SIVARAO1, KUMAR2, N., WIDODO3, W.S. and HAERYIP SIHOMBING4

1, 2

Department of Manufacturing Process 3

Department of Manufacturing Design 4

Department of Manufacturing Management Faculty of Manufacturing Engineering

Universiti Teknikal Malaysia Melaka

Hang Tuah Jaya, 76100, Durian Tunggal, Melaka, MALAYSIA 1

1.0 INTRODUCTION

Solvent extr action as a pr ocess utilizes solvents to extr act the r esidual oil fr om oil-bear ing seeds, cakes and br ans (Dacer a et al., 2003). Vegetable oil has been the main sour ce of fat for human consumption. Most edible oils and fats ar e soluble in liquid hydr ocar bons and hexane is the most commonly used hydr ocar bon fraction for solvent extr action (Dacera et al., 2003). The solvent used in this pr ocess is not expanded, but is used over and over again in the pr ocess of r ecycling and a lar ge volume of the solvent alw ays r emains in var ious stages of the closed pr ocessing cycles.

Reducing pr oduction cost by r educing the hexane loss dur ing the pr ocess is the key point of this study. The main aim of this r esearch w or k is to r educe hexane losses dur ing the oil extr acting pr ocess fr om palm ker nel and to study how effectively hexane and oil in the for m of mischella can be separ ated in or der to r educe the pr oduction cost w hile incr easing the pr ofit. Using Hexane to extr act oil is called solvent extr action or solvent extr action plant. Solvent is a liquid, solid, or gas that dissolves another solid, liquid, or gaseous solute, r esulting in a solution that is soluble in cer tain volume of solvent at a specified temper atur e.

In solvent extr action plant, hexane is commonly used as a solvent to extr act the oil fr om the palm ker nel. Hexane is a hydr ocar bon w ith the chemical for mula C6H14; that is, an alkane w ith six car bon atoms. Accor ding to

a r epor t by the Cor nucopia Institute, hexane is used to extr act oil fr om gr ains as w ell as pr otein fr om soy, to such an extent that in 2007, gr ain pr ocessor s w er e r esponsible for mor e than tw o-thir ds of hexane emissions in the United States (NVO Hexane Repor t, 2010). The r epor t also pointed out that the hexane can per sist in the final food pr oduct cr eated; in a sample of pr ocessed soy, the oil contained 10 ppm, the meal 21 ppm and the gr its 14 ppm hexane. Using hexane to extr act oil is commonly used for oil-cake extr action (soya bean meal, gr oundnut meal, r ice br an meal, cotton seed meal, sells seed, guar meal, copr a meal), oilseeds (soya bean, sunflow er seed, gr oundnut, cotton, sal, niger , mustar d, castor ), vegetable oils (palm olefins, soya bean oil, r ap seed oil, sunflow er seed oil), gr ains (w heat, cor n, r ice, sor ghum, millets, bar ley) (Yuhazr i et al., 2012) and (House et al., 1981).

In Malaysia ther e is a leading vegetable oil plant using hexane to extr act oil fr om palm ker nel. This is the only plant in Malaysia using hexane for dir ect extr action fr om palm ker nel flakes. This plant is divided into tw o sections w her e the fir st section is pr epar ation plant and the second section is a solvent extr action plant. In the

A BSTRA CT

Hexane (C6H14) is used as a solvent to extract oil from palm kernel to produce crude palm kernel oil (CPKO) which is a common cooking ingredient. The main intention of this research work is to reduce hexane loss during the extraction process of oil from palm kernel. This research project was carried out in a leading vegetable factory in M alaysia. Although this plant managed to get high yield (average 48.5 % ) compare with other similar conventional plants in M alaysia but the hexane loss is very high, 8.5 litre/M etric Ton (l/M T) in average. To reduce the hexane loss, few modification jobs were carried out; adding of new shell and tube condenser, sealing of leakages and developed a set of standard operating procedures. Preliminary investigation after the improvement steps found that, reduction of hexane loss showed a decrease of about 30 % from the average of 9.5 % litre/M T of palm kernel 6.5 litre/M T of palm kernel after the improvement. This amounted of hexane savings of 3 litre/M T of palm kernel which is equivalent to about RM 727,660 for 8 months after the process improvement taken into effect.

Key w ords: Palm Kernel, Hexane, Extraction, Condenser.

pr epar ation plant, the palm ker nels w ill be hammer ed, cr ushed, flaked and conditioned by indir ect steam and then, this flaked meal w ill be sent to the second section, solvent extr action plant w her e hexane w ill be pumped and flushed to these flakes to extr act the oils. By using hexane about 48 % of cr ude palm ker nel oils and 52 % of by-pr oduct, palm ker nel meal can be pr oduced.

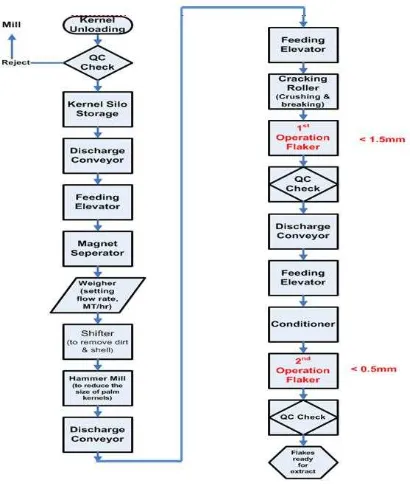

By using this technology this plant is able to extr act mor e cr ude palm ker nel oils, yield an aver age 48 % compar ed w ith conventional pr ess w hich w ould only be 44.5 % in average (Hai, 2002). Although this plant uses hexane for solvent extr action fr om palm ker nel and gain higher yield compar ed w ith other conventional methods, but they ar e facing pr oblem to r ecover hexane efficiently. Aver age hexane loss at the end of the day is about 9.5 of hexane per ton of palm ker nel losses encounter ed. Basically this plant faces pr oblem w ith high hexane losses dur ing the pr ocess of extr acting oils fr om palm ker nels. Complete pr ocess flow of pr epar ation and extr action sections ar e show in the for m of flow char t in Figur e 1.

Figur e 1 : Pr epar ation pl ant flow char t.

1.1 Preparation Plant

Pr epar ation plant is the place w her e daily pr oduction is set by key in the r equir ed flow r ate (MTs/ hour ) of palm ker nels in the w eigher machine. In this plant, after past the magnetic separator to separate metal pieces, palm ker nels fr om silos w ill send to w eigher to pr oduce r equir ed flow rate per hour . After the w eigher machine, the palm ker nels w ill enter to hammer mill w her e the palm ker nels w ill be hammer ed to r educe the size and for fur ther r eduction the ker nels w ill past to the cracking r oller machine w her e the ker nels w ill be cr ushed and br eak fur ther . To get high yield of cr ude palm ker nel oils (CPKO), the ker nels must be soft and small size. So to get that r esult, the br oken ker nels w ill send to 1st oper ation flaker w her e

all these ker nels w ill be flaked to below 1.5 mm thickness and then all these mater ials w ill send to conditioner w her e these flakes w ill be heated up w ith jacketed steam to get temper atur e about 70 °C.

After the conditioner these soft flakes w ill enter to 2nd oper ation flaker to get flakes thickness below 0.3 to

0.5 mm. Finally these flakes ar e r eady to extr act oil. All these pr ocess ar e online continuous pr ocess.

1.2 Extraction Plant

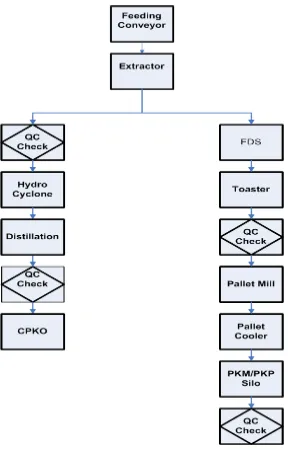

After the final pr ocess in pr epar ation plant, the flakes w ill be tr ansfer r ed to the ext r actor w ith 2 compar tments. In this extr actor , the fr esh hexane w ill be pumped into these flakes to extr act the oil. This oil called miscella, means oil and hexane mixed together w her e miscella contains about 60 % of hexane. To separ ate oil and hexane, this miscella w ill go thr ough another pr ocess in distillation plant. After the oils w er e extr acted fr om the flakes, the by-pr oduct, palm ker nels meals fr om the 2nd compar tment w ill be

pr oduced. This by-pr oduct, palm ker nel meals contains ar ound 40 % of hexane. To separ ate meals and hexane, these by pr oducts w ill be sent to another plant, meal de-solventizing. Pr ocess flow of the extr action plant is show n in Figur e 2.

[image:2.595.213.418.209.451.2]up by going thr ough a super heater and by using vacuum about –0.5bar , the hot hexane vapor w ill be sucked into condenser w her e, heat tr ansfer w ill take place to conver t the hexane into vapor to liquid for m. This liquid hexane w ill be stor ed in w or king tank and w ill be r ecycled to the extr actor .

Whatever hexane missed to collect in distillation and meal de-solventizing pr ocess, w ill be sent to absor ption plant w her e, in this plant absor ption oil w ill be used to tr ap w hatever missing hexane. The hexane, w hich dilute w ith abr uption oil, w ill send to absor ption column and follow ed by heat exchanger to heat up the hexane to separ ate it fr om absor ption oil and then w ill past to 2nd heat exchanger to br ing

back the hexane to liquid for m and finally all the collected hexane w ill be tr ansfer r ed to the hexane w or king tank. After the hexane r emoved thr ough the above pr ocess, the oil called cr ude palm ker nel oil, CPKO and the by-pr oduct is palm ker nel meal. By this ext r action pr ocess ar ound 48 % Cr ude palm ker nel oils and 52 % of by-pr oduct, palm ker nel meals is pr oduced. The CPKO w ill be t r ansfer r ed to main stor age tank to sell out or fur ther pr ocess in the r efiner y plant. The palm ker nel meal w ill send to palletizing plant to pr oduce palm ker nel pallets and palm ker nels meal.

Figur e 2 : Extr action plant flow char t.

2.0 MATERIALS AND METHODS

2.1 Pre-assessment

Pr e-assessment audit w er e car r ied out on high hexane loss follow ed an assessment to focus the major pr oblems and implementation to r educe the hexane loss and finally monitor ing and evaluation of the final r esult. The pr e-assessment audit w as conducted in May, 2011. Pr e-assessment audit w as conducted to focus ar ea of high hexane loss based on fish bone diagr am as show n in Figur e 3. Input details w er e collected thr ough cur r ent r esult, par ameter s, inter view s, questionnair es and br ain stor ming sections.

[image:3.595.259.403.230.455.2] [image:3.595.151.506.605.763.2]Based on the pr e-assessment findings, the audit w as focused on:

(i) Excess loss

Excess loss is the amount of additional loss thr ough:

(a) oil fr om the final oil str ipper . (b) air fr om the meal dr yer cooler . (c) meal fr om meal dr yer cooler . (d) air fr om the miner al oil system. (e) w ater fr om w aste w ater evapor ator . (f) inconsistent oper ation.

The excess loss due to inconsistent oper ation occur s dur ing the per iod star ting w hen the input conditions change and ending w hen the input conditions change back to nor mal, or dur ing the per iod star ting w hen the input condition change and ending w hen steady state is achieved after the oper ating par ameter s have changed.

(ii) Fugitive loss

Fugitive loss is the amount of solvent loss fr om the pr ocess equipment thr ough flanges, door s, packing glands, pump seals, valves stems, sight glasses, etc. This loss occur s w hen the pr essur e inside the vessel is higher than atmospher ic pr essur e, causing solvent vapour inside the vessel to leak out thr ough any or ifice.

(iii) Pur ging loss

Pur ging loss is amount of solvent loss fr om pr ocess equipment r esulting fr om fr eeing the pr ocess equipment of solvent vapour for inspection or maintenance. This loss occur s as a r esult of opening up the pr ocess equipment and as a r esult of using pur ge fans to pull air thr ough the pr ocess equipment. Dur ing nor mal oper ation, pur ging loss does not exist. Pur ging loss only exists w hen the plant is shutdow n. Thus, the solvent loss as a r esult of pur ging can not be quantified in ter ms of litter s of solvent loss per ton of palm ker nel pr ocessed on a dir ect basis, as w ith other categories of solvent loss.

2.2 Assessment

Based on findings in the fish bone diagram, the assessment audit w as conducted in July 2011. The assessment w as focused on excess loss, fugitive loss and pur ging loss. The pur pose of the assessment w as to collect detail infor mation on high hexane loss due to excess loss, fugitive loss and pur ging loss.

2.2.1 Assessment phase 1: excess loss

Excess loss is the only ar ea able to do analyse the quantity of hexane contains in cr ude palm ker nel oil, palm ker nel meal, vent gases fr om absor ption and w ater fr om w aste w ater system. Hexane contains in cr ude palm ker nel oil measur ed by flash point temper atur e meanw hile hexane contain in palm ker nel meal and w aste w ater measur ed by mg/ kg or ppm and hexane contain in vent gases fr om absor ption measur ed by kg/ or ppm. Accor ding to Solvent Extr actor s Association Handbook of India 9th r evised edition 2009, the allow able r ange for for flash point is min 100 °C, hexane

contain in palm ker nel meal is 170 ppm, hexane contain in vent gases is 50 mg/ and hexane contain in w aste w ater is 10 ppm. Detail audit of analyzing the hexane contains w er e car r ied on Januar y till May 2011 and the aver age for these 5 months ar e as per i n Table 1.

Table 1: Detail audit data.

Januar y

2011

Febr uar y 2011

Mar ch 2011

Apr il 2011

May

2011 Acceptable Palm Ker nel thr u put

(MT) 12,250 11,510 12,505 12,500 12,498 -

CPKO-Flash Point

(°C) 120 120 120 120 120 Min 100

Hexane i n Pal m Ker nel Meal

(ppm) 210 300 250 225 220 170

Vent gases fr om absor pt ion

(mg/ l tr ) 600 500 550 580 570 50

Wat er

Base on data fr om Table 1, four independent plots w er e developed to have a clear pictur e of the impr ovement in better hexane r ecover y.

(a) (b)

Figur e 4 : (a) compar i son of actual & allow abl e w it h PK thr u put, (b) compar ison of hexane contain in palm ker nel meal w it h PK thr u put.

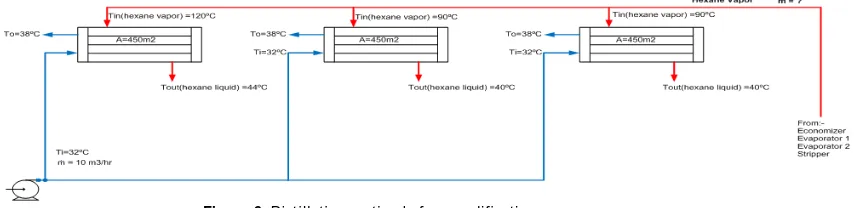

Fr om Figur e 4(a), 4(b), 5(a) and 5(b), it w as found that ther e is high hexane loss in vent air fr om absor ption compar e w ith other hexane losses in CPKO, palm ker nel meal and w aste w ater . Decision w as made to focus on hexane loss in vent air and to dr aft an action plan and impr ovement. Detail studies and audits w er e car r ied out in distillation section as show n in Figur e 6.

(a) (b)

Figur e 5 : Compar ison of hexane cont ai n i n (a) vent air w ith PK thr u put , (b) w aste w ater w ith PK thr u put.

The vent air blow s thr ough absor ption section but the unr ecover ed hexane vapor comes mainly fr om distillation section, w hile small amount from extr actor . To save 50 % steam of the distillation is achieved using hot De-solventizer vapor s in a unique falling film economizer . This r educes the steam consumption and the load on the final condenser . This is follow ed by a steam heated r ising film evaporator s and str ipping column oper ating under vacuum.

Figur e 6: Dist illation section befor e modification.

The vapor s fr om falling film economizer , r ising film evapor ator s 1 and 2 and fr om str ipper column w ill be sucked into condenser s to condense hexane vapor to liquid for m. The hexane vapor that is not condensed in the last condenser is typically passed thr ough a miner al oil absor ption system. The hexane liquid w ill be tr ansfer r ed into special w ater separ ator to r emove the w aste w ater . After maximum r ecover y by condensation fur ther hexane content in the exhaust air can be fur ther r educed only by an absor ption by intimate contact w ith chilled miner al oil in specially designed packed column. Ther eafter the air is exhausted to the atmospher e w ith the maximum hexane content and the absor ber oil is str ipped w ith dir ect str eam to r emove the t r aces of hexane and send for r e-cir culation to cold absor ber .

[image:5.595.85.544.100.222.2] [image:5.595.86.545.311.426.2] [image:5.595.126.553.528.632.2]exhaust air is cooled fir st in chilled w ater vent condenser to a temper atur e ar ound 20 °C for maximum r ecover y by condensation. To r educe the hexane content in vent air , ther e ar e tw o options consider ed: upgr ade complete absor ption section and add 1 mor e condenser to incr ease the condensation capacity. Since the cost is high to upgr ade the complete absor ption system, r ecommendation given to management to add 1 mor e condenser s in the distillation plant. Table 2 show s the existing and the r ecommendation.

Table 2: Existi ng and pr oposed di still ation i nst allation.

Condenser Ar ea (m2)

Wat er Flow Rate (m3)

Wat er Temper atur e (°C)

Hexane Vapour Temper atur e (°C)

In Out In Out

C1 450 200 32 38 120 44

C2 450 200 32 38 90 40

C3 450 200 32 38 90 40

*Recommendation: Add new condenser of 450m2

2.2.2 Assessment phase 2: fugitive loss

Decisions taken to car r y out pr essur e test all equipment and piping w ith pr essur ized w ater to ensur e that the syst em is fr ee of leaks pr ior to star t oper ation.

2.2.3 Assessment phase 3: purging loss

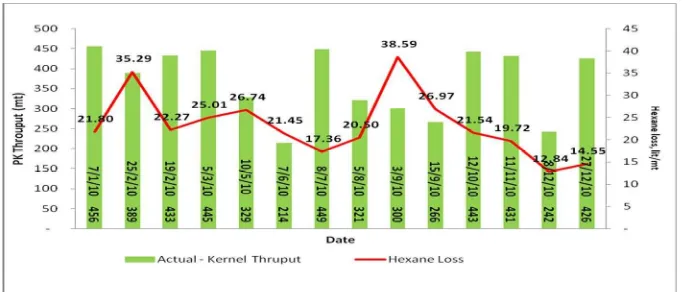

Pur ging loss only exist once the plant is star ting back after the shutdow n. Case study w as car r ied for the year 2010 of high hexane losses dur ing the plant star t back after mor e than 1 day shutdow n as show n in Figur e 7. The actions that can be taken to minimize the pur ging loss ar e:

(i) Impr ove equipment r eliability thr ough design impr ovement and tr ough pr eventive maintenance pr ocesses. This w ill r educe the fr equency for w hich maintenance and inspection ar e r equir ed, thus r educing the fr equency of vapor fr eeing and its r elated pur ging solvent loss.

(ii) Allow the nor mal vapor r ecover y system t o r un as long as possible pr ior opening up the pr ocess equipment. This w ill r ecover the major ity of the solvent pr ior to vapor fr eeing, thus r educing pur ging loss.

(iii) Dischar ge the pur ge fan thr ough a condenser to r ecover as much as the solvent vapor as possible, thus r educing pur ging solvent loss.

Decision w as taken to car r y out action plant no 2 due to able t o car r y out the action immediately w ithout any major cost.

Figur e 7: Hexane loss aft er pl ant st ar ti ng back fr om shut dow n.

2.3 I mplementation

Once the action plans w er e selected for excess, fugitive and pur ging loss, decision taken to implement the action plans in stages, 1st excess loss follow ed by fugitive loss and finally pur ging loss.

2.3.1 Excess loss

On 23 December 2011, added 1 mor e condenser , 450 m2 to incr ease the cooling capacity fr om

1350m2 to 1800m2 (r efer to Figur e 8). This mainly to condense the vapor fr om economizer s,

[image:6.595.157.499.498.644.2]2.3.2 Fugitive Loss

On 02 June 2012, the complete solvent extr action plant w as shutdow n for annual maintenance w or ks. The action taken to pr essur e tests all the equipment including economizer s, evapor ator s, str ipper , vapor s lines and vessels. The pr essur e test car r ied out by using w ater and found the w ater leaking fr om economizer top manhole, evapor ator s tr ansfer line flange, sever al piping flange and 1 elbow cr acked. Gaskets w er e changed to all the leaking ar ea and r eplaced new elbow .

2.3.3 Purging Loss

A shutdow n pr ocedur es w as planned and a case study w as car r ied out fr om June to August 2012, decision taken that vacuum pump, steam and cooling tow er need to be oper ated continuously for 3 hour s befor e the plant completely shut dow n. This due to allow the nor mal vapor r ecover y system and r ecover the major ity hexane vapor to be condensed.

Figur e 8 : Di stillation section after modification.

3.0 RESULTS AND DISCUSSION

The r esults after the impr ovement w er e r ecor ded in t hr ee differ ent stages. The findings and discussion ar e focused on hexane loss in excess loss, pur ging loss and fugitive loss.

3.1 Excess Loss

After installed new condenser to incr ease the cooling capacity fr om 1350 m2 to 1800 m2, r esults ar e

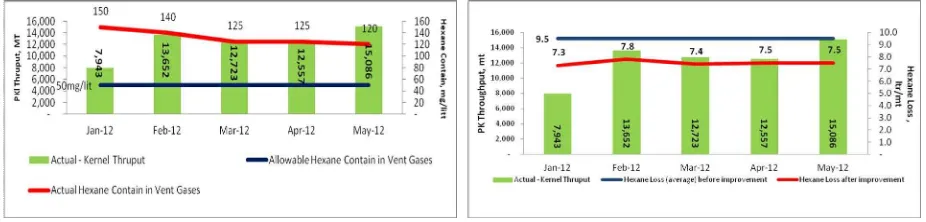

monitor ed for hexane content in ventilated air fr om Januar y 2012 to May 2012. Based on the r esults, a gr aph w as plotted as per Figur e 9(a). This graph show s hexane contains in vent r educed fr om average 560 mg/ litr e taken in Januar y-May 2011 to aver age 132 mg/ litr e. Detail analysis of hexane loss also car r ied in the same per iod. Figur e 9(b) is the r esults and found after the installed new condenser , the hexane loss r educed fr om aver age 9.5 litr e/ MT to 7.5 litr e/ MT.

Figur e 9 : (a) Monitor i ng hexane i n vent air , (b) hexane excess loss befor e and after modification.

3.2 Fugitive Loss

[image:7.595.161.524.218.386.2] [image:7.595.97.560.567.678.2]Figur e 10: Hexane befor e and aft er modificat ion, (a) fugitive loss, (b) Pur gi ng loss.

3.3 Purging Loss

Although the hexane loss due to pur ging cannot be quantified in ter ms of litr e of solvent loss per ton of palm ker nel pr ocessed on a dir ect basis but it’s ver y impor tant to keep the hexane loss as low as possible dur ing the plant star t up after shutdow n. Follow ing the specific shutdow n and star t-up pr ocedur es complying detailed checklists, the r esults have been impr oved as show n in Figur e 10(b).

4.0 CONCLUSION

[image:8.595.93.552.51.160.2]Hexane loss has alw ays been the significant r eason incurr ing cost for oper ating of an extr action plant. Per haps, in the past, ther e w er e times w hen additional solvent usage w as accepted as par t of having low er r esidual oils in the meal and mill feed or even low er ener gy costs in steam pr oduction, but discar ded by r ecent food and safety r egulations. How ever excessive expenditur e for additional solvent r ecover y or pollution contr ol equipment w ould not be necessar y if a plant is pr oper ly oper ated and maintained. Table 3 clear ly show s the total saving of RM 727, 660 fr om Januar y 2012 to August 2012 after the impr ovements w e implemented.

Table 3: Total saving of hexane

Januar y

2012

Febr uar y 2012

Mar ch 2012

Apr il 2012

May 2012

June 2012

July 2012

August 2012 PK thr oughput ( mt) 7,943 13,652 12,723 12,557 15,086 14,066 14,754 12,840

Hexane Loss (/ mt) 7.3 7.8 7.4 7.5 7.5 6.6 6.5 6.5

Hexane Pr ice (RM/ s) 2.89 2.82 2.82 2.43 3.17 3.22 3.05 2.94 Aver age Hexane loss

in year 2011 9.5 9.5 9.5 9.5 9.5 9.5 9.5 9.5

Saving (RM) 50,494 65,536 75,450 61,020 95,704 131,261 134,871 113,324

ACKNOWLEDMENTS

Author s w ould like to thank Faculty of Manufactur ing Engineer ing and Univer siti Teknikal Malaysia Melaka for suppor ting this r esear ch Special thanks to Ministr y of Higher Education (MOHE) for aw ar ding r esear ch gr ants (GLuar / 2012/ FKP(1)/ G00010) and (PRGS/ 2012/ TK01/ FKP/ 02/ 1/ T0003) w hich ver y much helped in completing the study w ithout much hur dles.

REFERENCES

[ 1] Dacer a, D., Jenvanitpanjakul, P., Nitisoravut, S. and Babel, S. (2003): Hexan Reduction in a Thai Rice Bran Oil factor y: A Cleaner Technology Appr oach. Thammasat Int . Jour nal of Science and Technol ogy, Vol.8, No.4, pp.6-16.

[ 2] NVO Hexane Repor t (2010): Soy Pr otein and Chemical Solvents in Nutr ition Bar s and Meat Alter natives, Cor nucopia Institute.

[ 3] Hai, T.C. (2002): The Palm Oil Industr y in Malaysia: Fr om Seed to Fr ying Pan, Plantation Agr icultur e - WWF Malaysia.

[ 4] House, R.J.R., Har combe, A.O. and Guinness R.G. (1981): Hexane Losses in Solvent Extr acted Soya Meal: Measur ement by Gas Chr omatography and Br ief Evaluation. Jour nal of t he Amer ican Oil Chemist ’ Societ y, pp.626-629.

[image:8.595.87.536.379.480.2]