1

iiiPL

%NARY

PAPER

AS IS A. DJAJADTNMGRAT Wastewater Management: Cumnt and Future Trends

KELI

yA SUMOTO M A G A M Technological A~;.roach in Setting-up Environmental KEmP~licy for Psveloping Countries t

ZAINf UJANG Modeling Approach for lntegrated Urban Water ET,F MI GENS

H E M E

Management: Integration of Sewer Processes,Activated Sludge Plants and Rivers

INV'ITD

PAPER

MCIHAMMAD SUHAIME TO <AOt-IOJO 001

SIP ICHI KINOSHITA

A Cleaner Production in Urban Water Management

-

d~

Framework for a New Approacl~ I

I

A New Lignin Degrading Bacterial Enzyme from

IN^

Phenol Feroxidase I

Site Remediation in Australia

-

Current Activities and IAY3Future Prospects I,

Aviation and Air Pollutiofi I N V ~

?

Nl UI;E SOEMIRAT SLAMET Environmental Toxicology nnd Hen1111 in IndonesiaI N V ~

1

EN:U D A M A N H W Solid Wnste Management in Indonesia W B1

hl. ;AmY.RlA6AR-A

i

TGF.

SUNARYOR.I. 7. WENAS SRl SUITASMI

)

T. SEMBIRWGLIE5 SRIWRYANDARF

1

EK( S AGUNG PUTRANTO1

I l r 7 t4'l

!- ID 1 lkr ;

Rumerical Simulation of Dissolved Organic Pollutant GET1 Degradation in Retention Tank

The Efficiency ~ ? f IRDLAI's Tannery Wastewater O E ~

Treatment Plant in Sitimulyo, Yogyakarta in Reducing

Pollution h a d

Treatment of Wastewater from Textile Industry using O E ? ~ Bacterial Tablets as Microorganism Sources

I

Cltaracterization of MSW fncinera~ion Resid~tc mid t!~e 0ET4

Effect of B io~eacl~ing

h. UI-IAMMAD LMDU Nutrification and Denitrification Process of Chocolate OEiT. V 'INARTI ANDAYANI Candies Wastewater using SRR

L FESTYOWATI SUSILO

I

PMYATNI SOEWONDO The BiolagicdE Process for Color and Organics 0 k ~ 6

PtTDn SETYKNlNGSIH Removal of Batik Wastewater under Ratch

Experiments

F

U DY

LAKSMONO Mechanism of Bioregeneration Activated Cubon using 0 , bSOEPANGAT SOEMART0 ~seudornon% Bacteria 1 :TSJNUPRAPTO

F IOHAJIT

1'. LUCIA NUGROHO Degradation of the Tcxtilc Colouring Agent C.1. OET8

1

r'rNNI ROCHAENI Reactive Blue 5

(CTRB

5 ) By Immobi!fzed Cells in aIFNW HANDAYANE C Sequencing Batch Reactor

r

TJINDRIANY SYAFILA The Influence of Filling to Reacting Time Ratio on

d~T9

'4OCHAMMAD CHAERUL Sequencing Batch Reactor Performance during IAnaerobic Biodegradation of Gluwsc-Containing

Effluent at Methanogenic Phase

TJANDEtA SETTAD1 Treatment of Textile Wastewaner by a Coupling of c2ETlb

:;UWARDNONO Activated Sludge Process with Membrane Separation

- GEDE W T E N

1

LUQMAN HAKTU The Technabgy of Liquid Membrane for Wastewater ~ E T I I

PFbIYITNO Treatment Containing Hzavy Metals I

BASTIAN ARIFEN Adsorption Isotherm of Mercury ion onto Wood b3~12

SOEPANGAT SOEMARTC) Particle

IIARUN SUKARUADlJAYA

I

XSIS

W

DJAJkDMPNCRkTt""

P.

SWDJONO Simulation Approach to Elevate Efficiency of b ~ n 3E.W. IRIA?VO Wastewater Treatment Pbnt Cisimng M. SYAFILA

D.

NASSARETTAi

VAMAN SLKRMAN Bialogica! Nuhienl Remcval from Agraindustrial h T l 4

AKAS

M

FAUZl '.Vssiewater asLrg a Two Reactor Systcr~iM U I % M D ROIMLI

SUPRIHATIN

ANDES ISMAYANA

NOVlAN JMAMSIAH POESLl Industrial Ecology: Towards a Sustainable lndurtrial ~ O E A ~

ANDRE KUNCOROYEKTl System, Experiences of PT. National Gobel I I'AJAR EKO ANTONO '

PU 1 LESTARI Chwacrerization of Atmospheric Pfifiiculate TSP and D E ~ ?

PMlo in an Urban Area Bandung

I

ARIANI DWI ASTUTI The Use o f Saccharomyes Cerevisiae from Beer Wl DYO

ASTONO

Industry's Fermentation Waste as Biosorbent toYC'LA AMBeMSURI Remove

cP'

from Electroplating Wastewater .E.1 WILOSO Continuous Dmlorization of Wastewater Containing O 2 V. RARLIANT7 Ornnge II using Penniciliurn sp. L2A in a Modified

EL

Bubble Column Reactor

T.

TEDJAKUSUMA Bacterial Decoloriult ion of Orange 1 6 OE 3T. 001

S . KWOSHITA

b

PI

YGKAN

ADITIAWATI D 3A NQRlANII. W O M A N P ARYANTHA

Sequential Bacterial Isojation from Crude Oil and 0 E b d

Optimization of Mixed Culture Variation of the Isolation in Cmds Oil Degradation and Biasurfactant

/

Product ion

Growth Optimization of Biosurfactanr Producing O&BS

Bacteria for Oil Sludge Rioremediat ion

P! ISTER SESSION

EVT ARATUN T h e Effect of Colour Concentration and Aeration P ~ S J

E *.IDA1 I MURIARTI Time on the Degradation of Colour Index Reactive C ATUT SUDARJA~!TO Blue 5 (CIRB 5) using Sequencing Batch Reactor

P

J UJWN KUShlAYATlI

'r' WN1AR-n

P.

KENTJANA 7 R1 FADMI DAMANHURISRI UTARI

T NDRA JOELXNTO F DWAN KARDENA

ThRAYATNI SOEWONDO

1 ; ART3 S ETI AN I MPMTALI

F

IYDON MERDIKASART

I t.1.F- WENAS !GN. SUNARYO

;R1 SUTYASMI

Kinetics of Wastewater Degradation Pmcess of the P@

Prayer-Paper Industsy in An Aerob Reactor Having a

Stirring Rod with Re-Circulation

Panm~rer Es!imatios, in Dechlcrination Pmccss of ~ b ~ 3

Cihorohydrin by Immobilized Agrobactdu:t~ sp. Strain S3B on CelIulose Beads using Genetic Algorithms

The Biological

P

~

ofs

Textile Wastewater POSsrTreatment using

.

Porous Concretes A SupportMaterials

I

Comparative Study of Characteristics of Tannery, $ 0 ~ 3

"Kerupuk Kulit" 'Tabu Tempe'', "T~npioka"

PUJi LESTARI Cl~aracterization of Atmospheric Particulate TSP and PMlo in an Urban Area Bandung

ENVIRONMENTAL BIOTECI

ARIANI DWI ASTUTI

WTD'IO ASTONO

YOlz 4 AMBUNSURI

Tile Use of Saccharomyces Cerevisiae from Beer Industry's Fermentation Waste as Biosorhnt to Remove from Electroplating Wastewater .

Continuous Decolorization of Wastewater Containing Orange XI using Pennicilium sp. L2A in a Modified

Bubble Column Reactor

Bacterial Decolori7ation of Orange 16

T. TI :DJAKUSUMA T. O( )I

S. K - NOSHXTA

DEA WDRIANI ASTUTI KOSASIH PADMAWTNATA

IBLiHIM SASTRAMIHARDJA

SOF

rlmso

SOEMITRQSequential Bacterial Isolafion from Cnrde Oil and Optimization of Mixed Cujture Variation af the Isolation in Cmde Oil Degradation nnd Biosurfactant

Production

PM( jKAN ADITlAWATI

DEA JNDFUANI

I. NT70MAN

P

ARYANTHAGrowth Optimization of Biosurfactant Producing Bacteria for OiI Sludge Bioremediation

POSTER

SESSION

EVI AFTATUN

ENL

!AH MUBlARTl GAI'UT SUDARJANTO W"UN KUSMAYATlThe Effect of Colour Co~~centration and Aeration

Time on the Degradation of Colour Index Reactive Blue 5 (CIRB 5 ) using Sequencing Batch Reactor

Kinetics of Wastewater Degradation Process of the Prayer-Paper Industry in An Aerob Reactor Having a Stirring Rod with Re-Circulation

Parcm~ter Estimatior, in Dechlcrination Prnccss of

Chlorohydrin by ?mmobilizec: Agrobacterium :Q.

Strain S3I3 on CeSlulose Beads using Genetic

Algorithms

PWiYATNI SOEWONDO BA I tTI SETIANI JiRNTALIF INL ION MERDIKASART

The Biological Process of Textile Wastewater Treatment using Porous Concretes A Suppoft Materials

R.I.F.

WENASIGT.,. SUNARYO SR; SWTYASMI

i

. DWIAm:

NUS.1lDAMANSAID EWTrWRCHAIRATl! M A C HDAR

I

I

PTNCFKAN ADITIAWATI Biodegmdation of Chlorolignin by Phanemhaete

OET !3AN LIANG chrysosporiurn BKMF I767

i

$OE!'ANGAT SOEMARTOIBW H I M SASTRAMlHARDJA

KER'I' BUDIANTO WSJNUPRAPTO I

'>

---.

-*

v i i

RAM ADHANI YANIDAR IDRJ:; MAXDONI KAMIL

MAY R M A FIRDAYATl

m

ABSTRACT

ED19 IN EFFENDI

P

RACH MAT BOEDlSANTOSO PUJI 1 ESTARJSUKA

NDAR

ENRl -11

Removal of BOD, COD, TSS, and Color from Jeans- POST

dyeing Wastewater by Using Combined-Biofilter Reactor with Cross Flow Module

Modeling of Water Demand Prediction using System POS9

Dynamics (Case Study Water Supply System City of

Bogor)

Flotation Rste in DissoFved Air Flotation Unit POSS--

Biodegradation of 3-Chloroanilin by Monoculture P O S I ~

Bacterial

I

- '

Biodegradation of LAS by Pure Culture Bacteria PO=)

Bacillus Iaterosporons 1

I

I

Model ling of 2,4dichlorophenal Degradation - OETI 5

Bacillus sp. 1

I

Treatme~t of Purified TephthaIic Acid (PTA) OETllb

Effluents in Anaerobic and Contact Stabilization I Aerobic Reactor

Characterization of Municipal Solid Waste from the 0.Eh4lb

Final Disposal Site of Keputih in Surabaya

I

4

NO, Abatement using Photo-Catalytic Process with OEM1 7 TiOz and Activatd Carbon io the Multi Plate Reactor

I

Land Use Impacts on the River Flow Regime and its O E M I ~

Wzter Quality (Case of Upper Citanlln Watershed)

I

Biosorption of Cadmium by Green Algae tising Zinc OEB6 1

as Detoxification Agent

PROCEEDINGS

BieIogical Nutrient Removal:

from

Agroindustrial Wastewater

Using

aTwo

Reactor System

M.

Sukiman, Am. Fauzi,M.

R o d i , Suprihatin an

d A. Ismayann Departcment o f Agiculturaf Industrial Technoloyy1 Bogor Agricultural University

Allstratt - Agroinduslrial wastewater is rich in organic material, especially organic carbon and n~ltrient. I n tlris work a two reactors system consists of anoxic and erobic reactor was operated d i t l i d l ferent recycle and C N ratio. Experimentation using molasses-bawd artificial wastewdfer ccntnining 114 mg/L of NH3-N, 10 m g F of

Nod,

25 rn@L of NO2-N, and 1300 m a COD, wi rich was fed directly into the anoxic reactor showed incrcaing ofDO

concentration in ~ h c anokic rc;]ctor from 0,13 mg/L to 0.32 rn& which increasing recycle rations from 100% to 300%. Desqitet h l anexic m c t o s was capable to reach a nerly 94% denitrification efficiency, the overall system

pra rduced final effuent containing 98.3 1 mg/L of N03-N. yet, this system was capable to redzaoed CI )D concentration from 1,284 mgVL to 186 rn&, reduced NOz-N concentration from 25.JlrngjL to 1.50 m g / t and NH3-N concentration from 114 rndZ to 0.91 11ig'L with a 100% recycle m ~ o .

Reducing the recycle ratio up to 50% still did not significantly improve the anoxic reactor for co~nplete denitrification process. It produced a final nutrient containing 96.99 m a NOI-N, 19 !m& sf COD, and 1.47 of NH3-N funher experimentat ion using higher cancentraton of COD (2t OOmgL) with 100% recycle ratio resulted increasing denitrificatiorl eficiency from 94% [to

97' 6 . 171e merall system produced final effuent contailling 94.48 tngk of NU3-N. this system %s ab!e to reduced COD concer~!ra!ior? from 2,644 m g k to 2?23@5 I

IN' rRODUCTION

r'

Nitrogen compound in wastewater decreases water perimetr quality. It is because bf

nit1 ogen compound at certain concentration decseas e oxygen concentration and caude

eutrophication. That's why nitrogen compound in wastewater should be decreased as mudh as ;~ossihle, A way ro separate nitrogen compound is by applying waste treatment process

I

bio ogsall jl. General pnnciyl of bilogicaI tratment which is applied ta scparate nitrogen

crrnrpound is nitrification and denitriftcation process.

I

Nit %cation and denitrification are biological process in wastewater where nitroge

.

con pound is changed into nitrogen gas. In nitrogen, ammonium oxidation becomes nitrid6

the1 I nitride

is

oxidized to be nitrate. Next step, nitfate is reduced to be nitrogen gas inI dm tification process. Both processes change chemical compound wllich is harmful for env ronrnent to be the advantageous ones.

I

To make nitrification and denitrification perfect, we need to know the condition ofenv~ ronrnent and waste chemical compound. Worth-consideringenvironmen t factors arc

diss Aved oxigen and hydraulic retention time (HRT), for exarnplcs chemical cnrnpound s

Ma~nan Sukiman et a!. OETI4-2

1

I.r+;

needed while it is hardly needed in denitsification. This will also be influential in reduct& oxidati 3n process, which can be measured by ORP-meter. Hydraulic remain time will&

ieprescntsd by circulation debit. Circulation from aerobic reactor to anoxic reactor is believed to be very influential in nitrification and denitri fication process perfection.

Chmi4:al compounds mentioned above are very influential in the process, as weII, Organic deposi? is needed for microorganism growth, so is ammonium nitride and nitrate.

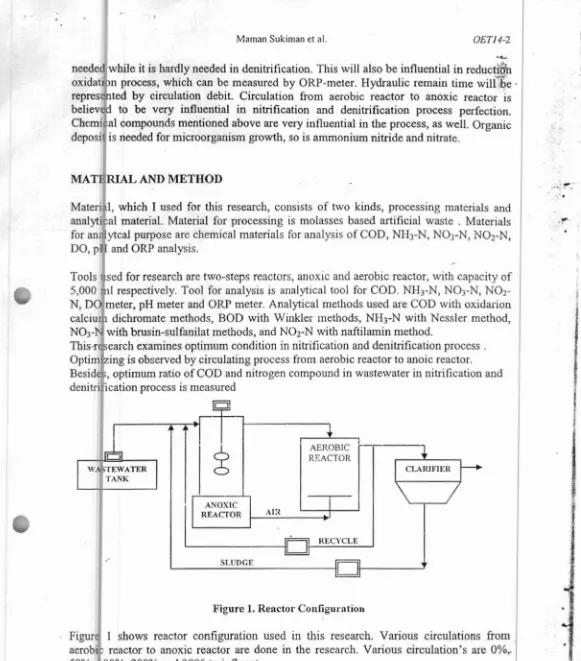

MATr RIAL AND METHOD

Materid, which

I

used for this research, consists of two kinds, processing materials and analyti :a! material. Materia1 for processing is moIasses based artificiaI waste.

Materials for an;. lflcal purpose are chemical materials For analysis of COD, NI-13-N, NO3-N, N02-N, DO, pl l and ORP analysis.>

Tools

i!sed for research are two-stepsreactors,

anaxic and aerobic reactor, with capacity ofP‘

5,000 .nl respectively. Tool for analysis i s analytical tool forCOD.

NH3-N, NO3-N, NOz-N,

DO

meter, pH meter and ORP meter. Analytical methods used are COD with oxidarion calciut 1 dichrornate methods, ROD with Winkler methods, NH3-N with Nessler method,N@-h with brusin-sulfanilat methods, and N02-N with nafiilamin method.

Tbis-rcsearch examines optimum condition in nitrification and denitrification process

.

Optimizing is observed by circulating process from aerobic reactor to anoic reactor. IBeside.;, optimum ratio of

COD

and nitrogen compound in wastewater in nitrification and denitr~ Fcation process i s measuredRlIACTOR

I AKOXIC

[image:8.612.9.590.13.674.2] [image:8.612.44.574.253.851.2]REACTOR AIR

d

Figure 1. Reactor Configuration

Figure 1 shows reactor

csnf

guration used in this research. Varjous circulations fromrterobi: reactor to nnoxic reactor are done in the research. Various circulation's are 0%,.

50%, 00%, 200% and 3005 to influent.

On

a research, which is done to examine the influence of burdened waste against6

Maman Sukiman el al.

RE

SULT

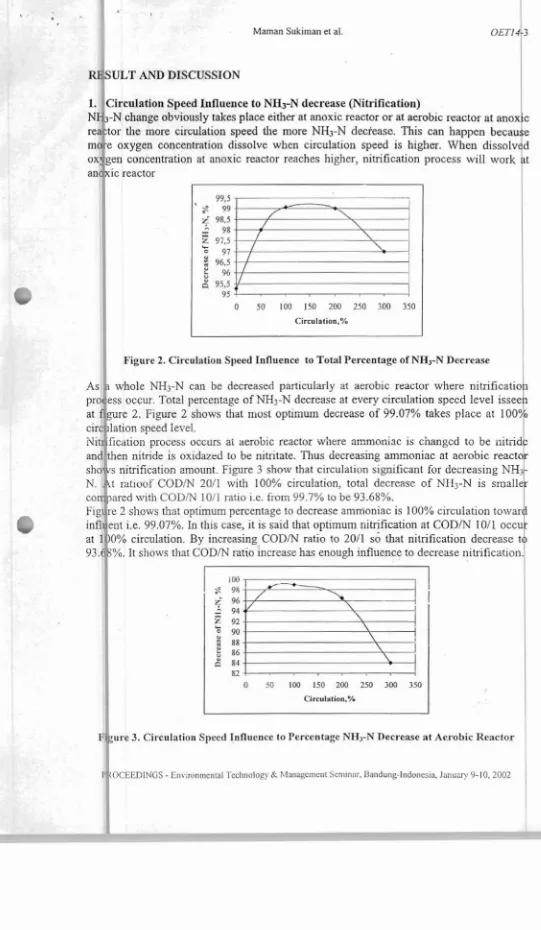

AND DISCUSSIONI. Circulation Speed Influence to NH3-N decrease (Nitrification)

Nk3-N change obviously takes pIace either at anoxic reactor or at aerobic reactor at anax

I

c rea:tor the more circulation speed the more N b - N decrease. This can happen becauSemare oxygen con cent ratio^^ dissolve when circulati~n speed is higher. When dissolv~d ox! gen concentration at nnoxic reactor reaches higher, nitrification process will work ht

[image:9.614.6.547.17.947.2]ancxic reactor

I

Figure 2, Circulation Speed Influence to Total Percentnge of NHrN Decrease

As ,% whole NH3-N can be decreased particularly at aerobic reactor where nitri ficatioh

pror ess occur. Totzl percentage of NH:-N decrease at every cimIation speed level isseen at f , y r e 2. F i p r e 2 shows that most optimum decrease of 39.07% takes place at 100%

circ tat ion speed level.

i\Titr ~fication process occ~lss at aerobic reactor where a m m o n i x is changcd to be nitrid

b

and then nitride

i s

oxidazed to be nititate. Thus decreasing amrnoniac at aerobic react&sho:vs nitrification emount. Figure 3 show that circulation significant for decreasing NHi- N, :It ratioof COD/N 2011 with 100% circulation, total decrease of NT-13-N is smallek

corr,pared \vith C O D N l O l i ratio i.e. from 99.7% to be 93.68%.

Figz re 2 shows that optimum percentage to decrease amrrioniac is 100% circulation towar

r'

Enfl~.ent i.e. 99.07%, In this case, it is said that optimum nitrification atCODm

1011 occukb

at 11)0% circulation. By increasing CODN ratio to 20/1 so that nitrification decrease tb

93.C8S%. It shows that COD/N ratio increase has enough influence to decrease nitrification.

I 1

I

Maman Sukiman et al. OETI 4-4

', 9

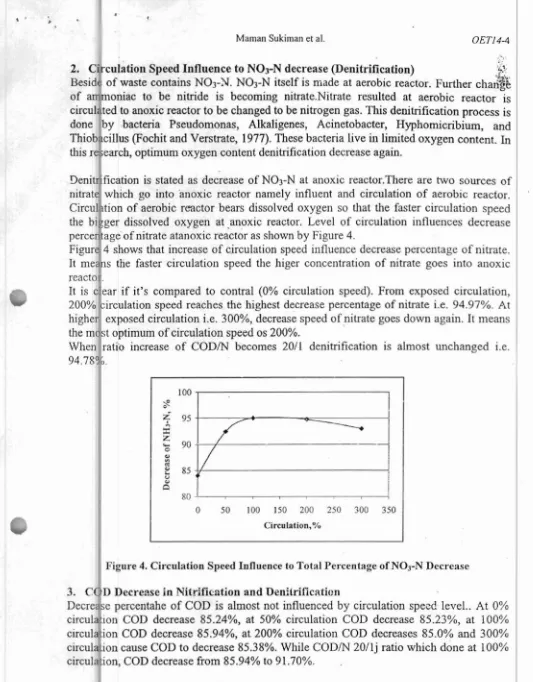

2. ~irculation Speed Influence to NOyN decrease (Denitrification) ,:+

&.

Besidt of waste contains

NOrW.

NOrN itself is made at aerobic reactor. Further change of arrrnoniac to be nitride is becoming nitrate.Nitsate resulted at aerobic reactor iscircul; .ted to anoxic reactor to be changed to be nitrogen gas. This denitrification process is done by bacteria Pseudomonas, Alkaligenes, Acinetobacter, Hyphornicribium, and Thiob:icillus (Fochit

and

Verstrate,1977).

These bacteria live in limited oxygen content. In this re ;earth, optimum oxygen content denitri ficntion decrease again.genitrification is stated as decrease of NO3-N at anoxic reactor.Thert are

mo

sources of I nitrate which go into 'anoxic reactor namely influent and circulation of aerobic reactor. , [image:10.612.11.544.10.692.2]Circul

aion

of aerobic reactor bears dissolved oxygen so that the faster circulation speed1

the bi ;;ger dissolved oxygen at anoxic reactor. Level of circulation influences decrease percertage of nitrate atanoxic reactor as shownby

Figure 4.Figure 4 shows that increase of circuIation speed influence decrease percentage of nitrate.

,

It merns the faster circulation speed the biger concentration of nitrate goes into anoxic/

reacro 1 .

K

- Tt is c ear if it's compared to contra1 (0% circulation speed). From exposed circulation,

200% circulation speed reaches the highest decrease percentage of nitrate i.e. 94.97%. At

higher exposed circulation i.e. 300%, decrease speed of nitrate goes down again. It means the mr st optimum of circulation speed os 200%.

When ratio increase of CODN becomes 20J1 denizrifrcation is almost unchanged i.e.

94.789 ;1.

Figure 4. Circulation Speed Influence to T o t a l Percentage of N03-N Decrease

3. C<!D Decrease in Nitrification and Denilrificaticn

Decrelmse percentahe of

COD

i s almost not influenced by circulation specd level.. At 0%circulaelon

COD

decrease 85.24%, at 50% circulationCOD

decrease 85.23%, at 100%circu1a:ion COD decrease 85.94%, at 200% circulation COD decreases 85.0% and 300% circula,.ion cause

COD

to decrease 85.38%. While CODm 2011j ratio which done at 100%circuln don, COD decrease from 85.94% to 9 1.70%.

4. To tal Nitrogen Compound Decrease

Total t itrogen is sum of NH3-N, NO3-N, and NO2-N concentration. At COD/N 10/1 ratio

averag : efficient decrease of nitrogen compound at 1 00% circulation is 60.13%, while CODCJ 2011 ratio is 59.46%. The highest compound if effluent is NO3-N. This compound

Maman Sukiman ct a!.

OEnC5

I

Optinurn nitrification of CODm 10/1 ratio can be reached at 100% circulation and 99.07% efficiency while COD/N 20/1

is

at the same circulation and 93.68% efficiency. Optir~um denitrification of CODN 1011 can be reached at 200% circlrlation and 94.97% effici :ncy while COD04 2011, is at 100% circulation and 94.78% efficency.Tota1 efficient decre rse of nitrogen compound at CODN 1011 ratio is60.13% while CODN 20/1 is59.46 56.

In on Fer to

raise efficient decmse of nitrogen compound, it should be added an anaxic react< r after aerobic to make nitrate concentration down.Refel en ces I

I

I A P H I ~ , 1 992, Stondnrd Method for the Exurninorion of Warer and iVmtvater, I 8"' ed.,

American Public Health Association, New York.Bitto1 0,

G,

1994, Wostewarer Microbiologv, John WiIey and Son, Singapore.Boonr ;strang, A, Matda, Y

.,

Suga,K.,

1 982, Nitrogen Xernoval rhrottghout Nitrifcoiion, Folloj ved by Denirrlj%caiion of n Syn rheric Wuszewarer with a Rotorilrg Disc Contractor.Journ.11 of Fermentation Technology, Vol60. No.4

Chris: ensen,

MH

andP

, Harremoes, 1 978. Nitnpcation and denitr:Pcarion in Wasrewater Treair sent, pp-3 1 9-4 14, In Water Pollution Microbiology. Vo1.2.R

MitchelE, ed Wiley.New '{ark.

Hammer M.J. t 986. Writer and Wastewater Technofogy. John Wiley & Sons.

New

Y

ork.Hao. r3.J and Kim

.

H.M 1990 Conrinuous Pre-Anoxic and Aerobic Digestion of WmleActivr fed Sludge. JoumaI of Environernen~al Engineefing. Vol. I 16 No.5

pa

Metc; If and Eddy 199 1. Wostowater Engeneering Treatmef~t Dispose1 Reme, 31h ed. McGraw-Hill Book Co, SingaporeNatha nson, J.A. I 997 Basic Envirorvnen fa1 TecfrtroIogl~ Wafer Suppij: Wmfe Manngea~en!

and

F

~ll!~ticri Control. Prentice-Hal!. Nzw Jersey.PR1 ICEEDINGS - Environmental 'rcchnolopy %t M a n s ~ c n r v r i ~ Sc~nii);lr. I t n r i t l u n y - l n d r ~ ~ ~ c ~ ~ ; ~ . J.I~III;I~! 0-1 0. 2002

Weisr nan,

U.

1994 Biological Nitrogen Rentoval jkom Wasrewater. Advance in Biochemical EngineeringJBiotechnology.Vo1.51.

A. Fiecher (ed) Springewerlag, Berlin Heidenberg.\

b

1AANAGEMENT

SEMINAR

2002

I

smg!h

--. .-.mi &,'&- ---I

1 _,_

january

9

-24

2001,

Bandung

-

Indonesia

I

)EPAIRTMENT

OF

ENVIRONMENTAL

ENGINEERING

I

I

Departemen

Pendidikan Nasional

Fakultas Tcknologi Pcrtanian

-

lnstitut Pertanian Bogor

1

DEPARTEMEN TEKNOLOGl TNDUSTRI PERTaIAN

Karnpus IPB Dannaga P.O. Box 220 Bogor 16002, Telp.lFox. (025 1 ) 62 J 974

Sumt Pendokumentasian Karya Ilmiah

Nomor :1a)fl.6.3 JPP12009

Karyl ilrniahJfiasiI penetitian atau hasil pemikiran ymg tidak dfpublikasikan, dengan judul :

Biolrhgical Nutrient Removal f b m Agroindustrial Wastewater Using a

T w

ReactorI

Systt m. 2002

I f- Penu l is : M. Su kiman, Anas Miflah Fauzi,

M.

Rornli, Suprihatin, Andes Tsmayana.Dido vumentasikan di Departemen Teknologi TndusZi Pertani an Faku l tas Teknologi

Pertmian lnstitut Pertanian Bogor.

Prof. Dr. Ir. Nmtiti Siswi hdrasti