FEASIBILITY STUDY AND CONCEPTUAL DESIGN ON THE AUTOMATIC FISH FEEDER

MOHD AZRUL BIN OMAR

This thesis is submitted in partial fulfillment of the requirements for the dgree of Mechanical Engineering (Design & Innovation)

UNIVERSITI TEKNIKAL MALAYSIA MELAKA

ii

DECLARATION

“I hereby acknowledge that this report is my own investigation except summaries and citations which every each of it that I state the sources”

Signature :

Author :

iii

iv

ACKNOWLEDGEMENT

v

ABSTRAK

vi

ABSTRACT

The project relates to a mechanism of automatic fish feeder. The main function of this product is to suit the fish feeding automatically by a machine and feed with the exact time and accurate amount of fish food so that there is no wasting in feeding. By using this gadget, the work to feed the fish become easier and efficient compared before. Automatic fish feeders help make our life as an aquarium owner much easier. It is often hard to remember whether or not we fed the fish, or if someone else in our house did already, and the automatic fish feeder eliminates missed feedings or over feeding altogether. Too much food in the water can easily clog up important filters, and cause us to have to spend more time cleaning our aquarium tank than enjoying it. Via this project, the improvement and enhancement of current automatic fish feeder can be done successfully. The automatic fish feeder will be analyses using Solidworks COSMOSWorks software. The analysis that be done on this design is structural analysis and motion analysis on mechanism.

vii

TABLE OF CONTENTS

CHAPTER ITEMS PAGES

DECLARATION ii

DEDICATION iii

ACKNOWLEDEMENT iv

ABSTRAK v

ABSTRACT vi

TABLE OF CONTENTS vii

LIST OF TABLES xi

LIST OF FIGURES xii

LIST OF SYMBOLS xv LIST OF APPENDICES xvi

1 INTRODUCTION 1

1.1 Project Background 1

1.2 Importance of the Project 2

1.3 Objectives 2 1.4 Scopes 3

1.5 Problem Statement 3

2 LITERATURE REVIEW 4

2.1 Feeding 4 2.2 Nutritional Aspect of Growth 7

viii

2.3.1 Flake Fish Food 10

2.3.2 Brine Shrimp 11

2.3.3 Blood Worms 11

2.3.4 Shrimp Pellets 12

2.3.5 Spirulina 12

2.3.6 Algae Wafers 12

2.3.7 Frozen Dried Fish Food 13

2.4 Automatic Fish Feeders 14

2.4.1 P21 Automatic Pond Feeder 14

2.4.2 Rena LG100 Automatic Feeder 16

2.4.3 Eheim 3581 "Feed-Air" Digital Automatic 17 Feeder

2.4.4 AquaChef Automatic Aquarium Fish

Feeder 19

2.4.5 Directional Broadcast Feeder Fish 20

2.5 Timer 23

2.5.1 Timer (555 timer IC) 23

2.5.2 DT-02/7-Day 12 VDC Timer & Housing 25 2.5.3 TS-10/7-Day Programmable Time Switch--

24VAC/12VDC 26

2.5.4 DT-06/24 Volt DC Digital Timer/spdt

Switching 27

2.5.5 TS-08/24-Hour Programmable Time

Switch--6-24 VDC or AC 28

2.6 Electric Motor 30

2.6.1 Stepper Motor 30

2.6.1.1 Unipolar Motors 31

2.6.1.2 Bipolar Motors 32

2.6.2 Other Types of Stepper Motor 33

ix

2.8 Patents 35

2.8.1 Automatic Aquarium Feeder Apparatus 36

2.8.2 Automatic Fish Feeder 38

2.8.3 Directional Broadcast Feeder for Fish and

Game 40

2.8.4 Fish Feeder with Water Filter and Heater 42

2.8.5 Wide Range Fish Feeder 44

2.8.6 Automatic Fish Feeder 46

2.8.7 Automatic Fish Feeder 48

2.9 SolidWorks COSMOSWorks 49

3 METHODOLOGY 50

3.1 Methodology Flow Chart 50

3.2 Conceptual Design 52

3.2.1 Concept 1 53

3.2.1.1 Introduction 54

3.2.1.2 Sketching 54

3.2.1.3 Working Concept 54

3.2.2 Concept 2 55

3.2.2.1 Introduction 56

3.2.2.2 Sketching 56

3.2.2.3 Working Concept 56

3.2.3 Concept 3 57

3.2.3.1 Introduction 58

3.2.3.2 Sketching 58

3.2.3.3 Working Concept 58

3.2.4 Concept 4 59

3.2.4.1 Introduction 60

3.2.4.2 Sketching 60

x

3.2.5 Concept 5 61

3.2.5.1 Introduction 62

3.2.5.2 Sketching 62

3.2.5.3 Working Concept 62

3.3 Design Selection 63

3.3.1 Introduction 63

3.3.2 Result 64

4 DETAILS DESIGN 66

4.1 Design Explanations 67

4.1.1 Bottom Body 67

4.1.2 Food Container 68

4.1.3 Lid 69

4.1.4 Base 70

4.1.5 Hollow Stand 71

4.1.6 90° Connector 72

4.1.7 Straight Arm 73

4.1.8 Hook 74

4.1.9 Feeder Funnel 75

4.1.10 Helix-shaped Screw Blade 76

4.1.11 Gears 77

4.1.12 Bolt and Nut 78

4.1.13 Battery Cover 79

4.1.14 Bipolar Motor 80

4.2 Full Assembly View 82

4.3 Exploded View 83

4.4 Full Assembly Section View 85

4.5 Components’ Quantity 86

4.6 Materials Selection 87

4.6.1 Physical Properties 87

xi

4.6.3 Chemical Properties 88

4.6.4 Classes of Material 88

4.7 Materials Selection for Automatic Fish Feeder 89 4.7.1 Specifications of Poly(vinyl chloride) (PVC) 90 4.7.2 Specifications of Carbon Steel (AISI 1020) 91 4.7.3 Specifications of Stainless Steel (AISI 36F) 94

4.7.4 Polyacetal (POM or Acetal) 95

4.7.5 Poly(methyl methacrylate) (PMMA) 96

4.8 Working Concept 96

5 ANALYSIS 97

5.1 Analysis 97

5.1.1 Structural Analysis 98

5.1.1.1 Procedure Analysis of a Hollow

Stand with Base 98

5.1.2 Analysis with COSMOSMotion 2007 102 5.1.2.1 Procedures of Analysis Using

COSMOSMotion 102

6 RESULTS AND DISCUSSIONS 108

6.1 Results 108

6.1.1 Analysis of Stand Assembly 108

6.1.2 Analysis of Hook 112

6.1.3 Analysis with COSMOSMotion 2007 116

6.1.3.1 Angular Velocity Analysis 116

6.1.3.2 Angular Acceleration Analysis 117

6.2 Theoretical Calculation 118

6.2.1 Bending Stress of Stand Assembly 118

xii

6.3 Discussions 122

7 CONCLUSION AND RECOMMENDATIONS 123

7.1 Conclusion 123

7.2 Recommendations 124

REFERENCES 125

APPENDIX A 127

APPENDIX B 128

APPENDIX C 129

xiii

LIST OF TABLES

NO. TITLE PAGES

2.1 Estimated food consumption by size of a typical 5 warm water fish

2.2 Recommended stocking and feeding rates for different

size group of tilapia in tanks, and estimated growth rates 6

3.1 Weighted Rating Method 65

4.1 List parts of the automatic fish feeder 84

4.2 Components’ quantity 86

4.3 Materials selection for Automatic Fish Feeder 89 4.4 Specifications of Poly(vinyl chloride) (PVC) 91

4.5 AISI 1020 92

4.6 Composition of AISI 1020 92

4.7 Mechanical properties of AISI 1020 93

4.8 Thermal properties of AISI 1020 93

4.9 AISI 316F 94

4.10 Composition of AISI 316F 94

4.11 Mechanical properties of AISI 316F 95

4.12 Thermal properties of AISI 316F 95

6.1 Analysis of Stand Assembly 111

6.2 Analysis of Hook 115

xiv

LIST OF FIGURES

NO. TITLE PAGES

2.1 Flake fish food 10

2.2 Brine shrimp 11

2.3 Blood worm 11

2.4 Shrimp pellets 12

2.5 P21 Automatic Pond Feeder 15

2.6 Rena LG100 Automatic Feeder 16

2.7 Eheim 3581 “Feed-Air” Digital Automatic Feeder 17

2.8 AquaChef Automatic Aquarium Fish Feeder 19

2.9 Directional Broadcast Feeder Fish 21

2.10 Timer (555 timer IC) 24

2.11 DT-02/7-Day 12 VDC Timer & Housing 25

2.12 TS-10/7-Day Programmable Time Switch

24VAC/12VDC 26

2.13 DT-06/24 Volt DC Digital Timer/spdt Switching 28 2.14 TS-08/24-Hour Programmable Time Switch--6-24 VDC

or AC 29

2.15 Unipolar motor structure 31

2.16 Bipolar motor structure 32

2.17 Bipolar motor structure 33

2.18 Gears and Pinion 34

xv

2.20 Automatic Fish Feeder 38

2.21 Directional Broadcast Feeder for Fish and Game 40

2.22 Fish Feeder with Water Filter and Heater 42

2.23 Wide Range Fish Feeder 44

2.24 Automatic Fish Feeder 46

2.25 Automatic Fish Feeder 48

3.1 Methodology Flow Chart 51

3.2 Concept 1 53

3.3 Concept 2 55

3.4 Concept 3 57

3.5 Concept 4 59

3.6 Concept 5 61

4.1 Bottom body 67

4.2 Food container 68

4.3 Lid 69

4.4 Base 70

4.5 Hollow stand 71

4.6 90° Connector 72

4.7 Straight arm 73

4.8 Hook 74

4.9 Feeder funnel 75

4.10 Helix-shaped screw blade 76

4.11 Gears 77

4.12 Bolt and nut 78

4.13 Battery cover 79

4.14 Bipolar motor 80

4.15 Stacked stepper specifications (Danaher Motion) 81

4.16 Full assembly view 82

4.17 Exploded view 83

xvi

5.1 COSMOSWorks Manager tab 98

5.2 Define a static study 99

5.3 Material selection 99

5.4 Apply fix restraints and force 100

5.5 Mesh the assembly 101

5.6 Run the analysis 101

5.7 The mechanism part that will analyze 103

5.8 Add-Ins tab 104

5.9 “Motion” menu 104

5.10 IntelliMotion Builder 105

5.11 Intellimotion Builder window 107

6.1 Von Misses stress analysis 109

6.2 Displacement analysis 110

6.3 Strain analysis 111

6.4 Material selection 112

6.5 Von Misses stress analysis 113

6.6 Displacement analysis 114

6.7 Strain analysis 115

6.8 Angular velocity graph 116

6.9 Angular acceleration graph 117

6.10 Cross section view of stand assembly 118

xvii

LIST OF SYMBOL

F = Fahrenheit

δ13C = A measure of the ratio of stable isotopes 13C:12C

σ = Bending stress

xviii

LIST OF APPENDICES

NO. TITLE PAGES

A Gantt Chart 136

B Sample of Survey Questioner 137

C Conceptual Design 138

1

CHAPTER 1

INTRODUCTION

1.1 Project Background

Nowadays, there are many types of automatic fish feeder in the market. Every type of them has their own advantages, disadvantages, different design, and different mechanism and so on. Automatic fish feeder is one of the gadgets that help user to feed their fish automatically without do it manually everyday. Using this gadget, user only need to set the timer and the gadget will feed their fish automatically according to the user setting. This gadget also helps the person who is willing to travel for a long time, maybe for their business trip or family vocation to feed their fish automatically while they are away. Therefore, they do not need to worry about their fish anymore while they are not around.

2

consider all aspect that required as a good automatic fish feeder and also environmental friendly.

1.2 Importance of the Project

The significant of this project is to provide a high quality of automatic fish feeder compared to the product that available in the market nowadays. By using this gadget, the work to feed the fish become easier and efficient compared before. Automatic fish feeders help make your life as an aquarium or pond owner much easier. It is often hard to remember whether or not you fed the fish, or if someone else in your house did already, and the automatic fish feeder eliminates missed feedings or over feeding altogether. Too much food in the water can easily clog up important filters, and cause you to have to spend more time cleaning your aquarium tank than enjoying it.

Besides, this design has a high commercial value. Because of the cost of this gadget is not very expansive, everyone can afford for it. This gadget is not too expensive because it uses a simple mechanism to work. Besides, the materials used are easy to obtain. This design also will provide big opportunities towards continuous development on design technique of any similar automatic feeder such as for birds, goats, cows and etcetera.

1.3 Objectives

Objectives are important element in the design. It must be clearly stated and understood to easier the designer to imagine or determine the goal of the project.

3

To design and improve the current automatic fish feeder.

1.4 Scopes

The scopes of the project are as follow:

This project focuses on development of a working mechanism.

The development includes simple analysis to show the effectiveness of the working mechanism using Solidworks COSMOSWorks software.

1.5 Problem Statement

The idea of developing a new automatic fish feeder is because the current automatic fish feeder in the market nowadays very expensive and quiet difficult to handle. The designs of the automatic fish feeder also not meet the customer taste and lack ergonomics.

The main factors that need to consider while choosing and determine the specification of the product are:

4

CHAPTER 2

LITERATURE REVIEW

Literature review is needed to get information and detail background that related about the project as such histories, articles and journals. This information is going to use in order to finish the project.

2.1 Feeding

5

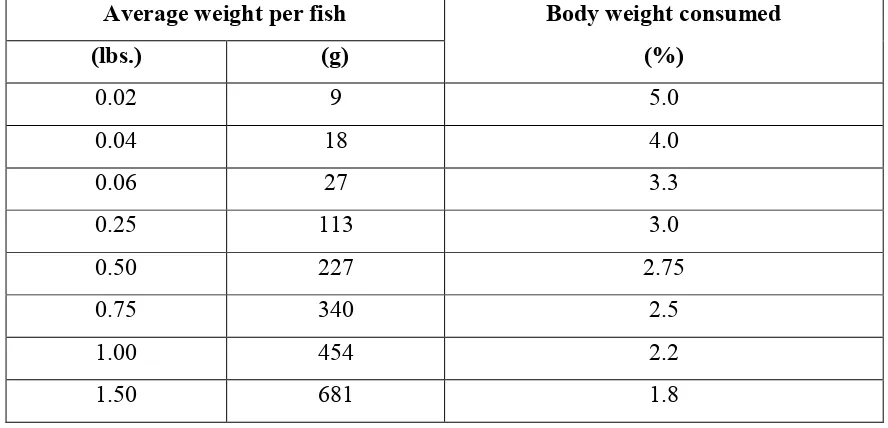

Table 2.2 approximates a feeding schedule for a warmwater fish (e.g., tilapia)

stocked into an 84o F recirculating system as fry and harvested at a weight of 1 pound

[image:24.612.105.549.360.574.2]after 250 feeding days. Feed conversion is estimated at 1.5: 1, or 1.5 pounds of feed to obtain 1 pound of gain. Tables 2.1 and 2.2 are estimate and should be used only as guidelines which can change with differing species and temperatures. Growth and feed conversion are estimated by weighing a sample of fish from each tank and then calculating the feed conversion ratios and new feeding rates from this sample. For example, 1,000 fish in a tank have been consuming 10 pounds of feed a day for the last 10 days (100 pounds total). The fish were sampled 10 days earlier and weighed an average of 0.33 pounds or an estimated total of 330 pounds.

Table 2.1: Estimated food consumption by size of a typical warmwater fish. (Source: Southern Regional Aquaculture Centre (SRAC publication no. 452, March ‘99)

Average weight per fish Body weight consumed

(%)

(lbs.) (g)

0.02 9 5.0

0.04 18 4.0

0.06 27 3.3

0.25 113 3.0

0.50 227 2.75

0.75 340 2.5

1.00 454 2.2

1.50 681 1.8