THE ROLE OF LOCAL GOVERNMENT IN SUPERVISING THE IMPLEMENTATION OF THE PROVISIONS ON WORK SAFETY FOR

LABORERS IN THE MINE AREAS OF KUTAI KARTANEGARA

UNDERGRADUATE THESIS

This undergraduate thesis proposal is submitted as one of the requirements to obtain the degree of Bachelor of Laws at Faculty of Law Universitas Muhammadiyah Yogyakarta

Name : Miftahurrahmah

Student Number : 20120610021

Faculty : Law

Major : International Program for Law and Sharia

Field of Study : Administrative Law

FACULTY OF LAW

MOTTO PAGE

Indeed, Allah will not change the condition of a people until they change what is in themselves.

(Q.S Ar-Ra’d: 13)

JUST ALLAH IS MY POWER

(Laa haula wa laa quwwata illa billahil aliyyil adzim)

Fighting has been enjoined upon you while it is hateful to you. But perhaps you hate a thing and it is good for you; and perhaps you love a thing and it is bad for

you. And Allah Knows, while you know not.

DEDICATIONS PAGE

The Undergraduate Thesis dedicates to:

My God, Allah SWT Prophet, Muhammad SAW

My beloved father and mother who have given me lots of trust to keep stepping My beloved brothers

All Lectures of Faculty of Law, UMY My Organizations’ friends

PREFACE

Assalamu’alaikum Wr. Wb.

Alhamdulillah, thanks to Allah SWT who always gives blessing, power and guidance to finish this undergraduate thesis. I say many thanks for my advisors, Mr. Nasrullah, H., S.H., S.Ag., MCL and Mr. Bagus Sarnawa, S.H., M. Hum who guided me through the journey with patient, wisdom and compassion. I also say thank you for the dean of Faculty of Law of UMY Dr. Trisno Rahardjo, S.H., M.Hum., and and all the lectures of Faculty of Law of UMY, especially for Mr. Iwan Satriawan, S.H., M.CL and Mr. Yordan Gunawan who have taught me patiently and best experience in IPOLS.

My special thanks are owed to my family, especially my lovely father Hamsi Hamzah, my mother Rizkiyah, my brothers Fajar Rausyanfikr Ramadhan and Rizha Ichlasul Amal. Thanks for everything all of you gave to me. May Allah bless us together.

and my colleagues in Student Representatives Council of UMY (DPM KM-UMY) 2014-2016.

I am also glad to say thank you for my friends in batch 2012 of IPOLS, namely Diana Setiawati, Sri Masitawati, Muhammad Mukhlis Dian Putra, Itsna Qurrotul ‘Ain, Aprianna Daru Prabowo Wati, Naseha Elkarima, Andika Putra,

Bagus Priyo Prasojo, Rofi Aulia Rahman, Khoirunnisa Aganovilia, Andi Pramawijaya SAR, Muhammad Hazyar Arumbinang, Fachrul Muhammad, Elida Rahajeng, Maidatul Husna, Gaidar Kenny Marcapada, Habib Kesuma Dharma, Zuhdan Fuad Reisnansyah, Yovi Cajapa Endyka, Muirdian, Munandar, Hary Abdul Hakim, Shofia Chairunnisa, Sofhan Gufran, Ilham Azikri Tasril, Wahyu Ridha Rahma Agustiana, Medisita Istiqmalia, Anindra Bagaswara, Sri Yulianti Joisagadji, Raiyan Maulana, Dicky Kurniawan, Moh. Meizuar Ahdiyad MJH, Teguh Abdullah Aldiansyah, Tendy Nurohman, Redhita Vebry Athifah, Wulansuci Putri Yanti Ismail. Few years with you all give me the unforgettable moments. Hopefully we still keep in touch wherever we are!

Finally, for my seniors and juniors also in IPOLS, thank you for everything you all did that have given me a motivation in life. And, For my friends in Faculty of Law, thank you so much guys.

Wassalamu’alaikum Wr. Wb.

TABLE OF CONTENTS

APPROVAL PAGE... i

VALIDATION PAGE... ii

DECLARATION………... iii

MOTTO PAGE... iv

DEDICATIONS PAGE... v

PREFACE... vii

ABSTRACT……… viii

TABLE OF CONTENTS... ix

CHAPTER I: INTRODUCTION A. Background... 1

B. Statement of Problems……...... 4

C. Objectives Research... 4

D. Benefits of Research... 5

CHAPTER II: LITERATURE REVIEW A. The Definition of Work Safety... 6

B. The Causes of Work Accident………..……... 7

C. Principles of Accident Prevention... 9

1. Heinrich Domino Theory………...………... 9

2. The Iceberg Theory……..……..…………...………... 10

D. The Classification of Accidents Based on the International Labor

Organization of 1962... 13

E. Work safety Management... 16

F. Legal Basis of Work Safety... 18

1. Law No. 1 of 1970 about Safety... 18

2. Law No. 13 of 2003 on Labor... 19

3. Guidelines for Safety and Health of Work based on the Decree of the Minister of Mines and Energy No. 555.K/26/M.PE/1995 on Safety and Health of Work of General Mining... 19

4. The Decree of the Minister of Energy and Mineral Resources of the Republic of Indonesia No. 38 of 2014 on Implementation of Safety Management of Mineral and Coal Mining... 21

G. Mining Accident Statistics Based on the Decree of the Ministerof Mines and Energy No. 555.K/26/M.PE/1995 on Safety and Health of Work of General Mining... 22

1. The Definition ofFrequency Rate (FR) and Severity Rate (SR)…… 22

2. The Calculation of Frequency Rate (FR) and Severity Rate (SR)….. 23

H. The Role of Government in Supervising the Implementation of the Provisions on Work Safety for Laborer in Mine Areas of Kutai Kartanegara………...……….……... 24

A. Type of Research………..……….. 28

B. Research Location………...………….. 29

C. Data Collection………...………..……….……….. 29

D. Data Analysis……….………..………..…….. 33

CHAPTER IV: RESULT AND ANALYSIS A. The Role of Local Government in Supervising the Implementation of the Provisions on Work Safety for Laborer in the Mine Areas of Kutai Kartanegara…...……… 34

1. Supervision Conducted by the Government………....…...…….. 34

2. Analysis of Accident Statistics………..………..……...……. 40

3. The Percentage of Accident Causes………...…...………….. 47

4. The Role of Local Government in Supervising the Implementation of the Provisions on Work Safety for Laborer in Mine Areas of Kutai Kartanegara………..………... 48

B. Obstacles Faced by Local Government in Supervising the Implementation of the Provisions on Work Safety for Laborer in Mine Areas of Kutai Kartanegara... 52

1. Lackof awareness of the company and laborers in applying the provisions of work safety……...…………...………... 52

2. Lack of human resources and completeness of local government in supervising the company... 63

CHAPTER V: CONCLUSION AND RECOMMENDATION

A. Conclusion…..………...……….. 67 B. Recommendation……...……….. 68

APPROVAL PAGE

This Undergraduate thesis has been approved by the Advisors

THE ROLE OF LOCAL GOVERMENT IN SUPERVISING THE

IMPLEMENTATION OF THE PROVISIONS ON WORK SAFETY FOR

LABORERS IN THE MINE AREAS OF KUTAI KARTANEGARA

Proposed by:

VALIDATION PAGE

UNDERGRADUATE THESIS

It has been defended in front of the board of examiners

THE ROLE OF LOCAL GOVERNMENT IN SUPERVISING THE

IMPLEMENTATION OF THE PROVISIONS ON WORK SAFETY FOR

LABORERS IN THE MINE AREAS OF KUTAI KARTANEGARA

On November 10th, 2016

Chairman

Iwan Satriawan, S.H., MCL., Ph. D NIK. 1970706199904 153 039

Examiner I Examiner II

Nasrullah, H., S.H., S.Ag., MCL. Yordan Gunawan, S.H., MBA

NIK. 19700617200004 153 045 NIK. 19820203200904 153 054

Validation Dean of Faculty of Law

Universitas Muhammadiyah Yogyakarta

ABSTRACT

The case of work safety always becomes a problem in mining activity, because the accident increases every year with less supervision by the local government. The type of the research is normative and empirical legal research. The objectives of the research are to examine the supervision of the implementation of the provisions on work safety for laborers in the mine areas in Kutai Kartanegara, to collect information on the obstacles faced by the local government in supervising companies regarding the implementation of the provisions on work safety for laborers in the mine areas in Kutai Kartanegara and to propose suggestions on the better implementation of the provisions on work safety for laborers in the mine areas in Kutai Kartanegara.

The result of the research answers the research questions which show that the role of local government in supervising the implementation of provisions on work safety for laborer in mine areas of Kutai Kartanegara is not significant. Thus, the research also gives the suggestion that Local Government should undertake more intensive supervision to the company and evaluate the care of the company in completing and improving the quality of APD for laborers in accordance with the fieldwork, more assertive in giving sanction to the company and laborers who do not obey the rules and increase the recruitment of expert and K3 officers to conduct routine check the completeness of the tools and transportation, considering there are many mining companies in Kutai Kartanegara.

CHAPTER I

INTRODUCTION

A. Background

A workplace accident in the coal mine area over the concession of PT Surya Teknik Anugerah (STA) occurred on Sunday (21/6/2015) at about 11:30 in Indonesia Central Time (WITA). The victim was Juliansyah (41), a bulldozer operator of the mine site and the accident caused him to die on the spot after a dump truck befell his body.1

It did not occur accidently, rather than due to the weakness in the side of either the laborer or the employer or both. The impact can bring a trauma for both parties. For laborers, injuries can affect their selves, families, and quality of life while the employer will suffer from production losses, wasted time for investigation, and, at worst, charges for legal proceedings.2

There is always a risk of failure in each process/work activity. In addition, when a work accident happens, no matter how small it is, it will cause losses. Therefore, as much as possible and as early as possible, accidents/potential workplace accidents must be prevented/removed, or at least mitigated. With reference to the work safety issue in a company, it should be taken seriously by all components of the business actors, and it

1Berita Borneo, 22 Juni 2015 “InsidenTerjadi di Tambang STA, 1 Tewas”,

http://beritaborneo.co.id/insiden-terjadi-di-tambang-sta-1-tewas/Accesed 5 October 2015 at 7.13 p.m in Indonesia Central Time (WITA)

2

cannot be done partially and treated as marginal discussions within the company.3

Work safety is an important aspect that must be considered in every activity of a company. One attempt to reach a safe condition is to avoid or reduce the occurrence of accidents. For that reason, a professional, efficient, effective, and fast investigation is necessary in the future. The root causes of any accident that happens should be sought.4

Laborers are a company’s important asset. Therefore, they must be

given protection in the case of K3 (which stands for Kesehatan dan

Keselamatan Kerja or “Health and Safety of Work”) because there are a

threat and potential hazards associated with the work. Considering the issue, the government has made a policy for the protection of laborers against the K3 aspects through the K3 legislation. The legislation governing K3 is needed to provide elucidation to all laborers and employers in order that they can understand the rules, especially regarding their rights and obligations.

The Law No. 1 of 1970 on Work Safety provides protection for the safety of workers, protection for other people who are entering the work area, and protection for production resources in order to be used safely, effectively, and efficiently. The scope of the Law on Work Safety covers workplaces on

3

I Gede Widayana and I Gede Wiratmaja, 2014, Kesehatan dan Keselamatan Kerja, Yogyakarta, Graha Ilmu, p. 123

4

land, soil and water surfaces. Moreover, in water and in the air there are elements of the business performed, labor, and hazards.5

Work safety can apply properly when the government and the company work together. The government, in this case, is represented by the Department of Manpower and Transmigration at the regional level, which conduct supervision to all companies in terms of the implementation of the provisions in mining areas of Kutai Kartanegara. The supervision undertaken by the Department of Manpower and Transmigration is handled by the Division of the Supervision Section. Their job is to collect data, make an evaluation every year, and give warning to any company which violates the provisions.

The case of work safety always becomes a problem in mining activity, because the accident increases every year without any supervision by the local government. By looking the problem, the writer takes the title “The Role of the Local Government in Supervising the Implementation of the Provisions on Works Safety for Laborers in the Mine Areas of Kutai

Kartanegara”. The title is derived from the result of observation of the writer

regarding the continuous accidents that happen in coalmine areas of Kutai Kartanegara.

5 Ibid

B. Statement of the Problems

Accidents in the workplace have often been discussed, therefore the writer thinks that safety is very important to be discussed and in this research, the writer takes some subject matters, namely:

1. How is the role of the local government in supervising the implementation of the provisions on work safety for laborers in the mine areas of Kutai Kartanegara?

2. Are there any obstacles faced by the local government in supervising the implementation of the provisions on the work safety in the mine areas of Kutai Kartanegara?

C. Objectives of the Research

The objectives of the research are:

1. To examine the supervision of the implementation of the provisions on work safety for laborers in the mine areas in Kutai Kartanegara;

2. To collect information on the obstacles faced by the local government in supervising companiesregarding the implementation of the provisions on work safety for laborers in the mine areas in Kutai Kartanegara;

D. Benefits of the Research

The benefits of this research are presented as follows:

1. The implementation of safety management in accordance with the procedures and rules that have been established in order to minimize the number of mining work accidents.

CHAPTER II

LITERATURE REVIEW

A. The Definition of Work Safety

Work safety is the primary means for the prevention of accidents, disabilities and deaths because of work accidents. Good protection of work safety is the gateway for the security of workers. Accidents besides being a direct obstacle can also indirectly damage the machinery, and work equipment. They may also lead to the cessation of the production process for some time, which eventually damages the workplace environment and others. Generally, work safety can be considered as a science, and its application is related to the work equipment, appliances, labor instruments, materials and processing, work conditions and the work environment, and how to perform the work to ensure the safety of workers and the company’s assets in order to

avoid accidents and other losses.1 addition, the problem of work safety in a company should be taken seriously

1

by all components of the business actors and thus cannot be done partially or treated as a marginal subject.

Work safety concerns all production and distribution processes, both goods and services. Work safety concerns the subject or the person doing the work, working tools used to complete the work, both machinery and other equipment, as well as the environment, people and objects. Therefore, it can be said that work safety is from, by, and for every laborer and society in general.

Work safety also includes the provisions of Personal Protective Equipment (APD), engine maintenance, determination of normal work hours, control of losses due to accidents, abilitiesas well aselimination of unacceptable risks.2

Development of industries in Indonesia is getting ahead. However, it is not supported by the awareness to understand and implement work safety in a proper way in order to prevent accidents that often occur in the workplace.3

B. The Causes of Work Accidents

A work accident is an unexpected event. Why is it unexpected? It is because there is no intention in such an event, or to be more specific, it is not

2

I Gede Widayana and I Gede Wiratmaja, Op.Cit., p. 6

3

planned deliberately. Also, the accident is commonly followed by material damage and suffering from the lightest to the heaviest ones.4

Generally, the causes of an accident in the workplace are: 1. Fatigue;

2. Environmental aspects and unsafe working conditions;

3. Lack of control over the job of workers, the pre-cause is the lack of training;

4. Characteristics of the work itself.5

According to Suma’mur, 80-85% of accidents are caused by negligence (unsafe human acts) and human errors. Accidents and human errors include age, gender, work experience and education. Errors will increase when workers are under stress due to the workload which is not normal or when the working capacity decreases due to exhaustion.6

The sources of accident causes can be divided into 2 (two) groups, namely:

a. Immediate Causes

This group consists of two factors, namely:

1) Unsafe Acts such as the use of a safety device that is not appropriate or is not working; attitudes and ways of working that are not appropriate; the use of unsafe equipment; and dangerous movements. 2) Unsafe Conditions such as the unavailability of safety equipment or

ineffective safety equipment, a dirty and messy workplace, improper

work clothes as well as physical and chemical factors in the work environment which do not qualify.

b. Contributing Causes

1) Safety Management Systems such as unclear instructions, violations of the rules, the absence of safety planning, absence of work safety socialization, unidentified danger factors, unavailability of safety devices and others.

2) Workers’ Mental Conditions such as poor awareness of work safety, the absence of coordination, bad attitudes, slow work pace, lack of attention to safety, unstable emotion, anger and others.

3) Workers’ Physical Conditions such as frequent seizures, ineligible health conditions, deafness, eye myopia and others.7

C. Principles of Accident Prevention

1. Heinrich’s Domino Theory

Heinrich, an expert in risk assessment from an insurance company in 1993, hasobserved and studied accident data. The conclusion of his observation is the particular sequence of the accident. If someone is injured then it is usually caused by an accident. Two things cause this accident, namely mechanical hazard or energy resource uncontrolled and unsafe acts. Both of these things happen because of errors, which

7 Ibid

according to Heinrich are caused by either environmental factors or heredity.8

Dominoes in Figure.1 illustrate the sequence of the cause (an incident or a situation) that initiates an accident causing injuries or damage. If one of the dominoes fall down, it will hit another domino closest to it and causes it to also fall down. It continues until all the dominoes fall down one after the other, indicating the occurrence of an accident. If one of the dominos (causes) is omitted, for example, we do a measurement of work safety properly, and then there will be no accidents.9

Figure 1

Heinrich’s Domino Theory

Source: Kesehatan dan Keselamatan Kerja 2008

8 Sajidi Hadiopoetro, Op. Cit., p. 31 9

2. The Iceberg Theory

The theory is proposed by Birds and is known as the Iceberg theory. In the workplace, there are always hazards. Hazards are defined as anything potential to cause injury to persons or property damage. Hazards can come from the environment or human behavior. Hazards follow the work pattern, determined by the characteristics of the workplace. Therefore, it can be said that for a certain number of hazards, there will be fatal and serious accidents or only material damage in a certain ratio. The National Safety Council obtain a comparison for every fatality, namely there were 29 cases of Minor Injury, 300 cases of Near Misses Injuries and 3000 Hazards.

Figure 2

The Iceberg Theory

A near miss needs attention because, if it is repeated, there will be a possibility of more serious even fatal consequences. Bricks falling from a height of several tens of centimeters above a worker may only make the workers concerned shocked and stop working for a moment. However, the same event, if repeated, may injure other workers and result in a serious injury. “Today’s laceration may be tomorrow’s amputation”.

Nearly infernal must get the same attention as an accident.10

3. Accident Prevention Efforts

Same as the incidence of accidents, accident prevention is an attempt to eliminate one or more of the causes of an accident. There are lots of ways to avoid, prevent or reduce accidents that occur. These methods are as follows:

a. Application of regulations, i.e. the provisions that must be met in various ways such as: general business conditions, design, construction, maintenance, supervision, testing, equipment operation, obligations and rights of employers/workers, supervision/health screening and training.

b. Standard implementation, which consists of the official, semi-official and unsemi-official standard. As an example: the semi-official standards on safe constructions of a piece of equipment, the

10

official standard on personal security devices, the standards do not formally appeal a safe and healthy habit.

c. Supervising, enforcing existing rules, warning or punishing any non-compliance.

d. Technical research, for example, researching machine guards, trying out various methods, preventing fire and explosion and testing masks for respiratory aids.

e. Medical research, for example, the physiological and pathological impact of studies on work environment factors.

f. Psychological research, for example, an investigation of behavior that can cause accidents.

g. Statistical research, such as research on the types of accidents in an industry.

h. Education, for example, making the work safety aspects one of the subject matters taught in schools/colleges.

i. Training, for example, provides work safety instructions to workers who have entered.

j. Persuasion, for example using print media to encourage the awareness of work safety.

k. Insurance, for example, providing a special budget for transfer the risk of accidents.

l. Each worker undertook security measures individually.11

11 Ibid,

D. The Classification of Accidents Based on the International Labor

Organization of 1962

The International Labor Organization of 1962 divides the classification of accidents into 4 (four) groups, namely:

1. The Classification of Accidents by the Types a. Fall

b. Struck down by falling objects

c. Crushed by objects, except falling objects 2. The Classification of Accidents by the Causes

a. Machines

1) Coalmine machines

2) Other machines excluded in the classification b. Conveyances

1) Conveyances 2) Other conveyances c. Equipment

1) Work equipment 2) Stairs

3) Other equipment excluded in the classification d. Materials

1) Dust

2) Hovering objects

e. Work Environment 1) Outside a building 2) Inside a building 3) Inside particular land

f. Other causes excluded in the classification 1) Animals

2) Other causes

3. The Classification of Accidents by the Nature of Injuries or Abnormalities

a. Fracture

b. Dislocation/sprain

c. Stretch the muscle/tendon d. Bruises and other injuries e. Amputation

f. Surface wounds

g. Concussion and broken h. Due to weather

i. Injured are numerous and different in nature

4. The Classification of Accidents by the Location of the Abnormalities or Injuries in the Body

d. Upper body e. Bottom body f. Many places

E. Work Safety Management

Work safety management is a part of the overall management processes and has an important role in the achievement of a company’s goals through loss of the company’s control. The application of work safety in a company

aims to prevent, reduce and mitigate any accident that can cause unexpected losses. An accident may occur due to a number of causes, which among other things is due to humans and equipment. The possible causes of an accident have to be prevented in order that such an accident does not occur since any work can be done safely.

The successful implementation of work safety in a mining industry relies heavily on the management's view on the work safety itself. Safety management is very important to consider, namely:

1. To rescue the laborers from suffering of pain or disability, work loss and loss of financial income.

2. To save the family from the sadness or distress, loss of financial income and the uncertain future.

The basic framework of safety management can be structured as follows:

a. The main function of management, which includes planning, organizing, implementing, controlling and decision-making related to work safety issues.

b. The main activities include financial management and reporting, operations, marketing and sales of products as well as communications and information systems. These activities are the goals and objectives to be achieved by the company.

c. The resources and limitation that include humans, materialism and equipment, consumers demand, economic conditions of the community and the workplace and government regulation can be a part of management activities and management functions.

Based on the basic framework of the safety management, the safety management goal is to prevent accidents or losses of the company, the realization of any management functions in activities is limited by the source or input. The 10 (ten) key for supervision of safety works are:

1) The determination of the administration of the work. 2) Improving the working methods.

3) Correct work placement

4) Guidance and supervision in performing their duties. 5) Improving safety.

7) Safety Inspection.

8) Resolution when problems are found and at the time of the accident.

9) Increasing safety awareness. 10) Creativity to prevent accidents.

The main target of any company is to reduce the costs to bear resulted from work accidents. Why every company should collate a framework as actions to prevent accidents. The action framework should include:

a) Supervision of working habits.

b) Adjustment of the current speed of production with optimum laborers’ abilities.

c) Improving the appropriate mechanisms.

d) Adjustment of volume production with the time of optimum process.

e) Establishment of Work Safety committee under a professional Safety Manager.

F. Legal Basis of Work Safety

1. Law No. 1 of 1970 on Work Safety

prevented as determined, so it does not occur in the workplace, as well as increased K3 to taking precedence over prevention.12

2. Law No. 13 of 2003 on Labor

Law No. 13 of 2003 on Labor contains an article on work safety, which is stated in Article 86 point 1 “Every worker/laborer has the right to the protection of safety& health of work”.13

3. Guidelines for Safety and Health of Work based on the Decree of the Minister of Mines and Energy No. 555.K/26/M.PE/1995 on Safety and Health of Work of General Mining

Some of the Articles regulating works safety are such as;

a. Article 24 of the Decree of the Minister of Mines and Energy No. 555.K/26/M.PE/1995 on Safety and Health of Work of General Mining, the task of Work Safety and Health has the following responsibilities:

1) Collecting the data and record the details from every accident or dangerous occurrences, events before the accident, analyzing accidents and accident prevention.

2) Collecting the data on the areas and activities requiring closer scrutiny, with a view of giving advice to the Head of Mining Engineering about mining or working procedures, tools,

12 Ibid,

p. 22

13

mining and the use of detection tools and instruments of personal protection.

3) Providing information and instructions regarding Work Safety and Health for all mining workers to hold meetings, lectures, discussions, film screenings, publications and so forth.

4) If necessary, establishing and training the members of the mining rescue team.

5) Compiling accident statistics. 6) Evaluating Work Safety and Health.

b. Article 32 of the Decree of the Minister of Mines and Energy No. 555.K/26/M.PE/1995 on Safety and Health of Work of General Mining, the obligations for miners are;

1) The mineworkers must comply with Work Safety and Health regulation.

2) The mineworkers are required to conduct work in accordance with the procedures for safe working.

3) The mining workers during work shall:

a) Pay attention or keep the safety of themselves and others who may be affected by their actions.

4) The mineworkers who see or hear any irregularities execution of the work required to immediately report to the supervisor on duty.

5) The mineworkers are compulsory to use and care personal protection equipment in their duties.

6) Provide correct information when questioned by the executor of Mine Inspection or the Head of Technical Mining.

7) The mineworkers are entitled to declare the work objection to his superiors when the Work Safety and Health requirements are not fulfilled.14

4. The Decree of the Minister of Energy and Mineral Resources of the Republic of Indonesia No. 38 of 2014 on Implementation of Safety Management of Mineral and Coal Mining

Article 1 point 2 mentioned "Mining Safeties are all activities that include health and safety management of mining and mining operational safety" and is continued in point 3, stating “Work Safety and Health of

mining, hereinafter called mining of K3, are all activities to ensure and protect the miners to survive and stay healthy through the efforts of the

14

management of work safety, work health, work environment, and safety management systems and work health”.15

G. Mining Accident Statistics Based on the Decree of the Ministerof Mines

and Energy No. 555.K/26/M.PE/1995 on Safety and Health of Work of

General Mining

Based on Article 47 of the Decree of the Minister of Mines and Energy No. 555.K/26/M.PE/1995 on Safety and Health of Work of General Mining, mine accident statistic is set every year based on the frequency and severity of accidents that occurred in miners.

Work accident statistic is the statistic caused by or suffered during the work, which results in death. Meanwhile, industrial accident statistics may also include labor accidents during the journey or inside of the company. 1. The Definition of Frequency Rate (FR) and Severity Rate (SR)

Frequency Rate calculation is useful for any organization because it measures the amount of injury caused by an accident at work compared to total employment. The value is very flexible and can be used to measure various types of accidents in large populations. The Severity Rate is a calculation to determine the severity of an accident. Severity Rate measures the number of days lost due to injury. However, this calculation cannot reveal the severity of chronic injury, such as hearing

15

loss and causes the significant laborers absenteeism due to new symptoms rise for a long time.

The unit calculation for statistic is an accident that happens in company. So, for one laborer suffering from two or more accidents is counted in the number of accidents. Special statistics may also be collected regarding certain types of accidents. Statistics about the same things for different years is very useful for assessing whether such accidents increases and decreases, and how effective or absence of prevention efforts. Accident statistics should be compiled on the basis of the same definition of the accidents in the industry, for the prevention goals in general and as a measure of the risks of accidents in particular. All of the accidents should be reported and tabulated simultaneously, namely:

a. Figures of frequency and severity of accidents should be collected based on equivalent ways. The restrictions should be queried about the accident, equivalent ways to measure time at risks, and ways to express the amount of the risks.

b. Industrial classification and work accidents for statistical purposes should always be equal.

2. The Calculation of Frequency Rate (FR) and Severity Rate (SR)

Based on Article 47 of the Decree of the Minister of Mines and Energy No. 555.K/26/M.PE/1995 on Safety and Health of Work of General Mining, mine accident statistic, they are:

a. Mining accident statistics are set every year based on the frequency and severity of accidents that occurred in miners, calculated from: 1) FR is the number of victims of accidents divided by the

number of working hours x 1,000,000

2) SR is the number of days lost divided by the number of working hours x 1,000,000

b. Accident statistics referred to paragraph 1 must be submitted to the Head of Mining Engineering to the Chief Executive Mining Inspection no later than 1 (one) month after the end of each calendar year.

H. The Role of Government in Supervising the Implementation of the

Provisions on Work Safety for Laborer in Mine Areas of Kutai

Kartanegara

The Office of Manpower and Transmigration of Kutai Kartanegara is the government agency that has an important role in the effort to ensure work safety. In the Regional Regulation of Kutai Kartanegara No. 13 of 2008 on the Organization and Work Procedure of Local Department, Chapter IV on Main Tasks, Functions and Organization, in section five on the Office of Manpower and Transmigration mentioned the main tasks and functions of government agency, namely:

1. Article 16, "the Office of Manpower and Transmigration has the tasks of decentralized authority and deconcentration tasks in the field of manpower and transmigration".

2. Article 17 "In carrying out the tasks referred to in Article 16, the Office of Manpower and Transmigration performs the following functions: 1. Formulating technical policy areas of manpower and

transmigration in accordance with the strategic plan established by the Local Government;

2. Planning, coaching and controlling the technical policy in the field of manpower and transmigration;

4. Formulation, planning, coaching and controlling the technical policy of labor inspection;

5. Formulation, planning, coaching and controlling the technical policy, the development of industrial relations and social security; 6. Formulation, planning, coaching and controlling the technical

policy of transmigration;

7. Implementation of the secretariat affairs;

8. Implementation of Technical Implementation Unit; 9. Coaching the Functional Group.16

In addition to preparing and monitoring the implementation of existing regulations, this institution plays a role in disseminating the legislation that already exists. In the regulation, it is also mentioned that the Office of Manpower and Transmigration has the function to provide guidance and supervision to the company in order to create work safety.

I. The Role of Company in Implementing the Provisions on Work Safety

for Laborer in Mine Areas of Kutai Kartanegara

In accordance with the Guidelines for Safety and Health of Work based on the Decree of the Minister of Mines and Energy No. 555.K/26/M.PE/1995 on Safety and Health of Work of General Mining, contained in article 4 point 3, 4 and 5, the obligations of mining employer are:

16

1. Employers must prepare all tools, equipment, personal protective equipment, facilities and costs required for the implementation of this regulation.

2. Employers have to provide free personal protective equipment that is required according to the type, nature and danger of the work he does and for everyone entering the mining business.

3. Based on consideration of the Chief Executive of Mining Inspection, employers have to provide worthy accommodation or close to mining operations for executing Mining Inspection in order to carry out their duties.17

Not only to provide a means of equipment, protective devices and others, but the company in this regard should also conduct safety training for the workforce. Work Safety training at the company is very important for both the new and existing workers. The purpose of safety training for new workers is extremely important to understand the missions of the company's objectives and roles in securing, and eventually increasing the production. Therefore, it has to recognize the potential hazards that can cause accidents, and should know how to control. Meanwhile, for workers, the safety training is intended for refreshment of the safety training. It is important because with increasing experience and flying hours, they often assume that workers have a

17

way of working that is more practical and more comfortable by cutting procedures (short-cut) if the methods are in high risk.18

18

CHAPTER III

RESEARCH METHODS

A. Type of Research

The research is included as normative and empirical legal researches. A normative legal research (normative law research) is a research that evaluates the applicable norms including the Constitution that have relevance to the issue as a source of law.1 The normative legal research focuses on the inventory of positive law, principles and legal doctrines, systematic law, the level of synchronization, comparative law and legal history.2

The empirical research is another term used in a socio-legal research, and can be called as a field research. The socio-legal research starts from the primary data. The socio-legal research can be socialized to the research on the effectiveness of legal or regulation in force, or a study of legal identification.3

Research on the legal effectiveness is a study that discusses on how the law operates in the community. The study is very relevant in developing countries, such as Indonesia. The research requires researchers to know jurisprudence, social science, and social science research. Factors that may affect the law functioning in society are (1) the rule of law/regulation itself;

1

Soerjono and Sri Mamudji, 2001, Penelitian Hukum Normatif: Suatu Tinjauan Singkat, Jakarta, PT. Raja Grafindo Persada, p. 14

2

Abdulkadir Muhammad, 2004, Hukum dan Penelitian Hukum, 1st edition, Bandung, PT. Citra Aditya Bakti, p. 52

3

(2) officers/law enforcement; (3) the means or facilities used by law enforcement; (4) public awareness.4

Based on the discussions above, the researcher decided to use empirical and normative legal research methods for conducting research and writing this paper as discussions of legal research methods. The use of empirical and normative research methods is an effort of the research and writing of this theory, backed with conformity of the required research methods by the writer.

B. Research Location

The locations of this research are mining companies in the area of Kutai Kartanegara, East Kalimantan. The reason why Kutai Kartanagera becomes the research location is because Kutai Kartanegara has more than thousands of coal mining companies and has a record of accidents considerably large, from year to year.

C. Data Collections

The data collected from the sources which are classified into two data sources, they are:

a. Primary data are data which are obtained from the result of research, which were conducted in the field by sampling and interviewing. The samples in this research are mining coal companies in Kutai

4

Kartanegara. There are 18 Sub-Districts in Kutai Kartanegara which became the sampling in the research, such as;

1. Samboja; writer conducted the interview process to the interviewees directly as

5

a source of information in order to know the response, opinion and actions from interviewees related to the supervision of the implementation of the provisions on work safety for laborer in Kutai Kartanegara. The interviewees in the research are:

1. H. DodiIskandar, S.H as the Head of Development of Labor Inspection;

2. Surianto, S.sos., SH as the Head of Supervision Section of K3; 3. Muhammad Syofyanuddin, S.T., M.T as the Head of Training

and Improvement of Labor Productivity.

b. Secondary data are the data which are obtained through the literature review on related reading materials. The secondary data are classified into three legal materials, such as:

of legislation. The court decision actually is a law in action. 6Primary legal materials or the relevant laws and regulations that have been used in this research were such as: a. Law No. 1 of 1970 on Work Safety;

b. Law No. 7 of 1981 on Labor Compulsory Reporting of Company;

c. Law No. 13 of 2003 on Labor;

d. The Decree of the Minister of Mines and Energy No. 555.K/26/M.PE/1995 on Safety and Health of Work of General Mining;

e. The Decree of the Minister of Energy and Mineral Resources of the Republic of Indonesia No. 38 of 2014 on Implementation of Safety Management of Mineral and Coal Mining;

f. Government Regulation No. 50 of 2012 on Application Management System Safety and Health of Work;

g. Regional Regulation of Kutai Kartanegara No. 13 of 2008 on the Organization and Work Procedure of Local Department;

h. Regional Regulation of Kutai Kartanegara No. 18 of 2013 on Labor Organization.

2. Secondary Legal Materials consist of the books or literatures, scientific journals, papers, and articles relating to the issue of this research.

3. Tertiary Legal Materials are the materials that support the primary and secondary materials such as Law Dictionary, English Dictionary, and Indonesian Dictionary.

A. Data Analysis

An analysis of various quantitative data was done in order to obtain temporary conclusions, which can further be used for further analysis in making suggestions. The quantitative research is research that uses the sample population in the data collection. The researcher generally chooses a small part of the whole objects of the study and a technique called sampling. Sampling technique is a procedure used by the researcher to gather the characteristics from a population, although only a few places or a partial sample taken or interviewed.7

7

CHAPTER IV

RESULTS AND ANALYSIS

Coal mining operations need control, supervision, work experience and good education levels of workers for preventing the dangers that are resulted from the mining process. The prevention of accidents in relation to work safety issues should be based and started at the concept of causes and effects of accidents, which controls the causes and reduces the impact of accidents. The direct causes of accidents are resulted from unsafe actions and unsafe conditions, thereby causing the cessation of human and the tools’ activities.

A. The Role of Local Government in Supervising the Implementation of the

Provisions on Work Safety for Laborer in the Mine Areas of Kutai

Kartanegara

1. Supervision Conducted by the Government

used by every company in mining area of Kutai Kartanegara that can be seen in Table 1 and Table 2 below.

Table. 1

The Number of Coal Mining Companies in KutaiKartanegara

No Name of Subdistricts Total

1 Samboja 73

2 Muara Jawa 108

3 Sanga-Sanga 101

4 Loa Janan 119

5 Loa Kulu Kota 76

6 Kota Bangun 33

7 Tenggarong 203

8 Sebulu 69

9 Tenggarong Seberang 138

10 Anggana 44

11 Muara Badak 240

12 Marang Kayu 31

13 Muara Kaman 38

14 Kembang Janggut 34

15 Tabang 36

17 Muara Muntai 3

18 Muara Wis -

Total 1347

Source: Sub Bidang Pengawasan Ketenagakerjaan Disnakertrans Kab. Kukar Table. 2

Tools and Materials Provided by the Companies

Source: Sub Bidang Pengawasan Ketenagakerjaan Disnakertrans Kab. Kukar

No Tools and Materials Total

1 Steam engines 65

2 Lift-haul aircrafts 791

3 Heavy equipment 217

4 Diesel motor/ generators 307 5 Electrical installation 63

6 PMK 40

7 Distributors lightning 176

8 Elevators 17

9 Pressure vessels 121

10 Hazardous materials 5

11 Turbines 9

12 Bottle Steel 5

13 Scaffolding 58

14 Radioactive materials 27

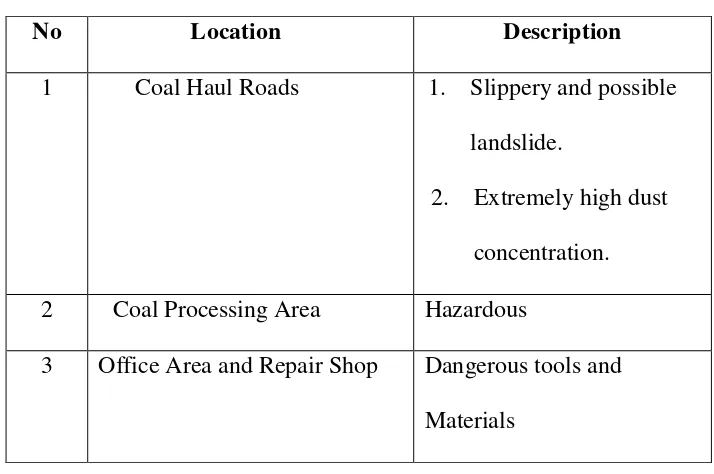

According to observation result by the Head of Supervision Section of K3, The Office of Manpower and Transmigration, Surianto, S.sos., S.H, the mining haul roads are the most vulnerable areas to work accidents. The vulnerability is shown in Table. 3 below:

Table. 3

Vulnerable Areas

No Location Description

1 Coal Haul Roads 1. Slippery and possible landslide.

2. Extremely high dust concentration.

2 Coal Processing Area Hazardous

3 Office Area and Repair Shop Dangerous tools and Materials

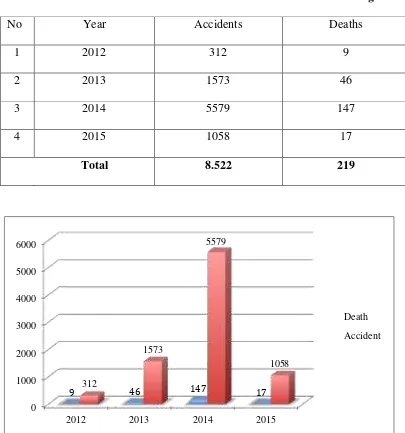

Table. 4

Cases that Occurred in 2012-2015 at Coalmine Areas of Kutai Kartanegara

No Year Accidents Deaths overcoming the laborer accidents during work in the field, because safety facilities are playing important role in work safety. The Office of Manpower and Transmigration of Kutai Kartanegara Regency, in this case is the Supervision Section of Labor Inspection conducts routine check to the safety facilities owned

by coalmining companies in Kutai Kartanegara. The facilities provided by company are shown in Table. 5 below.

Table. 5

Safety Facilities Provided by Companies in Mining Areas to Overcome

Accidents

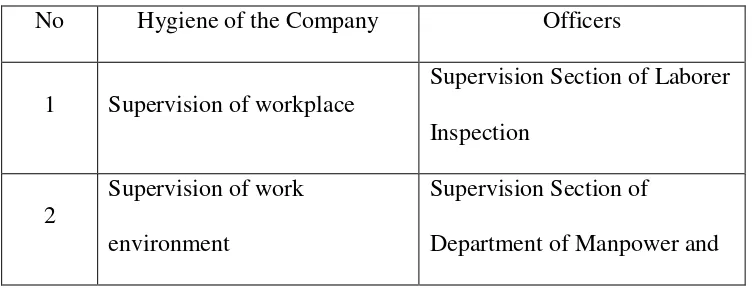

The government also handled the hygiene of the company to overcome the accident. The hygiene of the company is a part of solution to decrease the accidents happened in coalmining areas of Kutai Kartanagera. Some of the company’s hygiene handled by the government is shown in Table 6 below.

Transmigration

3 Supervision of Hazard Supervision Section of K3

4

Examination of work equipment

Expert Officer of K3

2. Analysis of Accident Statistics

According to the Decree of the Minister of Mines and Energy No. 555.K/26/M.PE/1995 Article 47 on the statistics of mining accident, the mining accident statistics are set each year based on the level of frequency and severity of accidents that occurred in mine areas.

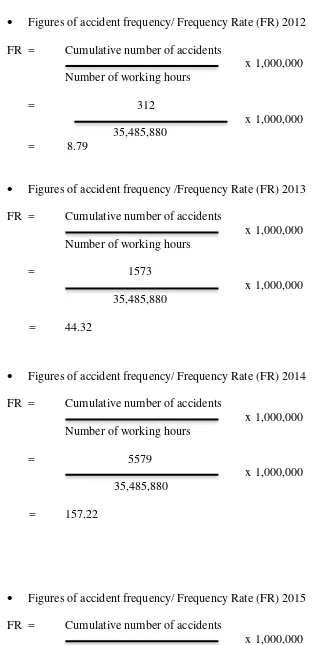

To know the Frequency Rate Accident and Severity Rate Accident, firstly we have to determine the number of working hours per year using the formulation as follow:

Number of working hours a day: 8 hours Number of working days a year: 335 days Number of workers: 133,241

Number of working hours per year from 2012-2015 = 8 hours/day x 335 days x 133.241= 35,485,880 hours.

2.1 Frequency Rate (FR) of Accidents

Figures of accident frequency/ Frequency Rate (FR) 2012

Figures of accident frequency /Frequency Rate (FR) 2013 FR = Cumulative number of accidents

Figures of accident frequency/ Frequency Rate (FR) 2014 FR = Cumulative number of accidents

Figures of accident frequency/ Frequency Rate (FR) 2015 FR = Cumulative number of accidents

Number of working hours = 1058

x 1,000,000

35,485,880 = 29.81

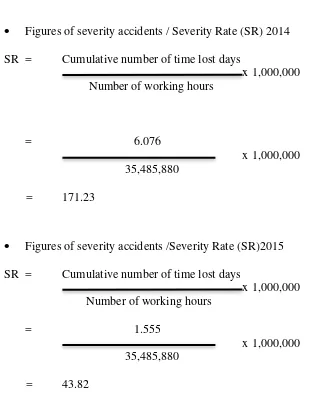

2.2 Severity Rate (SR) of Accidents

Severity Rate (SR) indicates that the company in 1,000,000 hours of productive time lost day at the value of SR.

Figures of severity accident / Severity Rate (SR) 2012 SR = Cumulative number of time lost days

x 1,000,000

Number of working hours

= 809

x 1,000,000

35,485,880 = 22.80

Figures of severity accidents / Severity Rate (SR) 2013 SR = Cumulative number of time lost days

x 1,000,000

Number of working hours

= 2070

x 1,000,000

Figures of severity accidents / Severity Rate (SR) 2014

Figures of severity accidents /Severity Rate (SR)2015 SR = Cumulative number of time lost days objective. These statistics are important to explain to all parties concerned on the circumstances of safety, to give warning to potential dangers, to make them aware, and to give enough attention to the accident rate, and sometimes it is necessary to present statistical data.

Table. 7

The Comparison between the Statistic of Frequency Rate and Severity Rate of Accidents in 2012-2015 increase of the number of accidents, the time loss also increases.

a. In 2012, Frequency Rate obtained was 8.79. The figure shows that in every 1.000.000 working hours, there were 8.79 accidents victims. It is obtained from 312 accidents that occurred in 2012 due to unsafe acts and unsafe condition. The figure of Severity Rate obtained was 22.80 in 2012 because some incidents happened were leading to the loss of working days as many as 33 days. It shows that the figure of Severity Rate Accident in every 1,000,000 working hours, there were 22, 80 days lost.

b. In 2013, Frequency Rate obtained was 44.32. The figure shows that in every 1,000,000 working hours, there are 44.32 accidents victims. It is obtained from 1573 accidents that occurred in 2013 due to unsafe acts and unsafe condition. The figure of Severity Rate was obtained 58.34 in 2013 because some incidents happening led to the loss of working days, as many as 86 days. It shows that the figure of Severity Rate Accident in every 1,000,000 working hours, there were 58.34 days lost.

shows that the figure of Severity Rate Accident in every 1,000,000 working hours, there were 171.23 days lost.

d. In 2015, Frequency Rate obtained was 29.81. The figure shows that in every 1.000.000 working hours, there are 29.81 accidents victims. It is obtained from 1058 accidents that occurred in 2015 due to unsafe acts and unsafe condition. The figure of Severity Rate obtained was 43.82 in 2015 because some incidents happening led to the loss of working days as many as 64 days. It shows that the figure of Severity Rate Accident in every 1,000,000 working hours, there were 43.82 days lost.

The company's main goal is the achievement of production targeted with zero accident. However, from 2012-2015 the accident happened in Kutai Kartanegara increased due to unsafe act and unsafe condition. Accidents due to unsafe act took place because the negligence of the miner itself, the miners mostly did not obey the rules. Some of the miners sometimes forget to use their Personal Protective Equipment (APD). The supervision administered by the Office of Manpower and Transmigration in the field often found out that many miners who did not wear their APD.

and slipping of vehicle due to the slippery road. Data of accident caused by unsafe act and unsafe condition are show in Table. 8 below.

Table. 8

Data of Accident Due to Unsafe Act and Unsafe Condition of 2012-2015 in

Kutai Kartanegara

No Year Unsafe Act Unsafe Condition Total

1 2012 219 93 312

2 2013 1.049 524 1.573

3 2014 4.185 1.394 5.579

4 2015 847 211 1.058

Total 6.300 2.222 8.522

The cause of the accident is mostly due to unsafe actions from the data above. The data showed iteration causes of accidents which occurred in 2012, 2013, 2014 and 2015, thereby, the zero accident is failed to be reached.

3. The Percentage of Accident Causes

2012-2015. Based on the calculation, the accident percentage is shown in Table. 9 below.

Table. 9

The Percentage of Accident Causes in Coalmine Areas of Kutai Kartanegera

No Causes of accident Total Accidents Percentage 1 Unsafe Acts 6.300 73.92%

2 Unsafe Condition 2.222 26.08%

Total 8.522 100%

4. The Role of the Local Government in Supervising the Implementation of

the Provisions on Work Safety for Laborer in Mine Areas of Kutai

Kartanegara

High rates of work accidents show the ineffectiveness of provisions concerning work safety in the coal mining areas of Kutai Kartanegara. To overcome this problem, the local government did intensive monitoring of the implementation of the provisions of safety in the coal mining company in Kutai Kartanegara. There are some roles of the local government which has been run in supervising the implementation of the provisions on work safety in coal mine areas as follow:

a. Socialization of the provisions on work safety

and distribution of guidance books and poster on work safety to the companies and laborers.

b. Training and Improvement of Labor Productivity to the laborers concerning on the implementation of provisions of work safety

The efforts done by the government concerning on the implementation of provisions of work safety are giving training and improvement of labor productivity to the laborers. Article 10 of Local Regulation of Kutai Kartanegara No. 18 of 2013 on Labor Organization mentions that “Work training of the Local Government Institutes are conducted by the Office which have the duties and responsibilities in the field of labor”.

In disseminating the importance of work safety, the Local Government did the training. The Training carried out by the local government is education in the form of courses and training on usage of all work equipment. To prevent the accidents, all laborers need training on work safety in order to eliminate potential dangers in the workplace.

and easy to be understood and should be in the form of written and practical tests, in order to determine whether the trainees can absorb the extent of materials already given.

c. Supervision, based on the Government Regulation No. 50 of 2012 on Application Management System Safety and Health of Work, Article 18 is accomplished to:

1) Ensure the development and implementation of commitments; 2) Organization;

3) Human Resources;

4) The Implementation of Provision of K3; 5) Security work;

6) Inspection, testing and measurement application SMK3; 7) Control emergencies and industrial hazards;

8) Report and repair deficiencies; and 9) Follow-up audit.

d. Sanction to the company which commits violation

According to Local Regulation of Kutai Kartanegara No. 18 of 2013 on Labor Organization, Article 68 mentions the stage of administration sanction, such as:

1) Oral Warning 2) Written warning

3) Cancellation of business activity 4) Suspension of business activity 5) Cancellation of agreement 6) Cancellation of registration

7) Temporary suspension of part or all of production equipment; and/or

8) License revocation

In running the supervision of the implementation of provisions on work safety the local government of Kutai Kartanegara gives the warning to the company, which commits violation in order to reduce the accidents in coalmine areas. The number of companies already warned by the Local Government shown in Table 10 below.

Table. 10

The Number of Companies Receiving Warnings from the Government

No Year Total

1 2012 17

3 2014 70

4 2015 23

In fact, the warnings given by the government still do not have effects to reduce the accidents in coalmine areas, because some of the companies do not pay too much attention regarding this matter.

B. The Obstacles Faced by the Local Government in Supervising the

Implementation of Provisions on Work Safety in Mine Areas of Kutai

Kartanegara

In supervising the implementation of work safety there are always obstacles faced by the local government. The obstacles faced by the local government in supervising the implementation of the provisions on work safety in the mine area of Kutai Kartanegara are as follow:

1. Lack of awareness of the company and laborers in applying the provisions of work safety

laborers have to be reported to the Local Government. The report will make the Local Government easier to do the investigation on the spot. In fact, the companies still conceal the accident and choose to solve the problem secretly without any intervention from the Local Government.

Not only should the companies run reports, but also they obligate to implement the control measure. Based on the Government Regulation No. 50, 2012 on Application Management System Safety and Health of Work, Article 11 stated that the companies should do the control measure. According to the supervision of the Local Government, the area of coalmine is the potential accident area. Therefore, the companies should concern to the potential area of accident. In fact, companies do not really concern on this matter. They think the area is safe from accidents and such a thought frequently causes frequent occurrences of accident, as shown in Table 11 below.

Table. 11

Potential Area of Accident in Coal Mine

No Condition Locations Description

1

opposite directions in the coal mining cannot clearly see one to another.

Source: Sub Bidang Pengawasan Ketenagakerjaan Disnakertrans Kab. Kukar

From Table 11 above it can be seen that caul haul roads are the most dangerous area and companies should give a concern to this area. To overcome this problem, companies can plug the sign to remain all laborers that the area is dangerous. Moreover, in fact, there are not enough traffic signs used by the company in mining areas. Some signs that required plug in the mine areas are:

Figure 3

Vulnerable Landslide Signs

Figure 4

Prioritizing Loaded Truck Signs

Plugs on segments where the coal haul road are required to queue when the two vehicles from the opposite direction will pass. These signs can be installed in segments of dangerous coal haul road.

Figure 5

Mandatory Areas for Ear Plugs and Face Mask

Based on the Guidelines for Safety and Health of Work based on the Decree of the Minister of Mines and Energy No. 555.K/26/M.PE/1995 on Safety and Health of Work of General Mining in article 4 point (3) “the obligation of company is providing all tools,

equipment, personal protective equipment”. Some of APD are:

Figure 6

APD (Personal Protective Equipment)

No Personal Protective Equipment Usage

welding, grinding, or

cutting machinery.

13. Headlamp

These safety devices are usually specifically used in underground mining. Night and day in the tunnel there is no difference, equally dark and headlamp required to be worn.

Table. 12

Action of Laborers, which become trigger of accident

No Action Locations Description

1

2 Smoking near fuel gallons Coal Processing Area

Nearby fuel gallons, people are frequently seen relaxing while smoking.

3 Working while joking with each other

4 Unsafe driving Coal Processing Area

Not heeding the signs of traffic.

The action of laborers in ignoring the circumspection and personal protective equipment (APD) becomes the reasons of accident. Based on the data of the Department of Manpower and Transmigration, there are many reasons why laborers ignore the APD shown in Table 13 below.

Table. 13

The Reasons why Laborers Ignored the Personal Protective Equipment

(APD)

No Personal Protective Equipment (APD)

Reasons to ignore the APD

1 Helmet a. The helmet provided by the company is not

comfortable to wear because it is too short. b. Feeling that a job or

activities are not harmful, especially to the head.

3 Ear plugs Feeling unfamiliar when working with ear plugs

4 Mask Feeling difficult to breathe when using mask

5 Vest Feeling that a work does not require vest usage

6 Gloves Feeling unfamiliar and uncomfortable when working with gloves.

From the table above, it can be known that laborers do not have the awareness of the safety to reduce the accident. Laborers just attach the importance of their convenience and ignore the safety.

2. Lack of human resources and completeness of Local Government in supervising the company

of Development of Labor Inspection, the experts and K3 officers that conduct the supervision only 25 supervisor, and not comparable with the number of companies in Kutai Kartanegara. These 25 supervisors from the Local Government cannot perform supervision completely each year.

Moreover, the area of coalmine also becomes the consideration, the caul haul road is one of the dangerous field in the area of coalmine. The Local government has limitation tools and transportation to reach all areas of company. In addition, the local government still needs more resources which are adequate to do supervision in dangerous areas.

3. Low of Level of Education, Knowledge and Skills of Laborers in Fieldwork of Coalmine

Table. 14

The Education Data of Mining Areas Laborers of Kutai Kartanegara

Source: Sub Bidang Pengawasan Ketenagakerjaan Disnakertrans Kab. Kukar

Table 14 above shows that the education level is still very low. The activities in coalmine are dangerous activities and laborers that have low education do not have the ability to do the job because the activities are relying on physicality. Based on the monitoring of the Local Government of Kutai Kartanegara, many laborers which possess low education do the dangerous job. For example, based on the supervision conducted by the Local Government, it is found that the job of bombing of coalmine was carried out by Laborers which graduate from High School. The activity may affect workplace accidents due to heavy load of physicality and it can result fatigue, which is one of the factors influencing the occurrence of accidents.

No Education Total Laborers

1 SD 7,098

2 SMP 36,147

3 SMA 84,435

4 D3 2,644

5 S1 4,987

Coalmine activities cannot be separated from the physical activities with very high risk. Consequently, these activities need professional or proficient persons. In fact, there are still many laborers that have low education, and do not have skills to do the high risk activities. Companies do not assign the jobs for laborers in accordance with their abilities. The companies, even, put the low education laborers in dangerous of fieldwork.

The local government makes the percentage of laborers in Kutai Kartanegara to know the percentage of laborers with low education as show in Table 15. The table shows the percentage of laborers in mining areas of Kutai Kartanegara still have low education; the majority of laborers in Kutai Kartanegara are elementary school, secondary school and high school graduates. It can be seen in the percentage level of education of the 135.311 laborers.

Table. 15

The Percentage of Education Data of Laborers in Mining Areas