A STUDY ON MANUFACTURING INFORMATION

REQUIREMENTS FOR ELECTRONICS ASSEMBLY

SOLEHA ROSSDY

UNIVERSITI TEKNIKAL MALAYSIA

MELAKA

A study on Manufacturing Information

Requirements for Electronics Assembly

Thesis submitted in accordance with the partial requirements of the Universiti

Teknikal Malaysia, Melaka for the

Bachelor of Manufacturing Engineering (Design)

By

SOLEHA BT ROSSDY

Faculty of Manufacturing Engineering

KUTKM Library (Pind.1/2005)

SULIT

TERHAD

TIDAK TERHAD

(Mengandungi maklumat yang berdarjah keselamatan atau kepentingan Malaysia yang termaktub di dalam AKTA RAHSIA RASMI 1972)

(Mengandungi maklumat TERHAD yang telah ditentukan oleh organisasi/badan di mana penyelidikan dijalankan)

(TANDATANGAN PENULIS)

* Tesis dimaksudkan sebagai tesis bagi Ijazah Doktor Falsafah dan Sarjana secara penyelidikan, atau BORANG PENGESAHAN STATUS TESIS*

JUDUL: A study on manufacturing information requirements for electronics assembly

SESI PENGAJIAN : 2006 / 2007

Saya SOLEHA BINTI ROSSDY ________________________________

mengaku membenarkan tesis (PSM/Sarjana/Doktor Falsafah) ini disimpan di

Perpustakaan Universiti Teknikal Kebangsaan Malaysia (UTeM) dengan syarat-syarat kegunaan seperti berikut:

1. Tesis adalah hak milik Universiti Teknikal Malaysia Melaka.

2. Perpustakaan Universiti Teknikal Malaysia Melaka dibenarkan membuat salinan untuk tujuan pengajian sahaja.

3. Perpustakaan dibenarkan membuat salinan tesis ini sebagai bahan pertukaran antara institusi pengajian tinggi.

4. **Sila tandakan (√)

(HURUF BESAR)

APPROVAL

This thesis submitted to the senate of UTeM and has been accepted as partial fulfilment of the requirements for the degree of Bachelor of Manufacturing Engineering (Design). The members of the supervisory committee are as follow:

………. Main Supervisor

(Mr Hafidz Fazli b Fauadi)

……… Co-Supervisor

DECLARATION

I hereby, declare this thesis entitled “A study on Manufacturing Information Requirements for Electronics Assembly” is the result of my own research

except as cited in the references.

Signature : ………. Author’s Name : Soleha bt Rossdy

ABSTRACT

In a manufacturing company, managing information is important. It is

involved of gathering data or information from the process before develop a

computerized system to store the data. Therefore, this project highlights three main

objectives, which are: to study the information requirements for underlying decision,

planning and operation for electronic assembly manufacturing, to design the

information requirements and to develop a database management system for the

assembly process. The study was conducted in an electronic factory, Cubic

Electronic Sdn Bhd (CESB). The study focuses on surface mount technology (SMT)

assembly, Manual Insert (MI) assembly and mechanical assembly (MA). For this

project, IDEF was selected as the methodology in modelling the functional and

information requirements. Microsoft Access is used to design database for the

designed model. The study has successfully achieved the objectives and may be as a

ABSTRAK

Dalam sebuah syarikat pembuatan, penyusunan data-data adalah penting. Ia

melibatkan pengumpulan data dari proses yg terlibat kemudian membangunkan satu

sistem yang meyimpan data dan boleh memanggil data jika dikehendaki. Oleh itu,

projek ini menekankan beberapa objektif di mana untuk mengkaji data-data dalam

membuat keputusan, membuat rangka kerja dan proses yg terlibat dalam pemasangan

alat elektronik di kilang yang dikaji merekabentuk data yang diperlukan dan

membangunkan sistem pangkalan data untuk proses pemasangan alat elektronik.

Kajian ini dilakukan di sebuah kilang elektronik , Cubic Electronic sdn bhd (CESB).

Fokus kajian adalah berdasarkan teknologi pemasangan surface mount technology

(SMT) dan pemasangan secara manual dan mekanikal (MIMA). Dalam projek ini,

IDEF telah dipilih sebagai kaedah dalam permodelan data. Pembangunan sistem

melibatkan penggunaan Microsoft Access dalam merekabentuk sistem pangkalan

data yang telah dianalisis. Sistem ini adalah praktikal untuk digunakan namun

beberapa batasan telah dibincangkan sebagai penambahbaikkan untuk masa akan

DEDICATION

ACKNOWLEGDEMENT

Bismillahhirrahmanirrahim,

Assalamualaikum w.b.t. and warm greeting

First of all, thank to ALLAH SWT for His blessings and for the strength given to

complete this Project Sarjana Muda (PSM) – I and II.

The author would like to thank to:

1. Mr. Muhammad Hafidz Fazli bin Md Fauadi, project supervisor for his

guidance, encouragement, wise suggestion and discussion, patience and

support in this project.

2. Mr. Zaimi Zainal as the second panel of this project and the cooperation he

gave.

3. Pn Yusnita Yusof and all the staffs in Cubic Electronics sdn bhd (CESB) for

the cooperation in sharing the information about the company.

4. Friends during Industrial Training – Nabila, Lim Pierre June and Voon for a

helpful hand and information about manufacturing assembly in CESB.

5. Yumi, from Information Technology faculty, University Technical Melaka,

Malaysia (UTeM) for knowledge gave and shared.

6. Fellow friends and housemates – for all assistance, motivation, courage and

time that we spent together.

TABLE OF CONTENTS

1.3 Objectives of the Research 4

1.4 Scope of Project 4

1.5 Advantages of the project 4

1.6 Project Methodology 5

2.4.1.3 Advantages & Disadvantages of IDEF 12

2.4.2 Object Oriented 13

2.4.3.2 Entity Relationship 17

2.5 Previous Development of Information System for Electronic

Manufacturing Industry 19

2.5.1 The effects of information system infrastructure and process

improvements on supply-chain time performance 19

2.5.2 An empirical study of business processes across Internet-based

Electronic marketplaces: A supply-chain-management perspective 20

2.5.3 Business process improvement through electronic data interchanges

(EDI) systems: an empirical study 22

2.5.4 Electronic trading in the supply chain: a holistic implementation

Framework 24

2.5.5 Linking warehouse complexity to warehouse planning and control

structure an exploratory study of the use of warehouse

management information systems 25

2.5.6 Manufacturing integration strategy using MRP II and RTMs:

a case study in South China 27

2.6 Web-based Application in Manufacturing Industry 30

2.6.1Virtual factory: an integrated approach to manufacturing systems

Modeling 30

2.6.2 Product data management based on Web technology 32

2.6.3 Proton PDM 33

2.6.4 Engineering requirement management system: A PLM Strategy 34

2.6.5 Knowledge Based Engineering Practice – TATA Consultancy

Services 34

2.6.6 Mattel Tooling Development Sdn Bhd 35

CHAPTER 3.0 CUBIC ELECTRONIC Sdn. Bhd. (CESB)

3.1 Company’s background 38

3.1.2 Factory wide build up area 39

3.3 Manufacturing Process in CESB

3.3.1 Introduction 46

3.3.2 Overall Manufacturing Process 49

3.3.3 SMT Process at CESB 49

3.3.4 MIMA Manufacturing Process 57

4.2.2 Identify objectives and scope of the projects 64

4.2.3 Literature study 64

4.2.4 Define generic function and information 64

CHAPTER 5.0 SYSTEM ANALYSIS & DESIGN

5.1 Introduction 67

5.2 System Advantages

5.2.1 Functional & Information Model Advantages 68

5.2.2 Database Advantages 69

5.3 Functional Model 69

5.3.1 Sound Blaster Manufacturing (A0 Level) 70

5.3.2 Sound Blaster Manufacturing (A1 Level) 71

5.3.3 Model Layout (A1) 72

5.3.4 Surface Mount Technology, SMT (A2 Level) 73

5.3.5 Manual Insert & Assembly, MIMA (A3 Level) 78

5.3.6 Testing (A4 Level) 82

5.3.7 Packaging (A5 Level) 83

REFERENCES 102

APPENDICES A

APPENDICES B

LIST OF FIGURE

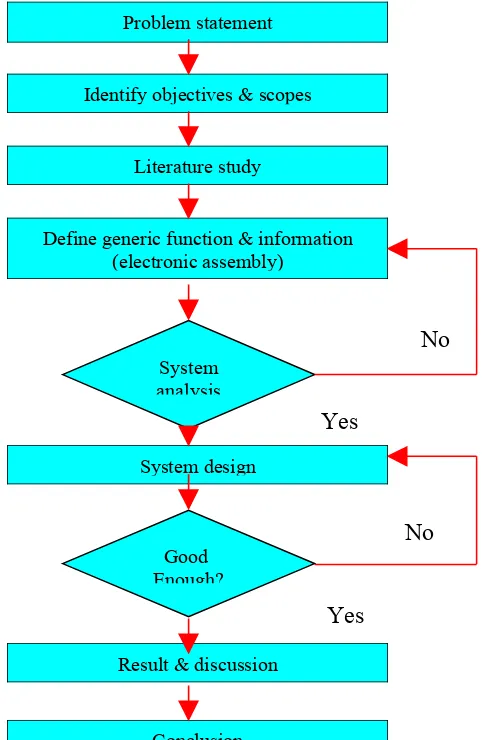

1.0 Project Methodology 5

2.0 Modelling Methodology 9

2.1 IDEF Box & Arrow Graphics 12

2.2 Object Oriented Road Map 14

2.3 An example of Yourdon system methods 15

2.4 An example of ERD (Yourdon system method) 17

2.5 Yourdon system methods, model driven methods, 1993 18

2.6 A model linking information system infrastructure, process

improvement and their interaction to supply-chain

time-based performance 20

2.7 A general supply-chain- management model 22

2.8 Research model – the relationship between EDI networks

and BPI with moderating effect of information intensity

of the industry. 24

2.9 Framework for assisting with the change towards

electronic commerce 25

2.10 WMS in relation to other management information and

technical systems 26

2.11 Integrated manufacturing system 28

2.12 IDEF design of MRP II and shop floor integration 29

2.13 Virtual factory model 31

2.14 Role of virtual factory during operations 31

2.15 An example of basic PDM data structure 32

2.16 The logical relationship of data in a PDM system 32

2.17 Product Data Management (PDM) 33

2.18 System Decomposition Diagram 36

2.19 IDEF functional model for mold making process 37

3.0 CESB Building 38

3.1 Building plan 42

3.2 Main organization in CESB 43

3.3 Manufacturing organization 43

3.4 MO1 Organization 44

3.5 MIMA Organization 45

3.6 Schematics Production MIMA/ICT 45

3.7 Process Flow in SMT 46

3.8 Process Flow in MIMA 47

3.9 Process Flow in FT 48

3.10 Process Flow in Packaging Department 48

3.11 Overall Manufacturing 49

5.0 Sound Blaster Manufacturing (A0 Level) 70

5.1 Sound Blaster Manufacturing (A1 Level) 71

5.2 Model Layout 72

5.3 Surface Mount Technology (SMT) 73

5.4 Screen Testing 74

5.5 Chip Mount 75

5.6 Integrated Circuit (IC) Mount 76

5.7 Oven 76

5.8 Testing 77

5.9 Manual Insert & Assembly (MIMA) 78

5.11 Wave Soldering 80

5.12 Mechanical Assembly 81

5.13 Visual Inspection 82

5.14 Testing 83

5.15 Packaging 84

5.16 Information Model of Sound Blaster manufacturing in CESB 85

5.17 System Flow Diagram 86

5.18 Front Page of Database System 91

5.19 Form of Production House in CESB 91

5.20 Surface Mount Technology (SMT) Form 92

5.21 Screen Printing 92

5.27 Machine used in MIMA Line 95

5.28 Wave Soldering 96

LIST OF TABLE

3.0 SMT Machine 51

3.1 Type of IC package use in CESB manufacturing 54

3.2 Product that running in each line 57

CHAPTER 1

INTRODUCTION

1.1 Introduction

The electronics sector, with it’s approximately $1 trillion world-wide market

volume, promises to create the highest employment in the 21st century – Foreign

Trade of Turkey (2004). Now, the electronics industry is no longer a branch of

manufacturing industry anymore, but rather has become a basic and prolific industry

itself developing all other industries.

Electronics industry includes the manufacture of passive components

(resistors, capacitors, and inductors), semiconductor components (discrete, integrated

circuits), printed circuit boards (single and multilayer boards) and printed wiring

assemblies.

In printed circuit board (PCB) manufacturing there are three types of boards:

1. single sided (circuits on one side only)

2. double sided (circuits on both sides)

3. multilayer (three or more circuit layers)

Board manufacturing is accomplished by producing patterns of conductive

material on a nonconductive substrate by subtractive or additive processes. (The

conductor is usually copper; the base can be pressed epoxy, Teflon, or glass.) In the

surface preparation of the base, electroless copperplating, pattern printing and

masking, electroplating, and etching.

Printed wiring assemblies consist of components attached to one or both sides of

the printed circuit board. The attachment may be by through-hole technology, in

which the ”legs” of the components are inserted through holes in the board and are

soldered in place from underneath, or by surface mount technology (SMT), in which

components are attached to the surface by solder or conductive adhesive. (The solder

is generally a tin-lead alloy.) In printed circuit boards of all types, drilled holes may

have to be copper-plated to ensure interconnections between the different copper

layers. SMT, which eliminates the drilled holes, allows much denser packing of

components, especially when components are mounted on both sides. It also offers

higher-speed performance and is gaining over through-hole technology.

1.2 Problem Background

The efficient coordination of design and production activities is a key

challenge faced by all manufacturing companies. The lead time to introduce new

products and ramp-up production has a major impact on the responsiveness of a firm

to market change and thus, its profitability.

Apart from studying the data requirements, manufacturing decision and

planning problems, this paper would discusses the benefits of an efficient Database

Management System (DBMS) in term of the improvements in production time,

engineering time and the product or process quality. Finally, future trends for DBMS

will be given.

ICT is a generic term covering computers, broadcasting, telecommunications,

data networks and smart components which are being increasingly applied in diverse

uses. It can be defined as the totality of the electronic means to collect, store, process

computer systems, data communication systems, knowledge systems, office systems

and consumer electronics.

ICT allows trade to become simpler and more streamlined, thus increasing

the value and speed of transactions. One major advantage of promoting electronic

commerce is that it can provide relatively cheap access to global markets even for

small and medium-sized enterprises in remote areas. The globalization of production

and componentization of production units through the use of ICT focuses attention

on the infrastructural and governance conditions and institutions within a country.

The expanding range of applications of information and communication

technology (ICT) which helps to increase the efficiency and flexibility of production,

marketing, financial and administrative activities for both the private and the public

sectors presents new multifaceted and important complications for governments.

These applications offer enormous opportunities to enhance the competitiveness of

industry, increase the returns from trade, attract foreign direct investment and other

forms of external capital, increase the integration of small and medium-sized

enterprises into the value chain, and enhance the service provided by the financial

sector.

Almost every aspect of society is affected by ICT. Manufacturing industry

uses ICT to control and plan production thus providing us with cheaper goods. As for

example, Computer Aided Design increases productivity of design staff and allows

costing and production scheduling to be modelled before production is undertaken.

This can be developed into Computer Aided Manufacturing where the actual

1.3 Objectives of the Research

a) To study the information requirements underlying decision, planning and

operation activities for electronics assembly task.

b) To design the information model for electronic assembly.

c) To develop a database management system (DBMS) to support electronic

assembly process

1.4 Scope of the Project

a) One electronics assembly methodology will be chosen, for example SMT

(surface mount technology).

b) The study will be conducted based on a case study company.

c) The DBMS will be a PC-based system

1.5 Advantages of the Project

The future vision of manufacturing evolution reveals the importance of

implementing integrated information systems. This system is build to provide a

measure of all production flow components in terms of design, reject, efficiency,

time, and productivity. The reports created in the database offer a complete image of

the production cycle. We can use this to identify problem occur successfully engineer

new products and re-engineer existing ones. Sharing a unique database for all

company applications is an important milestone towards implementing e

manufacturing.

The system can trace the history of any product along the assembly flow at

line, cell, or operator level. The system wills overview assembly flow, offering

reference. It can also use traceability to detect problems in the delivery chain, and

reject during assembly parts.

1.6 Project Methodology

Figure 1.0 is for Project methodology, the further description will be discussed in Chapter 4.

CHAPTER 2

LITERATURE REVIEW

2.1 Introduction

In this chapter contain elements of the project. It describe about assembly

practices in company process flow, the information system requirement, analysis of

system methodology, previous development of information system and web based

application for electronic industries.

2.2 Electronic Assembly Process

An assembly line is a manufacturing process in which interchangeable parts

are added to a product in a sequential manner to create a finished product. The

assembly line was improved largely by Henry Ford and his engineers; Ford was also

the first to build factories around the concept. It usually consists of each worker in

control of one specific job and their work related movements are reduced to a

minimum.

In the field of electronics comprises the study and use of systems that operate

by controlling the flow of electrons (or other charge carriers) in devices such as

thermionic valves (vacuum tubes) and semiconductors. The design and construction

of electronic circuits to solve practical problems is an integral technique in the field