SISTEM MODELING

Materi 1

System 2

SYSTEM

Definition:

•

A system is understood to be a wholecomposed of elements that are related to each other.

•

The cohesion will emerge from the fact that the elements are linked together by their relations.•

Briefly defined, one might say that a system is a collection of elements in their entirety and the relations between them.3

SYSTEM

• Theory: General system theory (L.V Bertalanffy,1956) • Symbolization of the concept system

• –Inner-System Boundary-Outer (Environment) • Open system vs. Closed system

• Content of the system:

• The complete collection of all elements without the interrelations of these elements being taken into consideration

• Structure of the system

• Consists of the pattern of these relations • Subsystem

• A partial collection of the elements of the system

4

5

Sub-System

6

Elements and the Relations between

Elements

• Elements of a system are characterised by certain features –e.g.

• physical,geometrical,aesthetic,social-psychological or economic • If a relationship exists between one or more elements

then if the characteristics of those elements change then the other elements will similarly change

• Relations between the elements are indicated by means of a simple line.

• Relations can be in terms of technical, economic, socio-psychological aspects.

7

System:

Relationship between

Elements

8

System thinking

• Thinking in terms of systems-as opposed to seeing snapshots or discrete events with little or no

interrelationship.

• Peter Senge, in his bestselling book The Fifth Discipline: describes how our mental models, or personal

paradigms, are often developed from our tendency to break down large problems into smaller

manageable parts.

• In doing this, we end up mentally isolating events

9

Why we need Systems Thinking

• Senge views the problem as systemic in nature

and not easily or quickly overcome in organizations. • The core of the problem is that our world is one of

dynamic complexity, the mastery of which cannot be achieved by focusing on details alone

without systems fluency.

• Senge describes a simulation, called The Beer Game. The game clearly demonstrates how experienced decision-makers can fall into a trap of thinking of their actions as isolatedand helps them to better understand their roles within systems.

10

System thinking

•

System thinking: Thinking in terms of systems•

System thinking: A problem methodology approach•

System thinking: Observing is viewed as mental activity –Mental Model11

System:Mental Model

12

Aspects System

• Represents a partial collection of the system relation

• There are various aspects of system –e.g. technical, economic, socio-psychological aspects

• The various aspects have been connected together by means of what are termed interrelations (A multi-aspect system)

• Interrelations are seen as the relations between the different aspect systems distinguishable within the original system

13 Multi-Aspect System: 3 Independent Aspects

14

Integrated System

15

Multi-Disciplinary Approach

• A mono-disciplinist is seen as someone with specialist knowledge in the area of a single – mono-discipline (He will only be able to construe a mono-aspect view)

• With increasing complexity of technical system and increase in the number of relevant aspects – This needs A Multi-Disciplinary Approach

• A Multi-Disciplinary Approach demands

integrative skillsfrom the problem solver or project manager

16

17

Example-2: Multi Disciplinary Approach

For A Multi-Aspect Problem

18

Example-3: An Interdisciplinary

Approach

For A Multi-Aspect Problem

19

Industrial Engineering (IE)

20

21

Typical IE Questions

• Is the system providing the best possible economic return to its owners?

• Are some products not economically viable? Which ones?

• Are resources being utilized appropriately? Where is capacity excessive or inadequate?

• Is the mix of resources appropriate? Are new technologies needed?

• Are the resources organized and managed

properly?

• Are suppliers' prices, terms, delivery, and quality

appropriate?

• Are the products/services meeting customers' needs? How could they be improved?

22

23

SISTEM MODELING

Materi 2 System Thinking

25

System Thinking

• Increased Complexity of Today’s Decision Making • The 20thcentury has been marked by unprecedented

technological progress

• Information Technology has revolutionized commercial activities

• The creation of huge multi-national corporations • The problems of overpopulation and others

• Today’s world has increased in complexity

• The traditional methods of problem solving based on the cause-and effect model cannot cope any longer.

26

Construction of the Aswan Dam

• Intended to increased agriculture production

• It also caused an unprecedented increased in

schistosomiasis (affected 60% fellahin)

• It trap fertile silt, increase use of fertilizers

• Together with poor drainage causes salinization

⇒land unsuitable for agriculture

• Destroyed the sardine fisheries

• Uncontrollable growth of water hyacinthin Lake

Naser⇒lost of water

27

Deterioration of Urban Transport

• Increased car owner after WW II

• ⇒Improve the road network & parking facilities ⇒ Reduce patronage of public transport facilities ⇒ resulted fare hikes & curtailment of service frequency & coverage.

• ⇒accelerated the shift from public to private transport.

28

Assessment of Unit Production

Costs

• Unit production cost is all material, energy, & labor costs then dividing the total by number of parts produce.

• The efficiency assessed on level of unit production cost.

• That rule works fine for simple one stage production process, when no difficulties in selling all its output

• How if we faced with complex product – multi-stage process? The machine center’s looks good, but ends up with excessive intermediate parts stocks that are costly to finance & maintain & run the risk of obsolete

29

Efficiency versus Effectiveness

• The firm may be very efficient in the use of its

resources, but this efficiency is not put to effective use in term of the firm’s overall objectives of goals.

• Technical efficiency, using a given set input to

produce the maximum level of output, or producing a given level of output with the minimum amount of input.

• Economic efficiency, in term of maximizing the

difference between revenues & total cost.

30

• Effectiveness, looks at how well the goals of

activity are achieved.

• Trade-off between variables will affect overall

effectiveness of the system.

• Efficiency is minimizing waste and maximizing

utilization of resource.

• Efficiency is not the enemy of effectiveness.

• Efficiency takes overall goals of organization into

account.

• Effectiveness deals with ‘doing the right thing’.

• Efficiency deals with ‘doing thing right’.

31

Unplanned & Counterintuitive

Outcomes

• Action A will cause the desired outcome B to be

realized.

• But in addition to B, A also causes C, D, and E to

happen

• Some of these outcomes are unintended,

unpredicted, and may negate the outcome B.

• Some of the outcomes may be counterintuitive

32

Reductionist and Cause-And-Effect

Thinking

• The traditional scientific model of thought are

based on two major ideas: Reductionist and Cause-and-Effect Thinking

• Reductionism:Everything can be reduced, decomposed, or disassembled to ultimately simple parts.

• Breaking a problem into a set of simpler subproblems, solving each of these individually and then

assembling their solutions into overall solution for the whole problem.

• But sum of individual solutions does not necessary produce a best solution for the whole system

33

• Cause-and-Effect Thinking

• All phenomena are explainable by using cause-and-effect relationship.

• A is taken to be the cause of B

• Viewing the world in this way, everything can be explained by decomposing it into parts and looking for cause-and-effect relationship between the parts. • But it may be inadequate to examine the causal

relationship one by one.

• New properties may emerge through the interaction between the parts (emergent properties).

34

Systems Thinking

•

With the systems thinking, something to be explained is viewed as parts of a larger whole, a system, and is explained in term of its role in that system.35

Systems Concept

• Defining Systems:

• Out-There View of Systems

• e.g., our solar system (sun & its 9 planets).

• Seen as absolute; Exists out-there; Viewed as independent of observer.

• Inside-us View of Systems

• Depend on what the person viewing something as a system • Different people may define the same system in different way. • Not seen as existing independently of the observer;

• Not out there;

36

Defining Systems

• Systems as a Human Conceptualization

Only human observer that may view something as a system.

• For examples:

• An estuary is viewed as a beautiful place (not a system)

• A few feet away from the path (not a system) • As an ecological system

• The point that system are human conceptualization is clearly driven home by the fact that majority of system conceive are not our personal view of some real assembly of thing out there in the real world.

37

Subjectivity of Systems Description

•

World view of observer/Weltanschauung (personal factors)•

Effect of Previous Knowledge•

System’s definitions are subjective• Cannot be labeled “right” or “valid” & “wrong” or “invalid”

• Valid for the person making it

• Dependent on the aim and purposefor building it

38

Formal Definition of The concept

System

1. A system is an organized assembly of components

2. The system does something.

3. Each component contributes towards the behavior of the system and is affected by being in the system.

4. Groups of components within the system may by themselves have properties (1)-(3) i.e., they may form subsystem.

5. The system has an outside- an environment.

6. The system has been identified by someone as of special interest.

39

The Crucial elements of a system

• Component

• Relationship

• Behavior (or the activities or the transformation

process)

• Environment

• Input from environment; Output to environment

• Special interest of the observer

40

System as Black Boxes

• The complexity of real live ⇒have no or only

incomplete knowledge of the inner workings of system, even where the physical components are able to identify.

• This lack of knowledge is affected by random

aspects.

• In other situation the transformation process is

known exactly. However, rather than represent it in full detail, it may be perfectly adequate to view as black box by single functional

relationship.

41

Hierarchy of Systems

Environment

Wider system of interest

Narrow system of interest

42

• Hierarchy system is the nesting systems within

systems.

• The containing system becomes the

environment of the contained system.

• Containing system exercise some control over

the contained system.

• The controlling may set the objective of the

contained system, monitoring it achieve the objectives, & have control over some crucial resources needed.

• The controlling system referred to as the wider

system of interest, while the contained

system becomes the narrow of interest.

43

System Behavior

• System state, the set of value assumed by all state

variables as of given point in time.

• State variables are attributes of system component, at any point in time each state variables has a given numerical or categorical value.

• Variety of system behavior, system behavior can be

almost infinitely varied, even for very simple system. (e.g. newscaster light bulb)

• Emergent properties, the system exhibits behaviors

44

Types of Systems

• Discrete system, the states of system jumps through a sequence of discrete states.

• Continuous system, the state of the system change continuously, because there are continuous variables.

• Deterministic system, the behavior is predictable in every detail.

• Stochastic system, the behavior is not completely predictable, affected by random or stochastic inputs.

• Closed system, is one that not receive anything from its environment.

• Open system, interact with the environment, by receiving inputs from it & providing output to it.

45

Control System

• Control is exercised by imposing something on

the system in form of inputs

• A set of decisions or decision rules, or simply an initial state for the system.

• Three conditions are needed for exercising

control over system behavior

• A target, objective, or goal for the system • A system capable of reaching the target or goal • Some means for influencing the system behavior - the

control inputs

46

Types of controls

• Open loop controls

• Often in the form of a recipe or a set of rules to follow (e.g. starting the engine)

• Closed loop controls (Feedback controls)

• Information about the system behaviour is fed back to the controller for evaluation.

• This may lead the controller to adjust the control signals (e.g. Control the temperature of the shower water)

• Feedback controls and Self Regulation

• Feedback controls: The rules supplied from external systems • Self Regulation: The rules are internal (See Fig. 3-4)

48

System in a decision making

context

•

A system is an organized set of components and relationships that do something that none of the components can do alone.•

We use system models as a convenient way to view something in order to aid decision making (to solve a problem).49

• A System is described by:

• Observer: Who is interested in the system? Decision

maker

• Purpose: Why define the system? Improve, output of

interest

• Environment: outside the system. Define the system

boundary

• Inputs: Affect the system but are not affected by it.

Can be controllable or uncontrollable. Decision variables/parameters

• Outputs: Are affected by the system. These are of

interest to the observer. Include measure of success

• Components: Both affect and are affected by the

system.

• Relationship/transformation process: Between

PEMODELAN SISTEM

Materi 3

Problem Formulation

51

Definition of A Problem

•

There must be an individual (or a group of individuals), referred as the decisionmaker who:

• Is dissatisfied with the current state of affairs • Knows when goals have been achieved

• Has control over aspects of problem situation that affect the extent to which goals can be achieved

52

Four Elements of A Problem

•

The decision maker•

The decision maker’s objective•

The performance measure for assessing how well the objectives have been achieved•

Alternative courses of action or decision variables for achieving the objectives53

Problem Elements:[LOD]

• The decision maker: the LOD manager

• The objective: keeping the cost of the LOD’s operation as low as possible, subject to

maintaining the same level of customer service.

• The performance measure: the total operating cost of the LOD

54 55

System Relevant [LOD]

•

The widest system: the company as a whole•

The refinery: one of its subsystem•

The LOD: a subsystem of the refinery system•

Within LOD system:• the production/inventory control operation form one of its major subsystem (i.e. the narrow system of interest)

56

Components of the Stock

Replenishment System

•

See Table 5-1, page 11057

Influence Diagram [LOD]

• Influence diagram shows:

• How the control inputs and other inputs affect the system variables for various system components, and • How these in turn affect the system outputs, in

particular the performance outputs.

58 59

Components of a Model

• Performance measure

• Uncontrollable Inputs

• Parameters

• Controllable Inputs:

• The collection of all possible courses of action you might take

• Interaction among These Components

• These are logical, and mathematical function representing the cause-and -effect relationships among inputs, parameters, and the outcome.

• There are also set of constraints which apply to each of these

PEMODELAN SISTEM

Materi 4

System Characterization

61

62

System Characterization:

[Murthy et.al,1990]• The SYSTEM APPROACH Offers a universal framework for treating such distinctly different problems

• In the systems approach the real world associated with the problem is viewed as a system

• The solution to the problem is viewed as a study of the system with a defined goals

• The starting point for such study is a proper description of the system.

63

System Characterization:

[Murthy et.al,1990]

• A total description -unmanageable

• Not all featuresof the real world are

relevant to the problem or its solution

• A partial descriptionis often adequate

• This partial description, called the system

characterization, retains only features, that

64

Basic Concepts

• System/Variable/Parameter

• Variables are attribute needed to describe interaction between objects (components) • Parameters are attribute intrinsic to an object • System/Environment

• The interaction between the system and its environment is through variables common to both • Relationships

• The interaction between objects are described through relationships linking the variables of the interacting objects

65

Degree of Detail

•

A Black Box description:• Described only by the variables through which it interacts with its environment, and the inner structure of the system is ignored (A Black Box description)

•

A White Box description:• If one can describe all objects in the system and their attributes (through variables and

relationships) -describing the system a greater detail (A White Box description)

66

Degree of Detail

• The degree of detail needed to describe a system appropriately depends on many factors

• If all the details are included - the description is unmanageable

• However, if significant details are omitted the description is incomplete

• One needs to find a sensible compromise (The art aspect of modelling process)

67

System Characterization

•

Static vs Dynamic• static systems -time does not play any part • dynamic systems-time plays a very important role

•

Continuous Time vs Discrete Time68

System Characterization

• Time Scale in Dynamic Systems

• the variables change with time

• The term ‘time scale’ is used to indicate the duration for significant changes to occur in a variable

• Deterministic vs Stochastic

• If the values assumed by the variables are predictable with certainty (Deterministic systems) • If not, then uncertainty is a significant feature of

the system -the changes in the variable are random and unpredictable (Stochastic systems)

69

Keputusan Pembelian Terigu

• Pabrik roti membeli terigu dengan harga $1000 per ton. Kebutuhan terigu relatif konstan selama setahun dengan total permintaan per bulan sebesar 20 ton. Terigu dikirim dari pabrik terigu dengan menggunakan truk dan ongkos per sekali kirim $132, tidak tergantung dari jumlah terigu yang diangkut.

• Uang yang digunakan untuk membeli terigu berasal dari suatu investasi dengan interest sebesar 8% per tahun. Juga, terigu yang disimpan diasuransikan dengan premi 16% yang dihitung berdasarkan nilai rata-rata

persediaan per tahun. Manajer pembelianingin mendapatkan kebijakan pembelian terigu yg lebih baik dari yang terjadi sekarang.

70

System Description

71

72

Mathematical Model

73

Mathematical Model

74

EOQ Model

75

76

Validation:[Internal]

77

Validation:[Internal]

78 79

SISTEM MODELING

Materi 5

Mathematical Modeling

81

OUTLINE

•

Introduction•

What is a mathematical model?•

Why do we build a mathematical model?•

How to build a mathematical model?•

An illustrative case (Case of LOD)•

Formal Approaches for finding the optimal solution82

INTRODUCTION

•

We use the OR/MS Methodology•

To capture the relationships between various elements of the relevant system in a mathematical model and explore its solution.83

What is a mathematical model?

•

A mathematical model: Express, in quantitative term, the relationships between various components, as defined in the relevant system for the problem (e.g. using Influence Diagram).•

Terminology:•Decision variables or the alternative courses of action (controllable inputs) •Performance measure(how well the

84

What is a mathematical model?

•

Terminology:• Objective function(the performance measure is expressed as a function of decision variables)

• Uncontrollable inputs: parameters, coefficients, or constants

• Constraints –limit the range of the decision variables

85

86

Relationship Between

Input-System-Output

87

Why build mathematical

models?

•

Real-life tests are not possible•Disruptive •Risky •Expensive

•Math Models are easy to manipulate

88

Properties of Good mathematical

models

•

Simple –simple models are more easily understood by the problem owner•

Complete–should include all significant aspect of the problem situation affecting the measure of effectiveness•

Easy to manipulate–possible to obtain answer from the model•

Adaptive–changes in the structure of the problem situation89

Properties of Good mathematical

models

•

Easy to communicate with –easy to prepare, update, and change the inputs and get answer quickly•

Appropriate for the situation studied – produces the relevant outputs at the lowest possible cost and in the time frame required•

Produce information that is relevant and appropriate for decision making –has to be useful for decision making90

The Art of Modeling

•

A scientific process•

More akin to art than science•

A few guidelines•

Ockham’s Razor:• “Things should not be muliplied without good reason”.

• The modeler has to be selective in including aspects into a model

91

The Art of Modeling

•

An iterative process of enhancements–begin with a very simple model and move in an evolutionary fashion toward more elaborate models

•

Working out a numerical example –observe how variables of interest behave

92

Math. Model For The

LOD

Problem

•

Simplification• Constraints (Warehouse space & mixing and filling capacities)

• Two decision variables (cutoff point, L and order size,Q)

•

First Approximation• Ignore the constraints

• Involve only one decision variable, Q

•

Performance measure• Total annual relevant cost (TAC) (per year) • TAC=Annual stock holding cost+Annual set up

cost+Annual handling cost+Annual product values

93

94

Math. Model For The

LOD

Problem

•

Annual stock holding cost• (Average stock level x Unit product value) x Holding cost/$/year

•

Annual set up cost• Setup cost per batch x Annual number of stock replenishments

•

Annual handling cost• Product handling cost per unit x annual volume met from stock

•

Annual product values• Unit product value x Annual volume of demand

95

Math. Model For The

LOD

Problem

] [ ] [ ] / [ ] 5 . 0 [ )

(Q Qvr sD1 Q h1D1 vD1

T = + + +

] [ ] / 5 . 0 [ ] [ ] [ ) ,

(Q L sN h2D2 Qvr sD1 Q h1D1

T = + + + +

96

Math. Model –

LOD

[Second Approximation]

• Two decision variables, L and Q.

• Two additional costs

• The annual set up cost for special production run

•Annual volume by special prod.runs x Product handling

cost per unit

• The annual handling cost for big order

•Production setup per batch x Annual number of special

prod.runs • Total cost =

The annual set up cost for special production run + The annual handling cost for big order +

Associated annual EOQ cost given L + The annual handling cost for small order.

97

98

Deriving A Solution To The Model

• Enumeration

• Search Methods

• Algorithmic Solution Methods

• Classical Methods of Calculus

• Heuristic Solution Methods

• Simulation 99

Deriving A Solution To The Model

•

Enumeration• Number of alternatives of action is relatively small. • Computational effort is relatively minor

• Optimal solution is obtained by evaluating the performance measure for each alternatives.

•

Search Methods• e.g. Golden section search

•

Algorithmic Solution Methods• A set of logical and mathematical operations performed repeatedly in a specific sequence • Iteration

100

Deriving A Solution To The Model

•

Classical Methods of Calculus•

Heuristic Solution Methods• Impossible to find the optimal solution with the computational means currently available (intractable) • If the optimal solution is possible to obtain, but the potential

benefit do not justify the computational effort needed. • Heuristic methods: to find a good solutions or to improve an

existing solutions (out put based techniques)

•

Simulation• For complex dynamic systems

• To identify good policies rather than the optimal one.

SISTEM MODELING

Materi 6

Model Testing & Sensitivity Analysis

103

Model Testing & Sensitivity Analysis

• Internal Validity (Verification)

• Is the model mathematically correct and logically

consistent?

• This also involves verifying that each expression is

dimensionallyconsistent.

• External Validity (Validation)

• Is the model a sufficiently valid representation of reality?

• Testing the solution performance

• To determine the expected benefits, such as net profits or net savings

104

Analysis of Sensitivity of Solution

•

Analysis of Sensitivity of Solution• Sensitivity analysis(evaluate the response of the best solution to changes in various inputs)

• Error analysis

•The input parameters are estimated on the basis of past data

•There is no guarantee that the future will be similar to the past

•There could be an error in input data

105

Rules for Testing Validity

• The evaluation of the proposed policy has to be

based on observations of actual(or

simulated) performance

• The data usedfor the test should be

independentof the data used to derive the best policy

• The test should not just give expected

performance, but also some measure of its

106

Purpose of Sensitivity Analysis

• If the optimal solution is relatively

insensitive, then the decision maker and user can place more confidence in the validity and usefulness of the model

• Sensitivity analysis provides information about

the value of additional amounts of each scarce resource(shadow price of the resource)

• Sensitivity analysis is used for exploring how the

optimal solution changes as a function of

such uncertain data

107

Procedure of Error Analysis

1.Determine the optimal policy based on the best estimate values for all input parameters (assume that one of these, say p, is in error).

2.Assume that the value of the input parameter p differs from the correct value, P(p=kP).Find the optimal policy, using the (assumed) correct value P.

3.Compute the actual value of the objective function if the pseudo-optimal policy determined in (1) were

implemented.

4.Find the difference between the optimal objective function values obtained from (2) –using the correct value and (3) –using the estimate value.

108

Math. Model For The LOD Problem

vr Ds EOQ= 2 /

Q sD Qvr Q

T( )=0.5 + /

Dsvr Q T Dsvr Dsvr Dsvr Q T vr Ds sD vr Ds vr Q T Q sD Qvr Q T 2 ) ( 5 . 0 2 5 . 0 5 . 0 ) ( / 2 / 2 5 . 0 ) ( / 5 . 0 ) ( = = + = + = + = 109

Sensitivity Analysis For The LOD

Problem

•

How do EOQ expression and T(Q) respond110

An Example

• A year later its is discovered that actual demand in not 4140, but only 2875 (over estimate 44%)

• If we had implemented this solution, the minimum relevan cost, would have been

• Instead, we implemented the pseudo-optimal solution

• The difference beetween actual cost & the minimum cost (lost in potential benefit)

2442 $ 18 . 0 ( 320 / 18 ) 2875 ( 2 ) 4 . 42 ( = = T 87 . 50 ) 18 . 0 ( 320 / 18 ) 4140 ( 2 /

2 = =

= Ds vr EOQ 4 . 42 ) 18 . 0 ( 320 / 18 ) 2875 ( 2 /

2 = =

= Ds vr EOQ 2482 $ 87 . 50 / ) 2875 ( 18 ) 18 . 0 )( 320 )( 87 . 50 ( 5 . 0 ) 87 . 50 ( = + = T % 64 . 1 % 100 2442 2442 2482 = − x 111

error in demand -80% -50% -20% 0% 20% 50% 100% 300% k (known) 20% 50% 80% 100% 120% 150% 200% 400% D implied (4140/k) 20700 8280 5175 4140 3450 2760 2070 1035 T(EOQ) based on D 6552 4144 3276 2930 2675 2392 2072 1465 T(50.87) based on D 8790 4395 3296 2930 2686 2442 2198 1831 Cost increase 34.2% 6.1% 0.6% 0.0% 0.4% 2.1% 6.1% 25.0%

cost increase 0.0% 5.0% 10.0% 15.0% 20.0% 25.0% 30.0% 35.0% 40.0%

-100% 0% 100% 200% 300% 400%

SISTEM MODELING

Materi 7

Implementation of Solution

113

Implementation

•

Putting the tested solution to work•

Means translating the mathematicalsolution into set of easily understood operating procedures or decision rules

•

Training all people involved for the properapplication of the rules, executing the transition, and preparing complete documentation for future reference

114

Implementation

•

Not easily handled by a systematic approach, good organization and coordination•

Fraught with difficulties that are largely ofa human nature –e.g. consider the LOD 115

Problem of Implementation

1.

Relating to the physical task of implementation2.

Relating to the problem user and other individuals affected by the solution –e.g. their personalities, their motivation and pride in the job116

Problem of Implementation

•

OR/MS analyst pays attention of the first factor•

The tendency is to neglect and overlook the human factors of (2) and (3).•

Note: neglecting the human constraints in a system can easily lead to a solution that is one on paper onlyand is notworkable in practice.

117

Problem of Implementation

The human constraints may be relaxed in a number of way:

•

More involvement of problem user(s)•

Individual who could become obstacles toproper implementation could be transferred (?)

•

Technical solution can be adjusted by simplifying the policy or solution rules118

Problem of Implementation

For LOD case:

•

The stock clerk was viewed as the most important stakeholder for the user’ group (pulled in as an active project teammember)

•

The LOD manager was kept fully informed and regularly consulted during the project.•

Hence, a strong impression of active LODparticipation and management support.

119

Planning for Implementation

•

Starts at the outset of any project•

It is not sufficient to start planning for the implementation once the solution has been tested and the report submitted•

Planning for ImplementationConsists of the following elements:

120

Planning for Implementation

•

Establishing effective lines of communication•

Exploring and managing the prior expectation for the project•

Keeping the problem owners and problem users regularly informed•

Checking out availability and sources of all input data needed121

Planning for Implementation

•

Ordering of special equipment and commercial computer software•

Developing all software•

Planning and executing the actual process of implementation•

Regularly following-up sessions with problem users122

Controlling and Maintaining

the Solution

•

The environment is constantly undergoing change•

Inputs into the system are also changing•

Such change may be quantitative orstructural

•

Any changes that only affect themagnitude of inputs –such as the volume of the annual demand for the LOD

(quantitative changes)

123

Controlling and Maintaining the

Solution

•

A change in the form or nature of an input is called structural –affects the influence relationship between the input and one or more intermediate variables in the model.•

For example –LOD problem (?)124

Controlling and Maintaining the

Solution

•

Establishing controls over the solution consists of:•

Listing for each input (parameters, constraints) –the quantitative change•

Listing of structural form of all influencerelationships between inputs and

intermediate variables; intermediate and outcome variables.

125

Controlling and Maintaining the

Solution

•

How each input has to be measured to assess if a change is significant•

Assigning responsibility for the control of each item•

How the solution has to be adjusted in response to changes (quantitative and structural changes)126

Following Up Implementation

and Model Performance

Monitoring Implementation:

•

The job of the OR/MS analyst is not finished once the solution has been implemented.•

After some time. Enforcement rules for using the solution becomes somewhat lax•

Short cut may have been taken by theusers

•

It is essential that analyst keepsmonitoring the performance of the model after implementation

127

Following Up Implementation

and Model Performance

•

If any misapplication or misinterpretation of the solution show up, corrective action must be initiated.Performance audit:

SISTEM MODELING

Materi 8

Manufacturing System

129

A Systems View of

Manufacturing

• Manufacturing can be viewed either as a transformation process or as a system.

• As a Transformation Process: A narrow

definition of manufacturing is that it a process of transformation where raw material are converted into products.

• As a System: Manufacturing is not limited to materials transformation performed in a factory. Rather, it is a complex system comprising of several elements.

130

Flow of Materials, Information and

Cost

Figure 2.3: Flow of Material, Information and Costs (Hitomi, 1996)

In

fo

rm

a

ti

o

n

F

low

of

RAW

MATERIALS PROCESS

Materials Flow of

CONTROL PLANNING

PRODUCTS

Flow of cost

131

A Systems View of

Manufacturing

•

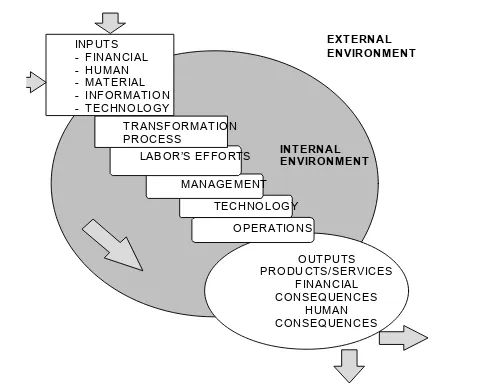

This involves an internal environment and an external environment.•

The inputs are from the externalenvironment and involve several variables.

132

Figure 2.2: Systems View of M anufacturing (Murthy, 1995a)

O UTPU TS PR O DU CTS/SER VIC ES

FIN ANC IAL C ON SEQ UEN C ES

H UMAN C ON SEQ UEN C ES O PER ATIO N S TECH NO LO G Y MANAG E MENT LAB OR ’S EF FO RTS TR ANSFO R MAT IO N PRO C ESS INP UTS - FINAN CIAL - H UMAN - MATER IAL - INFO RMATIO N - TEC HN O LO G Y

INT ERN AL ENV IRO N M ENT

EXT ERN AL EN VIR ON M EN T

133

A Systems View of

Manufacturing

•

Can be viewed from three different Aspects:•

Technical: Dealing with engineering, scienceand technology issues.

•

Commercial: Dealing with financial,marketing, legal issues

•

Management: Dealing with planning,operations and other related issues such as information. And also organisational issues dealing with human related issues.

134

MANUFACTURING: DIFFERENT

PERSPECTIVES

•

It can also be viewed from three different perspectives:• Firm level,

• Industry level and • Regional or global level.

135

Firm Level

•

Manufacturing at the firm level involves several variables which can be broadly grouped into the following three categories:136

Technical

•

The technical side has been discussed before and involves various issues related to the science, engineering and technology aspects of manufacturing.137

Commercial

•

The commercial side deals with issues such as costs, sales, revenue and profits. Each of these involves many variables.•

For example, the costs can be investment costs, unit manufacturing costs, cost of rework and so on. The basic bottom line for a firm is that it must make reasonable profit for its investment.138

Management

•

Deal with managing the various activities at strategic and operational levels taking into account the many different legal and socio-political aspects and various constraints.•

Another very important issue relates to the organizational side that deals with the human related issues – organisational structure, communication and flow of information, skill base of the workforce and so on.139

National Level

•

In the national level, a manufacturing firm is influenced by factors such as market competition and government policies.140

National Level

•

Some of the government policies that affect the manufacturing enterprise are indicated below.•

Industry or Technology developmentpolicies,

•

Taxation policies,•

Environmental policies.•

Trade policies – export and importsubsidies, protection

•

Financial investment141

Regional and Global Levels

•

Manufacturing at the regional and global levels deals with the following factors :•

Fierce competition•

Open market - free trade•

Trade organisation - regional partnerships142

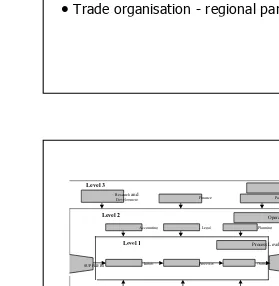

A THREE LEVEL MODEL OF

MANUFACTURING

•

Manufacturing is a complex systeminvolving several elements. It can be viewed as a three level system (Level 1 -3)

•

Note that Level 1 is nested within Level 2, in turn, is nested within Level 3. We briefly discuss the elements at each of these levels. [image:38.842.383.662.166.452.2]143

Figure 2.9: Three Level M odel of Manufacturing (M urthy, 1995b)

Strategic Level Level 3

Researchand

Developm ent Finance Partnerships

Operations Level

Level 2

Accounting Legal Planning

Process Level

Level 1

Inputs Processes Outputs

S UP PLIERS CUSTOMERS

Hum an Resource

Envir onmental M arketing

144

Level 1

•

This level corresponds to the shop floor level and has three key elements - Inputs, Process and Outputs.145

Level 2

•

This level includes Level 1 as well as six new elements. The focus of this level is management of business at the operations level and the six new elements with a range of operational issues.146

Level 3

•

This level includes the Levels 1 and 2 and six new elements. Here, the management focus is long term and strategic.