optimisins refined breached d"egdoriz.

end"P,"liH:T'JlJ:;,':'".'#iill,f,::ff'fJ?:',ffivarue

toprovide the stabre

Muhammad vusuf ditong

a

.

,,,--

4nirE

t6rt^n Departmentof chemicatEngineering,ru"rti'iiEiginiilrg,

u.niviiiiyotsumatera

utara' Medan 20155' lndonesia [email protected]

Vd.s

Nog

(SeP.2012)32S

lsst\t @7+6846 lndian Journal of Science and Technology

specJon 0-175 g/100 g'

: Distillation, lodine value, Bottom flash distiller standard, Distillate,

Feed ca

il

Tabte t. The composition of IRBDPSFA orhvd-rolv.zed RBDPS

and

ih;"'q';iitv

'

or

i:Ilut"

which

is

producHSRBDpSFA(Muhammad,2009)

--=-:-===^-

0'a]una'mmio,.

20.10;

YYlTTlg

,r?o'. Abstracton the commerciar scare, the quarity standard of erenoed siearic Acid Distiiled

(BS{D) courdn't be achieved by normal distilration. BSAD

iodine-;ilJ;;;stry

higher than maximu,qru'i',iv-"iliio*i1o

z

mg/100 g), with the same iodinevarue (0.80 s/100 s)

"t'i""i'Hvoios"nui"a

spiitt"Jiieois rutry'n.iioi

HiiraDFarA,ieed

ci'pacitv 5'5 ton/hour witt bottom frash dist,rer

t"r"p?riirIiEacning

zil;'c. rt

"ieparation

""oilor"ti"n

of chemical impurities (so sensitive tt oxidation/temp"r.trr"mJui "r,unging, and

ioi;;"rJ"r

*Ir"

0"r".

ir'"

"tr""t

of the reduction oi feed iodine value (lV) increasing of feed

"upu"ity ano uottom

t"rp"i"tu[?

tiair, aistitt"r

""rrrn

(BFD) w.ere ootimized to observeBSAD',t

iodine vatue trend by ,.in'g u factorial

q."tig;i3';?

*

sf'utntO

rn" tpiiti*"condition

was found on thefeed lV c

0.60 g/100 g, at tee^o"c-;p'"itv

o.o't"n/hou-r,'J"i

ero iemperature'iifd-

roai"e varue ofBSAD was stable and it

lntroduction

Brended stearic acid dist*rate (BSAD) contains -60

o/o

maximum-oi-

esnu

tv

specs)

which

is

producew/wof parmiticacid(c15H31cooHorc,,o)and

-4oo/owrw

"or*J*iurry

uy

using the. samelv

(0'80 9/100g)

<of stearic acid (c17H35cooH or c1s)'

'n'

*l'nil'"il;-t

H::I**i,

g::*"illfiI'fliil"

''i",,1:'-"i1?li"Ji

:*tt,;,::,j

!?;:'ii';'",8*,i:::'J;'Xii'ii'J'i:tp"J

I'..'"lJ'i

*;;n'tiioimur

and thJ iodine varue was unstabrachieved

using RBDps

as

raw

,.nri"riui-'rr.,"

bqr!" "r-

ti'"-

practicar

data,

the

increasing

rcomposirions

of

snsDpsrR

are

shownir"i"nr"

i.

HsRBDpt;Ris-tv'wtrich-is

higher

than 0'80

9/100 RBDps is highry suitabre to obrain oo "2"c.,u;+o'"7"-c.,ror

proau"li-tt"

r,ign"tBStq

lV (Yusuf' 2010)' Based c

BSAD by cutring a pario-t

i["

r"*",

and higrrer uoirerth-an

*',ur"

iiit.,'it'.

;rppo."d

that tire lower HSRBDPSFA

cro_ra

in

the

suitabre dist,ration process;;*Iti;";

;f

!v

toi.tirijil"

p-"!!i

t""d)

can reach, the rower BSAHSRBD,.FA.

distillatronprocess-

L-

rv on

ir,"

iing?t of it-quality standard will be. How mutThe

off

specsof

BSAD iodinevalue

(BSADlv)

.llouriin"

orl'l;'I:-*,lY o"'

lt

should be foundot

created lower competitive level in oleo

"n"rni"jt

,urfet.

li

Based

on

the

experience' practically

the

lowcourdn,t

be

producedin

tne

normar p,oorJiion"v"r".

nsne'op"-din]v

"un'ue-^obtainedthrough SRBDPS' producrion

wi,

be

i""*i"i""i

,no *ariing

""Ligv.'it

;

hydrosenition'

This was also

based

on

fatty

acovera, items of quarity specs courdn,t

ue.oiiainBt.

Tlr"

rrva.i".aii"n-tneorylRobert'

1990)'Thiswasn'ttheor

off specs rV are tne

laule

of the rowert"i.i"iutrru

ot

*"v tJ.orr"

*re pro',otem- rodinevaiue of BSAD was al

BFD corumn. rt

o"crelll;;;;,"

rii;c.-iriii

affecteo

nigher wtrentre'feed

capailtv higher than 5'5 ton/hc

BSADcompositions,frombigger-lossof

G+ra;iBSii.t9

1;1Y:yf''ZOiol' So thequestibn "what will the optimt smailer weight ratio

of c,u-to

c,r.ol Bq4D"l"o

a5no

aistilraiion "ohdition, togetthe

inspecs BSAD

lvr

hcompositions tend to

L;+i

tp""t'

tt.i" u big effect totire

to be studied'rower production

yieriLr-s;;;;;

uis t,oudtu arso tothe

t;*,"ru1X#:i,.J,'..,1,15:?l

#i:!ELrr":J,':tl;

U9

No Fatty acid name

Symbols double

bond

SRBDPSFA,

o/o wlw

HSnaopsrn,

o/o w/w

1 Lauric acid Ce 0

0,1 0.1

2. Myristic Acid Crl 0 1.3 1.3

3 Palmitic Acid Cro 0 57,4 57.4

4. Stearic Acid Crpo 0 6.1 40.2

tr Oleic Acid Craa 1 27.9

6, Linoleic Acid C'ts-z 2 6.2

ii"g"iJint-ihit,

the

optimum^feed

lY^'

oiiifiation" conditions of HSRBDPSFA have to

t"t"ri"n"O

carefullyand

commerciallyin

Istudy (Peter et' a1.,2004)

ioitinu value

was one

of

the

qu€ oarametersof the

commercial premium BSt[".iA"t

its

color, heat stability and fatty zIJrpoiitions

(Pr.xxx,

2005)'99tting,th:lT

the'better

and

the

more stable

lV'

Heliiii"""r'"0

DeodorizedPalm

Stea.rin (T?? 10)' There.is:'ffi

i;

n"J*uv

for getti'ng the in specs of BSAD in thewas

used

as

raw

material; becausethe

cheni-.,,,riii"s

or impurities that's so sensitive to oxidationir"tin""o;u"un

i""t".t"d

from RBDPS to a cenaink

normal Production cYcle'

lMta*

bft r-Uytt

E,r rdin ad ExvirqnErf GSe)7t)

lodirBmlrc'

http/Arr,vw.in{st.og

llY.Rt

It

is

so

suitableto

produce BSAD through hydrolysis, hydrogenationand

distillation. lmpurities

reduction (includes unsaturatedbondl

of

the

crude

fatty

acid (SRBDPSFA) can reduce fatty acid color and lV through fatty acid hydrogenation (Robert, 1990). The experience shows on the specific conditions, distillation process also separatedthe

impuritiesto

a

certain levelso

that the amountof

unsaturated bond (indicatedby

lV)

will

be lowerand

better.So

hydrogenated SRBDPSFA feed could reduce BSAD'lt/

also through distillation and/or fractional distillation.By

using

of

this

HSRBDPSFA,reduction

of

HSRBDPSFAIVand

optimization

ofdistillation process conditions

which

is

done

in

this research can reduce unsaturated bondor

obtain lower and more stable arnount of unsaturated bond or BSAD lV according to BSAD lV quality standard.According

to

the

practical

experiencesin

oleo chemical industry,crude

fatty acid

of

HSRBDPSFA contains impuritiessuch

as;

a

trace

of

caproic acid (CsHllCOOH) or C6, caprylic acid (C7H15, COOH) or Csand

capricacid

(C1gH21COOH)or

C16.The light

end composition of the first fractionation column of distillation showedthis

fact. These lower fractionsare

easier to oxidize and have bigger potential to form double bond or increasethe

iodine valueof

fatty acid whichis

being purified (Nur&

Septin, 2006; Yusuf, 2010). The otherimpurities

in

crude

fatty acid

are

hydrocarbons,aldehydes, ketones, sterols, phosphatides, glycerol and un-hydrolyzed RBDPS which also have big potential to increase the lV of fatty acid according to their chemical properties (Ketaren, 2008). The lower

the

impurities infatty acid are, the better the fatty acid quality is or the bigger

the

impurities canbe

separated,lhe

better the fatty acid quality is.lmpurities

of

crude fatty acid feed (CFAF) can be separated through distillation processto

improvelV

of fatty acid distillate. The impurities such as: fatty acid (< C12) and C14, hydrocarbons, aldehydes and ketones are separated as the light end fraction (low boilers) in the first fractionation column andthe

other impurities such as:sterols,

phosphatides,glycerol

and

un-hydrolyzed triglyceride is separated as heavy fraction (high boilers) or residue (Brocmann et al., 1981).lt can be also applied to purify CFAF of HSRBDPSFA.Providing the BSAD with the same quality standard as before had been done by increasing light fraction until

5

% of

feed capacity, togetherwith

increasing precut column temperature unde;' vacuum pressureto

remove more the impurities, such as color bodies, fatty acids that are lower than lauric acid (CrrHzaCCOH) or C12, myristicacid

(CrsHzTCOOH)or

C1a, hydrocarbons, aldehydes and/or ketonesof

HSRBDPSFA (thatare

sensitive to color changing which cause it to be darker and increase the lV of fatty acid). lt's follorred by reducing BSAD yielduntil 85%

(desired higher).The

increasingof

precut column temperature affectedthe

increasingof

BFD temperature andso

it

was

potentialto

increaselV

of lndian Journal of Science and TechnologyR€s€ardlatide

olrdian Soddyfor mucatim ard BNiro-rrert (See) 71

w7

Vd.

5

r.b.9

(Sep.2012)

lSSilt Cs74 6846BSAD relatively. The temperature had to be reduced so that lV will be relatively low. This was also based on the down grade acceleration of fatty acid that was affected by

temperature (Brocmann et al., 1987; Ketaren, 2008).

The

providingwas

done

by

recyclinglhe

rubber grade distillare to the drier as the other big potential to increase BSADlV,

besides CFAFlV

and

distillation procqss conditions (the present distillation facility or Feld and Hanh style) (PT. XXX, 2005). ln this research, it will be separated as a byproduct of rubber grade distillate to separate bigger the impurities of BSAD to obtain lower lV. See Fig. 1 (the modified Feld and Hanh style).Based on this fact, it's supposed that feed lV wasn't suitable yet to produce BSAD as its quality standard of lV (0.2 9i100 g) and

itwas

stable. lt has to be studied. The distillation operating conditions weren't optimum also. For this, light end yield will be kept constant on the range 1.5-3% so that BSAD yield will be higher and closer to 93.0 %

(as

a

normal specificyield

of

BSAD which could be obtained practically). To study, the feed capacity will be optimized above 5 ton/hour and BFD temperature will be set until finding new optimum point on the new optimum operating conditions of distillation.Method

The raw

material HSRBDPSFAwas

produced byhydrogenation

of

SRBDPS

from

Splitting

Plant (SRBDPFA was producedby

hydrolysisof

RBDPS) inPT. XXX's facility. The raw material HSRBDPSFA was used as crude fatty acid feed. lt was obtained and will be

purified

on the

same plant

site

of

the

same manufacturer's facility. Medium pressure steam (11 bars) was usedto

perform vacuum pressure and oil thermal heater was used to heat up fatty acid in order to purify it and to produce BSAD.The research was done by factorial method with 3

independent variables: feed rate (F) at level of 5.5; 5'75 and 6.0 ton/hour, feed lodine Value (lV) at level

of

0.7and 0.6 g/100 g and bottom temperature of flash distiller (B FD) at 218, 220 and222'C (5 mbar). Factorial method was designed

by

constant modet3 x 2 x 3

and was repeated 2 times for each factor and BSAD lV was one c'the

quality parameter whichwas

observed.Statistj-i

analysis was performed by Minitab Release -14 soft"'a'e (Nur

&

Septin, 2006). Samples were analyzed e'ie"..:

hours which amounts were 100 ml of liglttfract:cr

:.:':

-of BSAD and 100 ml of residue acid. Analysis!'::s:--=

lodirevdLE'

lfipl/lvvrwinq$.sg

Table 2. Steps of the research

Variables al (F=s,50) a2 ( F= 5,75 ) a3(F=6,0)

cr (zraoc)

br1o,z1 bz(o,o) br1o,z1 bz1o,o1 br 10,21 bz1o,o)

X X X X

x

Xcz (zzooc)

x

X X X Xx

X X X X X X

cg {zzzoc)

X X X X X X

X X X X X

x

-7

\r,

l---.]-r -:: =mf,@

,"f-*\

W

-,3,an Joumal of Science and Technology

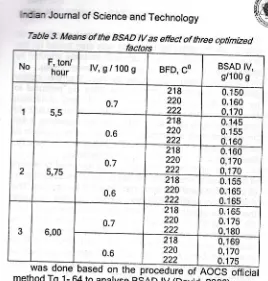

Tab/e 3. h|teans of the BSAD lV as e{fect of three optimized

No F, ton/

hour lV,g/1009 BFD, CO BSAD IV, g/1 00 g

1 5,5 0.7 218 220 222 0.150

0.1 60

0,1 70

0.6

218

220 222

0.145

0.1 55

0.1 60

2 5,75

0.7

218 220 222

0.1 60

0,1 70

0,1 70

0.6

218 220 222

0.155

0.1 65 0.16s 3 6,00 0.7 218 220 222 0.165

0.1 75 0,180

0.6

218 220

222

0,1 69 0,170

0.1 75

?98

Vd.s

M.9

(Sep.2012)

lssr\t 09746846symbol

of

*

betweentwo

symbolsof

this

process variable statesthe

interaction betweentwo

or

more variables. So F*lV is the interaction levels of F with lV and so on for the others, dk is degrees of freedom. uk is sumof

square,kt is

central-squ-are,f*"rr-anO

p4n6yuofe distribution test and significance tbstZnJlyiis of variance.

Effe_ct of process

varilutei-is-iii.rtn"j"i,'

tt bono,,.pq

_0.05.

f0y

significanceof

the

optimbed process variables effect on the BSAD iodine vaiueThe results of Factorial anatysis and its significance (Table

4)

describe the..influenc6-otipti-ired

process variables on the BSAD lV. Statistical

,nliyri"

shows tttat feed rrate,-F (p"no,u= 0,000) ano reeo-lJo-ine value-,lV

(P9"o^,=1 0,010), B FD (p,nova= 0,0p0)

*"r"

to*"r. than (po = 0.05), the effects were so significint

tolhl

changinj oi BSAD iV. lnteraction of F and iV 1e",*, = ii,gzOl, F and B FD (Pano,a = 0,67g), lV and

g

fD

ti;"*"

='O,]ZS),f

analV

also with

B

FD

(pano,a=

0,di"di

diin,r

affected significant (Puno,n> po = O.OSJ changing'of SSAD lV.The

iglT!9f

,"j.chmain factor toihe eS-AdM is shown in theI

L-l

it

-t,

f--Il:

:

iIN.

i-r

lz

I I ILr

lndii impur condi had gT and tl

can b

The e

BSAt TI CAUSE reduc Separi same CFAF condit lV car lower

Table

was done

oasea

riril""o

Fig.3.method Tg 1- 64 to anatyse.BsAD tV

(David,2006).

Eifect

of

O-ptimrlftrr'Iros f

g

r-o4loanalyseBSADlV(David,2006).

lffect

of

Optimizationof

the main

variablesand

lts The correct results will be obtained by keepingtop

lnteraction on BSADlv

temperature of pre-cut column

at

190oc"no

pr"i"u"r"

Jt

The increasingorgseo

v

was affected significantly21

mbar;

Flash

Distiller

pressureit-

b

'moar

;"d

by the optimizatio-n or ttre main variables (increasing of B temperature (B FD) as per the steps shown inrior"');

rb,

reeo'flow rater

uno o""r"asing of feed iodine value), residue distiller pressure

at

1 mbar andtemperai;;;;i

because significanceiest-anatysis

of

variance p,no,"2S0"C.

shows,pun*]_olBFD

E",_""

of F

and punouuof

lV wereThe

research stepswere

basedon

the

factorial

lower tnan-olstpol.

5i"

f'"'ir"

4. The trends can be seen method by 3 x 2 x 3 and were repeated 2 times.f;b|",

in Fig.2. [image:3.612.30.298.57.338.2]shows steps of research' The symboli

ire

useo intre

ih.e impact of the optimized main variables on BSADtable such

asi

o1,

a.z,3s

=

variationof

CFAFrate

lV is shown inig

,6;using

tuinita b 14 software).This (ton/hour); br, bz, bs = varii-tion of feedlvlg/l00

g)

and

picture showsthe-'sig;;i";;;effect

of the optimized main c1' G2' c3 = variation of BFD("c)'

variableso,

gsADiV.'il-"'.ur"

effect is also snown oy

Results and

discussions

the averagevalues of the increment

of

BSAD lV within The results are providedin

Table3.

The effectof

Tabte 5u,iJr.oru

ofi.riig.

zl.process variables were analyzed

with

MinitabRelease

The effecton

increasingof F

is

significantto

the14, where, F is feed rare, lV is feed iooine vaiue ano e

iD

in"rurrinj

oGs"AD';V.Ai"i

of s.5 ron/hour BSAD tV is is the bottom temperature of flashaisittLiiotumn,

*o u

0.15666/91199g,

;i i ;

5.75 ton/hour BSADIV

isTahta,

rT..An^/t/^-:^--_- ,

0.164167 g/100g

and

at F

6.0 ton/howgiAD

rV

i.

Tab/e,4. BSAD tV Variance analysis and significaiion

Source

DK JK kt I tr

anova I banova

Remark Variation

F a 0,0001256

0,0006028 18,08 0.000 Significant

IV 1 0,000278 0,0002778

8,33 0.01 0 Significant

BFD a 0,0012722

0,00063G1 19,08 0.000 Significant

F-IV

2 0,00000s6 0,0000028 0,08 0.920 Not significantF*BFD 4 0,0000778 0,00001 94 0,58 0.679 Not significant

IV-BFD 2 0,0000056 0,0000028 0,08 0.920 Not significant

F*IV-BFD 4 0,0000111 0,0000028 0,08 0.986

Not significant

Error 18 0,0006000 0,0000333

Total ,tr

Table4.

BSADtvVarianceanalrysandsrgnificaiion

0.170g33

9/100

nl

,H:

source

;;;l

i":?:x'.?*lJrfr?t?;irii

ffi

-"""

t

i

-"

I

""

I

'

from F of 5.5 kg/hour to 5.75I

r

i r

ks/hour ana O.6OOOO69/100 g from F S.75 kg/hour to 6.0

i

BFD

i ,

i_o,oorrrz

I

o,o

kg/hour. The averaoe vatue1,r",J3i,.J""i3,,

i8fi*jx

g/1 00 g.I

IV. BFD

| 2

i

0,0000056o,oooA

This is easy

toI

t

j

Hl,"J;,S,.r,"?u"",,."",'..,tI

impurities

which

were,ora,

r

t35i

I

r_l;l:ffi:::r:I,",35?,",Y;,,iT

Research artide2

J

1

R*eth

a lrdan S

73 @lrdian Societyfcr E L€atimand Fvirryrrerd

(isee)

frtto,ffiffiT*

tuly.RitorgalndianJ.$i.Td"nd.

lndian Journal of Science and Technology

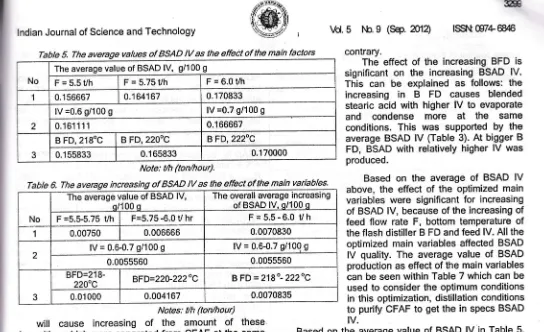

Table 5. The average vatues of BSAD lV as the e{fect of the main factors

-7

gg

Vd.s

hlo.g (Sep.2012)

lSSiltg/46846

contrary.

w.

1€ ESS ate )ce. d= lt.-)te> AD his ain by hin nce ESS l-rat lDa

lof

dB lnd ted -he the Its rtly ,fB re), nova ere )enTabte 6. The average increasing of BSAD lV as the effect of the main variables.

Notes: t/h (ton/hour)

will

cause

increasingof

the

amount

of

these impurities which were separated from CFAF at the same conditions. This increasing caused the produced BSAD had greater lV.The effect of reducing feed lV on BSAD lV reduction and the effect of increasing B FD on increasing BSAD lV can be seen on the same tables, Table 5 and Tables 6.

The effect of feed iodine value reduction is significant on BSAD lV reduction.

The average

of

BSADlV

reduction happened and causedthe

reductionof

feed

iodinevalue (lV).

This reductionof

iodinevalue

(lV)

caused more

difficult separation of the iodine value together with BSAD at the same conditions. So the purifying that had been done on CFAF with lower lV produced lower BSAD lV at the same conditions. These data proved that the reduction of feed lV can improve quality of BSAD lV. So raw material with lowerlV

will

produce BSADwith

lowerlV or

on

theTabte 7. The average BSAD production as the effect of the main variables.

No The average value of BSAD production, kg/hour

1 F=5.5Uh F = 5.75 Vh F=6.0Uh

4.943.7 5,168.12 5,400.09

2 lV =0.6 g/100 g lV =0.7 g/100 g

5,171.92 5,169.'13

3 B FD, 218" C B FD,22O. C BFD,222,C

5,148.77 5,161.53 5,201.28

Note: tth =ton/hour

The effect

of

the increasing BFD issignificant

on the

increasing BSAD lV.This can

be

explainedas

follows: the increasingin B

FD

causes

blended stearic acid with higher lVto

evaporateand

condense

more

at

the

sameconditions.

This was

supportedby

the average BSAD lV (Table 3). At bigger BFD, BSAD with relatively higher lV was produced.

Based

on the

averageof

BSAD lV above, the effect of the optimized main variables were significantfor

increasing of BSAD lV, because of the increasing of feed ftow rate F, bottom temperature of the flash distiller B FD and feed lV. All the optimized main variables affected BSADlV

quality. The average valueof

BSAD production as effect of the main variables can be seen within Table 7 which can be used to consider the optimum conditions in this optimization, distillation conditions to purify CFAF to get the in specs BSADtv. :he

'is

is is he IV. Based on the average value of BSAD lV in Table 5,

the best BSAD lV is 0.161111 g/100 g. Based on Table 7 above the best BSAD production is obtained on the feed flow rate (F) is 6.0 ton/hour, feed lV is 0.6 g/100 g

and

BFDis222"C.

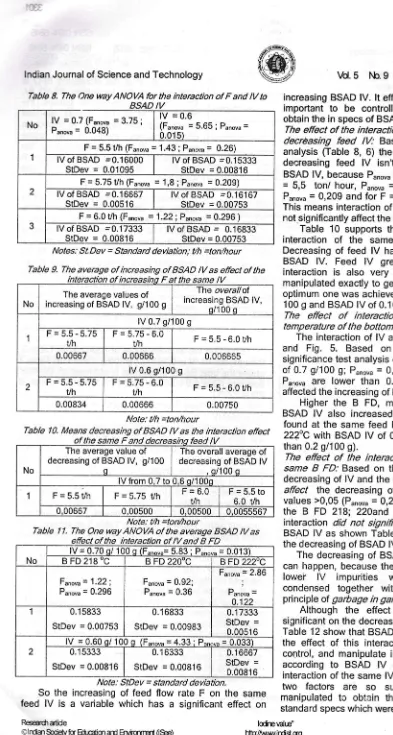

The effect of feed flow rate and iodine value interaction on BSAD lV.

The results of one way ANOVA statistical analysis on

the interaction

of F

with lVto

the BSADlV

are shown within the Table8.

Based on the data, significance test analysis of variance Punoru = 0.048 for the interaction ofincreasing

F

at the samelV

(0.7 9/100 g) and Puno,, =0.015 at the same lV (0.6 g/100 g). Both values of Panoua

are tbwer than 0.05 (Po). That's why the interaction of increasing

F

with

the

same

lV,

shows

significant increasingon

BSADlV,

also

basedon the

factorial analysis within Table 4. See also Table 9 as supportive of such explanation. These values explained that the etfect of the interaction of the increasing F factor with the samelV

on the

increasingof

BSADlV is

significanton

the same feed lV. The interaction trend of these 2 factors can be seen on the Fig. 3 and 3D surface plot on the Fig. 4'It

canbe

understood that the factof

this result is according to the mass and heat balance principles. The increasing of the CFAF mass, which was purified, needed more heator

proportional heatto

maintainthe

same temperature. This was caused by more evaporation and condensationof

the

BSAD

which

was

purified

or separated, includethe

impuritiesof lV in

BSAD' The increasing on F was caused by BSAD that was produced had more BSAD lV on the same feed lV')g

75 00 i.0 UE IV 30 to \F he rfe nd F F d. Researdt artideolrdian Socjetyfor klucdiot ard EUiffin'Ert ($e)

73

lodrcwlue' tttp/

^,rw.inq$.sg

ltv=---l#r i- -r

No

The average value of BSAD lV, g/1 00 g

F=5.5Vh F = 5.75 Vh F=6.0Uh

1 0.1 56667 0.164167 0"170833

2

lV =0.6 g/100 g lV =0.7 g/100 g

0.161 1 1 1 0.1 66667

3

B FD, 218"C B FD,22OOC BFD,222"C

0.155833 0.1 65833 0.1 70000

Note: t/h (ton/hour).

No

The average value of BSAD lV,

o/1 00 q

The overall average increasing of BSAD lV, g/100 s

F =5.5-5.75 Vh F=5.75 -6.0 V hr F=5.5-6.0 Vh

1 0.00750 0.006666 0.0070830

2 lV = 0.6-0.7 g/100

g lV = 0.6-0.7 g/10Q g

0.0055560 0.0055560

3

BFD=21

8-2200C BFD=220-222'C B FD = 2180-2220C

[image:4.612.35.579.33.365.2]uF

lndian Journal of Science and Technology

Table 8. The One way ANOVA for the interaction of F and lV to

Notes: St.Dev = Standard devbtion; yh =ton/hour

Table 9. The average of increasing of BSAD lV as effect of the

Note: t/h =ton/hour

Table 10. Means decreasing of BSAD lV as the interaction effect

Note: t/h =ton/hour

Table I /. The One way ANOVA of the average BSAD lV as

Note: StDev = standard deviation.

So the increasing of feed flow rate

F

on the same feedlV is a

variable which hasa

significant effect onResearch atide

: lrdian Socjdy fs ftfi.rcdlm

ai

&rvirtrrrert (See)330C

Vd.5

Nb.g (Sep.2012)

ISSNI G746846increasing BSAD lV. lt effect can't be neglected and very important

to be

controlledor

manipulated exactly to obtain the in specs of BSAD lV.The effect of the interaction of same feed flow rate F and decrbasing

feed

lW

Basedon the

one

way ANOVA analysis (Table8,

6) the interaction of the same F anddecreasing

feed

lV

isn't

significanton

decreasing ofBSAD lV, because Punouu is greater than Pcr = 0,05 (for F

=

5,5

ton/ hour, Punouu=

0,26 ; for F=

5,75 ton/hour ;Punoru = 0,209 and for F = 6,0 ton/ hour ; Purou, = 0.296). This means interaction of F and lV within the Table 4 did

[image:5.612.73.466.14.749.2]not.significantly affect the decreasing of BSAD lV.

Table 10 supports

the

explanationof

effectof

the interactionof

the

same

F

and

decreasingfeed

lV.Decreasing of feed

lV

has impact on the decreasing of BSADlV.

Feed

lV

greatly

affected BSADlV.

This interactionis

also very

importantto

be

controlled or manipulated exactly to get the in specs of BSAD IV. The optimum one was achieved at F = 6 ton/hour, lV = 0.6 g/100 g and BSAD lV of 0.16833 g/ 100 g (Table 8).

The effect

of

interactionof

feed iodine

value andtemperature of the bottom flash distiller on BSAD

lV

The interaction of lV and B FD is shown in the Fig. 3

and

Fig.

5.

Based

on the

data

in

the

Table

11,significance test analysis of variance Punou" = 0,013 for lV of 0.7 9/100 Qi Panova = 0,033 for lV of 0.6 9/100 g. Both

Prnor"

are

lowerthan 0.05 (Po).

lncreasingof B

FDaffected the increasing of BSAD lV or vice versa.

Higher

the

B

FD,

morethe

lodine value and the BSADlV

also increased. The optimum BSADlV

was found at the same feed lV 0.6g/

100 g and ata

B FD222oc with BSAD tV of 0.16667

g/

100 g (This is tower than 0.2 g/100 g).The effect

of

the interactionof

lV

decreasing and the sameB

FD.' Based on the Table 1''1, the interaction of decreasing of lV and the same B FD did not significantlyaffect

the decreasingof

BSADlV,

becauseall

P"no*values >0,05 (Punovu = 0,296 ; 0.36 and

0]22for

each ofthe B

FD

218; 220and 220oC). This meanslV.B

FDinteraction did not significantly affect the decreasing cf BSAD lV as shown Table 2. See the overallaverage of the decreasing of BSAD lV in Table 13.

The decreasing of BSAD lV in this case (see Fig. 5)

can happen, because the decreasing of lV impacted on

lowel

lV

impurities

which

was

evaporated and condensed togetherwith

BSAD.This

matches the principle of garbage in garbage out.Although

the

effect

of

this

interactionwas

not significant on the decreasing of BSAD lV, the data in the Table 12 show that BSAD lV was decreased. That's whythe

effectof

this

interactionare

alsoso

important to control, and manipulate in orderto

obtain the in specs accordingto

BSADlV

quaiity standard, besides the interaction of the same lV and lncreasing of BFD. Thesetwo

factors

are

so

sufficientto

be

controlled or manipulaiedtc

obtainthe

qualityof

BSADlV as

itsstandard specs which were settled.

.@

of lodiremlrc" Ittp/Aarr,wlindsLog tvlY.RitorEa lrdanJ.Si.Tednd. BSAD IVNo lV = 0.7 (Funouu = 3.75 ; Punoyu = 0.048)

lV = 0.6

(Funouu = 5.65 ; Punouu = 0.015)

1

F = 5.5 t/h (Fanoua = 1.43 ; Puno*

=

0.26) lV of BSAD =0.16000StDev = 0.01095 lV of BSAD --0.15333StDer, = 0.00816 2

F = 5.75 Uh (Fanov" = 1,8 ; Panora = 0.209)

lV of BSAD =0.16667

StDev = 0.00516

lV of BSAD --0.16'167

StDev = 0.00753

J

F = 6.0 Uh (Funou" = 1.22 i P"nov" = 0.296 ) IV of BSAD --0.17333

StDev = 0.00816

lVof BSAD

=

0.16833 StDev = 0.00753interaction of increasino F IV

No

The average values of increasing of BSAD lV, gi 100 g

fhe overallo'f increasing BSAD lV,

o/1 00 q

1

lV 0.7 g/100 g F=5.5-5.75

Uh

F=5.75-6.0

Uh F = 5.5 - 6.0 t/h

0.00667 0.00666 0.006665

2

lV 0.6 s/l00 g

F=5.5-5.75

Vh

F=5,75-6.0

i/h F=5.5"6.0Yh

0.00834 0.00666 0.00750

the same F and decreasino feed lV

No

The average value of decreasing of BSAD lV, g/100

o

The overall average of decreasing of BSAD lV

, q/'100 q

lV from 0,7 to 0,6 o/100o

1 F=5.5Uh F = 5.75 Uh F=6.0 UN

F=5.5to 6.0 uh

0,00667 0,00500 0,00500 0,0055567

effect of the interaction of lV and B FD

No

lV = 0.70 g/ 10C g (Funnuu= 5.83 ; Puno,u = 0.013)

B FD 218 OC B FD 220,C BFD222,C

Funon"= 1,22;

Punoru = 0.296

Fanovu = 0.92;

Punoru = 0.36

Funoru = 2.86

;

t)-I anova

-4.122

I 0.1 5833

StDev = 0.00753

0.1 6833

StDev = 0.00983

0.'17333

StDev = 0.00516

2

lV = 0.60 o/ 100 q (Funo*=4.33 ; P"nou, = 0.033) 0.1 5333

StDev = 0.00816

0.1 6333

StDev = 0.00816

0.1 6667

lndian Journal of Science and Technology

0.1:0

0.r55

--7

ml

Vd.5

1.b.9 (Sep.2012)

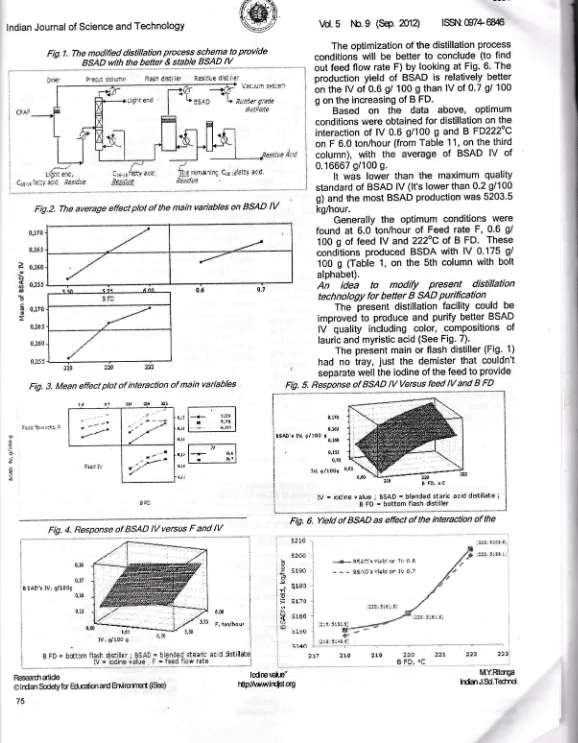

lsst\t G7+6&16 The optimization of the distillation process conditionswill

be betterto

conclude (to find out feed flow rate F) by looking at Fig. 6. The production yieldof

BSADis

relatively better on the lV of 0.6 g/ 100 g than lV of 0.7 gl 100g on the increasing of B FD.

Based

on

the

data

above,

optimumconditions were obtained for distillation on the interaction

of

lV 0.6 g/100 g and B FD222oCon F 6.0 ton/hour (from Table 11, on the third column),

with

the

averageof

BSADlV

of 0.16667 g/100 g.It

was

lower thanthe

maximum quality standard of BSAD lV (lt's lower than 0.2 9/100 g) and the most BSAD production was 5203'5 kg/hour.Generally

the

optimum conditions were foundat

6.0 ton/hourof

Feed rate F, 0.6 g/ 100 g of feedlV

and 222oC of BFD.

These conditions produced BSDA withlV

0'175 g/ 100g

(Table 1, on the Sth column with bolt alphabet).An

idea

to

modify

present

distillation technology for befter B SAD purificationThe

present distillation facility could be improvedto

produce and purify better BSADlV

quality includingcolor,

compositions of lauric and myristic acid (See Fig. 7).The present main or flash distiller (Fig. 1)

had

no

tray,just the

demister that couldn't'

separate well the iodine of the feed to provideFig. 5. Response of BSAD lV Versus feed lV and B FD

Ii*'

?:

{

ar)

d

o a

0,

7.

0,1{J

0*1ss

0.15J

0.1?0

0,165

0,I60

li

il;i :l)r' til:, t

r----

-::l

r-i: l+I r 5.731

qr( L_:__jIlJ

(lt0

0.t6J

&sAO', ,V. Urtoo , o.r,

,.,,1=-n;

| - o''l O,IJJ 0,?0 [image:6.612.22.600.24.767.2],!!:

o|::orns1

of BSAD tv*ny:_, ,r!_lv

gaAF'5 Iv, q/1008

i

e fn = bottom flash distiller; ESAD = bpnded dearic;

IV = iodine valuB. F = fecd IloH rEtet*-^^-*@*^.,*,

Researdatide

olndan Societyfor Elucatim ard ErvircrrErtft$e) 75

IV o/loog B'6j

2I8 g FD, oc

lV - iodine value j BSAD - blended staric acld distillate;

B FO = bottom flash distiller

Fig. 6. Yeld of BSAD as effect of the interaction of the

,.'....** iE:i'r ?;ili tr tt, C a

0,11 0,16

' r?10

f croo

- 51e'l

rE

: F ;1?6

< 5rov

I 515il

I

i {14i1 : i

1

I

t

t,

ll

l

"l_i

*-21*

acid iistillatel

lodrrwlrc'

fflp/

^!wjnq$.sg

21,3 3?i 22r

IvtY.Rito'ga

lrdanJ.$i.Tedrd

'@

Fig.1. The modified distillation process schema t9 Provide BSAD- with tle be!91e sbble B_SAD tV

.

Jaei ft{":i ({i!r;l Fn!'" clSi! it. i'tilite

c;s:rilt'-Fig.2. The average effect ptot of the main variables on BSAD

lV

?, *,r

a

aie

:io

217Fig. 3. Mean effect plot of interaction of main variables !j;g r*ra:riq C:;.::f;iS ffi{

3@ lrdianJournalof

scienceandrechnotogy @

vd.5

tb.9 (sep.2012)

rsst\t@746846Fig. 7. An idea to modify the present distillation facility to provide BSAD

with

inciudes BSAD.the befter and stable iodine

value

Conclusionspurification through distillation

are:

0.60 g/100 g of feed lV, 6.0 ton/hour of feed flowr'ntd!'t*

r

botton flush distilleits

FEjl on the BSADr

this optimization met the BSAD's lV quality:

standard

by

separating

rubber

gradei i,iili erd, c1113 r'att1 *t d i;1e. rerjr, ri 10 .::.:. :-4t:y .,:,d. distillate aS bypfOdUCt. All thg main faCtOfS

C... . '-F::r ;c f ;i_:,du, {*5,6,-6 .ii_. }-. f

lV

0.175 9/100g.

Blended Stearic Acid Distillate of RBDPS which was obtained inTable /2. The average of BSAD lV as effect of the interaction of the sam/ lV

and

The improvementis

believed will be able lmprovement of this equipmentwiil

be,""t

o"rriii"

i"

:1:"1?d the BSAD lV' These factors.can be manipulated achieve lowerlv

and more expansive"upuii1!?i5ni5

and,controlled to achieve better and more stable BSADpurification through fractionat

distiilation,'"i;;";;"-;H

lv^'.lncreasingof

the

feedflow

rateF,

temperature ofi",ist'e. capabilit|

to

compete

in

the

,.,.,r"t"'"i

H!t!,-,"'ir.J,S:",:,:T#t"?SSXJ]irrJ,r"l1i"':r#t,,:il1

"'.TH[:TfllitY

o""n

cristiler corumn

to

main

The interactions betwe-en the main fact.rs had impact onfractionationitor 1z'; cotumn in Fig. 7) with

rp""Lr

irrr" :f-

PSADlV,

although someof

the interaction effects (that have highei efficiency) and "doubte"#d*;;;;;;

yu-f-.not

significant'These

interactionshad

to

bepartial conderisers will increise efficiency

t"

1"*";

o"irirJ

manipulatedand

controlled carefullyand

exactly to point (includes iodine value or double Uo|Olu-"alr;;;

i:.TI"

BSAD lV which is according to the specs.boilinj

pointin sefiration

of

DoA

unai,i.,irn:ti;;:;;;

sussestionsi""#:tffi,?d';:l,lni,"u;*ixLas,*i*ilijs"*m

ed;yT0'.1y":::?x1','I

3l'i"":i;'iJ""Hffii:

S1,X1,HI*iaJ::liru:fif:f

;:t"1[i*:1"##;ti

;:"?"""J::'31Xi11il1X':'['i,,"

va,ue or 0 6 s/100 g or and odor better also. The partialconoensel'iliti;;;

lower

by

improving

the

present

hydrogenation easier separation of tight end, cotor ano oooi,;[; ilj;;

.

iperating

conditionsvalue (that can't be

ieparated

moreon

th;

;;;

';i'j;

2'

To -improve2nd

columnof

the

present distillation cotumn, becauseot

freaiitiess

;t;;,

i;i"";i;r;) ;"

facility

becomes fractionation columnwith

partiat BSAD quatity wiu be better and more stabte.;;;i';ii";;

condenserto

get

lower

BSAD

lv,

higher

plant is effeci to darker coror and odor of ruttv u"io'pltirii.,

;iffi,?t[

33Xo1too

vield,

betterand

more stableFD

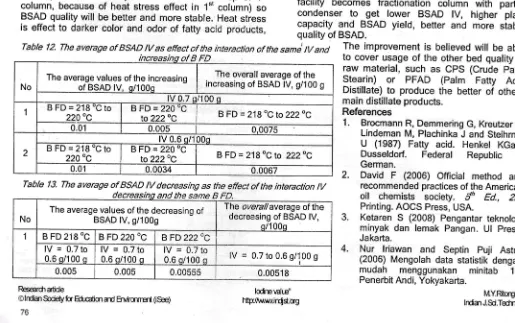

No

The average values of the increasing of BSAD lV, q/100o

The overall average of the increasing of BSAD lV, g/100 g

lV 0.7 q/100 q

1 BFD=218"Cto

22Q"C

B FD = 22AoC

to222oC B FD = 219 "C to 2220C

0.01 0.005 0,0075

2

lV 0.6 q/l00q

BFD=218oCto

2200C B FD = 220oCto222oC

BFD=21goC:

222',C0.01 0.0034 0.0067

Table /3. The average of BSAD lv decreasing as the effect of the interaction

ll/

and the same B FD.No The average values of the decreasing ofBSAD lV, g/1009

The overallaverage of the decreasing of BSAD lV,

o/1 00o

I B FD 218 0C B FD 220 "C BFD 222OC

lV = 0.7 to 0.6 o/100 o

lV

=

0.7 to0.6 s/100 q lV = 0.6 s/100 0.7 toq lV

=

0.7 to 0.6 9/100 g0.005 0.005 0.00555 0.00518

to cover usage of the other bed quality of raw material, such as CPS (Crude palm

Stearin)

or

PFAD (Patm Fatty

AcidDistillate)

to

produce the betterof

others main distillate products.References

1.

Brocmann R, Demmering G, Kreutzer U,Lindeman M, Plachinka J and Steihrner

U

(1987) Fattyacid.

Henket KGaA,Dusseldorf.

Federal

Republlc

ofGerman.

David

F

(2006) Officiat method andrecommended practices of the American

oil

chemists society.d'

Ed.,

2ndPrinting. AOCS Press, USA.

Ketaren

S

(2008) Pengantar teknologi minyak dan lemak Pangan.Ui

press. Jakafta.Nur

lriawanand

SeptinPuji

Astuti (2006) Mengolah data statistik denganmudah

menggunakanminitab

14.Penerbit Andi, Yokyakarta.

IilYRitorga lrdanJ.fti.Tednd. a

Z.

3.

4.

Researd artide

olrdian Soci@ fa ElLratim ard EnvirCI nBt (See)

-5

[image:7.612.57.559.27.695.2] [image:7.612.73.588.438.761.2]-3303

Vd.s

tS.g

(Sep.2012)

lsst\t @746846d;G;1\

rdian Journalof science and

rechnologv

'it[ryj|fl

5.

Muhammad YR (2009) Refined bleached deodorized palm oil (RBDPO) Sebagai Bahan B-aku PembuatanV tegs

S" J. Sisiim Teinik lndust., Fakultas Teknik,usu.

10(1),769-780.5.

Muhammad YR (2010) Optimization of palmitic acidcomposition

in

crude

oleic

acid

to

providespecifications of titer and cloud point of distillate oleic

acid

using a flash distiller.J.

Technol' & Sci' IPTEK, LPPM, lTS. 21(4), 203-213.7.

MuhammadVn

1ZOt1) Providing vegetable stearic acid superV

1895S

from hydrogenatedof

crude vegetabie stearicacid

HCV 1895S

with

A

single fraltionation column. |JET/IJENS. 1 1(4)' 5-15'8.

Peter W, Faesler, Karl Kolmezt and Wang SengKek (2004) Revamp strategiesfor

fatty .acid distillation sectionin

oteo-chemical plants. Sulzer Chemtech' Singapore.9.

pf

iiX

(2005) Production planning control' Medan, lndonesia.10. Roberl

C

Hastert (1990) Hydrogenating fatty acids: Hardening, furlher, faster a-nd cheaper' Proc' World Conf. Oleohemical into2'l't

Century, AOCS, Kuala Lumpur. PP: 16S171'11. Yusuf Riionga M (2010) Optimization of the providing of stearic

aiid

based on refined bleached deodorized palm stearin (RBDPS) whichis

stable according to ihe quality standard. FM\PA, USU. Medan, lndonesia' pp: 2-6.Researd artide

o lrdian Society fcr tlucdim ard Envirmrcri (See) 77

lodirE\alrc'

htipl^ rw.inq*W

lVtYRitorga