MANUAL OF IN/OUT TEST FOR SENSORY EVALUATION

TRAINING AT PT NESTLÉ INDONESIA

AKTRI’S MAULIDDIAN

DEPARTMENT OF FOOD SCIENCE AND TECHNOLOGY

FACULTY OF AGRICULTURAL ENGINEERING AND TECHNOLOGY BOGOR AGRICULTURAL UNIVERSITY

STATEMENT LETTER OF MANUSCRIPT, SOURCE OF

INFORMATION AND COPYRIGHT DEVOLUTION

Hereby I declare that the manuscript entitled Manual of In/Out Test for Sensory Evaluation Training at PT Nestlé Indonesia is an authentic work mine under the academic advisor and has not been presented in any form to any college. Resources derived or quoted from works published and unpublished from other writers had been mentioned in the texted and attached in the references at the end of themanuscript.

Hereby I bestow the copyright of my manuscript to the Bogor Agricultural university and PT Nestlé Indonesia.

Bogor, October 2013

Aktri’s Mauliddian

ABSTRACT

AKTRI’S MAULIDDIAN. Manual of In/Out Test for Sensory Evaluation Training at PT Nestlé Indonesia. Academic Advisor by AMAN WIRAKARTAKUSUMAH and Field Mentor:SCOTT BOXSHALL and ANAS NUR WAHID.

PT Nestlé Indonesia performs analysis sensory evaluation using In/Out test

method to maintain product quality. The evaluation always involved trained panelists as measuring tools, and need training session as analytical guide to the quality of the product tested. The objectives of this internship are organizing recruitment and selection trained panelist; collecting and evaluating the panelist results; and developing materials for training of key sensory attributes used in In/Out training.From the process of recruitment and selection using the departement A and marketing teams, it was choosen 39 panelist as trained panelist. During training, material and preparation sample are the most critical component. Based on consumer testing result it was obtained 20 critical attributes of Business A which will give effect if too dominating presence on the product.This attribute is completely explained in the available material training.

Manuscript

As one of the term to obtained a degree Bachelor of Food Technology

Department of Food Science and Technology

MANUAL OF IN/OUT TEST FOR SENSORY EVALUATION

TRAINING AT PT NESTLÉ INDONESIA

AKTRI’S MAULIDDIAN/F24090077

DEPARTMENT OF FOOD SCIENCE AND TECHNOLOGY

FFACULTY OF AGRICULTURAL ENGINEERING AND TECHNOLOGY BOGOR AGRICULTURAL UNIVERSITY

Entitle : Manual of In/Out Test for Sensory Evaluation Training at PT Nestlé Indonesia

Name : Aktri’s Mauliddian NIM : F24090077

Approved by

Prof. Dr. Ir. M. Aman Wirakartakusumah, M.Sc Academic Advisor

Scott Boxshall Field Mentor

Acknowledge by

Dr. Ir. Feri Kusnandar, M.Sc

Head of Food Science and Technology Department

PREFACE

First of all,the author would like to thank God for his blessing, strength, guidance and protection to accomplish the internship program and thesis. This manuscript which is entitled “Manual of In/Out Test for Sensory Evaluation Training at PT Nestlé Indonesia” was based on internship program from April 2013 to July 2013. The author would also like to thank and give big appreciation to:

1. My lovely Father Mr. Subekti B.Sc, mother Mrs. Itjah, my sister Titiek Indriantik and Selania Yuanita, my brother Hari Fitrianto for your biggest pray, love, support, caring, and understanding for my life.

2. My Academic Advisor, Prof. Dr. Ir. M. Aman Wirakartakusumah M. Sc., for his enormous help academically throughtout the completion of my manuscript. I thank for his valuable and inspiring advice,support and also his time providing me as internee at PT. Nestlé Indonesia Head Office as my final project option before a Bachelor of Agricultural and Technology degree is awarded.

3. Mr. Anas Noor Wahid, as field mentor from PT. Nestlé Indonesia Head Office Jakarta for his valuable time, support, assistance, guidance, knowledge, suggestion, critic to make a better me and his existence as my final examiner in completing my manuscript.

4. Mr. Scott Boxshall, as a mentor from PT. Nestlé Indonesia Head Office Jakarta for the great chance he gave me to have a great experience as an internee and his guidance and support during intership program there. 5. My final examiner, Prof. Dr.. Ir. Rizal Sjarief Sjaiful Nazli, DESS and

Yopi Setiawati M.Si thank for the valuable time, kindness, help, support and recommendation when the examination time.

6. All corporate of Quality Management Department at PT. Nestlé Indonesia Head Office Jakarta, Mr. Nana, Mr. Deddy, Mrs. Mimin for your precious time, knowledge, kindness, help, and advice for providing all my internship programs requirements.

7. All staff of PT. Nestlé Indonesia Head Office Jakarta, Ms. Fetty, Ms. Pinky, Ms. Mimi, Mr. Dipo, Mr. Sigit and all internees at PT. Nestlé Indonesia who cannot mention all, for friendship, togetherness, jokes, help. 8. All lecturers, laboratory assistants, and staffs of department of Food

Science and Technology.

9. My comrade Sarah Fidilah and Sally Wiedjarnarkofor your caring, help, jokes, togetherness and friendship during my internship programs.

10.All of my beloved Friends, Puput, Risya, Anggi, Ami, Dewi, Fey, Qisthy, Vioni, Sri Wulan, Intan, Astri, Mila, Ghesi, Aca, Ayash, Hayyu, Charles, Cicil, Gelar,Haidhar, Wal, Fahrul, Excel, Ratih for your love, laugh, friendship, togetherness, assistance and our beautiful moments.

11.All unforgettable friends with no exception in Departement of Food Science and Technology for the memories.

Truly hope that this manuscript will give useful information.

Bogor, September 2013

CONTENTS

LIST OF FIGURE x

LIST OF TABLE x

LIST OF APPENDIX x

INTRODUCTION 1

Background 1

Statement of Problem 2

Objective 2

LITERATURE REVIEW 2

Sensory Evaluation 2

Panelist 3

Training of Panelist 3

In/Out test Method 4

METHODOLOGY 4

Time and Place Of Internship 4

Methods 4

RESULT AND DISCUSSION 10

Recruitment and Selection Panelist 10

Training 14

CONCLUSION AND RECOMMENDATION 16

Conclusion 16

Recommendation 16

REFERENCES 16

APPENDIX 18

LIST OF FIGURE

Flow chart of implementation In/Out test method 5

LIST OF FIGURE

Concentration of solution for basic taste identification test 6

List of odour sample 6

Concentration of stock solution 8

Comparison of stock solution and water 8

Schedule of basic screening and threshold detection test 11

LIST OF APPENDIX

Sensory panel candidate questionnaire 18

Sample score sheet for basic taste identification test 18 Sample score sheet for odour identification test 19 Sample score sheet for Ishihara colour blindness test 20 Sample score sheet for threshold detevtion and recognition test 20 Sample score sheet for Ishihara colour blindness test 21 Result of basic screening test before repeat test 21 Result of basic screening test after have been done repeat test 23

Result of threshold detection test 25

INTRODUCTION

Background

Food is one of the basic needs that is essential for life. Right now, sensory properties for food products is a very important to derive consumer expectation. However the highquality, functional properties, good microbial and chemical quality, food products, will not be properly work for the consumer, if the food is not acceptable, not good, or not meeting the organoleptic preference of the consumer, then that product will not be consumed. Therefore, every food manufacturerultimately needs to conduct acceptance testing that is known as sensory evaluation.In fact, in 1956 sensory evaluation was elevated to the realm of ‘science’ (Gatchalian, 1989) through the efforts of the Institute of Food Technologists (IFT). Nowadays, sensory evaluation becomes a tool that is irreplaceable in food industry while interacting withother key attributes in food production.Nevertheless, consumer are buying decision is also based on sensory property/performanceand sensory consistency. Therefore, sensory evaluation should be an integral part in defining and controlling product quality.

PT Nestlé Indonesia is one of the world's food manufacturer leader which

carries the motto “Good Food, Good LifeTM” has made the commitment to produce items that are healthy, high quality, safety and standardized BU E in order for consumers to realize a better life. Nestlé continuously conducting research and development to make improvements in a range of product creation. One of the efforts to ensure the quality of the finished product is to carry out an analysis through sensory evaluation. To maintain the quality that has been owned,Nestlé has always conduct quality analysis on products, both for the existing products and for the new products that will be released to the market. The product to be marketed will be tested by sensory evaluation test to determine whether the product is appropriate for the market. This test is known as In/Out test method.

As stated by Munoz 1992, the In/Out test is one of the recommended method for QC/sensory evaluation. This method is mainly used to identify and reject the finished products that show gross deviation from production. The In/Out test method can be performed in the factory and the head office. In the factories, this method has been done to maintain the daily production whether it is compliant with standard. For the head office, the method is carried out to assess whether a new product deserves to be marketed or not.

2

familiarize the individual with test procedures, to improve an individual’s ability to recognize and identify sensory attributes, and to improve an individual’s sensitivity and memory thus permitting more precise and consistent sensory judgments. Training ensures the systematic utilization of the combined sensory perceptions of panelists as analytical guides to the quality of the product tested (ASTM 1981).

Statement of Problem

As a leading food company, Nestlé is always concerned about the quality of its products. One of them is a new product that will be release to the market. Before the products are marketed, the product are tested using the method In/Out tests by trained panellist to assess wheather the product is in conformity with the standard specifications and ensure that product corresponding with the expectation of the consumer. There are many stages of the process to perform In/Out test, starting from the selection of trained panelist until performing the In/Out test itself. This manuscript focuses on recruitment and selection trained panellist until the completion material procedures required in In/Out training.

Objective

The spesific objective of the internship activities is to be able to: 1. Organizing schedule recruitment and selection trained panelists 2. Collecting and evaluating panelist results

3. Create and setting procedures for sample preparation key sensory attributes training, In/Out training

4. Create and developing materials for training of key sensory attributes used in In/Out training.

LITERATURE REVIEW

Sensory Evaluation

3 widely regarded as consumer acceptance tests use human as a measurement tools is considered have sensitive taster, and is often used to assess the quality of various types of products.Different types of sensory testing methods have been used to assess and evaluate the sensory characteristics of food products. A sensory analyst should know the advantages and disadvantages of each test method to be used. Choose a test method that is a practical and efficient way to achieve the desired goal. Broadly speaking, sensory testing methods are classified into three sections: (1) Difference test, (2) Descriptive test, (3) Acceptance and preference tests.

Panelist

A panelist is a member of the panel or the people involved in the assessment of subjective impression from a variety of organoleptik food or drink are served. The use of human beings as the measuring instrument will cause data to vary widely. This is due to the different characteristics of each panelists. Therefore, the basics of Physiology and psychology factors that can have an effect on sensory assessments must be understood (Meilgaard et al. 1999).

As stated by American Society for Testing and Material (ASTM) 1981, in addition to screening panelist for these capabilities, panel leader must prescreen candidates for the following personal criteria:

1. Interest in full participation in the rigors of the trainings, practice, and going work phase of the test.

2. Availability to participant 80% or more of all phases of the panel’s work : conflict with work perhaps eventually causing the panelist to drop off the panel during or after training, thus lost one panelist from an already small number.

3. General good health and no illnesses related to the sensory properties being measured.

Sensory panel comprise of two categories: trained panelist and untrained panelist (Adawiyah and Waysima 2009). Trained panelist is a group of panelists who were recruited through the selection process and training, aimed to evaluating the quality of a particular product. Untrained panel is usually used to test the acceptability of food product.

Training of Panelists

4

will give more precise and consistent results than a large, untrained panel (Poste et all 1991). A trained panel is choosen of recruitment and selection step, then have continuous training and get passed on the skills evaluation. Level of sensitivity is not as high as expert panelists, but this group has been able to serve as an analysis tool in product testing.

The selection of panelists includes several stages, namely the screening phase, training phase, and evaluation phase capabilities. In the training phase of the selection panel used as training sets the stage deliberately done in order to:

1. Adjusting / get used to each individual in the testing procedures.

2. Improve the ability of each individual to recognize and identify the sensory attributes tested.

3. Improve sensitivity and memory of each individual so that the test results are more precise and consistent.

4. Training, in order to have the same understanding about the properties to be assessed, criteria and testing methods used and minimize the differences of each test in their assessments.

In/Out Test Method

This is the simplest method to compare product quality with a mental standard by expert (Costell 2002). It is mainly used to identify products that show clear deviations (presence of off-notes or other defects) from the normal productions. It can be recommended for the evaluation of raw material or relatively simple finished products. Its advantages are the simplicity and the direct use of result obtained. The main disadvantage is its inability to provide descriptive information and therefore its lack of direction and action ability to fix problem (Munoz et al. 1992). The validity of the information provided depend on whether the “experts” are indeed genuine experts. If this method is used by one or a small group of people in a company who do not passes the necessary expertise, each of them makes decisions based on his individual experience and on his product knowledge. This situation may leads to highly variable and subjective information.

METHODOLOGY

Time and Place of Internship

Internship be conducted over a period of four months at PT Nestlé

Indonesia, start from April until July 2013. Located at 5th Floor Wisma Nestlé,

5 Methods

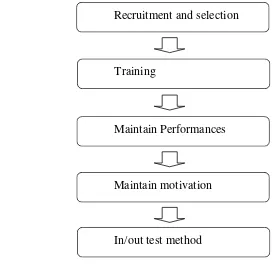

This research will conduct step preparation of performing In/Out test. In general, the step to performing In /Out test method, described in Figure 1.

Figure 1Flow chart of implementation In/Out test method

Based on the flow chart above, step of recruitment and selection trained panelist, training phase and implementation In/Out test is a initial step of performing In/Out test. Whereas, maintain performance and maintain motivation is continuous improvements step to maintain trained panelist who does exist.

Recruitment and selection trained panelist

Screening is the first step of selecting panelists to be trained panelists. This step is the critical things that must be done prior to the sensory test. A sensory screening has to be conducted once when starting a new In/Out panel and with new employees joining an existing panel. All employees takepart in the In/Out testing must be trained. The objective of the screening panel is to ensure that only those who have the ability to use the considerable sensory tasting events or participate as a panelist.On the first session, candidate panelists will get a brief summary presentation about sensory evaluation and questionnaire. The questionnaire to determine their interest and availabity for participation. Questionnaires have contain personal information of panelists about allergies/intolerances and colour blindnes. Health and safety risks have to be considered when conducting regular tasting of food products. Persons with any

Recruitment and selection

Training

Maintain Performances

Maintain motivation

6

allergies should not be included in the panels. The sensory panel candidates questionnaire can be found in Appendix 1.

Screening proceduresare done through two steps, the first step is called basic screening test, and the second step called threshold detection test. Basic screening test consist of basic taste identification test, odor identification test, ishihara color blindness test, and triangle test. And, for further screening tests are performed recognition and detection threshold of basic taste.

Basic taste identification test

Each potential panelists received a tray contain of six cups solution of four basic taste, one cup is water and one cupis repetition of one the basic taste. All samples have the same temperature and must be presented with the water or unsalted crackers to avoid carry over the taste left behind. Tabel 1 shows the concentration of solution for basic taste identification test. In this test, all the panelists should be able to detect all the flavors. Value that must be achieved is all correct. The score sheet of basic taste identification test can be seen in appendix 2.

Table 1 Concentration of solution for basic taste identification test

Basic Taste Standard material Concentration of solution

(gram/Liter)

Acid Citric acid 0.2

Bitter Caffeine 0.5

Salty Natrium chloride 1.6

Sweet Sucrose 10

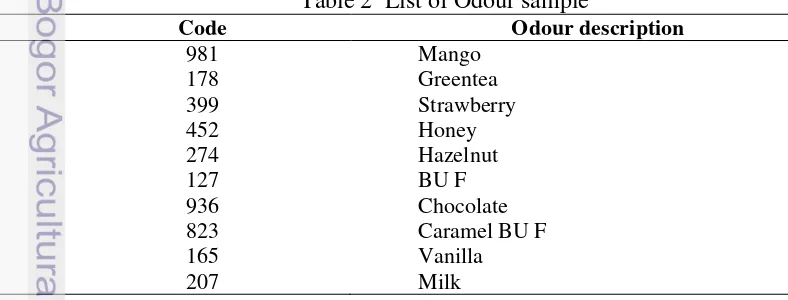

Odor identification test

7 Assessment criteria is 5 score to answer correctly, score of 4 to answer almost correct, score of 3 for the less true (there is a similarity of odor), score of 2 for answers that almost no right or smell that has little in common with those assessed, a score of 1 to answer is not correct because there is no similarity at all, and a score of 0 for that does not give an answer at all. Score to be obtained must be > 33 from a total of 50.The score sheet of odour identification test is presented in appendix 3.

Ishihara color blindness test

Ishihara color blindness test is using Ishihara book. Ishihara book consists of multiple images to test whether a person is suffering color blindness or have a particular weakness for color vision. All images in the book should be shown and answered by potential panelists. The answers will determine whether the potential panelists are suffering from color blindness or deficiency of certain colors such as red-green. There is no minimum value to be achieved by the potential panelists, but if the color is important to determine the quality of a product, the panelists who suffer from color blindness or color deficiency are not allowed to enter the sensory evaluation of the products. The score sheet of ishihara color blindness test is shown in appendix 4.

Triangle test

Triangle test is used to test the ability to detect differences in the two samples which similar. Through this test can be determined whether a potential panelists was allowed to participate in a variety of sensory testing.Triangle test where each potential panelists will be asked to choose one of three samples. Two of the three coded samples are identical and the other is the odd sample but only the experimenter knows this. Three-digit numbers, randomly selected to preclude bias, are used to label the samples. These coded samples are then randomly arranged in a tray, but presented in exactly the same manner to the panelists.Each candidate will have three trays which contain the samples are easy, medium, and difficult to distinguish.

Sample used for triangle test is orange juice or apple juice. Step of the preparation solution are: 1) Make the standard sample (A) containing juices and water in the ratio 9:1, 2) Make the second sample (B) containing 20 g sugar in 1L standard sample (A), 3)Make the third sample (C) containing 15 g sugar in 1L standard sample (A), and 4)Make the fourth sample (D) containing 10 g sugar in 1L standard sample (A). Easy set trays are contained combination among sample A and B, medium set are sample A and C, and difficult set are sample A and D.

8

This test can determine the detection threshold of the potential panelists against four types of basic tastes (sweet, salty, sour, bitter). First procedures of this test is by making a stock solution first. The concentration of stock solution can be seen in Tabel 3.

Table 3 Concentration of stock solution

Basic Taste Standardmaterial Concentration of stock solution

(gram/Liter)

Acid Citric acid 4.0

Bitter Caffeine 1.0

Salty Natrium chloride 12

Sweet Sucrose 32

Then be prepared six types of solutions with different concentrations (samples G1 until G6) by mixing the stock solutions and water as shown in Tabel 4.

Table 4 Comparison of stock solution and water

Concentration Stock solution (ml) Water (ml)

G1 15,5 984,5

Each potential panelists will receive a tray containing 7 solutions on glasses containing sequence starting from the neutral solution where code number 1 (G0) contain water to a solution of high concentration with code 7 (G6). Score derived from the sum of the concentration of detection rate and recognition rate. Criteria assessment to this test, if candidates begin to detect different taste in G2 and recognize the certain taste in G4, then the score obtained is 7 (the sum of 3 and 4). The score sheet of threshold detection test is available in appendix 6.

Training

This section describes the requirements for setting up, training and maintaining sensory panels. This is a continuous process that needs to be constantly monitored and improved. The training fulfils the following objectives, such as:

• Understand the role of sensory and the importance of early detection of defects.

• Understand the in/out test principle and its application.

• Familiar with Key Sensory Attributes and Acceptability Limits.

9 Any panelists involved in In/Out tasting must complete a training program. Panelists are taught on key sensory attributes and acceptability limits. Key Sensory Attributes is attributes identified from consumer tests as the ones driving consumer preference or linked to product label claims or sensitive to process / storage.The key sensory attributes need using sensory references to describe attributes to panelist. Sensory reference can describe uses sample or picture that illustrate a key sensory attributes at one or more intensity levels.

Acceptability limits is sensory boundaries that separate the In products from the Out products.This training phase focuses on teaching the panelist the ‘In’, ‘Just In’, and ‘Out’ product concept.‘In’ spec means that the product can be accepted by consumers in accordance with the desired specifications, ‘Just In’ means that there is minor deviation product but still can be received by consumer, and ‘Out’ spec means the product shows deviation that can not accepted by consumer.

Introduction of key sensory attributes and acceptability limits are the essential thing in the training phase. Therefore, panellists are required to really understand of both step of the training. Key sensory attributes and acceptability limits are performed on different session. This is done to prevent bias in panelistandboth of steps can be repeated to assure that this will be in the memory panelist.

Training for key sensory attributes

Sensory attributes is key importance in defining a product. Training session in required to introduce critical attributes that greatly affect finished product. The attributes is choosen in the management meeting with consumer. Generally, sensory attribute variability can result from the presence from the variation of intensity or strenghT of sensory attributes that are normally found in the product. The training for sensory attribute will be conducted in two steps. Firstly, trained panelists will be introduced to critical sensory attributes that simultaneously affect the product. And, secondlyis the step on evaluation session to panelist. Preparation sample for introduces attributes is important in training session. This period will be made schedule training and sample preparation to key sensory attributes for Business Unit A product.

Maintain performances and motivation

Maintain performance and motivation are a form of continuous improvement effort for In/Out test method. Monitoring panelist is critical in all QC/ sensory programs and will depend on criteria derived from the selected methodological approach. Panelist must take a part in the tasting session regularly, and result must be recorded.

10

checks during the routine tasting, they must be conducted in specific sessions. Underperforming panelists must be re-trained.

Motivation is maintained by showing the relevance of panelists contribution to product quality. In addition, the panel leader can give individual performance results for self development, offer small treats for participation and ask for feedback on informal meetings/formal trainings.

Panel motivation is secured by developing a reward system for panelist early. The size and frequency of the reward based on the skill and time provided by the panelists, the reward permitted under reunion or nonunion personnel rules, the commitment of the company and sensory analyst to recognizing a job well done.

In/Out test method

The In/Out test method is the simplest method to compare quality of product with a standard by trained panelist. Implementing sensory evaluation test along manufacturing allows early detection of defects, deviations and timely corrective actions. Minimum number panelist is 4 per sample, and the recommended maximum number of sample tasted per person during one session is 20.The decision rule is based on the In/Out score formula:

In/Out Score = [1 − ������������

���������������������� ] x 100

Score achieved=(Number of Out x 3)+(Number of Just In x 1)+(Number of In x 0) Highest score achievable=3 x Number of panelist per sample.

This manuscript focuses on development of instrument training for In/Out test, such as procedures and process for recruitment and selection trained panelist, procedure for sample preparation for key sensory attributes of In/Out training, and completing material for key sensory attributes of In/Out training.

RESULT AND DISCUSSION

Recruitment and Selection Trained Panelist

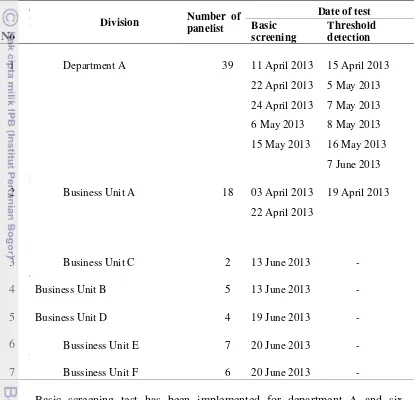

11 There are two steps in screening panelist that consist of basic screening tests and threshold detection test. Each step is done on different schedule to avoid fatigue due to too many samples are presented. Schedule for test was conducted for a few times to follow schedule of employee and tasting room capacity that are used. The schedule of selection trained panelist can bee seen in Tabel 5.

Table 5 Schedule of basic screening and threshold detection test o

N No

Division Number of panelist Basic Date of test

screening Threshold detection

1 Department A 39 11 April 2013 15 April 2013

22 April 2013 5 May 2013 24 April 2013 7 May 2013 6 May 2013 8 May 2013 15 May 2013 16 May 2013

7 June 2013 2

2 Business Unit A 18 03 April 2013 19 April 2013

22 April 2013

Basic screening test has been implemented for department A and six marketing business unit. There are two business units thatdid not conduct basic screening test because the schedule is still on discussion with the BU team to agree on the right time to conduct the test.

12

threshold test is planned at the end of August to Desember before training sessions conducted.

Before conducted the test, candidates get brief summary presentation about sensory evaluation by sensory coordinator. It took about 30 minutes. Potensial panelists are required to attend this session to understand about the applicationand properties of sensory evaluation. After the presentation, each candidate gets the data form about allergies and the availability of them to take the test.

As already described in the methods above, basic screening test is divided into four step, namely basic taste identification test, odour identification test, Ishihara colour blind test, and triangle test. Below is explanation about the result of basic screening test.

Basic taste identification test

Basic taste identification test is testing the sense of taste to the four basic tastes, such as sweet, salty, sour, and bitter. This test aims to test sensory tasting against potential panelist. More panelist can distinguish between salty and sweet with easy but more difficult to determine taste sour and bitter.Each basic taste must be recognized by potensial panelist. Not all the candidate was be able identify all the basic taste on the first test, they should be familiarized with basic taste sample first then be allowed to take the test again.

Based on the record, of the 81 employee who take the test, there are 13 panelists who did the repeat the test. Potensial panelist who can not recognize a certain taste must be guided in order to succeed at the repeat test by showing the structure of the tongue where the four basic tastes position. Repetition test conducted with the repetition of basic screening test.

Odour identification test

Our sense of smell can detect many different odours when sniffed through the nose, but it also important for detecting volatiles given off by food items in the mouth as part of the flavor perception (Carpenters 2000). The sense of smell is a key input to sensory analysis. Odour test is more difficult in comparison with the basic taste test. On this test, panelists are given jar coded as many as 10 jars, panellist must identify and describe the odor on the form that has been provided.

There are criteria assessments for the smell test. The minimum value to pass the smell test is 33 points. On testing, panelists are given 20 seconds to sniff the blind-coded samples are presented and then describe it in the form provided. To neutralize the sense of smell was done by sniffing the forehand. Panelist can do repetitions on the jar coded unanswered. Panelists who having respiratory problems and can not smell well not included for this test, because it can affect the outcome of the tests. Therefore, the panelist can take the schedule the next day.

13 Ishihara color blindness test

Of all the human sense, vision has the longest and most persistent investigation into its mechanism. The term vision and appearance are separated bye their definition. Vision may be regarded as the psychological response to the objective stimulus generated by the physical nature of the object viewed. Therefore, before conducting activities on color evaluation, panelists should be screened for color blindness. Color blindness is usually genetic in origin (Carpenters 2000). As stated by Lawless and Heymann 1999, males have more highrisk color blindness afflicts than females. This is best carried out using a series of colored plates such as Ishihara. The test carried out under normal daylight, or under artificial lighting that is design to match normal daylight conditions, and involves an individual either to read a number or alternatively to trace a line on a series of specially designed multicolored printed plates. Individuals with normal color discrimination will report a different outcome from those with a deficiency. For example, a person with normal color discrimination will read one of the plates as a number 29, but someone with red-green deficiency will see 70 on the same plate. Red-green color blindness is the most prevalent.

Based on the record, out of the 81 employee who take the test, two people have red-green color blindness deficiency. Panelists who are color blindness are not allowed to take the sensory evaluation test conducted on an assessment of the product color.

Triangle test

In the triangle test, three samples are presented simultaneously or sequentially.Samples are used to test the triangle is apple juice. Created 3 sets of concentration for this test, which is easy, medium, and difficult. Each concentration that were coded randomly presented on the glass sample to avoid bias between panelist. On this test, panelists are given neutralizing drink or solid food such as mineral water and unsalty crackers to avoid carry-over from the previous sample. Triangle test is most difficult than previous test. Based on the record, there are 49 respondents need repeat test. Some panelists had difficulty in choosing one sample among the three samples are provided, thus requiring concentration to give answer correctly. For triangle test, repeat test is performed only on sets that are failed, the test was not performed on all sets of concentration. Threshold detection test

14

recognition rate. The detection rate is dilute solution where the potential panelist knows difference from the previous sample but can not identify the name of the taste. Whereas, recognition rate of a solution in which the potential panelist have been able to identify name of the taste.

Number of panelist who took the second part equal to the previous part as many as 43 panelists. The result of threshold detection test can be seen in Appendix 9. There are criteria for threshold detection test. Panelist who get score below of 10 means the panelists are sensitive to a certain basic taste. Each panelists has different levels of sensitivity flavor. The result of this test, panelists can be grouped into very sensitive, sensitive, and not sensitive level. If testing is done to assess sensory attributes of a product of the sweet, panelist are sensitive to sweet taste can be invited. Threshold detection test does not require repeat test, because the test is intended to determine the level of sensitivity of sense panelists. Repeatation test

Repeat test is given to panelists who have record did not pass the test in stages selection test. Panelists are eligible to allow repeat test until they have passed to the selection test. The test given to panelists at the step where they need to repeat, do not conduct the test for all basic step screening test. On this test, there is no different in the sample provided and instruction how to do the test. During April until July period, repeat test was conducted twice. The test just implemented for Department Adivision and BU A.

The first session of the repeat test of basic screening test conducted on 22 May 2013. Panelists who take this test as many as 10 candidates, 5 panelists is the Department Aand 5 panelists is BU A marketing. Results of the repeat test, 6 panel of candidates Department Ateam has successfully passed, but marketing of BU A team is still need to do re-test again. The second session was conducted on 7 June 2013 by panelists as many as 12 candidates from Department Adivision. 10 candidates who took the test have passed and 2 candidates still need take a repeat test again. And the total candidates who have done repeat test period in the period of April-July asmany as 22 panelist, 15 panelists had passed basic screening test and 7 panel still need to take a repeat test.

Overall, based on the record in the period April until July 2013 of selection for trained panelists have been done acordingly, from 81 panelist who took the test, 39 panelists were choosen as trained panelists. And, there were 42 panelists still need a repeat test and 38 of them didn’t have take threshold detection test. Result of basic screening test before repeat test can bee seen in Appendix 7, and for the one after have been done repeat test can be seen in Appendix 8. The schedule for repeat test and threshold detection will be conducted again on end of August until December 2013 before the next training session.

Training

15 professional. The most important component of the training is the product’s training phase, where the panelist learns to evaluate the variable product characteristics for which sensory specifications were set. Training aims to train sensitivity and consistency of panelists so expected that the sensibility panel canbe increased. For In/Out test, the training focused on two things, namely the introduction of key sensory attributes and acceptability limit of the product. The objective of introduction of key sensory attributes is to familiarize panelist with the application of sensory evaluation, its importance within company and in the measurement of quality product and the basic concept physiology that play a role in the evaluation of the company’s product characteristic (e.g., appearance, flavor, aroma, etc). In the training phase for acceptability limit of product, each of the attributes, for which sensory specifications have been set, is discussed one at a time, its production sample that, representing range for each attributes that were previously identified, are presented to the panelist. The definition, evaluation procedures, and scoring of each attributes are covered, using In and Out (production samples) references.

Schedule training

Training schedule to perform thenext In/Out at PT Nestlé Indonesia has been planned on January untilApril 2014 (see in Appendix 10). Training activities will be carried out for each Business Unit that is on a different schedule. The session will be conducted on the following availability time of panelist. Panelists who have passed on the selection panel stage is required to attend this training session.

The main advantages of the In/Out training program are its simplicity and short time to complete. The total time required depends on the type of product in the program and varies between 5 and 10 hours. In/Out training sessions will be conducted in two sessions of training activities that are key attributes evaluation and acceptability In/Out limit of the product. For each session of this training activity takes time for 2-3 hours. On key attributes evaluation session panelists will be introduced to critical variables that are considered important attributes describing the product. For acceptability In/Out limit of product, training session focuses on teaching the panelists for In and Out product concept.

In each training session, each panelist is asked to evaluate selected production samples, presented as unknowns, on a daily basis. Evaluation of training is related to the material that has been taught, and aims to review the ability of panelists to understand and remember the material that has been given. Evaluation will be conducted at the end of the training session or make a new session outside training. Records of the evaluations are kept amd used for panel feedback. Therefore, descriptive evaluations are available and are necessary for judging panel performanced. Panelists who do not qualify can repeat this evaluation.

16

The samples used for training are the product references based on each attributes. The attributes were choosen in the management meeting with consumer. The recognition of each attributes aims to get harmonize or terminology among panelist that all panelist have same perception of sensory attributes.

Attributes are introduced for each product is different. Attribute must have the relevant criteria in defining the final product. Attributes can be grouped into categories based on appearance, odor, flavor, texture, after sensation, aroma, and after taste.

Sample preparation is critical point that reflect of key sensory attributes. if sample are not correctly made not to introduce key sensory attributes then the purpose to be achieved in the test will not be delivered to panelists correctly. For BU A products, based on consumer testing result, it was obtained 20 critical attributes which will give effect if the presence of this attributes in the products is too dominate. These attributes are divided into categories of appearance, odor and flavour, texture, after sensation and specific flavour. Each attributes have a different procedures for making the sample, procedure of this samples are explained detail in Nestlé instruction documents.Material training for In/Out test and Key sensory attributes ofBU A has been completed. This material is presented in power point as material are used by sensory coordinator for give a brief summary presentation.

CONCLUSION AND RECOMMENDATION

Conclusion

Result of selection trained panelists have been implemented forDepartment Aand marketing teams, and from 81 panelist who took the test, 39 panelist choosen as trained panelists, 42 panelist still need a repeat test and 38 of them need take threshold detection test. Panelists who have passed the selection step should be trained, and training schedule for each business unit has been preparedforJanuary untilApril 2014. During training, material and preparation sample are the most important component. Based on consumer testing result it was obtained 20 critical attributes of BU A which will give effect if presence dominantly on the product. This attribute is completely explained in the available material training.

Recommendation

17 clues about the samples (labels, packaging, preparation mode, e.g.).And, method of In/Out can be introduce as the course material in college which is one of part the description test that can be applied to use as quality evaluation of the product in food manufacturer.

REFERENCES

Adawiyah DR, Waysima. 2010. Evaluasi Sensori . Panduan Praktikum. Bogor : Fakultas Teknologi Pertanian IPB.

ASTM. 1981. Guidelines for the selection and training of sensory panel members. MNL 18. Philadelphia: American Society for Testing and Material.

Carpenter RP, DH Lyon, and TA Hasdell. 2000. Guidelines for Sensory Analysis in Food Product Development and Quality Control. Aspen Publisher. Maryland. USA.

Costell, E. 2002. A comparison of sensory methods in quality control.ELSVIER. 13: 341-353.

Gatchalian, M. Miflora. 1999. Quality Assessment through statistically-based sensory evaluation methods. MCB University press. 6 : 389-395.

Lawless HT, and H Heymann. 1999. Sensory Evaluation of Food. Principles and Practices. Aspen Publisher, Inc. Gaithersburg, Maryland. USA.

Meilgaard M, GV Civille, and BT Carr. 1999. Sensory Technique Evaluation. 3ed. CRC Press LLC. Florida. USA.

Munoz, A. M, G. V. Civille, and B. T. Carr. 1992. Sensory Evaluation in Quality Control. Van Nostrand Reinhold. New York.

Munoz, Alejandra. M. 2002. Sensory Evaluation in quality control: an overview, new developments and future opportunities. ELSEVIER. 13: 329-339. Poste LM, DA Mackie, G Butler, and E Larmond . 1991. Laboratory Methods for

Sensory Analysis of Foods. Research Branch Agriculture Canada Publication 1864/E. Canada.

18

APPENDIX

Appendix1Sensory panel candidate questionnaire

Note: All your personal information will be treated as please strictly confidential. If you have any question or concerns, do not hesitate to contact us. Name : ... Department :... Do you have any of the following:

Allergies or intolerances Food allergies or intolerances

• Yes

• No

If yes, list ALL foods and ingredients that you are allergic/intolerant to: ...

Colour blindness

• Yes

• No

Thank you

Date : ... Signature : ...

Appendix 2 Sample score sheet for basic taste identification test

Questionnaire

Name : ... Date : ...

In front of you are:

RECRUIT AND TRAIN A PANEL

RECRUIT AND SCREENING

19 A water reference sample and six coded cups containing aqueous solutions of basic tastes. One or several of the coded samples may be blank samples (water). For each coded sample, please note whether you think it is water, salty, sweet, acidic, or bitter. Remember to rinse your mouth between samples.

Sample Appendix 3 Sample score sheet for odour identification test

Questionnaire

Name : ... Date : ... Odour Identification Test

You have given 10 coded jars, each containing a sample of a familiar odour. Gently sniff each jar and try to identify the odour.

Please write your description of the odour in the box provided. If you cannot find the exam word to described the odour, a description of what you associate the odour with will be sufficient.

N No

ODOUR NAME OR DESCRIPTION SCORE

9

RECRUIT AND TRAIN A PANEL

20

Appendix 4 Sample score sheet for Ishihara colour blindness test

Questionnaire

Name : ...Date : ... Ishihara Colour Blindness Test

In front of you is a series of plate for Ishihara test. To do this test, stand up or sit in front of the plates.

Write down/show what you can you see in the colourful circles (i.e. bias of number/alphabet/others)

No DESCRIPTION SCORE

1

Appendix 5 Sample score sheet for threshold detection and recognition test

Name : ... Date : ... Read the test instruction provided before you begin to taste.

Mark the coloumn below:

0 : Plain / There’s no flavor detected. RECRUIT AND TRAIN A PANEL

RECRUIT AND SCREENING

SENSORY SCREENING

21 X : Flavor detected – you’re not able to recognize but knowing there’s little

difference in taste.

XX : Add mark (X) every time you notice an increase in thebasic taste of concentration.

Flavor detected: Write down the flavor if you’re able to detect.

Taste the samle based on serial number, before tasting each sample. Rinse your mouth with the available mineral water or biscuit.

Cup No 1 2 3 4 5 6 7

Sample A

Cup No 1 2 3 4 5 6 7

Sample B

Cup No 1 2 3 4 5 6 7

Sample C

Cup No 1 2 3 4 5 6 7

Sample D

Thank You.

Appendix 6 Sample score sheet for triangle test Triangle test

Name:... Tray:... Date:... In front of you are three coded samples. Two are the same and one is different. Starting from the left. Evaluate the samples and circle the code of the one that is different from the other two. You may reevaluate the samples. If no difference is apparent, enter your best guess, however uncertain.

Comments :

Appendix 7 Result of basic basic screening test before repeat test

No Name Division Sensory training (Basic screening)

Basic taste Odor Blind color Triangle

Easy Medium Difficult

1 ab BU A 6 34 13 1 1 1

2 ac BU A 6 40 13 1 1 1

23

Appendix 8 Result of basic basic screening test after have been done repeat test

No Name Division Sensory training (Basic screening)

Basic taste Odor Blind color Triangle

25

*candidates have been done repeat test and passed

**candidates have been done repeat test, but need to take repeat test again.

Appendix 9 Result of threshold detection test

No Name Division Threshold detection

26

38 bag Department A 7 5 4 8

39 bah Department A 6 6 4 8

40 baj Department A 8 6 5 7

41 bak Department A 9 7 10 13

42 bal Department A 8 6 5 5

43 bam Department A 13 8 4 9

Appendix 10 Schedule In/Out training

week no

Month 1 Month 2 Month 3 Month 4

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Training Activity : Product

Familiarization A, C A F D D, B G E E H

Key Attributes

Evaluation A, C A F D D, B G E E H

In-Out Test

(Mechanics) C A A F D, B D G E E, H

In Product

Familiarization C A A F D, B D G E E, L

Out Products C A A, F B D D G E, H E

27