TEMPERATURE EFFECT ON CARBONIZATION OF WATER HYACINTH AS A SOLID BIOFUEL

MOHD ZUBIR BIN OTHMAN

SUPERVISOR DECLARATION

“I hereby declare that I have read this thesis and in my opinion this thesis is sufficient in terms of scope and quality for the award of the degree of

Bachelor of Mechanical Engineering (Plant and Maintenance)”

Signature : ...

Supervisor : Dr Nona Merry Merpati Mitan

TEMPERATURE EFFECT ON CARBONIZATION OF WATER HYACINTH AS

A SOLID BIOFUEL

MOHD ZUBIR BIN OTHMAN

This thesis is partial fulfilment of the award of Bachelor of Mechanical Engineering

(Plant and Maintenance) with Honurs

Faculty of Mechanical Engineering

Universiti Teknikal Malaysia, Melaka (UTeM)

DECLARATION

“I hereby declare that the work in this thesis is my own except for summaries and quotations which have been duly acknowledged.”

Signature : ...

Author : Mohd Zubir Bin Othman

Dedication for Beloved,

ACKNOWLEDGEMENT

First of all, praise to the Almighty God that I was able to complete the final year

projectwith successful and could be done properly. We would like to take this

opportunity to thanks all organization or individuall who have helped me in finished my

final year project Universiti Teknikal Malaysia Melaka (UteM). In addition, I would like

to said thank you so much to my supervisor Dr. Nona Merry Merpati Mitan on her effort

to supervise and cooperate in any phase of the project. All knowledge and guidance that has been provided is really appreciated. Alhamdulilah, Bachelor’s degree project report finally reached at the end. I would like to said thank tou to my parent, my family who

gives a full support on me all the time with love and care. Not forgetting my gratitude to

the Universiti Teknikal Malaysia Melaka (UteM) and Jabatan Alam Sekitar Negeri

Melaka for provided a comfortable atmosphere, data and equipment in the laboratary

during the session and allows me to complete my project without any problems. Finally,

I would like to give greatest thanks to my friend who have been supportive,

understanding, motivation, patience and good cooperation in preparing this report.

ABSTRACT

Water hyacinth is one of the pest plants that live on the surface of water, river

and lake where it is able to remove the oxygen and nutrient in the water. Water hyacinth

consists of 10 % of lignin, 25 % of cellulose and 35 % of hemicelluloses. Therefore, the

components exist in water hyacinth have a potential to become a solid biofuel. Water

hyacinth can be converted into high quality fuel by carbonization process. Carbonization

is a treatment method for upgrading biomass feedstock into solid biofuels. The purpose of this research is to investigate the temperature effect of water hyacinth briquette which

carbonized at temperature 300, 400, 500 and 600 oC at heating rate 5 °C per minutes for

two hours. There are six steps involved to produce of water hyacinth as a briquette

which are collecting of raw material, drying, crushing, milling, carbonization and

densification. The briquette products produced have been passed through some analyses

such as proximate analysis, calorific test, compressive test, and FTIR test so that the

properties of briquette product can be determined. A comparison will be made between

these types of briquettes in order to identify the optimum temperature of carbonization in

producing highest quality briquette product in the future. The highest calorific value is

C300 briquette with 4414 cal/g. The lowest percentage of moisture content and volatile

matter is carbonization briquette with temperature 600 °C which is 3.00 and 20.33 %

respectively while for ash and fixed carbon content, C600 briquette shows the highest

percentage with 50.67 and 26.00 % respectively. The highest compressive value

obtained was C300 briquette compared with other carbonization briquette. Based on the

analysis, carbonization temperature at 300 °C are the optimum temperatures that can be

ABSTRAK

Keladi bunting adalah salah satu tumbuhan perosak yang hidup di permukaan air,

sungai dan tasik di mana ia mampu untuk mengeluarkan oksigen dan nutrien dalam air.

Keladi bunting terdiri daripada 10% daripada lignin, 25% daripada selulosa dan 35%

daripada hemicelluloses. Oleh itu, komponen wujud dalam keladi bunting mempunyai

potensi untuk menjadi biofuel yang kukuh. Keladi bunting boleh diprose menjadi bahan

api yang berkualiti tinggi melalui proses karbonisasi. Karbonisasi adalah satu kaedah rawatan untuk meningkatkan bahan mentah biojisim pepejal ke dalam bahan bakar bio.

Tujuan kajian ini adalah untuk mengkaji kesan suhu keladi bunting briket yang akan

dikarbonisasi pada suhu 300, 400,500 dan 600 °C pada kadar 5°C perminit selama dua

jam. Terdapat enam langkah dalam penyediaan keladi bunting sebagai briket iaitu

pengumpulan bahan mentah, pengeringan, penghancuran, pengisaran, karbonisasi dan

pemadatan. Produk briket terhasil melalui beberapa analisis seperti analisis proksimat,

ujian kalori, ujian mampatan dan FTIR supaya sifat-sifat produk briket boleh ditentukan.

Perbandingan akan dibuat di antara jenis briket untuk mengenal pasti suhu optimum

karbonisasi dalam menghasilkan produk yang berkualiti tinggi briket pada masa akan

datang. Nilai kalori paling tinggi ialah C300 briket dengan 4414 cal / g. Peratusan

terendah kandungan kelembapan dan perkara yang tidak menentu adalah karbonisasi

briket dengan suhu 600 ° C iaitu 3.00 dan 20.33% manakala bagi kandungan abu dan

kandungan karbon tetap, C600 briket menunjukkan peratusan tertinggi dengan 50.67 dan

26.00%. Ujian mampatan untuk C300 briket menunjukkan nilai yang paling tinggi

berbanding dengan karbonisasi briket lain. Berdasarkan analisis yang telah dilakukan,

suhu karbonisasi 300 °C menunjukkan suhu yang paling optimum yang boleh dikenakan

TABLE OF CONTENT

CHAPTER TITLE PAGE

SUPERVISOR DECLARATION

PROJECT TITLE

DECLARATION ii

DEDICATION iii

ACKNOWLEDGEMENT iv

ABSTRACT v

ABSTRAK vi

TABLE OF CONTENT vii

LIST OF TABLES x

LIST OF FIGURES xi

LIST OF EQUATIONS xiii

LIST OF APPENDICES xiv

CHAPTER I INTRODUCTION 1.1 Background 1

1.2 Problem Statement 2

1.3 Objectives 3

1.4 Scope 3

CHAPTER II LITERATURE REVIEW 2.0 Overview 4

2.1.1 Biomass Components 8

2.2 Biomass Conversion 9

2.2.1 Carbonization 10

2.4 Biofuel 12

2.5 Water Hyacinth 12

2.6 Sample Analysis 15

2.7 Past Studies 16

CHAPTER III METHODOLOGY

3.0 Overview 22

3.1 Sample Preparation 24

3.1.1 Collection of Raw Material 24

3.1.2 Drying of Raw Material 25

3.1.3 Crushing Process 26

3.1.4 Milling Process 26

3.1.5 Carbonization Process 27

3.1.6 Densification Process 27

3.2 Briquette Analysis 28

3.2.1 Proximate Analysis 28

3.2.1.1 Moisture Content 28

3.2.1.2 Ash Content 29

3.2.1.3 Volatile Matter 30

3.2.1.4 Fixed Carbon 30

3.2.2 Calorific Value 31

3.2.3 Compressive Test 32

3.2.4 Fourier Transformation Infrared 32

Spectroscopy (FTIR)

CHAPTER IV RESULTS AND ANALYSIS

4.1 Introduction 33

4.2.4 Fixed Carbon 37

4.3 Calorific value 38

4.4 Compressive Test 39

4.5 FTIR 40

CHAPTER V DISCUSSION

5.1 Proximate Analysis 42

5.1.1 Moisture content 43

5.1.2 Ash Content 43

5.1.3 Volatile Matter 44

5.1.4 Fixed Carbon 44

5.2 Calorific Value 45

5.3 Compressive Strength 45

5.4 FTIR Analysis 46

CHAPTER V I CONCLUSION AND RECOMMENDATION

6.1 Conclusion 48

6.2 Recommendation 50

REFERENCES 51

LIST OF TABLES

NO TITLE PAGE

2.1 Lignocelluloses constituent in biomass material 8

2.2 Element of fresh water hyacinth 13

2.3 Biomass composition of water hyacinth 13 2.4 Composition of shoot and root of water hyacinth 15

2.5 Durability rating 17

2.6 Past studies of water hyacinth 18

4.1 Analysis data on water hyacinth briquette 33

LIST OF FIGURES

NO. TITLE PAGE

2.1 World primary energy production and consumption in November 2010 5

2.2 Carbon cycle, photosynthesis and biomass technologies 7

2.3 Main biomass conversion process 9

2.4 Stage of degasification concept 11

2.5 Water hyacinth shoot and root diagram 14

3.1 Project flow chart of briquetting water hyacinth and analysis 23

3.2 The water hyacinth in the riverside 24

3.3 The digital analytical balance, circulating oven and dried water hyacinth 25

3.4 Crusher machines 26

3.5 Centrifugal mill (Retsch ZM 200) 26

3.6 Electrical furnaces (Carbolyte Type 201) for carbonization 27

3.7 Mold for densification process and briquette product 28

3.8 Decomposition vessels and bomb calorimeter 31

4.1 Moisture content of water hyacinth briquette 34

4.2 Ash content of water hyacinth briquette 35

4.3 Volatile matter of water hyacinth briquette 36

4.4 Fixed carbon of water hyacinth briquette 37

4.5 Calorific value of water hyacinth briquette 38

4.6 Compressive graph of water hyacinth briquette 39

4.7 FTIR spectra of water hyacinth briquette for every briquette produced 40

5.2 The result of FTIR spectra between NC and C600 sample 46

LIST OF EQUATIONS

NO TITLE PAGE

3.1 Percentage of moisture content, % 28

3.2 Percentage of ash content, % 28

3.3 Weight loss, % 29

3.4 Percentage of volatile matter, % 29

3.5 Percentage of fixed carbon, % 29

LIST OFAPPENDICES

NO TITLE PAGE

1 Appendix 1 (a) Proximate analysis non-carbonization of briquette 56

2 Appendix 1 (b) Proximate analysis carbonization of briquette (T= 300°C) 57

3 Appendix 1 (c) Proximate analysis carbonization of briquette (T= 400°C) 58

4 Appendix 1 (d) Proximate analysis carbonization of briquette (T= 500°C) 59

5 Appendix 1 (e) Proximate analysis carbonization of briquette (T= 600°C) 60

6 Appendix 2 (a) Compressive test for non-carbonization briquette 61

7 Appendix 2 (b) Compressive test carbonization of 300 °C briquette 61

8 Appendix 2 (c) Compressive test carbonization of 400 °C briquette 62

9 Appendix 2 (d) Compressive test carbonization of 500 °C briquette 63

10 Appendix 2 (e) Compressive test carbonization of 600 °C briquette 63

11 Appendix 3 Data for calorific value of briquette sample 64

12 Appendix 4 Water quality index of Sungai Putat 65

13 Appendix 5 (a) Gantt chart for final year project I 66

14 Appendix 5 (b) Gantt chart for final year project II 66

CHAPTER I

INTRODUCTION

1.1 BACKGROUND

The rising of oil prices and global warming is a major problem in this world. Therefore,

the Government of Malaysia implemented various initiatives to expand environmentally

practices and the application of green technology in an effort to preserve the country’s ecosystem while ensuring the conducive environment for life. One of the government’s initiatives is the sustainable development.

Renewable energy is one of the most efficient government initiatives to meet the

sustainable development advocated by the government. Hence, the government of

Malaysia has introduced a number of policies like National Green Technology Policies

2009 and Nation Renewable Energy 2010 where the aimed is to encourage the use of

renewable energy. According to Asia Pacific Economic Cooperation (APEC) 2014which

held at Beijing, a new goal was announced by President of United States which need to

double renewable energy used by 2030 (Schroeder, 2014). There are many renewable

energy sources such as biomass.

Biomass has recommended as an alternatives energy resources for fossil fuels in

recent years due to green house effect from fossil fuel combustion. This effect contains

many biomass resources that has in our country such as water hyacinth, cow manure,

durian peel and others which has a potential for renewable energy.

1.2 PROBLEM STATEMENT

The consumption of fossil fuel is tremendously increasing and causing fossil fuel

resources dwindling every year. By then, the world was introduced biomass as a source

of sustainable energy to meet the needs in the future.

Water hyacinth in scientific name Eichornia crassipes is one of pest that live on

the surface of the water, rivers and lakes. As the one of the most productive plants on

earth, they can growth up in two times from its normal size in a few weeks then spread rapidly, where it is able to form mats on the water surface along a river or lake. In

addition, the low oxygen condition below the surface of the water hyacinth will block

the flow of water will affect the ecosystem in which to make a river or lake as a breeding

ground for mosquitoes. Besides that, water hyacinth causes the loss of water and

obstruction of boat traffic. Water hyacinth also can block the suction lines of irrigation

and drainage pump where it can reduce the efficiency of pump and increase the cost of

maintenance if the pump failure or defect (Ndimele et., 2011).

Based on Tejinder et al. (2012), the water hyacinth is rich in polyphenol oxidase

where it can be easily combustible. In addition, the content of lignin in water hyacinth is

low, while the cellulose and hemicelluloses is high (Rezania et al.,2015). Due to this

content the water hyacinth have capability to become a biofuel. Therefore, the

advantages that existance in water hyacinth should be utilized as well as to reduce the

a) To produce briquette from water hyacinth.

b) To identify the effect of temperature on the calorific value of briquette.

c) To perform proximate analysis (moisture content, ash content, volatile matter and

fixed carbon) and mechanical properties (compressive test) of briquette product.

d) To determine the functional group of water hyacinth by using Fourier Transform

Infrared Spectroscopy (FTIR).

1.3 SCOPES

This project involves the preparation of water hyacinth as a raw material to produce

briquette as a solid biofuel by drying, pulverization (crushing and milling), carbonization

and densification process. The main focus of this project is to study the effect of

temperature on carbonization of water hyacinth as a solid biofuel. Water hyacinth have

been went through the carbonization process with different kind level of temperature.

Besides that, the proximate analysis of water hyacinth briquette was performed to

identify the percentage of moisture content, ash content, fixed carbon and volatile

matter. It also covered the calorific value test, FTIR test and compressive test of water

CHAPTER II

LITERATURE REVIEW

2.0 Overview

The uses of fossil fuel are tremendously increasing and causing fossil fuel resources

dwindling every year. Nasir et al. (2013) stated the recent production of fossil fuels like

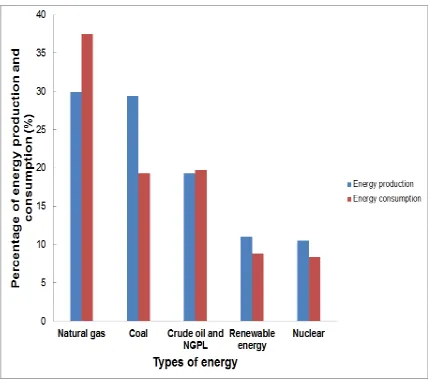

natural gas, coal, crude oil and natural gas plant liquid (NGPL) has increased up to 79 %

than to another energy sources as shown in the figure below. Figure 2.1 shows the world

primary energy production and consumption in November 2010. Based on the world

primary energy, natural gas shows the highest consumption compared to other energy

and this problem closely related to the increasing of the world’s population every year.

The increasing of this number had made the world worrying because the

emission of carbon from the fossil fuel combustion will cause the environmental issue

like the depletion of ozon layer and the climate changes. Therefore, the renewable

energy was introduced as an option which purposely to reduce the reliance on fossil

fuels. Renewable energy is the energy that are constantly replenish and will never run

out. There are many types of renewable energy such as solar energy, wind energy,

bioenergy and ocean energy. Bioenergy is the energy that produce from orgarnic matter

or known as biomass. Water hyacinth is one of the biomass sources that contains 35% of

hemicellulose, 25 % cellulose and 10 % of lignin. The constituent of water hyacinth will

become solid biofuel

Figure 2.1 World primary energy production and consumption in November 2010

(Source: Nasir (2013))

2.1 Biomass

The use of fossil fuel as the primary energy production in the world today, is a threat to

carbon from fossil fuel combustion. The increase of greenhouse gases (CO2, CH4, NOx)

can cause global warming which can lead to dangerous phenomenon such as tornadoes

and unexpected flood (Ciubota-Rosie et al., 2008). Therefore, one of the solutions is by

using the biomass as sustainable energy.

According to Demirbas (2009) biomass is refers to biodegradable organic

material from living such as plants, animal which derived from biological sources.

Agbor et al. (2014) in their study, stated biomass is a renewable energy sources where it

is derived from organic matters which are friendly to environment (carbon neutral). The

example of organic matter is agricultural crops, harvest residue, seaweed and organic

waste. In addition, biomass is consisting of living organism or biological material from

living (Piech, 2012).

Biomass resources can be categorized into four which is waste, forest product,

energy crop and aquatic plant. The example of waste stock is mill wood waste,

agricultural production waste and others. The forest product is like wood and trees that

comes from forest clearings. The energy crops are like short-cycle crops such as wheat,

sugarcane and other while aquatic plant likes algae and water hyacinth (Ciubota-Rosie et

al., 2008).

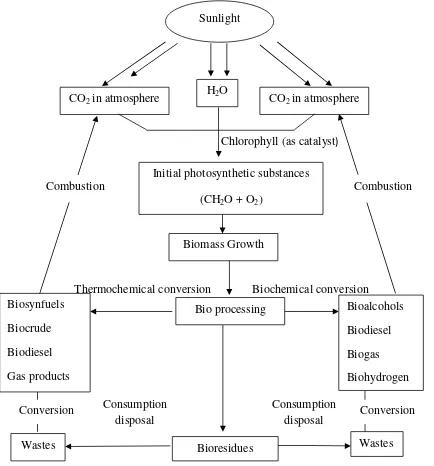

Photosynthesis process is closely related to biomass. Photosynthesis is a process

by which they convert solar energy into chemical energy to produce carbohydrates that

form the basis formation of biomass and the carbon fixation by reduction of carbon

dioxide (Demirbas, 2009). Figure 2.2 shows the biomass production technologies which

involve of carbon cycle and photosynthesis. It is a cyclic process in which it is able to

generate new biomass and continuous. The majority of photosynthetic will be utilized

and directly towards the production of biomass growth. During the processing and

consumption of biomass, the waste organic material will be generated, which can be

Figure 2.2 Carbon cycle, photosynthesis and biomass technologies

(Source: Demirbas, (2009))

Consumption disposal

Wastes

Wastes Bioresidues

Conversion Conversion Consumption

disposal

Thermochemical conversion Biochemical conversion

Bioalcohols Biodiesel Biogas Biohydrogen Biosynfuels Biocrude Biodiesel Gas products Bio processing Biomass Growth

Initial photosynthetic substances

(CH2O + O2)

Chlorophyll (as catalyst) Sunlight

CO2 in atmosphere H2O CO2 in atmosphere