THERMOMECHANICAL AND MORPHOLOGICAL INTERRELATIONSHIP OF

POLYPROPYLENE-MUTIWALLED CARBON NANOTUBES (PP/MWCNTs)

NANOCOMPOSITES

A.R., Jeefferie

a, M.Y. Yuhazri

a, O. Nooririnah

a,

M.M. Haidir

a,

Haeryip Sihombing

b, M.A.,

Mohd Salleh

c, N.A., Ibrahim

da

Engineering Materials Department, bManufacturing Management Department, Faculty of Manufacturing Engineering, Universiti Teknikal Malaysia Melaka, Durian Tunggal, 76109, Melaka, Malaysia.

c

Chemical Engineering Department, Faculty of Engineering, dChemistry Department, Faculty of Science, Universiti Putra Malaysia, 43400 UPM, Serdang, Selangor Darul Ehsan, Malaysia.

Email: [email protected]

Abstract - In this research, the significance effects of

MWCNTs at lower percentage addition in affecting the thermomechanical behavior of the fabricated PP/MWCNTs nanocomposites were studied. PP/MWCNTs nanocomposites were compounded by using the internal mixer, through the simple melt blending technique. The improvement effects of MWCNTs addition were well justified by the transmission electron microscopy (TEM) surface morphological observation. The interrelationships between the TEM surface observations with the thermomechanical results were established by manipulating the three major plots of dynamic mechanical analysis of storage modulus, loss modulus and damping modulus (tanδ). From this work, it was found that the improvement of dynamic thermomechanical properties is directly related to the amount of MWCNTs added and the quality of MWCNTs dispersion within the PP matrix.

Keywords: Thermomechanical, PP/MWCNTs nanocomposites, Surface morphological, Interrelationships.

1.0 INTRODUCTION

Most fillers and reinforcements are purely elastic systems while the polymer and the filler/polymer interface are viscoelastic. A better understanding of the dynamic thermo-mechanical properties of the composite will help to define structure/property relationships and subsequently to relate these properties to the product final performance [1]. Dynamic mechanical analysis (DMA), measures the response of a given material to a cyclic deformation as a function of temperature [2]. DMA provides information on storage modulus, loss modulus and damping factor behavior of materials. The dynamic storage modulus (G’) is approximately similar to the Young or elastic modulus,

or materials stiffness. It provides the information on elastic response to the deformation resistance [3]. The remarkable increased in composite thermo-mechanical stability cannot be only understood by the interactions between the polymer chains and carbon nanotubes (CNTs) surface, but the formation of a percolating entangled CNTs network within the materials has to be taken seriously into consideration [4]. Entanglements within a fibrous structure are indeed responsible for the elastic response of the composites structure [4].

However, entanglements between the CNTs appear to have a low effect on the mechanical reinforcement. Thus, the increase in modulus is mainly due to stress transfer between the matrix and CNTs. In filled polymer systems, the presence of fibers perturbs the normal flow of polymer and hinders the mobility of chain segments in flow. The type of polymers (semicrystalline or amorphous), the glass transition temperature of the polymers, the filler type, geometry (including aspect ratio), concentration and the interaction of the fillers to the matrix molecular chains are all the factors which affecting the molecular motions within the matrix [1]. These are the factor which affects the behavior of the storage modulus curve.

(MWCNTs) composites were considerably higher or more viscous [7]. The damping factor (tanδ) is the ratio of the loss modulus to the storage modulus. It may also be obtained as the ratio of the real part to the imaginary part of the complex viscosity [1]. The damping factor (tanδ) provides information on the relative contributions of the viscous and elastic components of a viscoelastic material. It is very useful for determining the occurrence of molecular mobility transition such as the glass transition temperature which also represents the ability to the heat resistance [1].

Through this study, the effects of lower percentages of MWCNTs filler addition to the thermomechanical properties of fabricated PP/MWCNTs nanocomposites were investigated. The efficacy of the internal mixer method to compound the MWCNTs within the PP matrix was tested in the course of transmission electron microscopy (TEM) observation. The interrelationships between the microscopy observations to the final thermomechanical results were further established. It is anticipated that the nanocomposites compounding by using this route much probably will gives better nanofiller homogenization within the polymer matrix which resulting better end properties of the fabricated nanocomposites. In parallel, it is also interesting to observe the significant effect caused by the addition of extremely lower percentages of MWCNTs to the mechanical properties, subject to the thermal and mechanical effects.

2.0 METHOD

2.1. Raw Materials

Thermoplastic PP grade Titan Pro SM950 used as matrix material was purchased from Titan Petchem (M) Sdn. Bhd. As-produced MWCNTs which synthesized by the floating catalysts chemical vapor deposition (FC-CVD) method are used as filler reinforcement. As-produced MWCNTs with 55% of purity are depicted as in the Figure 1.

2.2. Preparation of PP/MWCNTs Nanocomposites

PP/MWCNTs nanocomposites were prepared by melt blending process in an internal mixer using Thermo Haake PolyDrive with Rheomix R600/610 at 175°C of compounding temperature and 60 rpm of roller rotor speed. Eight minutes of compounding period were allocated and required amount of MWCNTs (0, 0.25, 0.50, 0.75 & 1.00 wt %) were added at the midst of compounding duration. The compounded recipes were then compression molded using HSINCHU hot press machine for 5 minutes preheat and another 5 minutes of compression period under the pressure of 150 kg/cm2 at 185°C. The sheets obtained were immediately cooled for 10 minutes of cooling cycle.

2.3. DMA Thermomechanical Analysis of PP/MWCNTs Nanocomposites

The compression molded sample plaques were cut into rectangular shape with the dimension of ~12.6 mm in their length, ~5.0 mm in their width and ~1.0 mm in their thickness. The measurement was carried out using a three point bending fixture of dynamic mechanical analyzer (DMA) model Perkin Elmer TE. The samples were subjected to an oscillating frequency of 1 Hz and 10 µm oscillating amplitude in the temperature ranges of -50°C to 150°C at the heating rate of 2°C/min. The signals are automatically used to determine the dynamic storage modulus (G’), loss modulus (G’’) and the damping factor (tanδ), which were plotted as a function of temperature. The tanδ peak was taken as the glass transition temperature (Tg) of the tested samples. To verify the thermomechanical experimental results, the surface morphologies observation from the transmission electron microscopy (TEM) observation were conducted.

Figure 1: As-produced MWCNTs observed through

HRTEM imaging

2.4. Surface Morphological Observation through TEM

TEM observation was performed to the ultra-thin section of the PP/MWCNTs nanocomposites film as to check the dispersion state of MWCNTs added within the PP matrix. The observation was conducted by using the TEM-100 CX-II (JEOL Co., Japan), at an acceleration voltage of 120 kV. The specimens were prepared by using a Leica ultra-cut microtome equipped with a cyro-chamber. Thin sections of about 100 nm were prepared by using a diamond knife at -80°C of liquid nitrogen temperature.

3.0 RESULTS AND DISCUSSION

3.1 Storage Modulus (G’) of PP/MWCNTs Nanocomposites

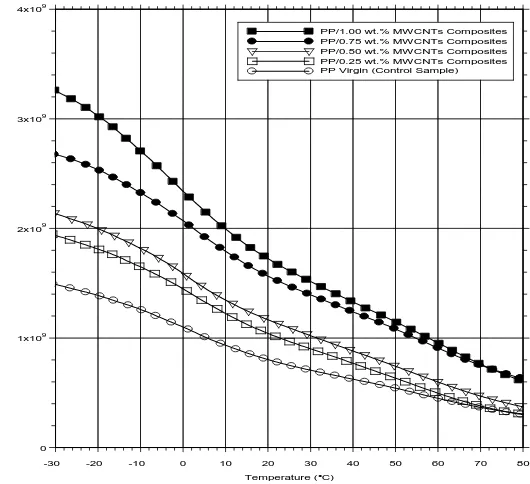

Figure 2 displayed the plot of storage modulus (G’) as a function of temperature for the PP/MWCNTs nanocomposites with different weight percentage addition of MWCNTs. Storage modulus curve for pure PP is overlaid as for the comparison purpose. Basically, at the initial stage of analysis, the Figure 2 shows the storage modulus of the samples increases from about 1.50x109 to 3.25x109 Pa with the increasing amount of MWCNTs. A mechanical reinforcement effects are increasing with the nanotubes content [4], [8].

The stiffness effects introduced by MWCNTs enable the PP to sustain high storage modulus value [1]. This also, will suggest that the MWCNTs added behaves as good reinforcement and allow homogeneous stress transferred from the matrix to the fiber. As the fiber loading increased, the stress is more evenly distributed and thus will increase the storage modulus [9]. As can be seen, the initial value of storage modulus is higher for each sample at the sub-ambient temperature due to the facts that, at this stage the molecules are in the frozen state, therefore they retain high stiffness properties in the glassy condition [2]. E’ is higher when the molecular movement is limited or restricted and it consequently will caused the storage of mechanical energy increased [10], [11]. The stiffening effect was more remarkable at lower temperature. This phenomenon was explained by the mismatch in coefficient of thermal expansion between the matrix and inorganic fillers, which might allow better stress transfer between matrices and fillers at low temperatures [11].

The storage modulus curves for each sample is decrease dramatically with the increase of temperature from -30 to 80°C. This finding is in agreement with the works done by many researchers [1], [2], [4], [5], [10]. The pattern of decrement in the storage modulus value with the increasing temperature is due to the fact that PP reaches its softening point therefore reduced the elastic response of the material. With the increase of temperature to the melting temperature, the storage modulus of the composites was dominated by the matrix intrinsic modulus [1]. As the temperatures approaches the glass transition temperature region, there is a large drop in the storage modulus values, indicating the phase transition from the rigid glassy state where the molecular motions are restricted to a more flexible rubbery state and the molecular chains have greater freedom to move. When the polymer is viscous, as only few entanglements exist between nanotubes, the composite will flow because of interaction between polymer chains and nanotubes [4].

0

Figure 2: Variation of storage modulus (G’) of

PP/MWCNTs composites as a function of temperature

When the PP polymer and its composites are heated above their Tg, an increase in free volume typically occurs followed by an increase in molecular mobility [10]. Under this situation, the chain segments gradually align with the applied force [5]. When this occurs, the E’ decreased. However there is no distinct characteristic peak of the storage modulus can be detected to determine the Tg for the tested samples. Thus damping factor or loss modulus curves will be utilized for this purpose.

3.2 Loss Modulus (G’’) of PP/MWCNTs Composites

Referring to Figure 3, loss modulus of unfilled PP increased with addition of CNTs for PP/MWCNTs nanocomposites. This finding seems to agreed the finding by Yang et al., (2007) where they found that G” value was increased along with the inclusion of nanofiller [1]. Khalina, 2005 reported that the increase pattern of loss modulus amplitude with the presence of fibers indicating that the filled PP system was experiencing the increasing amount of amorphous part of PP chain which involved in the transition. This indicates higher viscosity as a result of the molecular movement restriction due to the presence of the fillers [5]. Thus, the higher the CNTs content, the higher the viscosity, which at the end requires higher needs for energy dissipation [7].

When the composites were subjected to external stresses, energy was dissipated by frictions between the fiber-fiber and fiber-polymer interactions. Additionally, similar to the storage modulus results, when approaching the melting temperature of PP, the curves tend to converge and exhibit the intrinsic properties of PP matrix. As can be seen, the inclusion of MWCNTs showed negligible effect to the peak temperature of loss modulus. The peak was not significantly shifted with regard to the effect of different MWCNTs loading. This condition indicates that the inclusion of CNTs did not significantly affect the relaxation behavior of PP. The relaxation transition peak shown in E’’ is around -2 to 4°C is thought to be related to the complex multi-relaxation process, which is mainly concerned with the molecular motion of the crystalline region of PP [1].

The G” peak reached a maximum peak near the Tg and then decreased sharply with the increasing temperature. The temperature range from -10 to 10°C represent a transition region from the glassy state to a rubbery state [5]. Above the transition temperature, the G” curve dropped gradually indicating the increases flow of the chain movement, thus reducing the viscosity.

G” can be used to indicate the rheological change (phase and flow) which occur during the processing of materials. As the temperature increase, the viscosity of the materials decreased gradually. The maximum dissipation of heat per unit deformation occurs at the temperature where G” is maximum. Above the phase transition region, the decrease in the G” is sharper indicating a sharp decrease in their viscosity. In this research, the peaks of loss modulus can be detected varies from -2 to 4°C with negligible influence of different amount of MWCNTs loading. As can be seen, after the maximum peak of the curves, the loss modulus values dropped significantly with the increasing of temperature until ~ 30°C, before it form stabilization

plateau prior to the convergence of the curves caused by the melting temperature.

Figure 3: Variation of loss modulus (G’’) of PP/MWCNTs

composites as a function of temperature

3.3 Damping Factor (tanδ) of PP/MWCNTs Composites

Tanδ indicates the relative importance of both viscous and elastic behaviors of materials, whereby tanδ < 1 exhibits more elastic behavior and may behave like solid, while tanδ > 1 exhibits more viscous behavior and behaves more like liquid [10]. Referring to the Figure 4, it shows that the range of tanδ is < 1, exhibits that the fabricated composites behave like a solid. It was also shown that the composites showed a slightly higher damping than the pure PP owing to the viscoelastic energy dissipation as a result of fiber-fiber friction and fiber-fiber-PP interaction. However, this finding is not in agreement with the findings obtained by Fateme (2006), where the author found that the tanδ value is decreased with the increasing amount of carbon fiber content in the PP matrix [10].

secondary relaxation due to the movement of short chain segments. It can be assigned as glass transition temperature (Tg). However, by referring to the Figure 4, it was also shown that there is no significant shift in the Tg temperatures, with respect to the difference amount of MWCNTs added into the PP matrix. The maximum peak for each curve falls at slightly the same Tg temperature, which is ~ 7°C. This phenomenon may be contributed by the factor of extremely low percentages of CNTs used, where it does not gives any little changes to the Tg properties of the tested nanocomposites. The relatively no changes in transition temperature of composites suggest that there is no change in the rigidity of the fiber matrix interfacial zone and no change in the mobility of the interfacial region. This situation was consistent with the work done by Zhang & Zhang (2007) which found that addition of 1 wt.% MWCNTs into PP matrix does not gives any significance increase to the glass temperature, where it fall around ~13°C which is almost equivalent with the Tg of the tested virgin PP [11]. However, addition of MWCNTs even at lower percentages of filler loading is still capable to gives identical separated peak position with respect to the tanδ value, where addition of only 1.00 wt.% MWCNTs to the PP, make intense shift to their tanδ value, almost 0.8 compared to the virgin PP which only had maximum peak of tanδ around 0.65.

PP/MWCNTs composites as a function of temperature

3.4 TEM Analysis of PP/MWCNTs Composites Surfaces

Magnification at about 35 500 times was applied in this observation. In overall, as can be seen from Figures 5, the dispersion patterns of MWCNTs were totally influenced by the percentages of MWCNTs loading. It is obviously can be seen as depicted in the Figure 5(a) and Figure 5(b), that the CNTs added were successfully dispersed, whereby the CNTs were isolated into the single nanotubes and homogeneously distributed between each other in certain remarkable distance. Referring to the Figure 5(a), CNTs seem likes embedded within the PP matrix. This is an indication of good compatibility between the matrix and the filler used. Well distribution of CNTs will provide good stress transfer during the mechanical loading which resulting better mechanical properties of the fabricated nanocomposites. Thus, it can be said that this observation well supported the positive results of the thermomechanical properties as obtained from the DMA testing.

As depicted in the Figure 5(b), it is clearly observed that the embedded CNTs have different thickness and diameter between each other or even at the same single nanotubes. MWCNTs seem to be shorter and the presence of CNTs in one single observation region is much dominant as clearly depicted in the Figure 5(b), in comparison with the Figure 5(a), since the quantity of CNTs loading was increased and the observation done at relatively small thickness of specimen [4]. All the nanotubes showed very well separation between each other in both fabricated nanocomposites. Micrograph of Figure 5(c) showed that the nanocomposites revealed the layer of PP that seems to cover the CNTs surfaces, indicating some degree of wetting and phase adhesion, unlike the hydrophobic polymer system. Good wettability of MWCNTs will creates good interphase between the filler and matrix which later will creates strong interfacial bonding between them (Liao, 2003). Addition of up to 0.75wt.% of MWCNTs exhibits excellence nanotubes dispersion where each of MWCNTs bundle has been isolated. It is known that good dispersion will lead better thermomechanical properties of nanocomposites [3]. Good dispersion of the tubes will increase the available surface area of the tubes to be bonded with the matrix of PP. TEM coupled with all the thermomechanical properties results, provides strong evidence that CNTs isolation is the prime key to maximizing reinforcement effects, which finally affecting the thermal and mechanical properties [15].

produced nanocomposites with 0.75 wt.% MWCNTs addition. The agglomerates and bundles of the tubes can be recognized as a black or big dark spots in the composites surfaces. Formation of CNTs agglomerates is due to high intermolecular van der Waals interactions between the CNTs which induced tangled intertwined aggregates as shown in the TEM observations [16]. Presence of all these entities caused the weakening to the mechanical properties of the fabricated nanocomposites. Agglomerates and bundles of CNTs in polymer nanocomposites will act as stress concentration sites that caused early failure due to the factor of uneven stress transfer during the mechanical loading of the nanocomposites. Liao (2003) successfully explained the mechanism of failure due to this phenomenon [3].

In this study, the formation of agglomerates of tubes aggregation can be detected clearly since the dispersion process was solely rely on the capability of the melt blending process to separate the CNTs bundles without assistance from any chemical surface modification onto the surface of CNTs. Surprisingly, at lower filler content, MWCNTs were successfully dispersed quite well, especially for the PP/MWCNTs composites with filler loading of lower than 1.00 wt.%.

4.0 CONCLUSION

PP/MWCNTs nanocomposites were successfully prepared through the simple melt blending technique. Addition of low loading of nanotubes provides extensive improvement to the thermomechanical properties for the fabricated nanocomposites. This situation was assisted by the contribution of well dispersion of MWCNTs within the matrix of PP, as validated through the surface observation by TEM. This phenomenon further revealed the importance of filler dispersion and distribution in affecting the resulted thermal-mechanical properties of the fabricated composites. In addition, through this study, the interaction between the morphological natures with the resulted dynamic thermomechanical behavior was understood and established. In overall, MWCNTs have a great potential to influence the characteristic and engineering behavior of the produced nanocomposites, even though at the extremely lower percentages of filler addition.

5.0 REFERENCES

[1] Yang, S., Tijerina, J.T., Diaz, V.S., Hernandez, K., and Lozano, K. : Dynamic Mechanical and Thermal Analysis of Aligned Vapor Grown Carbon Nanofibre Reinforced Polyethylene, Composites Part B, 38,

2007, p.228-235.

[2] Jamaliah, S.: Preparation and Characterization of Natural Rubber/Clay, Poly(ethylene-co-vinyl acetate)/Clay Nanocomposites. PhD. Thesis, Universiti Putra Malaysia, 2005.

[3] Liao, Y. H. : Processing Technique and Mechanical Properties of Functionalized SWNT-Reinforced Composites. MSc. Thesis. The Florida State University, College of Engineering, 2003.

[4] Dalmas, F., Cavaille, J.-Y., Gauthier, C., Chazeau, L., and Dendievel, R. : Viscoelastic Behavior and Electrical Properties of Flexible Nanofober Filled Polymer Nanocomposites. Influences of Processing Conditions. Composites Science and Technology. 67,

2007, p.829 – 839.

[5] Khalina, A. : Rheological Behavior and Properties of Injection Moulded Oil Palm (Elaeis Guineensis Jacq.) Empty Fruit Bunch Fibres / Polypropylene Composites. PhD Thesis. Universiti Putra Malaysia, 2005.

[6] Green, J., and Wilkes: Steady State and Dynamic Properties of Concentrated Fiber Filled Thermoplastic. Polymer Engineering and Science, 35: 21, 1995, p. 1670-1681.

[7] Abdel-Goad, M., and Potschke, P.: Rheological Characterization of Melt Pressed Polycarbonate-Multiwalled Carbon Nanotube Composites. Journal Non-Newtonian Fluid Mechanics, 128, 2005, p.2-6. [8] Choi, Y.-K., Gotoh, Y., Sugimoto, K.I., Song, S.-M.,

Yanagisawa, T., and Endo, M.: Processing and Characterization of Epoxy Nanocomposites Reinforced by Cup-Stacked Carbon Nanotubes. Polymer,46, 2005, p.11489-11498.

[9] Joseph, P.V., Mathew, G., Joseph, K., Groeninckx, G., and Sabu, T. : Dynamic Mechanical of Short Sisal Fiber Reinforced Polypropylene Composites. Composites Part A, 34, 2003, p.275-290.

[10] Fateme, R. : Development of Short Carbon Fibre Reinforced Polypropylene Composites for Car Bonnet Application. MSc. Thesis. Universiti Putra Malaysia, 2006.

[11] Zhang, H., and Zhang, Z. : Impact Behaviour of Polypropylene Filled with Multi-Walled Carbon Nanotubes. Macromolecular Nanotechnology. European Polymer Journal, 43, 2007, p.3197-3207. [12] McNally, T., Potschke, P., Halley, P., Murphy, M.,

Martin, D., Bell, S.E.J., Brennane, G.P., Beinf, D., Lemoine, P. and Ouinn, J.P. : Polyethylene Multiwalled Carbon Nanotubes Composites. Polymer. 46, 2005, p. 8222-8232.

[13] Seo, M.K., and Park, S.J. : Electrical Resistivity and Rheological Behaviors of Carbon Nanotubes-Filled Polypropylene Composites. Chemical Physics Letters.395, 2004, p.44-48.

[15] Ryan, K.P., Cadek, M., Nicolosi, V., Blond, D., Ruether., Armstrong, G., Swan, H., Fonseca, A., Nagy, J.B., Maser, W.K., Blau, W.J., and Coleman, J.N. : Carbon Nanotubes Reinforcement of Plastics? A Case Study with Poly(vinyl alcohol). Composites Science and Technology, 2006. <doi:10.1016/j.compscitech.2006.07.06>.

[16] Potschke, P., Bhattacharyya, A.R., and Janke, A. : Carbon Nanotubes-Filled Polycarbonate Composites Produced by Melt Mixing and Their Use in Blends with Polyethylene. Carbon. 42, 2004, p. 965-969.

Figure 5: TEM observation of cryo thin sectioning of (a) PP/ 0.25wt.%; (b) PP/0.50wt.%; (c) PP/0.75wt.% and (d)

PP/1.00wt.% MWCNTs nanocomposites surfaces with 35 500X of magnification power

(a)

(c)

(b)

CNTs CNTs

(a)

CNTs Entanglement

(c)

(d)

CNTs Coiledand Entangled Structure CNTs