lESS

THE 3

RDINTERNATIONAL CONFERENC E

ON INDUSTRIAL ENGINEERING AND SE RVICE SCIENCE

M elia Pu rosani Hotel - Yogyaka rta, 1 - 3 September 20 15

PROCEEDINGS

PROCEEDINGS

CREATING VALUE

THROUGH INNOVATION

Organized by:

Organized by:

Industrial Engineering Department, Institut Teknologi Sepuluh Nopember (ITS) Surabaya and

Universitas Atma Jaya Yogyakarta - Indonesia

Supported by:

Rajamangala University of Technology Suvamabhumi (RMUTSB) - Thailand

Universitas Islam Indonesia (UII) - Indonesia

,ISSN:

2338.7939

@20is

Edited by:

Iwan Vanany

Nani Kurniati

Dyah Santhi Dewi

Cover page

Preface

Table of Contents

• Welcome Speech from Conference Chair

• Welcome Message from Rector of ITS Surabaya

• Welcome Message from Rector of Universitas Atma Jaya Yogyakarta

• Keynote Speakers

• Industrial Engineering ITS

• Universitas Atma Jaya Yogyakarta

Committee

Conference Sponsor

List of Papers

Industrial Engineering - Decision Making

1. Annisaa Novieningtyas and Pri Hermawan. Group Model Building for Policy Making (Case Study: Beef Cattle at West Sumatra)

2. Pri Hermawan, Yuliati Komar and S<?ehartati Gondhowiardjo. A Network-based Collaborative

Decision Making Model in Reducing Cervical Cancer Spread in Indonesia. 13

3. , Erika F.atma. dセカ・ャYーュ・ョエ@ ッセsオウエ。ゥョ。「ャ・@ Tuna Processing htdustry through Syste,m Dynamics

. :Simulation: •. ' ' ,. " . . " , , . ' ' . 2()

4. I Made Ronyastra, I Ketut Gunarta and Udisubakti Ciptomulyono. A Multi Criteria Decision Analysis for Reinvestment Action Portfolio Selection Problem in an Indonesian Real Estate

Company 27

5. Stcfanus Eko Wiratno, Em Latimanti and Kevin Karmadi Wirawan. Selection of Business Funding Proposals Using Analytical Network Process: A Case Study at a Venture Capital

Company 36

Industrial Engineering - Logistics

I. Farida Pulansari, Dwi Donoriyanto and Iriani. Performance Assessment Mechanism for Reverse Logistics Maturity Implementation toward Sustainable Manufacturing Systems: A Conceptual

Framework 42

2. Adi Budipriyanto, Budisantoso Wirjodirdjo, Nyoman Pujawan and Saut Guming. Berth

Allocation Problem under Uncertainty: A Conceptual Model Using Collaborative Approach 51

3. Nur Utfa Hidayatullah and Ali Musyafa. Hazop Study on Fuel Distribution System Based on

Anfis Layer of Protection Analysis in Surabaya Installation Group PT Pertamina Tanjung Perak 59

4. Ardian Rizaldi. Meditya Wasesa and M Noviar Rahman. Yard Cranes Coordination Schemes for

Automated Container Terminals: An Agent-Based Approach 66

5. Meditya Wasesa, M Noviar Rachman, Ardian Rizaldi and M Mashuri. Relocating

Multiple-Tenants Logistics Center: Lesson Learned from an Air Cargo Terminal Relocation Project 74

6. Siti Nurminarsih. Ahmad Rusdiansyah and Nurhadi Siswanto. Inventory Ship Routing Problem

(ISRP) Model Considering Port Dwelling Time Infonnation 80

7. Sonny Sanjaya and Tomy Perdana. Logistics System Model Development on Supply Chain

Industrial Engineering - Manufacturing system

I. Wiwin Widiaslh, Putu Dana Kamingsih and Udisubakti Ciptomulyono. Development of Integrated Model for Managing Risk in Lean Manufacturing Implementation: A Case Study in an

Indonesian Manufacturing Company 95

2. Joko Sulistio and Tri Astuti Rini. A Structural Literature Review on Models and Methods

Analysis of Green Supply Chain Management 103

3. Sri Indrawati and Muhammad Ridwansyah. Manufacturing Continuous Improvement Using

Lean Six Sigma: An Iron Ores Industry Case Application III

4. Sri Hartini and Udisubakti Ciptomulyono. The Relathionship between Lean and Sustainable

Manufacturing on Performance: literature review 117

5. Maria Anityasari and Aulia Nadia Rachmat. Lesson Learnt from Top-Down Medium

Enterprises Selection for Green Industry Pilot Project in Surabaya 126

6 Putu Karningsih, Dewanti Anggrahini and Muhammad Syafi'i, ConcureDt Engineering

Implementation Assesment. Case Study in an Indonesia Manufacturing Company 133

7 Nani Kurniati, Ruey-Huei Yeh and Jong-Jang Lin. Quality Inspection and maintenance: the

framework of interaction 140

Industrial Engineering.;.. Operation management

l. Suhendi Irawan. The Effect of Choosing a Transportation Vendor and the Performance of Transportation Vendor on the Performance of Shipping Goods to Consumer: A Case Study of DB Schenker Freigh Forwarder

. 2. jセァォイゥエ@ Mahoran,Sukanya Wonglakron, Sumalee n。ュセ」ィッエ・M。ョ、@ Na(Uphon OaQwimon.Risk . Management of Village fオゥャ、セ@ in mオセョァNdゥウエイゥ」エL@ Suphanbuti ·Province. . ',:' '., . ' ..

3. Susanto Sudiro and Sha'Ri Mohd Yusof. Managing WIP buffer with combination of feeding materials scenario and conventional control theory of single type of hospital bed production

4. Agung Sutrisno, Indra Gunawan and Stenly Tangkuman. Modified FMEA Model for Acessing the Risk of Maintenance Waste

5. Filemon Yoga Adhisatya, The Jin Ai and Dah-Chuan Gong. Economic Lot Scheduling Problem

with Two Imperfect Key Modules .

6. Bupe Mwanza and Charles Mbohwa. An Assessment of the Effectiveness of Equipment Maintenance Practices in Public Hospitals.

7. Bupe Mwanza and Charles Mbohwa. Design ofa Total Productive Maintenance Model for Effective Implementation: A case study ofa Chemical Manufacturing Company

8. Hafid Budiman. Increasing Compressor Reliability with The Weibull Distribution Analysis

9. Paulus Wisnu Anggoro and Baju Bawono. Reverse Engineering Technology in Redesign Process Ceramics: Application for CNN Plate

10. Endang RetRo Wedowati, Moses Laksono Singgih and I Ketut Gunarta. Integrated Production Planning and Scheduling for Mass Customization in Food Industry; A Conceptual Framework

I I. Taufik Djatna and WeRRY Dwi Kurniati. A System Analysis and Design for Packaging Design of Powder Shaped Fresheners Based on Kansei Engineering

12. Taufik Djatna and Muhammad Raja (hsan. A Fuzzy Associative Memory Modeling for Production Equipment Status Assessment

13. Taufik Djatna and Fajar Munichputranto. An Analysis and Design of Mobile Business

Intelligence System for Productivity Measurement and Evaluation in Tire Curing Production Line

147

, 152

159

167

173

179

185

194

199

205

213

220

14.Sazlf Tutur Risyahadi. Scheduling Model of Harvesting Stmwberry Considering Product Decay

During Storage 231

15. Chaterine Alvina Prima Hapsari, Deny Ratna Yuniartha and Ignatius Luddy Indm

Pumama. Tour and Break Scheduling for Shift Operators in Hard Disk Drive Manufacturer 239

16. Jwannaraksu Phen. An influence of packaging design on customer purchase intention 247

17. Dewanti Anggrahini. Putu Dana Kamingsih and Martian Sulistiyono. Managing Quality Risk In

A Frozen Shrimp Supply Chain (A Case Study) 251

18. Anny i\1aryani. Sritomo Wignjosoebroto and Sri Gunani Partiwi. A System Dynamics Approach

for Modeling Construction Accidents 259

19. Naning Arant! Wessianl and Satria Oktaufanus Sarwoko. Risk Analysis of Poultry Feed

Production Using Fuzzy FMEA 265

20. Mohamad Faisal Mohamad Sobri, Hawa Hishamuddin. Noraida Azura Md Darom- Disruption OM I

Pecovery for a Single Stage Production-Inventory System with Optimal Safety Stock

Industrial Engineering - Operation research

I. Wahyuda and Budi Santosa. Dynamic Pricing in Electricity: Research Potential in Indonesia 276

.., Chirag Sanchcti, Aditya Balu and Amit Kumar Gupta. Simulation based optimization of

productivity using Flexsim 283

3. Budi Santosa and I Gusti Ngurah Agung Kresna. Simulated Annealing· Algorithm to Solve

Single Stage Capacitated Warehouse Location Problem (Case Study: PT. Petrokimia Gresik) 289

4. Yuanita Handayat!, Togar Simatupang and Tomy Perdana. Value Co-Creation in Agri-Chains Network: A Hard Agent Based Simulation

5;

B.udi Santosa and Ade' Lia,Santri .. Biogeogtaphy-based .Ol?timization Algorithm for Single:MachineTotal Weighted イ。イ、ゥョセウウ@ Problem '. , " . . .

6. Gilang Almaghribi Sarkara Putra and Rendm Agus Triyono. Proposing a Neural Network Method for Instrumentation and Control Cost Estimation of the EPC Companies Bidding Proposal

7. Sattarpoom Thaiparnit, Baramee Osateerakul and Danupon Kumpanya. Algorithm Design in Leaf Surface Separation by Degree in US\' Color :\'Iodel and Estimation of Leaf Area by Linear Regression

8. Danupon Kumpanya and Sattarpoom Thaipamit. Pammeter Identification of BLOC Motor

Model via Metaheuristic Optimization Techniques

9. Sinta Dewi, Imam Baihaqi and ElWin Wi dodo. Modeling sエイ。エ・セセ@ ッヲpオイ」ィ。ウゥセァ@ セッョウッイエゥオュ@ to

Optimize Total Purchasing Cost Considering the Dynamic Condmon ofOrgamzalon

10.

Taufik Djatna and Imam Muharram AUtu. An Application of Association Rule Mining inセッエ。ャ@

Productive Maintenance Strategy: An Analysis and Modelling for Wooden Door Manufactunng

Industry

Industrial Engineering - Product Development fP d t

. Aini Masruroh and Indm Bastian. The Scheme 0 ro uc

1. Yosephine Suharyanti,

sオ「セァケッL@

nセ@

duct Success: A Theoretical FrameworkDevelopment Process as a Tngger to ro O. ted Product Design

d W'fi . Azlia Development of Customer nen

2. Ishardita

p。ュ「オセゥ@

tセュ。@

an 1アセッ、・エG@

(Case study of Cemmic Souvenir)Using Kansei Engmeenng and Kano .

Dharma Yoga Santo sa. Balmese

3. Taufik Djatna. Lub Putu wras

t iati

。ョョエ、biZZ・ZセァョオZuョウ・ゥ@

Engineering And Customer PersonalityAromatherapy Product Deve opme

Type

298

307

313

320

326

332

340

347

355

....

"4. Dyah Santhi Dewi, Bambang Syairudin and Eka Nahdliyatun Nikmah. Risk Management in

New Product Development Process for Fashion Industry (Case Study: Hijab Industry) 368

Industrial Engineering - Project Management

1. Jeyanthl Ramasamy and Sha'Ri Mohd Yusof. A Literature Review of Subsea Asset Integrity

Framework for Project Execution Phase 376

2. Baju Bawono and Paulus Wisnu Anggoro. Utilization Of Rapid Prototyping Technology to

Improve Quality Souvenir Product 384

Industrial Engineering - Supply Chain Engineering

I. (rwnn Syahrlr, Supamo and Iwan Vanany. Healthcare and Disaster Supply Chain: Literature Review and Future Research

2. Yudi Fernando and Sofri Yahya. Challenges in Implementing Renewable Energy Supply Chain in Service Economy Era

3. Araya Uengpaiboonkit. The Marketing's Factors that Effect to Consumers Decisions of Organic Rice in Surin, Thailand

4. Layung Prasetyanti and Togar Simatupang. Proposed Framework for Service-Dominant-Logic

5.

6.

. 7.

8.

9.

Based Supply Chain

Taufik Djatna and Rohmah Luthnyanti. An Analysis and D.esign of Responsive Supply Chain for Pineapple Multi Products SME !3ased On Digital Business Ecosystem (DBE) .

Erwin Widodo. A Model Reflecting the Impact of Producer Substitution in Dual-Channel Supply-Chain Inventory Policy

. • • • ' , . " " . . " . ' " . ' I

tセオヲゥォ@

Ojatna and. "ety 'Handllyiml Hidayat. An Optimized Supplycセ。ゥョ@

Model'ff,lr Determination of Distribution Center and Inventory Level in A Coconut Water'Agro-lndustrySlamct Selio Wigati and The Jin Ai. An Integrated Production System Model for Multi Supplier Single Buyer with Non Conforming Item and Product Warranty

Yoshua Perwira Hartono, Ririn Dlar Astanti and The Jin Ai. Enabler to Successful Implementation of Lean Supply Chain in A Book Publisher

10.

Sutrisno and Pumawan Adi Wicaksono. Optimal Strategy for Multi-product Inventory System with Supplier Selection By Using Model Predictive Control11.Iwan Vanany, Anny Maryani and Bilqis Amaliah. Blood Traceability System for Indonesian Blood Supply Chain

Industrial Engineering - Safety & Ergonomic

l. Natalie Carol Skeepcrs and Charles Mbohwa. A Study on the leadership behaviour, safety leadership and safety performance in the Construction industry in South Africa

2. Herry Christian Palit and Debora Anne Yang Aysia. The Effect of Pop Musical Tempo during Post Treadmill Exercise Recovery Time

3. Eko Nurmianto, Udisubakti Ciptomulyono, Suparno and Sudiyono Kromodihardjo. Manual Handling Problem Identification in Mining Industry: the Ergonomic Perspective

4. Wiyono Sutari, Mumi Dwi Astuti, YusufNugroho Doyobekti and Yuvie Mutiarasari. Analysis of Working Posture Effect on Muscular Skeleton Disorder of Operator in Stamp Scraping in Batik Stamp Industry

S. Rino Andias Anugraha, Wiyono Sutari and lima Mufidah, The Design of Working Desk of Batik Scraper by Using the Principles of Ergonomy

390

398

404

408

416

423

430

436

443

450

457

464 470475

483 488..

'. ,

6. Budi Praptono, YusufNugroho Doyo Yekti, I Gede Wisuda Pura and Franslskus Tatas Dwl Atmadji. Prevention ofMusculo Skeletal Disorders of Green Beans Farmer Through Application

of Ergonomics in Order to Developing Manual Handling Equipment 496

7. Manik Mahachandra, Yassierli and Erdo Gamaby. The effectiveness of in-vehicle peppermint

fragrance to maintain car drivers' alertness 500

8. Yassierli, Manlk Mahachandra and lftikar Sutalaksana. Fatigue Evaluation of Fuel Truck

Drivers 506

9. Ayu Bidlawati and Eva Suryani. Improving the Work Position of Worker's Based on Quick

Exposure Check Method to Reduce the Risk of Work Related Musculoskeletal Disorders 512

10. Bernadus Kristyanto, Brillianta Budi Nugraha, Anugrah Kusumo P and Kristanto Agung

N. Head and Neck Movement: Simulation And Kinematics Analysis 518

II. Ronny Noriyati, Wisnu Rozaaq, Ali Musyafa and Adi Supriyanto. Hazard & Operability Study And Determining Safety Integrity Level On Sulfur Furnace Unit: A Case Study In Fertilizer

Industry 525

12. Dyah Santhi Dewi and Tyasiliah Scptiana. Workforce Scheduling Considering Physical And

Mental Workload: A Case Study Of Domestic Freight Forwarding 531

Industrial Engineering - Suporting topics in 'Industrial Egineering

I. Hatma Suryoharyo and Niken Larasati. Sustainable Livelihood Framework As An Approach To

Build Community Based Security 539

2. Ngurah Wira, Amelia Kumiawat,i and Umar Yunan. The Design of Best Practice on The Media

Transfer Activities and Preservation Based on Knowledge Conversion with'SECI Method 546

3. , Sri Gunani Part!wi, Elly Agustiani and. Anny Maryani. Preparation for Designing, bオウゥョ・ウセ@ .

, Strategy of BaQlboo cオャエゥカセエゥッャャGゥョ@ Bondowoso ' , ' . . , : , " . . " 552

4. Yosephine Suharyanti and Alva Edy Tontowi. Market Response as a function of Design,

Competition, and Socio-political Condition: An Empirical Model 558

Service Science - Service Business Design & Strategy

l. Tri Ramadhan, Dermawan Wibisono, Reza Ashari Naslltion and Santi Novani. Design of Self

Service Teclmology on Passenger Shipping Transportation Service System in Indonesia 566

2. Ratna HidayaU and Santi Novani. A Conceptual Complaint Model for Value co-Creation

Process 574

3. Mikhael Tjhi, Jann Hidajat Tjakraatmadja and Santi Novani. Designing value co-creation

process in organic food product distribution Case study in Bandung 579

4. Nurtam! Prlhadl and Santi Novani. Value Co-Creation among Stakeholders in Solo Tourism

Development: Service System Science Perspective 591

5. Arlavlanyssa Pradiva Arru and Santi Novani. Value Co-Creation in Solo Tourism by Using

Soft System Dynamics Methodology 60 I

6. Rizki S. Nurfitria and Mursyid H. Basri. Developing Clinical Pathway Model in Public Hospital

as Basic Component of Casemix System 609

7. Watcharee Phetwong and Krisorn Sawangsire. The Development of Computer Game for

Historic Sites Learning in Supbanburi. 617

8. Lidia Mayangsari and Santi Novani. Multi-stakeholder Co-Creation Analysis in Smart City

Service Science - Service Delivery & Operations

I. Imam Djati Widodo and Hanvati Sutanto. AR MBA: Linkage Pattern of Visited Tourism

セセ@ セ@

2. Liane Okdinawati, Togar M. Simatupang and Yos Sunitiyoso. Value Co-creation Map in

Collaborative Transportation 635

3. Americo Azevedo and Maratus Shollhah. Innovative Costing System Framework in Industrial

Product-Service System Environment 642

4. hvan Vanany, Udisubakti Ciptomulyono, Muhammad Khoiri, Oody Hartanto and Putri Nur

Imani. Willingness to Pay for Surabaya Mass Rapid Transit (SMART) Options 649

Service Science - Service Quality

1. Agus Mansur and Rizky Oestiana lIapsari. Analysis of the Public Transportation Service Quality

on Trans logia Transportation 658

2. Zya Labiba and Mulih Wijaya. Improvement Quality of Industrial Training Center Through

Service Quality Based on Participation Perspective 663

Service Science - Supporting topics in service science

I. Gembong Baskoro. The concept of balancing Higher Education Institution (HEI) organization

towards global and regional challenges 670

2. S.amhuri Ikbal Pradana, Amelia Kumiawatiand Nia Ambarsari. Knowledge Management System Implementation Readin.ess Measurement in POll LIPI Based On People and

I.rm:eetling oj j QOHャャャNセャイゥサOQ@ EflJ.:illeerillg /l1It1 Serl'ice Sdeflce , 20 15

An Application of Association Rule Mining in Total

Productive Maintenance Strategy: An Analysis and

Modelli ng

in

Wooden Door Manufacturing

Industry

Tnufi k Djatnaa; Imam Muharram AlitLIb

" Postgraduatc Progmm of Agroinduslrial T cc!lIlology. Bogor Agricultural Uni vcrsity. Indonesia. lau lik.d jalnalil iph.ac.id

bUndergrndlHl tc Program of Agroinduslri ul Tl!chnology. Bogor Agricll ltllrl! Indonesia. lndoncsia. ゥュ[ ャャョュ セャャウ ` ャipjャウNゥ}ャ 「 N。」Nゥ、@

ABSTRACT

One oj Ihe c1wllenges ill Ih e implemelllflfioll of TOIOI ProduCII\'e Mailllenallce (TP A'Q ill Ihe mamtjaclllrillg inr/uSII)' is a slow mal/agerial deci.\·ioll -making 10 re.\'fJOllt! Ihe cOlldiliol/ ill lite f OCIOI),. This "esearch illl'esligflfe$ Ihe (lII.nfers of Ihese challenges by (II1(I1)dl/g and modeling Ihe eq/dpmelll condilillll (/lui Ihe /·e.\'/JulISe oj (lcliom' reqllired ill {/ II'OU(Ie" (Joor 1I/(lIlltjaclllring illd/lslIJ'. TPM implemelll(l{ion ill Ihis compOlly iOHON セ@ deployed the O l'erall Equipment Effeclirel/e.r.\' (DEE)

meaS/lrement as all il1dicalOr oj Ihe eqllipmelll 1IIi1i: atiol/ mill cOllflilioll. Through all (!!wiysis (lilt! modelillg oj the DEE

mille obtained from the JacIOIl'. the JO/'lll/llOlioll oj A.uocimioll Rille I\ /inillg (A R I\ Q aims 10 fint! (J ntle IIml sholl's Ihe

lI'ell comlmled I'e/(Ifiollship be/ll'ecllmemlll'llble i"dic(I(fJl'.f ofOEE lI'i,h Ihe re.l1xJllse of acliOlI reqllired 10 /{Ike ill cerwill cOlldilioll of machille II/ili:mioll. RI!SIIlts "IUaillet! fi'o m ARM (Ilx cie /'{lte the dcc:;s;oll to eSllIhli.\·h ( III (lflPropriale TPM

1I/(/IIl1gemel1l sirmegy based 011 the rulc.\', The generalcd dylltill/ic イオャ・ Nセ@ foml lIml jilCililme Ihe pl'oces.\· oj deci,\'ion-moking by I'eiflled slCIkeholden;. Fllrthermore. reiy illg O/llfwse rilles Ihc (IcliOll taken by Ihe company indllced 10 a hig h/!/' reliable fllld illcreasillg the effecl;l·elle.H of 1'I!.VlOlIse WId efficicllcy uf lillie (lIItI emU,

Ke)'lI'ords: Ol'e/'{/II Eqllipmelll Effectil'cllel·s. Association Rille .\lill;l/g. 0(110 Millillg. TOlal Prndllcliw Mailllcllwlce

I.

Introd u ction

As one of the global company in wooden door lllanufacturing indust!'y, C II se lls hi gh-variation produc ts that arc fully

exported ac ross the world to fu lfill market demand. With limited number of mach ine and limited production capacit y,

this high-va riation product ion leads to higher changeover rate in the main fac tory. To adjust the production machine from

one type of product to another Olle, the m:lchine must be turned

on'

which res ulted to a higher downt ime. E:lrl y 20 15 datafro m mai ntenance departme nt in C[ I shows that JJ% o f p[an llillg p1'Oductio n time is the downtime. lli gher percentagc or

downtime in thi s company resul!s to a slower production rate and higher overtime.

In thct, C lI management has been implemented a tッ エ セQ@ Productive Maintenance (TPM) program to maill1ain thc factory

p[,lI1t and its equipment. TPi'\,1 is ma nufacturi ng program designed primarily to maximize the eITectivencss of equipment by participation and mot ivation or the entire workforce [[}. TPr-,'1 strategy implemented in this company is a benchmarkcd stm tegy from a nother nmnufaclUring compa ny. But. due to lack o f human resources, the implemented strategy could not

significantly affect the machine performance. According to these condition, there is a necessity to perform an

improve-me nt to the TPM strategy in C II to make it fit and suit with compan y condition.

The stmtegy develo ped in this research to improve the TPM in C II is predicti ve mainte na nce. This research focused on pred icti ve maintenance than other llw intenance strategy, [ike autonolllo us maintenance and prevc nti ve nminte nance, due to the 」 セー。「ゥ ャ ゥエケ@ of 、。エセ@ mining technique ttl supports the development of pre{lictive maintenance to improve plant :l1Id

machine condition in industry [2J . Usi ng measurable parameters when breakdown is eminen t, pred icti ve maintenance

intends to make an intervention to the mac hine itsel f or イ・ャセエ 」 、@ factors before lwrmful eve nts may oceur

PJ.

II mean thereis a requirement of d:lla-drivelltechnique like da ta mini ng to process illJlulied data and make the pred ict ion well targeted. One of data mining tcehni([ues is Associat ion Rule Mining (ARM). Act uall y. the prototypica l application of J\ Rt--1 is market basket ana lysis to mine the sets of items that arc frequen tl y bought together at a supcrmarkct by an:dY.ling the

customer shopping, A RM has a capabi lity to show thc dependenc ies bClween attributes and define it in assoc iation rules

I

I

An A ppli c:llion o f Associ alion Ru le Mining ill TOI:ll l'roducli ve f-.. 1:limc n:lIlee Strfllcgy: An f\nal ysis and Modelling in Wooden Door Manuf.1cturing Industry

f4]. A RM could cl:lrify the relationship between the pArameters .md the observed variable with the interve ntion res ponse Ihat will be taken by the re lated stake holder and prcsc nt it in a model consisted by associ:llion niles.

Based 0 11 motivation abovc, the main obj ecti ve of this research is to so lve the problem in C II with research Approach

AS formu lated as: I) to identify the effecti veness of used machine. 2) to dc\'elop association mles of observed va riables

and interve ntion responses, 3) to de velop a model of the m;lintenance strategy, The maintenance stra legy deve loped by

thi s research aiTlls to support the decision-ma king process in mamlge rncnt of C II . and other related stakeholder likc nmime nallce depanmcnt.

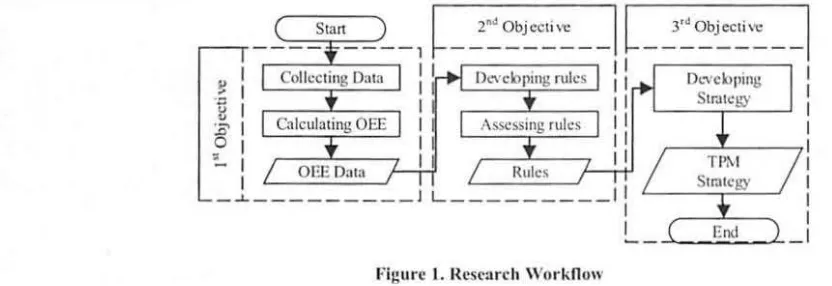

2, Met hodology of Research

To accomplish the researc h objectives. a methodology was designed wilh rcsearch approach. The research met hodology

representcd in Fig ure I .

( :; ) _,

セ⦅A

Zセセ」Z|セ

⦅Mャ@ l⦅セ

セセセcセ|セ@

__

I

!! 1 Collcctillg l)a'3 :

iセ@

ョ セB|」「ーゥョァ

イ|ャャ」 ウ@

::...J

1JweblllllgII

.- I I II .... ] StrJh:gy :

II

I

D!clll:lting OEE Iエ| ウウ」セゥョァ@

rules I I I Io

I I I I ... I:.. I _ I II / TI'1I.1 / 1

I / Ol!h Dala

f--I-

/

Rull: sf--i-t

StrJ'C gy I_-I. _ _ _ _ _ _ _ _ _ J L ______ _ __ I [ ... [

[image:10.602.54.470.234.377.2]セ⦅@

l

Em _IFigure 1. Ill'scarc h W orkn llll"

The research stans wi th the coll ecting machine cond ition data from mouldi ng machine as sample used C(lui pmelll. Then. the collected data processed with O verall Equipmellt EITecti ve ness (OEE) method to idc ntify mac hine effectivencss

as presented ill seclion 3. A fl erward, using Assoc iation Rule l\'lining (ARM). the OEE dala assigned to binary through

disc reti 7..1Iion and processed with apTiod algorithm to get nl lcs of elat;' as prese nted in section 4. To accomplish 3nl

objec-ti ve. the niles gOI from A RM develo ped to model to be evaluated and 10 sho w the association of mach ine condition and

npplied ma nageme nt strategy in TPM as prese11led in seclion 5.

3. Identifi catio n of Mac hin c Effcctiveness

In order to answer Ihe first research objective. lhe calculation of DEE IS required 10 identify Ihe effectivcness of the

moulding machi ne, T he moulding machine has becn chosen as research la rget due 10 its importance as component pro fil er

that make th is machine has high ehangeovcr ratc. The data used in Ihis analysis is sccondary data collected from

ell

produclion department record. First, the data was processed wi th OEE measureme1ll. DEE is a key performance illde.>; to

measure the effectiveness of the used equipment. plant. or 1l1llchine [5). T he fo n nula ofOEE is shown be low.

Wherein:

A : avai lability (%)

Pe : pcrfonnallce efficiency (%)

Qr : qualit y ralc (%)

OEE=AxP x Q ( I )

t\\'ailability lIleans the actual available time 10 produce goods using A machine. Perfonnance rate shows Ihe products

produced according to the avai lable time. Then the quality ra te concludes the good products produced alo ng Ihe avai la ble

time into OEE score [6]. Each of Ihe fa ctors that compose the OEE formula can be calculated by processing production

d:lIa and machine cond ition .

A =OT+ POT

(2)

Wherein :

OT : opcrat ing time (minutes)

POT : planned opcrating timc (minutes)

All t\pplication of Association Rule /'o,'lining in Towl Productive Ml,intemlnce Slrmegy: An Analysis and Modelling in Wooden ])oor Manut:1clu ring Induslry

Pe

=

RRR + I RRWherein :

RRR : real nUl rate (pieces/minutes) IRR : ideal mn rute (pieces per minutes)

Wherein:

GP : good product (pieces) Til : 10lal producl (pieces)

Qr=GP +TP

(3)

(4)

The calcul ation ofOEE shows l!tn t DEE ofC l1 mouldi ng mach ine on ly reac h 51 %, with avai lab il ity 67%, performa nce

80%. and qual ity 98%. The comparison between Ihe calcu latio n result wi th lIIa nu f.,c turing company avemge in the world

and world-class standard defined by JIPM in Figure 2. shows tlmt DEE in

ell

cannot rcach world avemge mainl y due to its availabil ity. To find out the causes of this availability. a Si:ot-Big Losses assessment was conducted using data of 12 days records 3S sample. P3Teto cl13rt tha t shows this assessmellt result shown in Fig ure 3 .,

> •

:: "

'"

(I) p

",

,

..

,

s

],

" "

III ,

fゥ ァ オイ セ@ 2. D Et: COIll ]lariso n c hart

LセB@ GNGセN@

,

..

"

,

.

.,..

"

-,

セ@""

,,,.'

.,

f

セ@"

,",

;,.,..

, .... ..,. !oJ1" O... ...., ••.••• " セ@.. '.,,' ., .. ; " .... ' .." .. " .... "!oJ " ' ."" gu r e J. Six-Big lones " a relO c har t

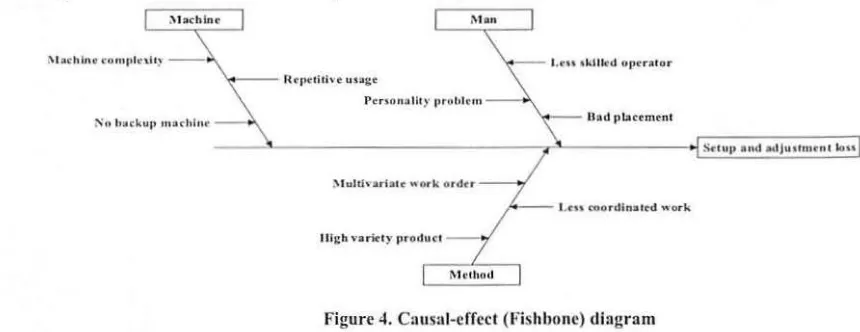

Bascd on these assessmcnt. main c:luse of availability loss in Cllmoulding machi ne (about 73%) is setup and adjust-ment loss usnally caused by stoppage due to pre-product ion set-up or cllilllgcover while in product ion time. or in lit is case as adjustment lime for clmnging cUller blade in moulding machine to lit de manded doo r componenl specification. A lishbone diagram to identi fy lhe source o f llle problem of setup and adj ustmelllioss is shown in Figure 4.

セ i@. .

'-- - 1

... ';.I ...

u."l:<" • .,Oft.II.,· ,,,.10, .. ,,

-.1

sN Gセ iG NBB@ .. i ェセBュオG@ ...1

[image:11.600.71.501.522.688.2]iN セ@... 'dlft . .. d ... 1<

Figure 4. C ausal-effect (Fishholle) d iag ram

OEE calculatioll. Six,Big Losses :ISseSSlllcnt. and source problem identification using fi shbone diagralll was aimed to identifying used machine condition. and provide a better visualization of current machine slate. In the ne.-.;t phase of Ihis research. a strategy to resolve the sollllion of this condition was developed using data processed in this phase and pro-cessed with ARM.

An Application o f Assoc;at;oll Ru le 1'. li ning in Toml I' roduetivc Maintenance Strmcgy: An Almlysis lind Model ling in Wooden Door Manufacturing Industry

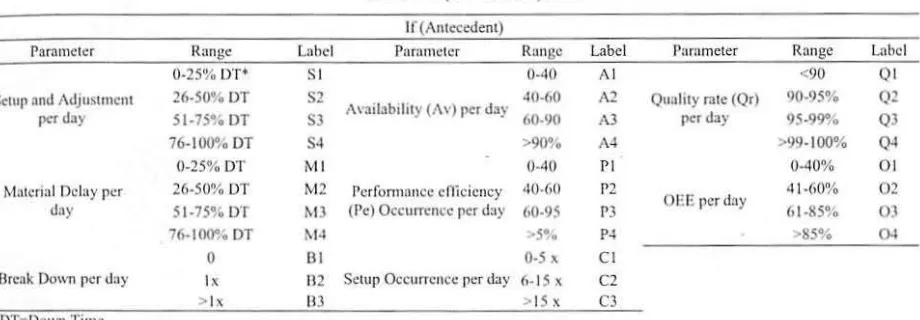

4. Associ;ltion Ru le M inin g

The second phase of this researc h is deve loping mles using AR1111. AIt!\-1 sta rt with mi ning frequent itellls with their sup port values using freq ucnt item mining :tlgorithm like Apriori algori thm. T his algorithm works over numeric or non -numeric da ta because the da ta itscl f wi ll be conve rted into code [4]. All of the attributes wcre pre-processed with di screti· zation in a certai n range. Measumble par;Hlleter like DEE measurement result was converted into an tecedent code. while res ponse ac tivities cOllve rted imo consequent code. The data of each attributes was compiled and converted into di screte binary data. Then. aftcr combin ing the item-sets to co mbination 2·i tcIII sets up to 4· itel11 se ts. Apriori algorithm formed candidate item set, the n it generated large item set consist of mles [7J. Each combination generally called as transaction.

To case the combinat ion process using Apriori algorithm. every att ributes has been grouped into certain r;lIlgc and labeled through disercti.lation. Di scretization. also ca lled binning. cOllverts numeric attributes into categorical o nes. Di s· crctizat ion c:m also heIr in reducinti the numbl!r of values for an attributc, especblly if there is noise in the numeric measurements \4]. The nleasurable parameter of 11loutdiug machi ne has been de termined as mle antecedent. while re-sponsc :Lctiv ities ofC llmanagclIlcllt has bee n determined as ru le consequent.

T a bl e I H (A nt ecede nt ) 1:lhe l If(Amcredent)

l'ar:lInelcr Run ge Lnbel I'n rJrnclcr R:mgc Label j^ セイョ ュ」エ・イ@ lhuge l..llbcl

oᄋRUセ N@ DP SI 0·40 AI <90 01

Setup and ,\ dJU5trnent 26·50" . DT 52 セP ᄋVP@ A2 Onallty rollC (Or) 9Q·9S%

02

pI.'f 、セI@ 51·75'. DT SJ AI·;ulab,hty (A\')]'("f 、Sセ ᄋ@ "'·90 AJ pt'f d:Ly 9S·m. OJ

WVᄋ|セ N d t@ 54 >9M.

'"

>99·\00"/. Q-O0·2S% DT "I 0·40 PI 0·40% 01

Mal cria tlld:Ly pef 26·50"/0 DT 1'-12 !'crfonna ll cc effi cie ncy 40·(j\J P2 4\·60% 02 day SI·75'. Dr MJ (I'e) Occnm:ncc]'("r 、。セ G@ 60·95 Pl O EE Ilcr day V}ᄋXs セN@ OJ

76·\O<r.. DT 1'-1-l ^sセN@

"

>850 • Ol0 " I 0·5 x CI

nrcak [)oUT! ]ler day I, 11 2 Se tup Qc,urrence I"'f ,b y ('·IS セ@ C2

>1, IIJ > tS セ@ CJ ' DT" ])o\\T! Tim e

[image:12.598.64.524.278.438.2]The used attribute in anh .. "Cedem code is determined according to the DEE calculation of field data. While accordi ng to the requireme nt analysis using fi shbone diagram in previous phase. the response target has been determined into thrce object: the moulding machine itsdf. the machine operator. and the used mcthod included thc implemented production stra1egy. The response acti vit ies has bcen classified by definin g the source prob lem into an ac tionnble activit ies. as pre-sented in Table 2.

Table 2 Thl'll ( co n Sl.'Il lI l.' n t ) Ill hel TIleu (Conscqucm)

ResporlSc Illrgcl ItI:spome aCli\'itic$ Label

Targclro Machine Moniloring Xt

Machinc Full Performance Monitoring X2

I'tanlled Ma inlC:nanee XJ

Opennor E\,alu:Ll1on VI

1'-bn OperalOr Shifting Y2

Operator Training YJ

イイゥ ッイゥ エゥ セ・@ One T ype PmdLLcl ZI

Met hod WOfI;·Order E,·a lu:Llion Zl

MUl1agcmCTII 1'-kctmg Zl

The resu lt of discretizatio n then has been rep resented in binary database. A binary database is a bi nary relatio n OJlthe SCt of tids (transaction identifie rs) and items \4]. Ifce rtain value in an attributcs has been qualified into certain disc re te the va lue wi ll be represcnted as tnte value ( I). while the rcst of other range will get fal sc value (0). The example bi",,,. lObi, is presented in Tab le 3 .

Availabil ity 65% 74% 53% 81% 55% 84%

An Application of Association Rule セ G ャゥ ョゥョァ@ in Total Produc tive Maintenance Strategy; An Analysis and Modelling in Wooden Door M3nufacturing iョ、オ セエイケ@

T:lble 3 Availability score rCJlrcsented in bilmry tahlc

0·40 40-60 60-90

0 0

0 0 I

0 I 0

0 0 I

0 I 0

0 0

>90% 0

0 0 0 0 0

To generate the ru les, each antecedent has been combined with consequent, with limitation 4-sel combination. The example ofantecedenl-conscquel1t combination is presented in Tab le 4. The resu lt of this combinat ion is 30228 rules.

Tuble 4 Cil mhiualillll of:llltcccdcnt ,\ -I'-Q :Iud consctlu cn t X- Y-Z

2-sel combinalion 3-scl combination 4-sel combinalion

A I----X I A I-PI_XI A I-PI-Ql-X I

AI-YI A I-P2_Y I A I-P I-Q2 - YI

A3-Z3 A3-Q3-Y3 A3-P3-Q3-Z3.

Although there arc ma ny rules obtained, most of the rules were discarded or e li minated due to their low value with nIle assessment. Rule assessment is a method consist ufdi ffen:nt rule interestingness measures to quanti fy the dependence betwecn the antecedent and conSC<luent [8]. There are 4 measures lIsed in thi s assessment : support . contidenee, lift. and bond. As example an association rule X _ Y , where X is anlt!cedcllt and Y is consequent . the support (sup) of til is nile is defined in (5), With It(XY)1 is a total of transaction contain both X and Y in a combinat ion, Relati ve support (rsup) or support value compared relatively to the size of da tabase was defined in (6), wi th IDI is a total of tra nsaction in databasc.

sup (X _ Y)

=

Stlp( X n Y)=

IIXYIr sup (X _ Y) = sup{ X n Y) II DI

(5)

(6)

Confidcnce (crm/) of a nI le is the cond itional probability that a transaction contains the consequent Y given thai it contains the ,lIltecedent X.

conf(X --> Y)

=

s up (X n Y)/SIlIl (X)(7)

Uft ofa rule is a ratio of the observed joint probability of X and Y to the expected joint probability if they were statistically independent.

Iift{X - Y)

=

cOllf{X - Y) /Sllp (Y)(S)

Bond shows the strength of ile m SCI wilh comparing conjunctive (combination contain only true value) and disj ullcti\'c (Iotal of all combination) of each tmnsaction.

bond(X _ Y) = COlljzHlC(X n Y) / ciisjzmctive(X n Y) (9)

Usi ng trial and error method, the user threshold has been determined. The minimum relative support. confidence. lift, and bond used in thi s research is 0.2, I, 2, and 0,2. By using this threshold, the rule assess ment was resulting 83 qualified mles. Table 5 below shows the summary of top 10 <Jualifi ed nIles ranked by bond,

Tallie 5 TUII 15 fUIeS nll1kt'd h y bond

If('\Ulcccdcnt) 'nlen (Consequent)

oi'. ,s'P Conf

lin

Bondt- Condition 2" Condition )'# Condilion Rcsponse

0.25 1,00 2,22 1.00 OE[-I0-6O% Work-Order r:.valuation

2 0,30 1.00 3,33 1.00 OEE 60·SS% One-TyJlC FocIIsiug

Production

3 0,30 1,00 4,00 1,00 OEE <40% Management Meeting_

,\n Application of Associntion Ituk セiゥョゥョァ@ III Total I'roducti\c セiZャゥョエ・ョ。ョ・」@ Strlltegy:

An Analysis and セ ャ ッ、・ャャゥョァ@ in wooden Door セ ャ 。ョ|ャヲS・エオ イ ゥョァ@ Industry

4 0,30 1,00 2,22 0,67 Setup Occurrcnce I· Targctcd f.,·l:Ichinc

5, mOnitoring

5 0.30 1.00 2.50 0.63 a|GTPᄋVセ N@ I' lanned l\laintenancc

6 0.30 1.00 2.22 0,57 SCHIP Occurrcncc 6· OEE TPᄋHLP セオ@ Work·Order EVllluation

15x

7 0.30 1.00 J.J3 0,50 i\\' 6O·H5% OEE fiO·R5% One.Type Focusing l' nuluctio n

,

0.30 1.00 2.22 0.50 SC\UI}OCcurrcncc I· 5, OEE60·85% Tnrgctcd Mac hincmon itoring

9 0.30 1,00 2.22 0,44 Pc 60·90% OEE40·60% Work·Order [ \':llu:uiol1

10 0.30 1.00 2.22 0.42 ScUll' Occurrence I· 5, A\' 6O·R5°o T:lrgek'd Machine

monitoring

5. Mai nt cn:lIl cc S trat cgy Dcvc lop ment

Using 83 qualified nIles from AR1 ... 1 compm:uion, a model ofl1lainten:lI1ce strategy was developed. Basicall y. three types of 1ll3inten:mce exisl. n:lI11ely correcth'c. pn!\·entive. and prcdicti\'e mainte nance. In this model. the antecedent of the n Iles consists of me as umble pammeters that desc ribe the machine condition. up to three condition. while the consequent of the ru les consists of responds to be laken if the condition in antecede nt was occurred.

For instance, if cond ition of the mac hine. in Ihis case mou lding mac hine. was showed OEE v:tlue 40·60% . the n Ihe manage ment shou ld conduct a work-o nler evaluatiotl. OEE wi th v:l luc below 60% is lower thu ll world average OEE.

ManufacllL ring company with high changeover rate like

ell

maybe has low OEE due to the current work -order. So, toprevent further decreasing in O EE value, the work·orde r should be eva luated.

Based 011 this model. improvemenl o fT Pr ... 1 strategy in C ll is expected. Usi ng the model as" 1001 to he lp in dec isioll lllakin g process, ma nage ment orC lI c.lII ll1ake :l decision easier to solve machine·related prob lems wi th consi dering th l.!

qualifie d rules. T he imp lementation o r A RM to develop TI' M stra tegy is ve ry potent ial. To imple metH A RM model to

develop T PM strategy fo r olher machi ne in

ell

o r even itt another rn anutheturing company, the manage ment can changeused all ributes and d:lla in ARM so it w ill generated n tles tha t fit and su it wilh the machine comlition itse lf. The ad vantage ofthi 5 model is ge nerated dynamic n Iles thaI always updated by the d:Ha changi ng comparing to othe r Slratcgy

develop-ment tool like Analytic Hierarchy Process tha t uses slatic da ta (21. Besides that. as one of data mi ning techniq ue. the

implementation o f AR.M to the T N ... I is a right choicl.!. due to its ability to handle big-data with high \'eiocity and \'olume thaI is ge nl.!r:ued by mac hine condi tion.

6. Conclu sio n and Rccomm cnd at ion

This paper presents a novel implementation o f data mining techniques \0 solve real indust ry proble m cspeciall y in

ma-chine mai nte nance in a woode n door manufaeluring industry targe ting moulding mama-chine. The OEE ca lculat ion of mould· ing mac hine shows a machine availabili ty loss due to low cflcctive ness caused by high setup and adjustment loss. The deployment of A RM usi ng a' priory algo rithm and ge nemtes 30228 if-then niles. Rule assessment has conducted to quu l· ify niles using user threshold to limit s upport, confidence. li ft . and bond valuc which res ulted 83 qualified mles for pre-dicti ve maintena nce strategy. As recommendation. the model itse lf call be mounled 10 software. Using if· then m les ge n-erated by ARM . an if·e lse looping algo rithm can be deve loped 10 11I0ullt the model to the so ft wa re of mobil e apI's to ma ke it morc user-friendl y, ne:< ible, and increase the usabil ity. The OEE measuremcnt ,lIld d:tta acquisition im prove d by USing sensor in the m .. chine.

7. Refcrenccs

II J S. Nak:ljinm. "Introd uction to TI' M: Total Prod uctive j\·taintcn:lI1ce:· I'roduetivit)'. Ponland. 1988.

{2] P. Bantos. l. Lopes. and L. PireS."A maintenance prediction S)'StI.!1l1 using data mining techniqucs:'l'rocf.'cdillgsojthe H'm-ld

COI/gress Oil £IIgil/eerillg 1011. Vol II!. London. Jul y 4-6. 2012.

T. Ahmad, S. M. Ali, M. M. Allam:t. and M.S. ParYCl. "A T01:lII'roducti\'c Maintenance (TPj\'I) approach to impro\'ccou ld Ix:

impro\'cd production efficienc), and dC \'elopment ofloss stnlcture in a phamlttCClnieal industry:' Glob(ll JOIi/"iW/ oj Mallagemf.'lIt

An Application of Association Rule Mining in Total Producti ve Maintenance Strategy: An Analys is and Modelling in Wooden Door /I.'b nufa(;turing Industry

[4] M. Z:lId, and W. Meira, "Data Mining and i\nnlysis: Furu\:nnelllni Concepts :Inti ;\Igorithln," Cambridge Univcrsi ty, Carn.

bridgc, 20 14.

[5] D. Mc C:t rthy, and N. Rich. "Lean TI'M : A J3hl(;print for Cha nge," Elsevier, Ox ton\, 2004.

[6J S.A Kumar. and N Surcsh, "Pro<!u(;tion and Operations M:magcmcnl: with Skill Developmen t, Caselets and Cases:' New Age

Intemalion:ll. New Delhi. 2008.

[7J R. Agmw;tl, and R. Sribnt, "Fast algorithms for mining association mles:' l'I"occctlillgs oj thc 20111 IIII('mllfiOlwl Conjen'nce

OIl Vel ) ' Large D(l1O /J(lSe.I·, September 1994 , pp. 487-t99.

[!:IJ G. l. Webb. "' Discovering Significant n Il es," PnJccedings oj Ihe 12th tlCM SIGKDD inlem(ltional conjen:llcc 011 Knowledge

discol'!!/)' alld datct lIIinil/g. 200(), pp. 434--443.