UNIVERSITI TEKNIKAL MALAYSIA MELAKA

DESIGN AND ANALYSIS OF CASTING VALVE FOR HIGH

VOLTAGE ABC DEAD END CLAMP BY USING FINITE

ELEMENT ANALYSIS

This report submitted in accordance with requirement of the Universiti Teknikal Malaysia Melaka (UTeM) for the Bachelor Degree of Manufacturing Engineering

(Manufacturing Design)

by

SITI NUR MADIHAH BT APANDI B050810074

UNIVERSITI TEKNIKAL MALAYSIA MELAKA

BORANG PENGESAHAN STATUS LAPORAN PROJEK SARJANA MUDA

TAJUK: Design and Analysis of Casting Valve for High Voltage ABC Dead End Clamp by

Using Finite Element Analysis

SESI PENGAJIAN: 2011/ 12 Semest er 2

Saya SITI NUR MADIHAH BT APANDI

mengaku membenarkan Laporan PSM ini disimpan di Perpust akaan Universit i Teknikal Malaysia Melaka (UTeM) dengan syarat -syarat kegunaan sepert i berikut :

1. Laporan PSM adalah hak milik Universit i Teknikal Malaysia Melaka dan penulis.

2. Perpust akaan Universit i Teknikal Malaysia Melaka dibenarkan membuat salinan unt uk

t uj uan pengaj ian sahaj a dengan izin penulis.

3. Perpust akaan dibenarkan membuat salinan lapor an PSM ini sebagai bahan pert ukaran

ant ara inst it usi pengaj ian t inggi. 4. **Sila t andakan (√)

PENYELIA PSM

Tarikh: _______________________

** Jika Laporan PSM ini SULIT at au TERHAD, sila lampirkan surat daripada pihak berkuasa/ organisasi berkenaan dengan menyat akan sekali sebab dan t empoh laporan PSM ini perlu dikelaskan sebagai SULIT at au TERHAD.

(Mengandungi maklumat TERHAD yang t elah dit ent ukan oleh organisasi/ badan di mana penyelidikan dij alankan)

DECLARATION

I hereby, declared this report entitled “Design and Analysis of Casting Valve for ABC Dead End Clamp, HV by using Finite Element Analysis” is the results of my

own research except as cited in references.

Signature : ……….

Author’s Name : ………

APPROVAL

This report is submitted to the Faculty of Manufacturing Engineering of UTeM as a partial fulfilment of the requirements for the degree of Bachelor of Manufacturing Engineering (Manufacturing Design). The member of the supervisory committee is as follow:

i

ABSTRAK

ii

ABSTRACT

iii

DEDICATION

For My Industrial Supervisor, Mr. Hirmanto Bin Suib and all my family members that support me physically and mentally, Father & Mother, Apandi Bin Yaa’cob & Ramlah

iv

ACKNOWLEDGEMENT

v

2.1 Finite Element Analysis 11

2.1.1 Matrix Analysis of Trusses 14

2.2 Factor of Safety 15

2.2.1 Mohr Columb 18

vi

3.1.2 Phase 1: Research Establishment 31

3.1.3 Phase 2: Design Development 31

3.1.4 Phase 3: Analysis & Comparison 32

3.1.5 Phase 4: Report Submission & Presentation 32

3.2 Analysis of Casting Valve 32

3.2.1 Finite Element Model 33

3.2.2 Geometrical Modeling 34

3.2.3 Loading 34

3.2.4 Material Properties 35

3.2.5 Static Structural Analysis 36

3.2.6 Finite Element in ANSYS 41

3.2.7 Selection of Safety Factor 41

3.3 Cause & Effect Analysis 43

3.4 Design Parameter 46

4. PROCEDURE FOR ANALYSIS BY USING ANSYS 48

4.1 Create Analysis System 48

4.2 Engineering Data 51

4.3 Geometry 52

4.4 Stiffness Behaviour 53

vii

4.5.1 Physics Based Meshing 55

4.6 Establish Analysis Setting 57

4.6.1 Fixed support 57

4.6.2 Force 58

4.7 Solve 60

4.7.1 Equivalent (Von-Mises) Stress 60

4.8 Stress Tool 61

5.2 Results for Improvement Design of Casting Valve 69

5.2.1 Improvement Design 1 69

6. COMPARISON & DISCUSSION 78

6.1 Comparison 78

viii

7. CONCLUSION AND RECOMMENDATION 82

7.1 Conclusion 82

7.2 Recommendation 83

REFERENCES 84

APPENDICES

A General Concept Design B Gantt Chart PSM 1 & PSM 2

ix

LIST OF TABLES

1.1 The description of HV ABC Dead End Clamp 3

1.2 Result of Sample Test 7

2.1 Description of Shear Strength Reduction Algorithm 16

3.1 Alloy Composition in Aluminum Ingot A380 35

3.2 The mechanical properties of Aluminum Ingot A380 35

3.3 The characteristics of Aluminum Ingot A380 36

3.4 Description of factor of safety 42

5.1 Result of Safety Factor for Current Design Analysis 68

5.2 Result of Safety Factor for Improvement Design 1 71

5.3 Result of Safety Factor for Improvement Design 2 74

5.4 Result of Safety Factor for Improvement Design 3 77

x

3.3 The illustration of Casting Valve during Sample Test 34

3.4 Cause & Effect Analysis of Casting Valve 45

3.5 Design parameter at front view of casting valve 46

3.6 Design parameter at bottom view of casting valve 47

4.1 New Analysis System was created for Static Structural (ANSYS) 49

4.2 Windows for attaching geometry from SolidWorks 2010 50

4.3 Engineering Data workspace 51

4.4 Length unit option before start DesignModeler workspace 52

4.5 DesignModeler workspace 53

4.6 Details view toolbox for current design 54

4.7 Meshing option in Mechanical application 55

4.8 Meshing result for current design analysis 56

4.9 Fixed Support on Current Design Analysis 58

4.10 Graph Force vs Time 59

4.11 Force Load on Current Design Analysis 59

xi

4.13 Safety Factor of Current Design Analysis 62

4.14 Safety Margin of Current Design Analysis 63

4.15 Stress Ratio of Current Design Analysis 64

4.16 Solution Information in Worksheet 65

5.1 Minimum Safety Factor 67

5.2 Improvement Design 1 of Casting Valve 69

5.3 Safety factor for Improvement Design 70

5.4 Improvement design 2 of Casting Valve 72

5.5 Safety Factor for Improvement Design 2 73

5.6 Improvement design 3 of Casting Valve 75

5.7 Safety Factor for Improvement Design 3 76

6.1 Design parameter at front view 78

6.2 Design parameter at bottom view 79

6.3 Comparison between current and improvement design 80

xii

LIST OF ABBREVIATIONS

2D - Second Dimensional

3D - Third Dimensional

ABC - Area Bundle Cable

API - Application Programming Interface

ANSI - American National Standards Institute

ASTM - American Standard Testing Method

CAD - Computer-Aided Design

IGES - Initial Graphics Exchange Specification

JBSB - Jati Beringin Sdn.Bhd.

SPH - Smoothed Particle Hydrodynamics

TM - Telekom Malaysia Berhad

1

CHAPTER 1

INTRODUCTION

This first chapter discussed about the introduction of casting valve for ABC Dead End Clamp, HV. Casting valve is a part of ABC Dead End Clamp, HV that is one of pole accessories for TNB’s product. The background, problem statement, objectives and scope of this research are discussed. The expected of this research is briefly discussed in this chapter.

1.1 Background of Company

2

1.2 Background of Product

The HV ABC Dead End Clamp is used as an accessory for High Voltage (HV) ABC System and suitably designed to hold and grip the 11kV and 33kV HV ABC 50 mm2 galvanized standard messenger steel wire to support it on to 10m-19-5kN spun

concrete poles via HV Dead End Clamp Brackets (Single or Double). The HV ABC Dead End Clamp capable to withstand a minimum breaking load of 65 kN or 6630 kg-force or 7.3 ton kg-force for 60 seconds. The general concept design of High Voltage ABC Dead End Clamp is shown in Appendix A. Meanwhile, figure 1.1 shows High Voltage ABC Dead End Clamp for current use.

3

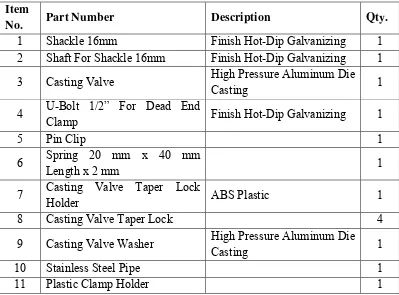

The description of High Voltage ABC Dead End Clamp is shown in the table 1.1.

Table 1.1: The description of HV ABC Dead End Clamp Item

No. Part Number Description Qty.

1 Shackle 16mm Finish Hot-Dip Galvanizing 1

2 Shaft For Shackle 16mm Finish Hot-Dip Galvanizing 1

3 Casting Valve High Pressure Aluminum Die Casting 1

4 U-Bolt 1/2” For Dead End Clamp Finish Hot-Dip Galvanizing 1

5 Pin Clip 1

6 Spring 20 mm x 40 mm Length x 2 mm 1

7 Casting Valve Taper Lock Holder ABS Plastic 1

8 Casting Valve Taper Lock 4

9 Casting Valve Washer High Pressure Aluminum Die Casting 1

10 Stainless Steel Pipe 1

4

1.2.1 Casting Valve

Casting valve is one of the parts in the HV ABC Dead End Clamp. The function of the casting valve is to hold and grip the galvanized standard messenger steel wire to support it on the spun concrete poles via HV Dead End Clamp Brackets (Single or Double). Figure 1.2 shows casting valve before make the Sample Test.

5

1.2.2 Tensile Test

In mechanical testing, tensile test is used as the testing to test the structural failure of casting valve. Basically, there are two classes of testing machines; electromechanical and hydraulic. Tensile test that is provided by this company is hydraulic machine. A hydraulic testing machine uses either a single- or dual-acting piston to move the crosshead up or down. (Richard Gedney, 2005)

Mechanical properties are an important measure of product quality in production line and tensile testing is a way to certify the product included to test the structure of casting valve for High Voltage ABC Dead End Clamp. Figure 1.3 shows the tensile test that used during Sample Test for Casting Valve and other product in this company.

6

1.2.3 Application of Casting Valve

Casting valve is one of the important parts of High Voltage ABC Dead End Clamp. Figure 1.4 shows one of the applications for High Voltage TNB distribution that is held and grip the galvanized standard messenger steel wire to support it on the spun concrete poles via HV Dead End Clamp Brackets (Single or Double).

Figure 1.4: Application of Casting Valve (Source: Jati Beringin Sdn. Bhd., 2011)

1.3 Problem statement

7

Figure 1.5: Sample fracture of casting valve during sample test (Source: Jati Beringin Sdn. Bhd., 2011)

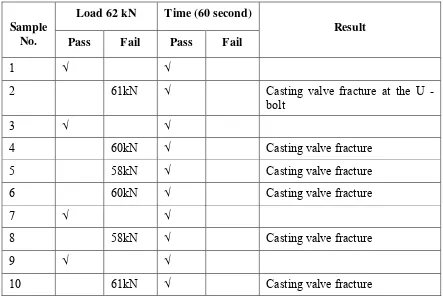

Figure 1.5 shows a few samples of casting valve during sample test by using tensile test. Meanwhile, table 1.2 shows the summary of the result for the sample test. From the table 1.2, the fracture of casting valve happened five times during 10 samples of casting valve is tested. It shows that the design of casting valve is failing to maintain 10% and it will be improved.

Table 1.2: Result of sample test

8

1.4 Objectives of research

The objectives of this research are:

a) To investigate design parameter of casting valve for ABC Dead End Clamp, HV. b) To analyze the current design of casting valve for ABC Dead End Clamp, HV by

using Finite Element Analysis (FEA) software.

c) To propose new design of casting valve for ABC Dead End Clamp, HV.

1.5 Scope of research

This research investigates the current design of casting valve for ABC Dead End Clamp, High Voltage weakness, strength, and fracture or structure failure of this part. ANSYS software will be used to carry out this analysis and improvement on existing design based on the founding. The cover topic for this research is use design parameter and factor of safety for design improvement by using finite element analysis (FEA). It is used to study on current design by comparing actual experimental data from sample test. Then, new design of casting valve is drawn by using SolidWorks software.

1.6 Structure of research