ECONOMIC LOT SCHEDULING PROBLEM

IN IMPERFECT PRODUCTION SYSTEM WITH TWO KEY MODULES

A THESIS

Submitted in Partial Fulfillment of the Requirement for the Bachelor Degree of Engineering in Industrial Engineering

FILEMON YOGA ADHISATYA 10 14 06247

INTERNATIONAL INDUSTRIAL ENGINEERING PROGRAM DEPARTMENT OF INDUSTRIAL ENGINEERING

FACULTY OF INDUSTRIAL TECHNOLOGY UNIVERSITAS ATMA JAYA YOGYAKARTA

ACKNOWLEDGEMENT

The author conducted the research on Economic Lot Scheduling Problem in Imperfect Production System with Two Key Modules to fulfill partial requirement

to earn bachelor degree of Industrial Engineer of Universitas Atma Jaya Yogyakarta.

The author would like to deliver highest appreciation to Mr. The Jin Ai, D.Eng. and Mrs. Ririn Diar Astanti, D.Eng. as the faculty supervisor and co-supervisor for

the help to the author while conducting this research. Moreover, Mr. The Jin Ai, D.Eng. and Mrs. Ririn Diar Astanti, D.Eng. have also been guiding and

encouraging the author to achieve highest achievements during his study in Universitas Atma Jaya Yogyakarta.

The deepest appreciation for love and dedication goes to the author‟s parents, Mr. Fidelis Priyo Djatmiko and Mrs. Zita Pancawesti. Their love and dedication for

the author have been the main power to start, conduct and finally finish this research.

All other appreciation goes to author‟s family, relatives and friends in Himpunan Mahasiswa Teknik Industri UAJY and Industrial Engineering batch 2010 for all the supports given to the author to finish this thesis. Last but not least, author is

TABLE OF CONTENT

CHAPTER TITLE PAGE

Title Page i

Identification Page ii

Declaration of Originality iii

Acknowledgement iv

Table of Content v

List of Table viii

List of Figure ix

Abstract xi

1 Introduction 1

1.1. Background 1

1.2. Problem Formulation 2

1.3. Objectives 3

1.4. Scopes and Limitations 4

2. Literature Review and Theoretical Background 5

2.1. Economic Lot Scheduling Problem 5

2.2. Economic Production Quantity Model with Two Imperfect

Modules 8

2.3. ELSP Five Key Research Themes 9

2.4. Gap Analysis and Research Contributions 15

3 Research Methodology 17

3.1. Literature Review 17

3.2. Problem Identification 17

3.3. Problem Generation 18

3.5. Result Analysis 19

3.6. Conclusion 20

4 Development of ELSP Model in Perfect Production System 22

4.1. Data and Problem Formulation 22

4.2. ELSP in Perfect Production System Using Independent

Solution Approach 24

4.3. ELSP in Perfect Production System Using Common Cycle

Approach 27

4.4. ELSP in Perfect Production System Using Basic Period

Approach 30

5 ELSP in Imperfect Production System with One Key Module 33

5.1. Data and Problem Formulation 33

5.2. ELSP in Imperfect Production System with One Key Module

Using IS Approach 35

5.3. ELSP in Imperfect Production System with One Key Module

Using CC Approach 39

6 Development of ELSP Model in Imperfect Production System

with Two Key Modules 42

6.1. Data and Problem Formulation 42

6.2. Economic Production Quantity Model in Imperfect

Production System with Two Key Modules 45

6.3. ELSP Model in Imperfect Production System with Two Key

Modules 50

7.1. Result Analysis on ELSP in Perfect Production System 60

7.2. Result Analysis on ELSP in Imperfect Production System

with One Key Module 61

7.3. Result Analysis on ELSP in Imperfect Production System

with Two Key Modules 62

7.4. Verification on ELSP Model in Imperfect Production System

with Two Key Modules 63

8 Conclusion 68

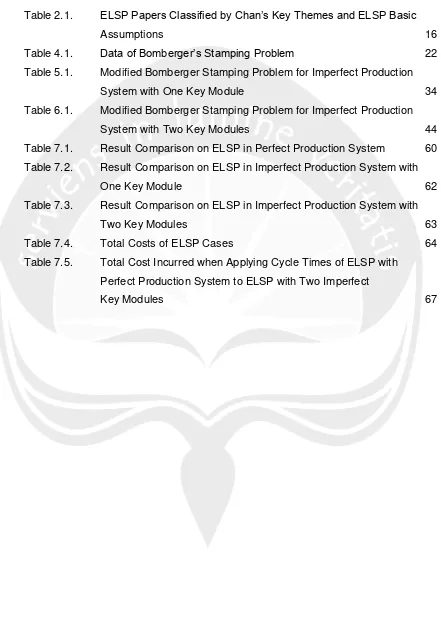

List of Table

Table 2.1. ELSP Papers Classified by Chan‟s Key Themes and ELSP Basic

Assumptions 16

Table 4.1. Data of Bomberger‟s Stamping Problem 22

Table 5.1. Modified Bomberger Stamping Problem for Imperfect Production

System with One Key Module 34

Table 6.1. Modified Bomberger Stamping Problem for Imperfect Production

System with Two Key Modules 44

Table 7.1. Result Comparison on ELSP in Perfect Production System 60

Table 7.2. Result Comparison on ELSP in Imperfect Production System with

One Key Module 62

Table 7.3. Result Comparison on ELSP in Imperfect Production System with

Two Key Modules 63

Table 7.4. Total Costs of ELSP Cases 64

Table 7.5. Total Cost Incurred when Applying Cycle Times of ELSP with Perfect Production System to ELSP with Two Imperfect

List of Figure

Figure 3.1. Research Methodology 20

Figure 4.1. Solver for Independent Solution Perfect ELSP Model 24

Figure 4.2. Microsoft® Excel Spreadsheet of ELSP Model under IS Approach 25

Figure 4.3. Solver for Common Cycle Perfect ELSP Model 27 Figure 4.4. Microsoft® Excel Spreadsheet of ELSP Model under CC

Approach 28

Figure 4.5. Solver for Basic Period Perfect ELSP Model 30

Figure 4.6. Microsoft® Excel Spreadsheet of ELSP Model under BP

Approach 31

Figure 5.1. Solver for Independent Solution Imperfect ELSP Model with

One Key Module 36

Figure 5.2. Microsoft® Excel Spreadsheet of ELSP Model for Imperfect

Production System with One Key Module under IS Approach 37 Figure 5.3. Solver for Common Cycle Imperfect ELSP Model with

One Key Module 39

Figure 5.4. Microsoft® Excel Spreadsheet of ELSP Model for Imperfect

Production System with One Key Module under CC Approach 40

Figure 6.1. Production Uptime Segmentation 45

Figure 6.2. Solver for Independent Solution Imperfect ELSP Model with Two

Key Modules 53

Figure 6.3. Microsoft® Excel Spreadsheet of ELSP Model for Imperfect

Production System with Two Key Modules under IS Approach 54

Figure 6.4. Solver of Common Cycle Approach for Imperfect ELSP Model

with Two Key Modules 57

Figure 6.5. Microsoft® Excel Spreadsheet of ELSP Model for Imperfect

ABSTRACT

The thesis entitled “Economic Lot Scheduling Problem in Imperfect Production System with Two Key Modules” began with the problem identification based on literature review under the theme Economic Lot Scheduling Problem (ELSP). It

was revealed that no paper had been discussing about ELSP in imperfect production system with two key modules. Discussion of ELSP in imperfect

production context had only been written under one key module problem. Based on this literature review, the problem in this research was defined as finding the

cycle times for ten items of modified Bomberger (1966) stamping problem under ELSP in imperfect production system with two key modules context in order to

minimize the total cost covering holding cost, setup cost and quality-related cost of producing non-conforming items.

In pursue of these optimum cycle times, the algorithm of finding the cycle times was developed through a series of modeling from ELSP in perfect production

system, ELSP in imperfect production system with one key module and finally the ELSP in imperfect production system with two key modules. Solver function in Microsoft® Excel 2010 was used to obtain the optimum cycle times under

Independent Solution (IS) and Common Cycle (CC) approaches. Before applying this model to ELSP in imperfect production system with two key modules, an

Economic Production Quantity (EPQ) model with two imperfect modules proposed by Gong et al. (2012) must be proved. Only if the formula of expected

number of non-conforming items in the EPQ can be proved, this formula can be used in ELSP context with adjustments.

Since the formula to calculate the expected number of non-conforming items could be proven, the model and algorithm development of ELSP in imperfect

production system with two key modules could be done. Under the IS approach, the cycle times for modified Bomberger (1966) stamping problem was calculated as T={33.2, 23.6, 22.6, 11.2, 52.5, 85.9, 160, 20.7, 18.6, 38.6} for item 1, β, …,

10, respectively with total cost in one year of $101,307.9. Under the CC approach, the cycle time for modified Bomberger (1966) stamping problem was

calculated as T=31.892 with total cost in one year of $247,592.43. These two costs were higher than those of perfect production system problem since there