consequences.

However, studies on the effect of flow equalization on plant operation and performance have led to conflicting conclusions.

OUTLINE OF METHODOLOGY

Through successive visits to ten different textile composites and dyes factories in Bangladesh, the necessary data related to the economic, technological and environmental aspects of the project were collected for this study. A detailed review of existing information and literature on ETP operation, management and governance issues was undertaken to identify gaps in information and knowledge.

SELECTION OF FACTORIES

FACTORY VISIT

Manager (Accounts & Finance), Maintenance Manager, General Manager Operations, Manager Research & Development, Supervisor ETP; company officials were interviewed to collect preliminary and general information about the wastewater treatment plant.

DATA COLLECTION

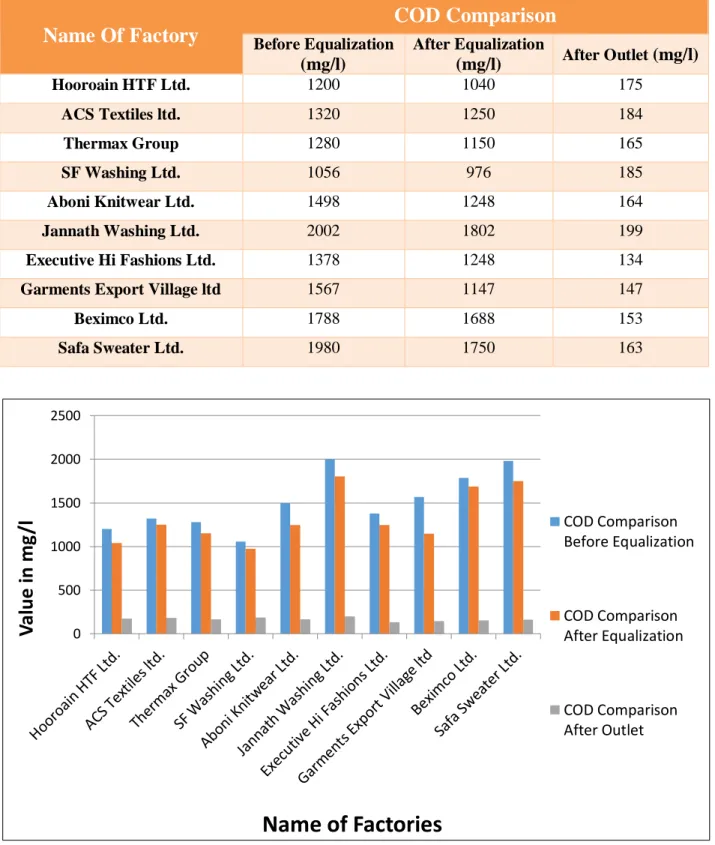

In case of color removal, the effectiveness of the biological treatment is not so high. On the other hand, presence of toxic metal inhibits the growth of the bacteria in the aeration basin, which can be effectively removed by chemical treatment. As a fourth treatment option, Chemical Treatment Process Prior to Biological Treatment Process was considered to reduce COD, BOD and color of the effluent.

The effects of toxic metal (if any) for this particular wastewater and the effects of pretreatment of the wastewater by chemical process on biological treatment are observed by this setup.

ANALYSIS AND COMPARISON

A portion of the MLSS may be inorganic and under certain conditions may represent a significant portion of the solids present. To overcome this, many operators estimate the organic fraction of the sludge by measuring the combustible material in the MLSS by burning the dried sludge in a muffle furnace at 500°C. As a first approach for the treatment of the waste water from the Textile factory, a laboratory set-up was made for the aeration of the waste water.

The raw waste water was aerated for different periods of time to obtain the required detention time at which the effluent from the industry could be treated up to the standard set by DoE.

MIXING AND AERATION REQUIREMENTS

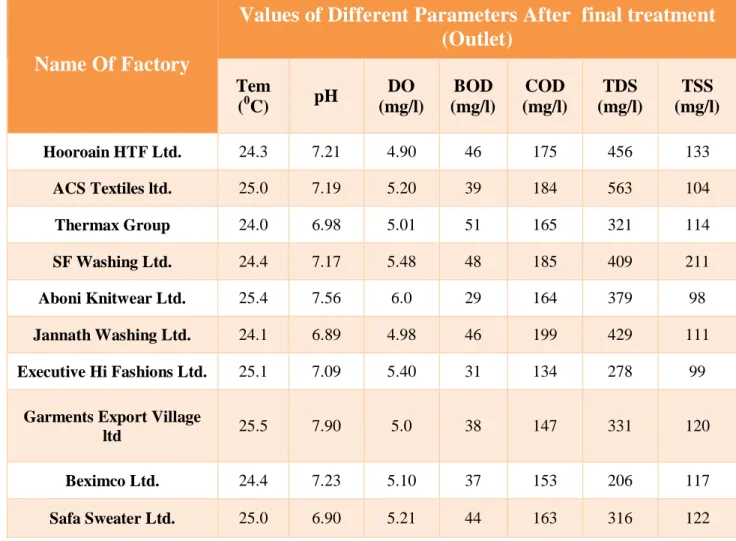

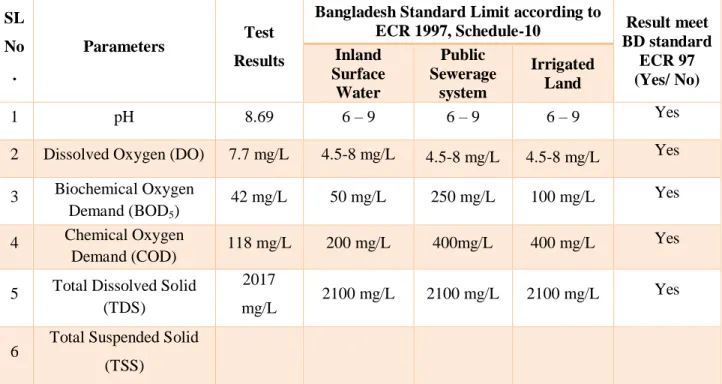

The system must have logic controls to decide which pumps are on and to add back excess wastewater at rates that keep the rest of the plant operating at near-constant conditions. Performance performance of the post-treatment results of ten different treatment plants of ten factories in terms of percent recovery compared to the national standard. Considering the overall efficiency, the biological treatment plant is the most desirable among the physicochemical and electrochemical treatment plants.

On the other hand, the role of the equalization tank is mainly involved in controlling the economic performance of ETP.

RESULT OF OPERATIONAL EFFICIENCY

The results obtained from the analysis of biological, physico-chemical and electrochemical wastewater treatment plants of textile dyeing industry and detailed discussion about this study have been presented here in the following categories.

CAPACITY DESIGN FROM FLOW FLUCTUATION

- Factory - Thermax Group Ltd

- Factory - ACS Textiles Ltd

- Factory - Hoorain HTF Ltd

- Factory- SF Washing

- Factory - Aboni knitwear

- Factory - Executive Hi Fashion

- Factory - Garments Export Village

- Factory - Beximco Ltd

The industry is adding to the current production of readymade garments in the country as well as providing employment to a significant number of personnel/total factory strength 4000 people, monthly production capacity is 10000000 yards/month, this factory earns a significant amount of foreign exchange foreign and thus contributing to the growth of the national and social economy. The industry is adding to the current production of ready-made garments in the country as well as providing employment to a significant number of personnel/total factory strength 2900 people, the monthly production capacity is 2000000 pieces/month, this factory earns a significant amount of foreign exchange foreign and thus contributing to the growth of the national and social economy. The industry is adding to the current readymade garment production of the country as well as employing a significant number of personnel/total factory strength 2657 people, monthly production capacity is 5500 cubic meters, this factory earns a significant amount of foreigners. currency and thus contributing to the national economy and social upliftment.

The industry adds to the current ready-made Garment production of the country and provides employment to a considerable number of personnel/the total manpower of the factories 6215 Persons, monthly production capacity is 500000 Pcs/Month, this factory earns a considerable amount of foreign exchange and thus contribute to national economy and social upliftment. The industry adds to the current ready-made Garments production of the country and provides employment to a considerable number of personnel/the total manpower of the factories 1100 Persons, monthly production capacity is 200000 Pcs/Month, this factory earns a considerable amount of foreign exchange and thus contribute to national economy and social upliftment. The industry is adding to the current ready-made Garments production of the country as well as providing employment to a considerable number of personnel/the total manpower of the factories 11515 Person, monthly production capacity is 2200000 meters/month, this factory earns a considerable amount of foreign exchange thereby contributing to national economy and social upliftments.

Retention time variations are given in below table

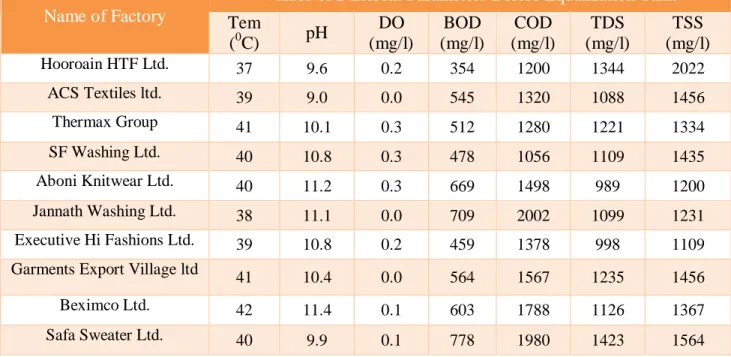

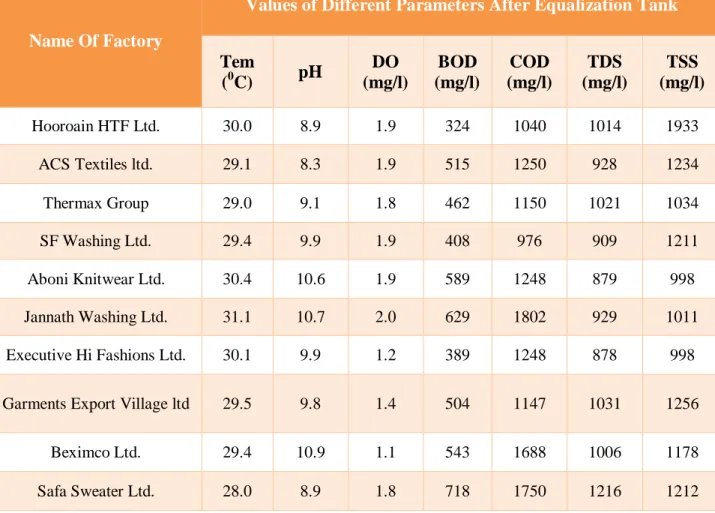

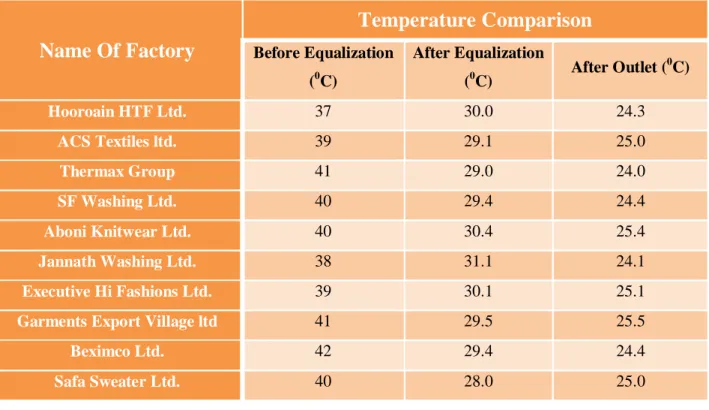

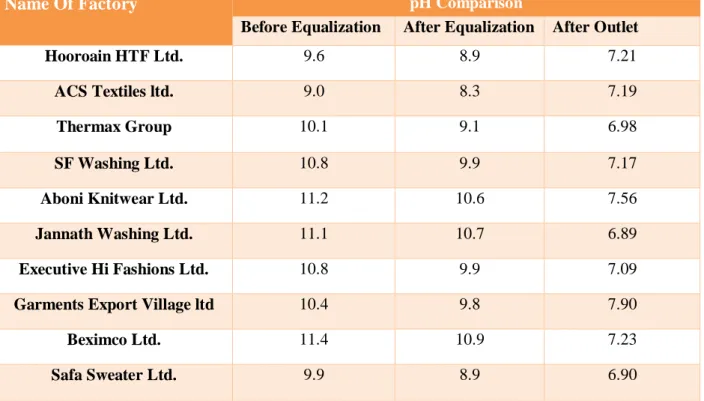

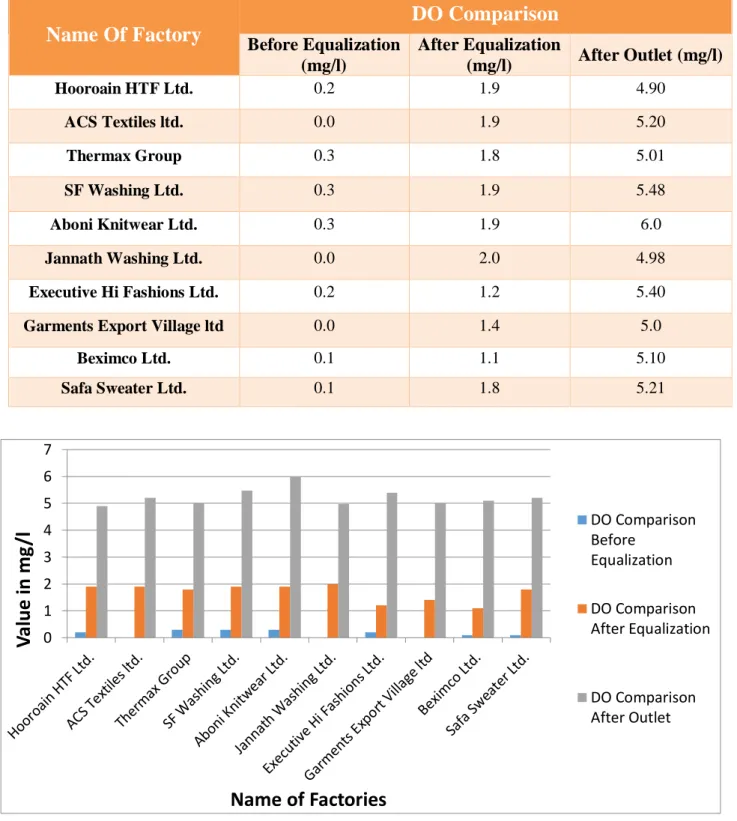

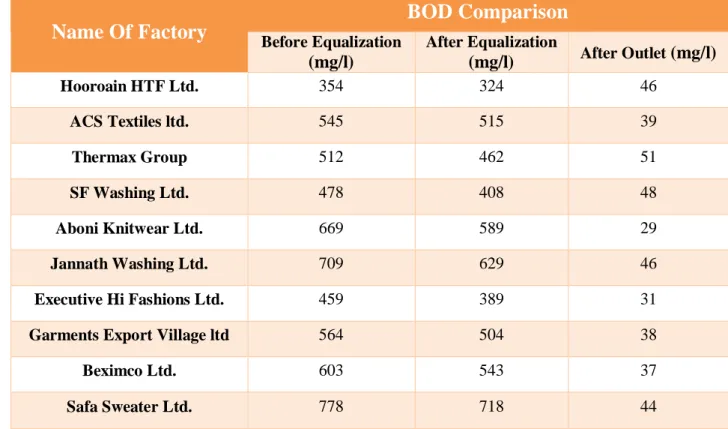

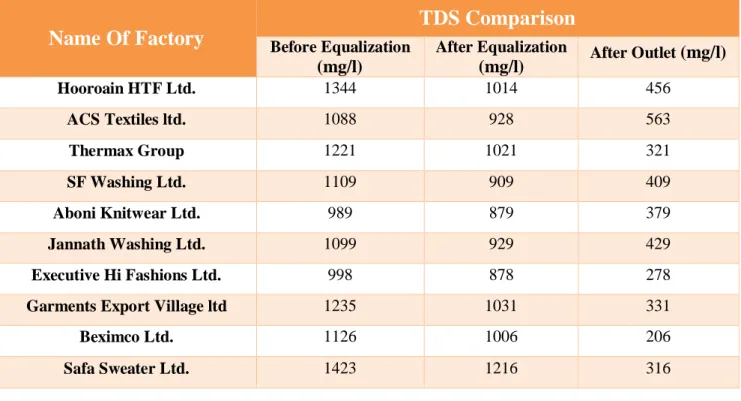

Comparison of parameters of different industries: The comparison are presented

Discussion

This thesis was carried out to achieve the above mentioned parameters in accordance with the mentioned objectives among the factories. It was also found from the above that the fluctuation of wastewater flow between the factories was not too great, which would become the reason for the overcapacity of the tank. It has also been found that the holding time of the equalization vessel for some plants is greater than the standard limit, which must be responsible for the overcapacity.

Finally, we can say that from the above result and discussion, the equalization tank is one of the most important things for a sewage treatment plant (ETP).

RECOMMENDATIONS

Since the equalization tank is the main and main/or initial part of the ETP, the role of this tank in this treatment process is limitless. Through this tank, the temperature level is lowered by homogenization, as well as by eliminating shock, stabilizing the pH, maintaining a constant flow, etc. Since the tank plays a key role in processing, the tank volume should be designed considering the retention time as the capacity depends on it.

Therefore, the retention time must be taken into account during the planning period of the tank volume.