* Corresponding author. Tel.: +44-0-151-794-4819; fax: +44-0-151-794-4819. E-mail address: [email protected]

ICM11

Characterization of selectively laser melted Ti-6Al-4V

micro-lattice struts

Rafidah Hasan

a,b, Robert Mines

a*, Peter Fox

aaDepartment of Engineering, University of Liverpool, The Quadrangle, Liverpool L69 3GH, UK

bFaculty of Mechanical Engineering, Universiti Teknikal Malaysia Melaka, Hang Tuah Jaya, 76100 Durian Tunggal, Melaka,

Malaysia

Abstract

This paper presents a characterization study of titanium alloy (Ti-6Al-4V) micro-struts manufactured using selective laser melting (SLM). Previous test results from sandwich structures with titanium alloy micro-lattice cores showed that the material experienced brittle fracture failure, although it had a reasonable specific strength. Therefore, the microstructure present in the struts has been investigated in order to understand its influence on the mechanical behaviour. Conclusions on the way forward for improved mechanical behaviour, by the use of subsequent heat treatment and careful control of the manufacturing process can then be identified.

© 2011 Published by Elsevier Ltd. Selection and peer-review under responsibility of ICM11

Keywords: selective laser melting; titanium alloy; micro-lattice; sandwich structure

1. Introduction

The University of Liverpool has investigated the use of selectively laser melted (SLM) micro-lattice structures within a number of engineering areas including medical devices and aerospace mechanical structures, such as lightweight sandwich constructions [1, 2]. Previous work reported that the specific strength of titanium alloy (Ti-6Al-4V) micro-lattice structures is competitive with that of aluminum honeycomb [3] and this is especially true if the energy density is high (higher laser powers and long exposure times) during the SLM process, with optimum results being obtained with a laser power of 200 Watts and an exposure time of 1000 s. This combination of parameters for the Ti-6Al-4V micro-lattice structure core resulted in a more localized impact area in the sandwich constructions as compared to aluminum honeycomb core [4]. A more localized impact area means that a smaller area is affected by

1877-7058 © 2011 Published by Elsevier Ltd. Selection and peer-review under responsibility of ICM11 doi:10.1016/j.proeng.2011.04.090

im

mpact damage he impacted a howing almos oad bearing s 4V micro-lattic behavior of th failure of the m brittle fracture need to be dete

1.1. Micro-latt

The micro-p 1] from their attice block w truts protrudin hat fracture oc SLM Ti-6Al-4

trut ends can b

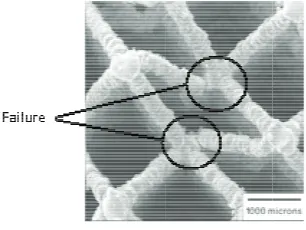

Fig. 1. (a) side vie nit cell with 8 str

Fig. 2. SEM image ode area [7]

Previous w possibility that hat a similar p

e, and this is p area of the T st flat fracture tructure perfo ce structures n he basic micro micro-struts i e failure obser ermined by th

tice strut

plastic and -e basic buildin with 2.5 mm u ng from a nod ccurred in the 4V micro-latti be clearly obs

ew of 20 mm X 2 ruts [2]

e of 200W X 100

work on the SL t the ‘cast’ mi problem may

preferred by t Ti-6Al-4V mic

e surfaces. Sin ormance, espe

needs to be fu o-strut build is thought to rved needs to e use of a reli

lastic properti ng block whic unit cell size, w

de at the centr e end part of c ice block fails served in the s

20 mm X 20 mm

00s SLM Ti-6Al

LM processin icrostructure m

occur with Ti

the aircraft ma cro-lattice str nce plasticity ecially in aero urther studied is an importa predict the be be found, and able micro-str

ies of SLM T ch is the micr

while Fig 1(b re. When subj certain struts, s on a 45° dia scanning elect

m BCC Ti 6Al 4V

l-4V micro-lattice

ng of stainles may contribut i-6Al-4V and

(a)

anufacturer [5 ructure core e is an importa ospace applica d and analyzed ant part of cu ehavior of the d in parallel, rut test.

Ti-6Al-4V mic ro-strut. Fig 1 b) graphically

jected to impa near the node agonal plane tron microscop

V micro-lattice str

e block which sho

ss steel micro e to the less d that this issu

5]. However, i experienced b ant criterion f ations [6], the d. Therefore, t urrent researc e micro-lattice

the elastic pro

cro-lattice stru 1(a) shows a shows a BCC act or compre e region. As r as shown in F py (SEM) ima

ructure block; (b)

ows failure at cer

-lattice struct ductile behavio ue could be cla

it has been ob brittle failure, for energy abs e failure of the the investigati ch, as the pro e. An explana operties of th

uctures can be BCC Ti-6Al-C unit cell wit ession load, it reported by Sh Fig 2. The fai age in the figu

) graphic illustrat

rtain point in the

tures [1] high or. It has been arified by exa

(b)

bserved that with struts sorbency in ese Ti-6Al-ion into the operties and ation of the e structures

e quantified -4V th 8

micro-strut, near

m phases presen ubsequent he tudied and rep have not been

2. Material

SLM Ti-6A tructures in p Technik GmbH a 35° angle to

ength being manufactured micro-struts w were then poli optical micros analysis mappi

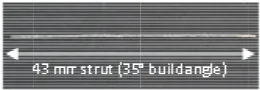

Fig. 3. A 43 mm m

3. Geometry,

Fig 4(a) sho 35° to the po

ongitudinal cr imilar to the w o the solid sta with heat treate

Fig. 4. (a) Optical manufactured SLM

e present. The the strength o nt, while the eat treatment.

ported, with a resolved in pr

Al-4V micro-previous rese H & Co., Germ

the horizonta limited to 43

SLM Ti-6Al were prepared shed followin scopy and SE

ing.

micro-strut of SLM

Microstructu

ows the circu owder bed, di ross-section o welded structu ate transforma ed Ti-6Al-4V

l microscopic vie M Ti-6Al-4V sing

e effect of mi of SLM Ti-6A

microstructu In this pape an objective o revious resear

struts were p arch [7], whi many. As the l, the single st 3 mm by th l-4V micro-st

by hot-moun ng a standard m EM, incorpora

M Ti-6Al-4V ma

ure and Elem

ular cross-sect iameter appro of a micro-stru

ure of titanium ations that oc V [10].

w of circular cro gle strut built at 3

icrostructure o Al-4V produc ure varied w

r, the micros of clarifying th rch work.

produced from ich was Titan micro-struts i truts were ma e manufactur trut. For mic nting in condu

metallurgical ated with ele

anufactured at the

ment Analysis

tion of an as-m oximately 380

ut, with micr m alloy. Need cur on coolin

oss-section; (b) M 35° angle laser be

on behavior i cts varied wit ith the SLM structure of th he SLM Ti-6A

m the same p nium Powder in the BCC ar anufactured at ring process. crostructure st uctive resin u

procedure, be ectron dispers

University of Liv

of Micro-str

manufactured 0 m. The o o-voids withi dle like structu ng. This struct

Microstructure of eam at 200 W lase Dendriticst

s also implied th the micros M process par he SLM Ti-6 Al-4V

micro-powder mater r Grade 5 AS rchitecture of

a 35° build a Fig 3 show tudies, metall sing a 20 mm efore being etc ive spectrosc

verpool (200W

rut

SLM Ti-6Al optical microg in the strut, an

ures are prese ture is differe

f longitudinal sect er power and 100 100 tructures

microͲ

voids

d in other rese tructure form rameters used

Al-4V micro lattice failure

rial as the m STM produce the micro-latt angle, with the ws an image lurgical samp m diameter m

ched and obse copy (EDS) f

X 1000s)

l-4V micro-str graph Fig 4(b nd a dendritic ent within the nt to that nor

tioned; both figur 00 s laser exposu

ђm (b)

earch work med and the d and any -struts was

issues that

micro-lattice ed by TLS tices was at e maximum of the as-ples of the mould. They

erved under for element

rut build at b) shows a c structure, grains due rmally used

th

F 4V

sp T st u ra a a p th w st c p

F

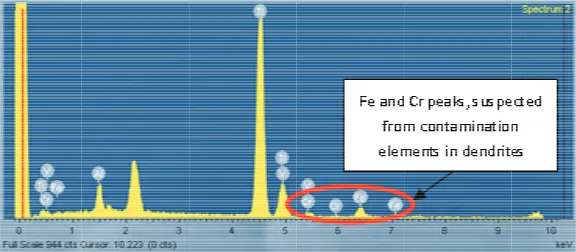

Within the he material (F

Fig. 5. A focused V micro-strut wit

Elemental a pectrum 2) th These included tructures are used in this SL

ather than po atmosphere is and within inte precipitation in hat the dendri weak point in

trong as the compared with present in thes

Fig. 6. The EDS p

microstructur Fig 5).

SEM image of d th 200W X 1000

analysis of th hey were rich d relatively hi due to the cro LM machine. owder prepara carefully filte er-layer areas n the solid sta ite formation

the micro-str weakest poin h 373 HV) tha

e regions.

plot of spectrum 1

re were region

dendritic structure s)

hese regions ( h in elements

igh amounts o oss contamina It is likely t ation and ma ered [11]. Sin these phases ate and are lik

affects the me rut initiating c nt. It was fo at the bulk of t

for elemental an

ns that althoug

e with indicated p

(Fig 6, spectr not normally of iron (Fe) an ation of the p that this conta ay have come nce most of th

probably form kely to form p echanical prop cracking acro ound that the the structure.

nalysis of as-recei

gh dendritic lo

points for spectru

rum 1) showe y found in Ti nd chromium powder bed w amination occ e from the po

hese dendritic m due to segre part of the las perties as if th oss the strut in ese structures It has not yet

ived micro-strut c

ooked very di

um 1 and 2 in ele

ed that compa itanium Powd (Cr). It is lik with 316L stain

curred during owder feed sy c structures w

egation during st liquid to fre hey are brittle n that region, were signifi been possible

confirmed with T

ifferent from

emental analysis (

ared to the bu der Grade 5 A kely, therefore

nless steel wh the manufactu ystem as the were found at

g freezing rath eeze. It is also e or soft they w

, the strut onl icantly harder e to determine

Ti-6Al-4V elemen

the bulk of

(SLM

Ti-6Al-ulk (Fig 7, ASTM [7]. e, that these hich is also uring stage argon gas boundaries her than by o suspected will form a ly being as r (419 HV e the phases

F uspected due to c

4. Heat Treatm

A simple h properties of th

he resultant m elements has b

ealed within a he formation he needle stru expected in T contamination heat treatment

egions of wea truts are one affect their stre SLM Ti-6Al-4

Fig. 8. (a) Schema

plot of spectrum contamination

ment on SLM

heat treatment he struts. Fig microstructure been redistrib an evacuated q

of Į and ȕ reg ucture. Result Ti-6Al-4V, w was below th t has produced akness; howe grain wide. T ength. Furthe 4V micro-lattic

atic of heat treatm /ȕ phase of Ti-6A

m 2 for elemental

M Ti-6Al-4V m

t process was 8(a) schemati e, which is c uted. The hea quartz tube. T gions, the rem ts from EDS while no Cr he detection l d a more uni ever the heat The presence o

er analysis to u ce structure is

ment process on S Al-4V

4hours ecipitation

attreatment

l analysis of as-r

micro-strut

used to stud ically illustrat closer to that

at treatment w The heat treatm moval of the c

analysis sho was detecte limit of the E form structur

treatment has of a large grai understand th s now being ca

SLM Ti-6Al-4V m

Time(h Air cooled

received micro-st

dy how the m tes the heat tre

normally use was done in a ment led to a s chromium and owed that nor d throughout EDS system. T

e and is there s not induced in size within he heat treatme

arried out.

micro-strut; (b) r

our) (a)

trut showed the e

microstructure eatment proce ed and in wh a normal furn

somewhat coa d iron rich reg rmal amounts

t the sample This change i efore likely to d significant g n such small st ent effect on m

esulted microstru

existence of Fe a

affected the m ess while Fig hich any segr

ace but with arser microstru gions and the

of Fe were ed area, as t in the micros o produce stru grain growth

truts would si mechanical pr

ucture of heat trea

and Cr peaks,

mechanical 8(b) shows regation of

the sample ucture with removal of present, as the overall

tructure on uts without so that the ignificantly roperties of

5. Conclusion and Ongoing Study

In this study the diameter of the SLM Ti-6Al-4V micro-struts was determined from the transverse cross-section geometry. The characterization of the microstructure has led to the observation of dendritic structures due to cross contamination with other powders, which had caused uneven mechanical properties along the micro-struts. Elemental analysis identified the problem of contamination and it is likely to be a significant problem with this technology if the equipment is used with more than one powder. It has been shown that heat treatment can significantly change the microstructure dispersing the contamination and creating a uniform microstructure, but without causing excessive grain growth that would have a deleterious effect on the mechanical properties. Based on these results, the current ongoing study focuses on effect of contaminant on mechanical properties of SLM Ti-6Al-4V micro-lattice structure and looking forward in ways to improve the condition.

Acknowledgements

Financial support from grants sponsored by EPSRC/EP/C009525/1, EPSRC/EP/009398/1 and EU FP6 CELPACT is gratefully acknowledged. Acknowledgements also extended to Dr S. Tsopanos and Dr C. Sutcliffe for specimen manufacturing; and Prof X. Wu from University of Birmingham. R. Hasan acknowledges Malaysian Government and UTeM for her PhD study sponsorship.

References

[1] Mines RAW. On the characterization of foam and micro-lattice materials used in sandwich construction. Strain. 2008; 44(1): p. 71-83.

[2] McKown S, Cantwell WJ, Brooks WK, Mines RAW, Sutcliffe CJ. High performance sandwich structures with hierarchical lattice cores. SAMPE Europe Conference & Exhibition. Paris. 2007; paper no. 68-8.

[3] Mines R, Girard Y, Fascio V. On the development of conventional and micro lattice cellular metals as core materials in aerospace sandwich construction. SAMPE Europe Conference & Exhibition. Paris. 2009; p. 248-256.

[4] Hasan R, Mines R, Shen E, Tsopanos S, Cantwell W, Brooks W, Sutcliffe C. Comparison of the drop weight impact performance of sandwich panels with aluminium honeycomb and titanium alloy micro lattice cores. Applied Mechanics and Materials. 2010; 24-25: p. 413-418.

[5] Morteau E and Fualdes C. FAA Workshop for Composite Damage Tolerance and Maintenance. National Institute for Aviation Research. Chicago; 2006.

[6] Gibson LJ and Ashby MF. Cellular solids: structure and properties. 2nd ed. Cambridge University Press: Cambridge; 1999.

[7] Shen Y. High performance sandwich structures based on novel metal cores. PhD Thesis. University of Liverpool: United Kingdom; 2009.

[8] Murr LE, Quinones SA, Gaytan SM, Lopez MI, Rodela A, Martinez EY, Hernandez DH, Martinez E, Medina F, Wicker RB. Microstructure and mechanical behavior of Ti-6Al-4V produced by rapid-layer manufacturing, for biomedical applications. Journal of the Mechanical Behavior of Biomedical Materials. 2009; 2: p. 20-32.

[9] Facchini L, Magalini E, Robotti P, Molinari A. Microstructure and mechanical properties of Ti-6Al-4V produced by electron beam melting of pre-alloyed powders. Rapid Prototyping Journal. 2009; 15(3): p. 171-178.

[10] Polmear IJ. Light alloys: From traditional alloys to nanocrystals. 4th ed. Elsevier/Butterworth-Heinemann: Amsterdam;

2006.