BAB 6 KESIMPULAN

6.1. Kesimpulan

Suhu stress relieving yang digunakan alternatif 8 adalah 6500C. Holding time stress relieving yang digunakan alternatif 8 adalah 180 menit. Holding time pendinginan stress relieving yang digunakan alternatif 8 adalah metode slow cooling. Suhu pre-heating yang digunakan alternatif 1 sampai dengan alternatif 8 adalah 5000C. Suhu austenitizing yang digunakan alternatif 1 sampai dengan alternatif 8 secara berturut-turut adalah 8500C, 8500C, 8500C, 8100C, 8100C,

8100C, 8500C, dan 8500C. Holding time austenitizing yang digunakan alternatif 1, 2, 3, 4, 5, 6, dan 8 adalah 7 menit. Alternatif 7 menggunakan holding time austenitizing 7 menit + 30 menit. Media austenitizing yang digunakan alternatif 7 adalah arang, sedangkan alternatif lainnya tidak menggunakan arang. Media

quenching yang digunakan alternatif 1 sampai dengan alternatif 8 secara berturut-turut adalah oil, water, water-oil, oil, water, water-oil, water-oil, dan water-oil. Suhu tempering yang digunakan alternatif 1 sampai dengan alternatif 8 adalah 2000C. Holding time yang digunakan alternatif 1 sampai dengan alternatif 8 adalah 1 jam. Hasil kekerasan alternatif 1 sampai dengan alternatif 8 secara

berturut-turut adalah 47 HRC, 56 HRC, 54 HRC, 51 HRC, 59 HRC, 55 HRC, 54

HRC, dan 57 HRC.

Penerapannya penulis dan pihak Politeknik ATMI Surakarta lebih memilih

alternatif 3. Pertama, kekerasan yang diperoleh sudah cukup mendekati data

BOHLER dan hasil tersebut masih masuk dalam toleransi nilai kekerasan yang

digunakan di Politeknik ATMI Surakarta, yaitu ± 2 HRC. Hasil kekerasan yang

diperoleh hanya berbeda sedikit dari hasil alternatif 6. Kedua, penghematan

waktu proses dan penghematan listrik penggunaan oven juga menjadi

pertimbangan terbesar untuk memilih alternatif 3. Ketiga, resiko material

mengalami crack juga menjadi minimal karena ada penurunan laju kecepatan pendinginan. Ketiga alasan tersebut menunjukkan bahwa alternatif 3 dipilih

sebagai alternatif terbaik agar hasil penelitian ini semakin riil mendekati kondisi

sebenarnya di lapangan.

namun apabila terdapat material/produk dengan desain yang kritis (memperbesar

DAFTAR PUSTAKA

BOHLER. Special Steel. PT. Bhinneka Bajanas (Distributor) : Jakarta.

Brammer, P., Mauvoisin, G., Bartier, O., Hernot, X., & Sablin, S.-S. (2011).

Influence of sample thickness and experimental device configuration on the spherical indentation of AISI 1095 steel. Journal of Materials Research, 27(01), 76–84. doi:10.1557/jmr.2011.247

Clarke, K. D., Van Tyne, C. J., Vigil, C. J., & Hackenberg, R. E. (2011). Induction Hardening 5150 Steel: Effects of Initial Microstructure and Heating Rate. Journal of Materials Engineering and Performance, 20(2), 161–168. doi:10.1007/s11665-010-9825-8

Creswell, J. W. (2010). Research Design Pendekatan Kualitatif, Kuantitatif, dan Mixed. Hal 3-28 dan 304-324. Pustaka Pelajar : Yogyakarta.

H.M., Jogiyanto. (2008). Pedoman Survei Kuesioner (Ed. 1). Hal 169-175. Badan

Penerbit Fakultas Ekonomika dan Bisnis UGM. Yogyakarta.

Kuscu, H., Becenen, I., & Sahin, M. (2008). Evaluation of temperature and properties at interface of AISI 1040 steels joined by friction welding. Assembly Automation, 28 (4), 308 – 316. doi: 10.1108/ 01445150810904468

Rajan, T.V., Sharma, C.P., dan Sharma, A. (1994). Heat Treatment-Principles and Techniques (Ed. 4). 1-3, 97-122, 238-240. Jaipur-India: Prentice Hall of India.

Raygan, S., Rassizadehghani, J., & Askari, M. (2008). Comparison of Microstructure and Surface Properties of AISI 1045 Steel After Quenching in Hot Alkaline Salt Bath and Oil. Journal of Materials Engineering and Performance, 18(2), 168–173. doi:10.1007/s11665-008-9273-x

Shin, H. S., Kim, S. W., Kim, H. P., & Park, J. K. (2009). Effect of Decarburization Heat Treatment and Chromium Addition on Corrosion Behavior of Carbon Steel, (May)

Lampiran 1

Rekapan Data Pengerjaan S45C Selama 1 Tahun Terakhir di Politeknik ATMI Surakarta

Tgl. Order number Customer Material Item

name

Quantity Hrc dwg.

Austenit Holding time

Media quench

Temper Hrc

result

Weight

13.09.13 EODU130458 Indofood

CBP Sukses

S45C As

Vertical Sealed

1pcs 45 2 850 5 menit Water-Oil 320 45-48 2.7

13.08.13 - PT ATMI IGI S45C Ring

M12

30pcs 52 2 850 Water-Oil 200 53-55 0.6

24.07.13 No IP 317 Internal IGI

WI S45C Ring

M16

48pcs 52 2 850 2 menit Water-Oil 200 52-53 2

24.07.13 No IP 308 Internal IGI

WI S45C Ring

M12

10pcs 52 2 850 2 menit Water-Oil 200 54 0.2

11.07.13 EODC120177 Bp Kun

Abidin

S45C Rack

Gear M1 z30

1pcs 45 2 850 3 menit Water-Oil 320 47 0.1

03.07.13 EODC120177 Bp Kun

Abidin

S45C Axle 1pcs 52 2 850 2 menit Water-Oil 200 54-55 0.1

02.07.13 MDC WF 12014 PT ATMI

Solo

S45C Bolt M6 2pcs 48 2 850 1 menit Water-Oil 270 50 -

02.07.13 MDC WF 12014 PT ATMI

Solo

S45C Bolt

M6-2

1pcs 48 2 850 1 menit Water-Oil 270 49 -

03.07.13 STDC 12013 PT ATMI

Solo

S45C Pusher 5pcs

45-50

850 7 menit Water-Oil 270 48-50 11.3

01.07.13 EODC 130079 Antakesuma

Inti R

S45C Pin

Small

1pc 48 2 850 1 menit Water-Oil 270 49 -

01.07.13 EODC 130079 Antakesuma

Inti R

S45C Pin Big 1pc 48 2 850 1 menit Water-Oil 270 50 -

26.06.13 MNDU 13005 ATMI Solo S45C Shaft - 52 2 850 3 menit Water-Oil 200 54 0.1

24.05.13 EODC 120177 Bp Kun

Abidin

S45C Wall L 2pcs 50 2 850 2 menit Press+

Water-Oil

250 52 0.9

Lanjutan Lampiran 1

Tgl. Order number Customer Material Item

name

Quantity Hrc dwg.

Austenit Holding time

Media quench

Temper Hrc

result

Weight

22.04.13 12/SO/IGI/0347 PT Meshindo Alloy Wheel

S45C Spindle

Shaft

1pc

30-35

850 5 menit Oil 200 33 12.8

22.04.13 12/SO/IGI/0347 PT Meshindo Alloy Wheel

S45C Chuck

Loader

1pc

30-35

850 5 menit Oil 200 33 4.2

18.04.13 EODU 130254 Solo

Technopark

S45C Jaw

Plate

10pcs max 850 3 menit Water

-Oil

200 55 10.4

17.04.13 EODU 130249 Rekanesa

Karya Mandiri

S45C Gear

Shaft

1pc max 850 7 menit Water

-Oil

200 54 12

04.04.13 EODU 130223 Tunas

Mandiri

S45C Clamping

Set

8pcs 40 2 850 3 menit Oil 400 37-39 6.7

04.04.13 EODC 120169 Guna Era

Manufacture

S45C Shaft

Pulley

2pcs 45 2 850 3 menit Oil 400 43 0.6

19.03.13 13/SO/IGI/0089 PT Indonesia Stanley Electric

S45C Angular

Block 1

2pcs 50 2 850 2 menit Oil 400 51 0.3

19.03.13 EODC 130034 Santa

Teresia_R

S45C Middle

Shaft

1pc 35 2 850 3 menit Oil 200 31 1.5

18.03.13 EODC 120169 Guna Era

Manufaktur

S45C Main

Drive shaft handle

1 pc 30 2 850 2 menit Oil 550 37 0.2

18.03.13 EODC 120169 Guna Era

Manufaktur

S45C Main

Drive Shaft

1 pc 30 2 850 2 menit Oil 550 31 0.15

18.03.13 EODC 120169 Guna Era

Manufaktur

S45C Shaft

Bearing

2 pcs 45 2 850 2 menit Oil 200 32 0.05

18.03.13 EODC 120169 Guna Era

Manufaktur

S45C Shaft

Bearing

Lanjutan Lampiran 1

Tgl. Order number Customer Material Item

name

Quantity Hrc dwg.

Austenit Holding time

Media quench

Temper Hrc

result

Weight

04.03.13 EODC 120169 Guna Era Manufaktur

S45C Main

Shaft Bear

2 pcs 45 2 850 Flame

harden

Oil 400 45 0.1

01.03.13 EODC 120169 Guna Era Manufaktur

S45C Transport

Shaft 59

4 pcs 45 2 850 3 menit Oil 200 32-37 2.2

28.02.13 EODC 120169 Guna Era Manufaktur

S45C Main

Shaft 51

4 pcs 45 2 850 2 menit Oil 400 45-46 0.1

19.02.13 EODU 130132 Bengkel King S45C Colour

Flange

1 pc 58 2 850 5 menit Oil 250 53 10

13.02.13 EODC 120168 PT Indospring S45C Baut

Bearing

2 pcs 35 2 850 2 menit Oil 550 40 0.1

05.02.13 EODC 120169 Guna Era manufaktur

S45C Eccentric

Bolt Short

2 pcs 40 2 850 2 menit Oil 450 39-43 0.15

05.02.13 EODC 120169 Guna Era manufaktur

S45C Eccentric

Bolt Long

8 pcs 45 2 850 2 menit Oil 400 41-45 0.5

29.01.13 EODU 130081 Bengkel King S45C Couple 1 pc Max 850 5 menit Oil 250 51 9

23.01.13 EODU 130076 Tunas Mandiri S45C Jig 1 pc 40 2 850 7 menit Oil 400 45 6.1

16.01.13 EODU 120822 Dan Liris S45C TCH-B

Right

8 pcs 42+1 850 3 menit Oil 420 41-43 0.4

16.01.13 EODU 120822 Dan Liris S45C TCH-A

Left

8 pcs 42+1 850 3 menit Oil 420 41-43 0.4

11.01.13 EODC 120168 PT ATMI Solo S45C Pin

Stopper

2 pcs 40 2 850 3 menit Oil 400 22-41 0.4

11.01.13 EODU 120822 Dan Liris S45C TCA 90

CM 8L

8 pcs 42+1 850 2 menit Oil 300 45-50 0.4

07.01.13 12/SO/IGI/0510 UNS fak. Teknik mesin

S45C Dies 1 pcs 50 2 850 6 menit Oil 200 38-50 3.7

02.01.13 EODC 120008 PT ATMI Solo S45C Follower

Bolt

Lanjutan Lampiran 1

Tgl. Order number Customer Material Item

name

Quantity Hrc dwg.

Austenit Holding time

Media quench

Temper Hrc

result

Weight

17.12.12 EODU 120866 Atmaja Jaya S45C Double

Gear

1 pc 42 2 850 4 menit Oil 400 45 6.2

03.12.12 12/SO/IGI/0510 UNS Fak. Teknik Mesin

S45C Die Press

Set (Die)

1 pc 50 2 850 5 menit Oil 200 33 3,7

30.11.12 12/SO/IGI/0510 UNS Fak. Teknik Mesin

S45C Die Press

Set (Punch)

1 pc 50 2 850 3 menit Oil 200 31 0,7

21.11.12 EODU 120815 Bp. Herry S45C Spline

Shaft

1 pc Max 850 3 menit Oil 450 48 0,4

24.10.12 EODU 120764 Sinergi Solo S S45C Stripper Plate

1 pc

40-45

850 5 menit Oil 430 43 8,5

19.10.12 12/SO/IGI/0426 UNS Fak. Teknik Mesin

S45C Punch

Holder

1 pc 50 2 850 3 menit Oil 250 51 2,0

15.10.12 12/SO/IGI/0347 PT Meshindo Alloy Wheel

S45C Plug

Gauge

1 pc

40-45

850 3 menit Oil 450 45 0.5

15.10.12 12/SO/IGI/0425 UNS Fak. Teknik Mesin

S45C Loading

Arm

1 pc 40 2 850 2 menit Oil 450 43 0.2

10.10.12 12/SO/IGI/0347 PT Meshindo Alloy Wheel

S45C Chuck

Holder

1 pc

30-35

850 3 menit Oil 250 36 4

02.10.12 12/SO/IGI/0426 UNS Fak. Teknik Mesin

S45C Punch

Holder

1 pc 50 2 850 3 menit Oil 250 51 2

02.10.12 12/SO/IGI/0417 PT ISE S45C Sprue

Bush

1 pc 48 2 850 3 menit Oil 200 49 0.3

28.09.12 EODU 120687 Bengkel

Cokro

S45C Harden

Gear

2 pcs Max 850 3 menit Oil 250 51-52 4.5

24.09.12 EODU 12653 Bengkel

Tunas Mandiri

S45C Helical

Gear 53T

1 pc 40 2 850 7 menit Oil 430 40 28

14.09.12 EODC 120118 Djarum S45C Bending

Jig 1-2

Lanjutan Lampiran 1

Tgl. Order number Customer Material Item

name

Quantity Hrc dwg.

Austenit Holding time

Media quench

Temper Hrc

result

Weight

14.09.12 EODC 120118 Djarum S45C Bending

Jig 3-4

1 pc 52 2 850 3 menit Oil 200 40 1.6

07.09.12 12/SO/IGI/0346 PT Meshindo Alloy Steel

S45C Plug

gauge ø 73

2 pcs

40-45

850 5 menit Oil 400 41 1

07.09.12 12/SO/IGI/0346 PT Meshindo Alloy Steel

S45C Plug

gauge ø 52

2 pcs

40-45

850 5 menit Oil 400 41 0.6

07.09.12 12/SO/IGI/0347 PT Meshindo Alloy Steel

S45C Spindle

Shaft

1 pc

30-35

850 8 menit Oil 200 27 13

07.09.12 12/SO/IGI/0347 PT Meshindo Alloy Steel

S45C Chuck

Holder

1 pc

30-35

850 7 menit Oil 450 42 3.5

24.08.12 EODC 110166 Extrupack S45C Housing

Bearing ø 40 x 50

2 pcs 40 2 850 2 menit Oil 300 38 0.3

24.08.12 EODC 110166 Extrupack S45C Housing

Bearing ø 26 x 43

2 pcs 40 2 850 2 menit Oil 300 47 0.1

24.08.12 EODC 110166 Extrupack S45C Housing

Bearing ø 35 x 98

1 pc 40 2 850 2 menit Oil 300 40 0.15

24.08.12 EODC 110166 Extrupack S45C Housing

Bearing ø 26 x 53

1 pc 40 2 850 2 menit Oil 300 42 0.5

06.08.12 EODC 110166 Extrupack S45C Item 3.3 2 pcs 40 2 850 3 menit Oil 350 43 1

06.08.12 EODC 110166 Extrupack S45C Item 3.11 1 pc 40 2 850 3 menit Oil 350 45 0.5

Lanjutan Lampiran 1

Tgl. Order number Customer Material Item

name

Quantity Hrc dwg.

Austenit Holding time

Media quench

Temper Hrc

result

Weight

12.07.12 12/SO/IGI/0293 PT Meshindo Alloy

S45C Plug

Gauge ø 60

1 pc

40-45

850 3 menit Oil 430 41 0.8

09.07.12 EODU 120526 Bp. Herry Tri Saputro

S45C Spline

Shaft

1 pc 45 2 850 3 menit Oil 200 45 0.4

27.06.12 EODU 120463 Dan Liris S45C Double

Gear 53T/59T

1 pc 45 2 850 5 menit Oil 400 43 3

15.06.12 12/SO/IGI/0268 UNS Fak. Teknik Mesin

S45C Die 1 pc

40-45

850 3 menit Oil 430 35 0.1

15.06.12 12/SO/IGI/0268 UNS Fak. Teknik Mesin

S45C Top Plate 1 pc

40-45

850 3 menit Oil 430 44 0.5

13.06.12 EODU 120340 PT Sinergi Solo

S45C Stripper

Plate

1 pc

42-45

Lampiran 2

Gambar Oven Borel AG

Gambar Oven Wilmon

Gambar Oven Smit

Lanjutan Lampiran 2

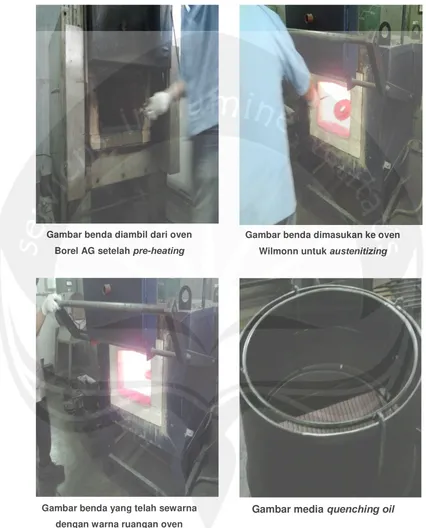

Gambar benda diambil dari oven

Borel AG setelah pre-heating

Gambar benda yang telah sewarna

dengan warna ruangan oven

Gambar benda dimasukan ke oven

Wilmonn untuk austenitizing

Lanjutan Lampiran 2

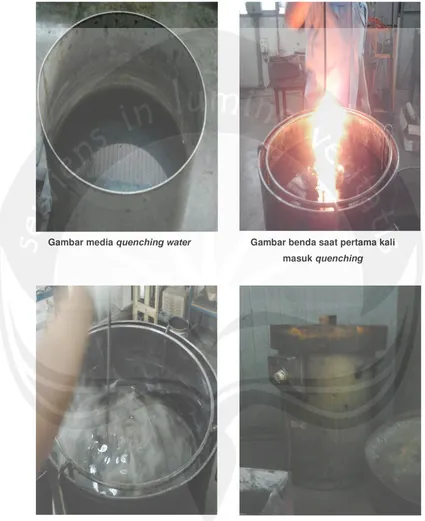

Gambar media quenching water

Gambar benda mulai dingin di dalam

media quenching

Gambar benda saat pertama kali

masuk quenching

Lanjutan Lampiran 2

Gambar hardnesstester merk Albert Gnehm Horgenn tipe OM-150 dengan

skala Rockwell-C