?h*

T**

f&*K#s$#r

Pr*f,*edlnS$

tr

nte trz*t*,*n#*

C*r*ter

**#,* *n

r?"

*"Hru *ru##SYffit{Ptrffi$trtr*}

H il

e

*tr*csl

**gin

e

*r*n#

&

ffi

f*rff!

n*4*x

Mrffiffiffiil

ffi

ffiffi

h{

*s{J

il

u

d*irz

L}*iv

*r*ity,

M***ss#r,

Ind

*n

*si*

N*v*m**{

}3-}4,2***

ffr#ffinlxmd

by:gr

nr1

*****

2*#&

f,

*

trt

rffilffe*

"

$p$n$sred

hy:

?T.

FLrut?ffrSf;ft#:

rT" &ttruAru&&.

geStHG

WILAY

hM

g#tSfrLRA*AR

SULAWTSI

Fuhlixh*d

by;

#epmrfruerrut

*f

#l**tr***t

*n#tffi

e*r*n#

F*##*tV

*f

ffiru#$m*erlng

ffi

*s*

n

arddtn

tJmfrv*r*ifg

MICEET

2OO8

COMMITTEE

III{TERNATIONAL AI}YISORY COMMITTEE

Chair

:

Muhammad

Arief

(Indonesia)

Mernbers

:

Dadang

suryamiharja

(Indonesia)

Keigo

Watanabe

(JaPan)

Azah Mohamed

(MalaYsia)

David

V. Thiel

(Australia)

Muharnmad

Tola

(Indonesia)

ME id Al-Dabbagh (Australia)

Josaphat

Tetuko

sri

sumantyo

(Japan)

Ivan

Azis

(Indonesia)

Harnzah

Berahim

(Indonesia)

IITTERITATIOI\AL PROGRAM

COMMITTEE

Chair

Mernbers

:

Salama

Manjang

(Indonesia)

:

Lukito

Edi I'{ugroho

(Indonesia)

Tumiran

(Indonesia)

Eniman

Syarnsuddin (Indonesia)

Hamzah

Hilal

(Indonesia)

Rhiza

S. Sadjad (Indonesia)

Syamsir

Abduh

(Indonesia)

ZUfajri

B.

Hasanuddin (Indonesia)

Mochamad

Anshari

(Indonesia)

Rafiuddin

SYam (Indonesia)

Anton

$atria Prabuwono

(Malaysia)

Elyas Palantei (Indonesia)

Armin

Lawi

(Indonesia)

ill

ORGANIZING COMMITTEE

General

Chair

Co-Chair

Secre

tariat

Chair

\fembers

Finance

Committee

Chair

\f

embers

Nadjamuddin Harun

Zahjr

Zairntddin

Yusri

Syam

Akil

Intan

Sari

Areni

Fitrianti

Mayasari

Sri

Mawar

Said

Ansar Suyuti

Zaenaf.

Muslimin

Mukhtar

Saleh

Tahir

Ali

Rachmat Santosa

Publication Committee

Chair

:h{ernbers

:Local Arrangements Committee

Chair

:

A.

Toyib

Raharjo

fuIembers

:

Indrabayu

Indrajaya

Joseph

Galla

Herman Rombe

Andani

Syafruddin

Syarif

Christoforus

Yohannes

Ingrid lrlurtanio

Dewiani

Gassing

Indar

Chaerah

Gunadin

Yusran

ill-"'*l*

ldn.

Bhd,

Lingkaran Teknokrat

Timur,

63000

cyberjaya,

selangor,

Malaysia;

-Faculty of

Engineering,

Multimedia University,

Malaysia)

l\z

-'l

j'ovel

Randorn

Frequency

Generator

Methodfor

Anti-Jamming

Communication

system,

Eko Patra

T.w.t,

Arwin

D.w.

sumaril2

{lDepartment

of

Electronics,

Indonesian

Air

Force Academy, Yogyakarta,

Indonesia;

2school

of

Electrical

Engineering

and

Informatics, Bandung Institute

of

Technology,

Bandung,

Indonesia)

125

Error

Performance

Analysis

of

Cooperative Relaying

Communications

with

Fixed

Gain and

csl-Assisted Relays,

sirmayanti

{The

state

polytechnic

of

ujung

Pandang)

l3o

i' tlrl*

--"*-L

:exsion

7.

Computer Engineering

& Informatics (CEI-2)

i

:IEI

Designing

MultiAgent-based

Information

Fusio,n

System,

Arwin

Datumaya

Wahyudi

Sumarilz,

Adang

Suwandi Ahmad2

{lDepartment

of

Electronics,

Indonesian

Air

Force

Academy, Yogyakarta

-

.55002, Indonesia;

2School

of

Electrical Engineering

and

Informatics, Bandung Institute

of

Technology,

Bandung,Indonesia)

87

-r"'9CEI

Context-Based

Information Retrieval

of

Athtetic Sport

Management

System

(ASA[S),

Nuridawati

Mustafa, Muhammad

Haziq

Lim

Abdullah, Norazlin

Mohammed,

Nur

Filzah Zainan

{Faculty

of

lnformation and

Communication

Technology,

Universiti Teknikal

Malaysia Melaka, Locked

Bag

1200, Hang Tuah

1aya,75450

Ayer

Keroh, Melaka,

Malaysia)

144

''rt.rgp1

Preliminary

Analysts

of Dynamic Fleet

Management Support

System,

Abdulah

Fajar, Anton

Satria Prabuwono, Nanna Suryana

Heiman,

Zulkifli

Tahir

{Industrial Computing

Department,

Technical University Malaysia

Malacca,

Locked Bag

1200,

Ayer KerohTs4sa,

Malacca

Malaysia)

l4g

'r-iCEI

A

Review

of

Optimization

Models

and

Techniques

for

Maintenance

Decision

Support

Systems

in

Small and Medtum

Industries,

Zulkifli

Tahir, Anton

Satria

Prabuwono,

M.A.

Burhanuddin,

Habibullah

Akbar

{Industrial

Computing

Department,

Faculty

of

Information

and Communication Technology, Technical

University

of

Malaysia Melaka,Locked

Bag

1200,

Ayer Keron,li+SO

Melaka,

Malaysia)

153012CEI

A

Binary

Tree

Construction

from

Its Preorder and

Inorder

Traversals,

Armin

Lawi

{Department

of

Mathematics,

Faculty

of

Mathematics

and

Natural

Science,

Hasanuddin

University,

Indonesia)

fig

013CEI

Assessing e-Government

Security

Risk:

A

Preliminary

Study,Irfan

Syamsuddin

{'State

Polytechnic

of

Ujung

Pandang, Makassar, Indonesia;

2Techno-Management

,

Economics

and

Policy

Program, College

of

Engineering,

Seoul

National

University

South

Korea)

162

014CEI

ComponenbBased,

Automatic

HDL

and

C

Code

Generation

for

Control

System

Design

Using Metamodeling

Techniques,

Andreas

Voget

{Department

of

Electrical

Engineering,

Faculty of

Engineering, Hasanuddin

Univeisity,

Indonesia)

166

Ol 1CEI

ru)irffiiuLruiiii,ai: -,: : - resia November 13-14, 2008

e\\-

of Optimrzation Models

and

Techniques

\Iaintenance Decision

Support

Systems

in

Small

and

Medium Industriss

l-jir"ili

Tahir, Anton

Satria Prabuwono,

M.A.

Burhanuddin, Habibullah Akbar

Industrial

Computing DepartmentFacalty

ofInformation

and Communication Technologt Technical University of Malaysia MelakaLocked Bag 1200, Ayer Keroh,

7 5 4 5 0 Melalca, MalaYsia

:.:-i:iili

ra, antonsatria,

burhanuddin,

habibullah

ralOutem.edu.my

'xrusnrn&.ir"rth is based on the fact that decision support

[image:5.595.69.532.70.475.2]n

meededfor

maintenance processin

commonlyirrr||luur:-

maintenance

functions

with

varietiesmnnuuris

nnd

techniques have been proposedfor

ilmffr',ffinil$trmk The

aim

of

this

r€search wasto

identifyn

models

and

techniques

to

conduct;ru:xi"riinn

support

systemin

small and

medium.,

A

s1 stematicliterature

revielv w&$ performedr: ln-fCIrmation. The results shown several trends ffiffi "frrnr,'ts area. Next. the research direction has been

mp, *d'h-S rhe svstems.

I.

IxTRonUCTION,'*r'*

',-

oi

maintenancefunctions

for

maintenancernly

industries has gro\#ingrapidly.

A

r-

:;':

endpublications

in

the field

rnaintenance *, .,,1;'-;

and

techniques

have

been

published

to:i'rru$

tf:,;:r\"eness of

maintenance process. As a partof

_.,rnrrrlrr:r*i

for

maintenancedecision support

systemin

r,;;

'r*rn industries.we

needto

collect the

related rrrl,:

those areas.The

specific objectives

on

this""''i

:r:.:dbe

the classifications andavailable

literafurellulr

tir,r

field

of

rnaintenance

decision models

anditlltl|llt":trfl* ilL]es.

i, n: ,:,entif1 trends

in

thefield of

maintenance decision ilt;;:l;r]a S)'Stem.'-

I

f:;ggest directions

for

future fesearchesin

thisfield'

il.

ManqTENANCE TncnxIQUESrilrmllitfi:inence

technique

is

the

procedure

that

used by

:

r

rnanagement

for

doing

their

rnaintenance:rocess.

It

is

expectedthat the most

appropriate:.rn;e

strategy

(such

as

predictive,

preventive,r,

i

,Jrcorrective)

canbe

determined. There are many iln;e techniquss have been introduced. References[1]

;;ssified

various

maintenance techniques

from

54papers

into

tsn areas maintenance techniques as shown in Fig.1.

Fig. t Maintenance Techniques Classification [1]

Each

classification

and available literatureof

maintenance techniques has been described asfollow:

A)

Total

Productive Maintennnce

{TPM);

it is

thernaintenance

theory

which has

been introduced

by

Nakajima

[2]

that identified

rnaintenanceactivities

as thefive

major pillars,

and then,now

have improved becomeeight

pillars,

consistsof

health and safefy, education andtraining,

autonomousmaintenance,

planned preventivemaintenance,

quality

maintenance, focused irnprovement,support

systerns,

and

initial

phase

managernent(t3]-[ 1 5]).

B)

Reliahility

Centered Maintenance(RCM):

A

setof

tasks generated on the basisof

a systematic evaluations that areused

to

develop

or

optirnize &

maintenancs pfogfam.RCM

incorporatesdecision

logic to

ascertainthe

safetyand operational

consequsncesof

failures and

identifies the rnechanism responsiblefor

those failures([16]-[21]).

C)

Preventive Maintennnce

(PM):

it is

an

importantrnaintenance

activity.

Within

a maintenance organizationit

usually

accountsfor

&

major

proportion

of

the

totalsTg- 979-18765-0-6

Proceedings of The I"u' Makassar Infemarional Cr:nference on

Elecmical Engineering and Informarics

Hasanuddin Universiry, Makassar, Indonesia November 13 "L4,2008

maintenancc

effort, PM

may be described as the care andservicing

by

individual involved

with

maintenance to keepequipment/facilities

in

satisfactory operational stateby

providing

for

semantic inspection, detection,

andcorrection

of

incipient failures either

prior

to

their

occulrencs

or

prior

to

their

developrnent

into

rnajorfailure.

Some

of

the main

objectives

of

TpM

are

to:enhance capital equipment

production

life,

reducecritical

equipment breakdowns,

allow

better

planning

andscheduling

of

needed

maintenance

work,

minimize

production losses due

to

equipment failures, and promote health and safetyof

maintenance personnel ([BJ,[g],

lzzJ-[41]).

D)

Conditton Based Maintennnce(CBM);

ThepM

service is basedon

some reading,

measurernentgoing

beyond

a.predetermined

limit.

If

the

machine cannot

hold

atolerance? a

CBM

isinitialized (t12l-t4Sl)"

E)

Computerized

Maintenance

Managemerct

System(CMMS);

it

is

oneof

a

computer softwarsprogram

thatdesigned

to

assist

in

the planning,

management, andadministrative

functions required

for

effectivemaintenance.

These functions include

the

generating,planning, and reporting

of

work

orders

(wos);

thedeveloprnent

of

traceryhistory;

and the recordingof

parts transactions 1491.One

of

the

researchby

t50]

proposedecision making

grid

(DMG)

to

support

the

CMMS

applications ([5 1 ]-t571)

F)

Predictive Maintenence:it

is consists in deciding whether or not to maintenance a systern accordingto

its state{[58],

tsel).

G)

Maintewtnce Outsourcing:

this

refers

to

transferringworkload

to

consider

with

the

goals

of

getring

higherquality

maintenanceat

faster, safer andlower

cost. Theothers

goal are

to

reduce

the

number

of

full-tirne

equivalents

(FTEs)

and concentrate organization's talent, energy and rssourcesin

to areas called core competencies (t601-t621)H)

Effectiveness CenteredMaintenance (ECM).'

it

stresses"doing

the

right things"

insteadof "doing

things right".

This

approach focuseson

systemfunctions

and customerservice,

and has

several feafures

that are practical

to enhancethe performance

of

maintenancepractices

and encompasses cors conceptsof

quality

management,TpM

and

RCM.

TheECM

approach is more comprehensive ascompared

with

TPM

andRCM,

It

is

composedof

peopleparticipation,

qualify

improvement,

and

maintenancestrategy development and performance rneasurement [63].

il

Str*tegic Maintenance Managenxent (SMM).'In

theSMM

approach, maintenance

is

viewed

asa

multi

disciplinary

activify.

This

approach overcome$

some

of

the

thedeficiencies

of RCM

andTPM

approaches as these do not dealwith

issueslike

operating load on the equipment and ints effect on the degradation process, long term strategic issues and outsourcingof

maintenance,etc.

in

addition, these approachesto

large extent arequalitative or at

themost

quantitative.

The SMM

aFpsd

more

quantitative,

involving the

rffi

models

that

integrate

technicim-operational aspects

from

businessri

SMM

views

rnaintenancefrom

&broader than that of

RCM

andTPM

[6S$..J)

rtrsfr BasedMaintenilnce (RBM).'

R.BMmaintenance strategy

meeting

the

ffi

minimization

of

hazard caused bvequipment and a cost

effectiv.

,t*r*gy

itrm"III"

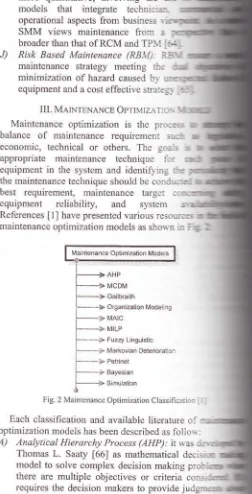

MaTNTENANCE OprnrrzATTorMaintenance

optimization

is

the

proces$m

balance

of

maintenance requirement

snffi

n

economic, technical

or

others.

The

goels

b

appropriate maintenance technique

for

ililib

equipment

in

the

systemand identifying

ec Wfl

the maintenance technique should be conduc@d

best

requirement,

maintenance

target

sequipment

reliability,

and

systemReferences [ 1] have presented various resouruer fr

maintenance optimization models as shown in

fq:"

AHP MCDM Gailbraith

Organization Modeling MAIC

MILP

**tr

Fuzzy Linguistic**,'&F Markovian Deterioration

Fig. 2 Maintenance Optimization Classificariom l. j

Each

classification

and available literafureof

optinrization models has been described as follow':

A)

Analytical Hierarchy

Process(AHP):

it

was Thoma$L.

Saaty[66]

a$ mathematicaldecisim

model

to

solvecomplex

decision making prthere are

multiple

objectives

or criteria

consic requires the decision makersto

providejud

the

relative

importance

criterion

for

each alternative([67],

[68]).B)

AdultipleCriteria

DecisionMaking (MCDM):

selecting between alternates

is

a relatively

coften

difficult

task.

MCDM

refers

to

thedecision and planning

problernsinvolving

mgenerally collectittg

requirements.The

Decisiom(DM)

one

reasonablealternative

from

among

r

available ones

{[69],

[70]). **'ig" Fetrinet'!r Bayesian

[image:6.595.312.564.95.589.2]'

)'{akassar International Conference on- ,nci informatics

""," )uiakassar, Indonesia November 13-14, 2008

The

theory

believes

that

'othe

greater;

r*-,

:f

the task, the greater amountof

information:

i

processsd betweendecision

makers duringi,,':i : - -:t

r,l of

the

task

to

get

&

given level of

.**

-;'

Industries can reduceuncertainfy

through-:::rg

and coordination, often by rules, hierarchy,,**"-r

Modeling:

References

[72]

reviews*

:-

ri

organization

models,

s.g.

advancedl-:

:.;sical

rnodel(ATM),

Eindhoven {Jniversityof

::",

model(EuT),

total

quality

managemen!,,

:

i,ai

;*d#;;fir-i;;#-

Crir'ajl[-r?-u'riir;

:

:, ;=':jrtf--jffH;,1?j-i,l'fu

.#

x-JTl

*

-

.:

technology(IT)

and

showedthat

integrated'.'rrr"r'*'

'i

:,-r-planfling of productionwith

maintenance,Aet-erences

[73]

have

presenteda

krrowled"ge-::

::slurn support system,MAIC for

maintenanceof

"* ,

-;"

nlant."n?et'

Linear

Programming

(MILP);

It

is

vsry

-

;rrnervork

for

capturing problems

with

both1r

;

r,'cislons and continuous variable.This

includes;:

*

;i:

problems,

control

of

hybrids

system,:': ii,,

,:-affine (PWA)

system(including

approxirnation*

:rer

system),

and

problems

with

non-convex011CEI

of

eventsA

andB

both ocsurring

canbe

written

as theprobability of

A

occurringmultiplied by probability

of

Boccurring given that

A

has occulred([82], t83l).

This

iswritten

as:P(A

and

B)

=P(A) P(B/A)

K)

Simulation:

t84l

andtSsl

use the Monte Carlo simulationto

determine optimum

maintenanc€

policy

and

for

modeling

on

continuously monitored

systems.[86]

hasused simulation

model

to

reduce

maintenance

andinventory

costfor

a manufacturing systemwith

stochasticitern failure,

replacement

and order lead times.

[87]demonstrates application

of

sirnulation models to evaluate maintenancepolicies

for

an automatedproduction line in

a steel

rolling

mill.

IV.

TnnT{DS I nENI.TIFICATIONAfter a brief

description

of

classific,ationin

rnaintenanceoptimization models

and

techniques,

we

have

identified

several trends that related

in

thefield of

maintenance decision support systems, each ofwhich

have been described asfollow:

1)

From

all

described

publications, there

are

limited

models

have been

implemented

in

industrial maintenance process.The

data problems andthe

gap between theories and practice have always become the reason.2)

It

seems alot

of

maintenance optirnization models and techniques have been publishedfor

this

arsa. Varioussimulating

tools

and

mathematical models have been attempted.Although

the irnprovernentof

IT

(both

softand

Hardware)

can

support

to

easy develop

of

thesystem

with law

cost and

systematicmodules,

it

islimited

work

has directed toward

developing

intooperational applications such as computerized system

or

DSS.

It

can

be said that the

impact

of

decisionmaking

within

a

maintenance organization hasso

far beenlimited.

3)

Someof

the publications have designed the integrationof

existing

maintenance

optirnization models

andtechniques such as

DMG, ECM, SMM

and

RBM. It

can be notice that a new potential research have existed

to

irnplement

them

in

the real

CMMS

or

DSSapplications.

4)

Much

designof CMMSs

is as a devicefor

analysis andcoordination

to

storehouse

the

maintenanceinformation,

such

as

a

PM

tool

and

a

maintenancework

planning

tool.

However, less

of

them

have embeddedwith

decision support modulesto be

linkedin

the actual industrial maintenance process.V.

RESSnRCHDmpcnoN

AND AcTIvITIESThe direction is highlighting

to

emerging trendsthat

havebeen

identified.

The

futures

researcherscan

conduct

themaintenance

decision support system

with

consider

the-:'-

:.

ii4).

lurff:

-

,::Jiistic:

Fuzzylogic

was inhoducedby Dr

Lofti

,,,

'

:-

UC/Berkeley

in

1960s

as

a

superset

of

:'

-. : "lalor

Booleanlogic

that has been extended to,:r;

r

: -i

concepts of partial truth-

truth values between-*'

:

r::1r,

trLle"

and

"completely

false".

It

was

llliiiur,-::,:"

r'-'irl t75]. By the

term

"fuzzinsss"

Zadeh meant;ik:

:"!

in

which

there

is

no

sharp transition

from

lllilllllln:.T : :::f Ship 1767,

'

,,

, ;it't

Deteriorntion: Markovian

deterioration

is

a1rlffi ; r;i'r,l

i:ient

(t77]-tB0]).

ilp:.,;,"'" r

"' Petri nets,

it

is

one

of

sevsral

mathe maticalr

rrL,, I ,:.-::lE

languages

for

the

description

of

discrete*fi.: 'r* :'"-;ted

system.

A

Petri net

is

a

directed

bipartite,4r:-;:::

in

which

the

nodes represent

transitions

(i,e. '.fi':,",.*-.i eventsthat may occur),

places(i.e.

conditions),luu

j

:-rected arch (that

describewhich

places areprs

*

, ,K

l

::

post conditionsfor which

transitionsxS l ].J,;-

: - .-ut:

Bayesianstatistic

is

basedon

Bayes'

rule

or'rj*

* :::ronal

probability,

It

is well

larown

thatprobability

0

"s " g7g .l 9765-0.6

Proceedings of The 1" Makassar Intemational conference on

Elecrical Engineering and Informarics

Hasanuddin university, Makassar, Indonesia November 13-14, z00B

finding

trends. Thefollowing

step is suggested to conduct the systems.I

)

choosing

the

rnaintennnce

techniqttes:

it is

thefundamental steps

that

we

must

concernto

follow

in

industrial

maintenance process.

There

are

tentechniques

that

we

can

choose

frorn

this

papers description. Eachof

thern havespecific

characteristic.We

can

choosethe

most

appropriate techniques thatcan be irnplemented

in

thereal industrial

maintenance process.2)

Data Analysis:

it

is

a fundamental issuein

optirnizing

maintenance decision

making. The

decisionbased

on incorrectinfonnation

may be useless orharmful.

Sometimes

datais

seernsto

beplentiful, by

rnaynot be

of

quality of

thequality

expected.3)

Maintenance

information

system

interfuce:

one

of

popular interfaces

in

industriesis

CMMS.

It

is mainly

serves as databases. The rnaintenance data

in CMMS

isthe most

important information

to

help

maintenancedepartrnent

rnaking

the right

decision

for

getting

theright

maintenance strategies.Fig.

3 is describedbf

tggl

as prototype to get decision out

from

maintenance data in CNTMS indusrries.internal and

externatdata) and

knowledge qi.G"and

explicit knowledge)

availablein

various the industries or its external environment. Donisi be conductfrom identify

the related datawith

decision making models.'.\

VI. CoNCLUsIoNS

we

have

reportedthe

ongoing

research project conduct maintenance decision support systemsfor

rnedium industries. The research is develnped

with

idthe

appropriate

literature

from

published

maioptirnization

models and techniques. Ttre results havethe trends that related

in

the fields arsa. Irlext, those bedefinitely giving

benefitfor

assist the ressarchproplr

to develop the system.

ACKNOWLEDCMENT

The authors

would like

to thank Faculty ofInforrnmi

Communication Technology,

Technical

UnivensmyMalaysia Melaka

for

providing facilities and Mrnisur

science, Technology and Innovation Malaysia

for

fr*il

support.

Employee $ki[s Data PM Inspe*tion Data Repairs Parts Data Vendor Data Labor Performance Data Time and Attendance Data

Job Estimating ,.-**-*;ts

Labor Utilization **---**,*.

Lebor Ferforrnance Overall Labor Productivity lnventory Control & Management Parts Availabitity Status Purchase Requistioning & Status Vendor Performsnce Evaluation Customer Serviees Analysis PM effectiveness

Maintenance Budget Data Customer Request & Complaints Equipment Priority Data Downtime Data Equipment Data Work Order Data

Work Order Status Work Order Coeting Work Order Prioritization Backfog Summary & Anatysis Equipment Downtime & Cause Anatysis Maintenance Budgets Variance Maintenance Budget Requirements Equipment Repair Procedures Planning & Scheduting Effectiveness Overall Maintenance Effectiveness

lll

t}J

REr.nnrNCES

A.

Garg ands- G.

Desgmukh, "Application and ca-semaintenance management: literafure review and directions," Jr

Qrtality in Maintenilnce Engineering, vol. 12, no. 3,2006.

s.

Nakajima, Introduction to TpM; Total productive Mai Productivity Press, USA, lggg. .,,|-!q**-* t3ll4l

lsl t6l t7] t8l telt i0l

[11j

I l2l

n3l

s.

Bonris, Total Productive Mai*tenance proven stratrywtechniqttes to k*rp equipment running at peak fficiency, McGran

Journal of operation Management, vol. 19, no. l, pp.ig-ss,2c*.;_ F. Ireland and B. G. Dale, "study of total productive mainm

usA, 2006.

F.

K,

wang,w-

Lee, "Learning curve anarysis in total pmaintenance," Ornega, vol. Zg, no. 6, pp. 49l-g, 2001.

K. E' McKone, R. G. schroeder, and K. o. cua, "The impac nff

productive maintenance practices on manufacturing perfor:nn

implementation," Journal of euatity in Maintendnce Engineemry,

7, no. 3, pp. 183-g l, Z00l.

4)

;:;,'!.:l',r.-t.i.:,...:,:;.'-ii|- -+-i_]i1i+!-.::.::;

Fig. 3 Maintenance Decisions Out [gg]

Choosing

optimization

models".rt

seems

a

lot

of

maintenance

optimization rnodels

with

varioussimulating'tools

and mathematical rnodelshave

beenproposed

in

our

area. Choosing

the

right

one

that rnatchwith

our

data measurementis

one stepto

do.A

true

maintenance

optimization process

continually

monitors

and

optimizes

the

current

maintenancsprogram

to

improve

its

overall efficiency

andeffectiveness.

Decision

out:

In

the

process

of

decision

makiirg,decision makers

combine

difrferent fypesof

data(i.;.

D.

Das, "Total predictive maintenance:a

comprehensive &aCIsachieving excellence in operational systems," Iniustrial Ensir,w

Jourrtal, vol. 30, no. 10, pp lS-23,2001.

D.

Gupta,Y.

Gunalay, andM. M.

srinivasan, '*The relatibefween preventive maintenance

and

manufacfuring rperformance'', European Journat of operational Research,

v&

no. l, pp. 146-62,2001.

R-

c.

Gupta, J. sonwalker, andA.

K. chitale, *,overall equieffectiveness through total productive maintenance", prestige

af Adanagement and Research, vol. 5, no. L, pp. 6t -7Z,Z0Al. R. Kodali, "Qualifieation

of

TpM benefits through AHp Prodactivity, vol. 42, no. Z, pp 265-73, 2001.R. Kadali and s, chandra, o'Analytic hierarchy process of justil of total productive maintenance" , production ptanning and C

vol. I 2, no. 7, pp, 693-705. 2001.

T.

Finlow-Bates,B.

visser, andc.

Finlow-Bates,"An

inrapproach to problem solving: linking K-T, TeM, and RcA to

The TQIvI Magazine, vol. 12, no. 4, pp. 2&4-9,2000.

F. L.

cooke, "ImplementingTpM

in

plant maintenance:organizational barriers," International

iournal

of

eualitT-Reliability Managemerxt, vol lT. no. g,Z0AA.

s)

MAINTENAHCE DATA IN

[image:8.595.56.345.87.735.2]E

=imgs of The 1" Makassar International conference on

:i c"ai Engineering and Informarics

:.:llin

university, Makassar, Incionesia November 1i-14, z00BOl lCEI

K. .E. McKone, R. G. Schroeder, and K. O. Cua, "Total

productive

[37]

K. K. Lai, F. K. N. Laung, B. Tao, and S.y.

Wang, .,practices ofrBmtenance: a contextual view," Journal in Operations

Management,

preventive maintenance and replacement for engines: a case study,','o1 17, no' 2, pp'

12344,1999.

European Journal of operatioial Research, vol, 124, no. z, pp.294-.{.

Shamsuddin,M.

H. Hassan,T.

Zahari, *TpM can gobeyond

fOO,}OOO.malntenanc€: excerptfromcaseinplementation,"JournalofQuatityin

i38]

M.

Ben-Daya andA.

S. Alghamdi, ..On an imperfect preventive I{aintendnce Engineertng, vol. I 1 No. l,pp. 19-42,2005.

maintenance model," Internatianal Journal ofguitity &

Reliability\

B. Bloorq Reliability Centered Maintenance implementationmade

Management, vol.. lT, no. 6, pp" 661-70, 2000.|tlaile'

McGraw-HilI, UsA'2006.

t39l

I-. gsu, 'simultaneous dete;ination of preventive maintenance andH' ^{' Gabbar, H' Yamashita, K' Suzuki, and Y. Shimada,

"Computer-

replacement policies in a queue-like production system with minimalaided-RCM-based plant maintenance management systenf',

robotte

rwaa," Reli;bility Engineiring and System Safety, vol. 63, 11o.2, pp.11d _Computer-integrated Manufacnrin/, vol. 19, no. 5, pp.

449-5g,

l6l-7,1g99.1003.

R..W.-.Wessels, "Cost optimized schedule maintenance interval

for

system to prevantive maintenance interruptions," production plaqing reliability centered maintenance," Proceeding Annuat Reliabilityand

ind Contrit,vol. 9, no.4, pp. 349-59, 199g.rlainninabilitySvmposiumlEEE,pp.4l2-6.2003.

t41l

M. Gopalakrishnan,l.

S.inite,

and M. D. Miller, Maximizing theS'

Eisinger andU. K.

Rakowsky, "Modelingof

uncertaintyin

effectivenessof a

preventive maintenance system:an

adaptiverefiability centered maintenance- a probalistic approach,"

Reliabitity

modeling approach," 'Mooogement Science, vol. 43, no. 6,pp.827-ao,Engineering nad System Safety, vol. 71. bo. z,pp.

159-64,2001.

lgg./.L B.

Hipkins andC.

D.

Cock, "TQM and BPR: Iessonsfor

1421 A. Grall, L. Dieulle, C. Berenguer, and M. Rousignol, "Conrinous timernaintenancemanagement,"Omega,vol.28,no.3,pp.277-92,2000, predictive maintenance scheJuling for deteriorating system;" lAEd

!1.

Rausand, "Reliabilitycenterd

maintenance,"Retiabitity

Transaction on Reliability, vol. 51, no. 2,pp. 1trI-SO,1}OZ.EngineeringandSystemSafety,vol.65,no.2,pp.llg-24,1998.

143)D.

Chen andK.

S.i.in.di,

"Clo."d-form analytical resulrs forB. S' Dhillon, Enginering Maintenonce

A

Modern Approach,CRC

condition-based maintenance," Retiability Engineiring ancl System Press LLC, Florida,2002.

Safety, vo1.76, no. 1 , pp. 43_sl, 2002.-i.. Chelbi, and D- Ait-Kadi, "Analysis

of

a

production/inventoryt44j M.

Marseguerra,E.

Zio,

andL.

Podofillini, "Condition basedslstem with randomly failing production unit submitted to

regular

maintenance optimization by means of genetic algorithms and Montepreventive maintenance," European Jownal of Operational

Research,

Carlo simulation," Retiability Engineeriig and Syitem Safety, vol. 77,lol.

156, pp.712-9,20A4.

no. 2, pp. tSI-6s, 2002.A. Charles, L. Floru, C. Azzaro-Pantel, L. Pibouleau, and S. Dbmenech,

t45l

M. A" Jamali, D. Air-Kadi, R. Cleroux, antl A. Artibq "Joint optimal "'Optimization of preventive maintenance strategies ina

multipurpose

periodic and conditional maintenance strategy", Journal ofeaiw n

batch plant: application to semiconductor manufacturing,"

Computer

MaintenanceEngineering,vol.ll,no.2,pp.

i07-14,2005: -tnd Chemical Engineering, vol.27, no-4, pp.449-67,2AC6.

W6J H. Saranga and J" Knezevic, 'Reliabiliry irediction for condition-basedC.

H

Qian, L Kodo, and N. Thosio, "Optimal preventivemaintenance

maintained systems," Reliability Engineering and Systen Safety, vol. policies for a shock model with given damage level," Journalof

71,no.2,pp.zl9-24,2001.QuolityinMaintenanceEngineering,vol

.ll,

no.3,pp.216-27,2005.l47l

F.

Barbeia,H.

Scheneider, andE.

watson,.,A

condition basedC. Chen, Y' Chen, and J. Yuan, "On dynamic preventive

maintenance

maintenance model for a two-unit series system," Erupean Journal of policy for a system under inspection," Retiability Engineeringand

OperationalResearch,vol. ll6,no.2,pp.iAf-SO,pel.

S;st_emsafetl' vol.76,no.

l,pp.41-7,20l3.

t48l

S. Luce, "Choice criteriain

conclitional preventive maintenance,"S. Bloch Mercier,

"A

preventive maintenance policy withsequential

Mechanical Systems and Signal Processing, vol. 13, no. I, pp. 163-8,:hecking procedure for a Markov deteriorating system,"

European

lggg.JournalofoperationalResearch,vol142,no.3,pp.

548,2002.

t49l

K. Bagadia, Computerizecl Maintenance Managenrcnt Systems McrdeS- Sheu, R. Yeh, Y. Lin, and M. Juang, "A Bayesian approach to

an

Easy" Mc.craw Hill, usA,2006.adaptive preventive maintenance model," Reliability Engineering

and t50]

O. Femandes, A. W. Labib, R. Walmisley, and D. J- petty,.,A decision Sistem Sa"fety, vol. 71, no- 1, pp. 19-42,2001.

support maintenance management system: development and\t

Juang andG'

Anderson,"A

Bayesian methodon

adaptive

implementation," Internationil Journalof

eualityAi

arliobitity preventive maintenance problem," European Journal ofOperational

Management, vol. 20, no. 8, pp.965-79, 2001.Research, vol. 155, no. 2, pp.

453-73,2004.

t5l]

J. B. Leger and C. Movel, "lniegration ofmaintenance in the enterprise:Y X

Zhao,"Onpreventivemaintenancepolicyofacriticalreliabilify

toward an enterprise modelirig based framework compliant with level for system subject to degradation," Reliabitity Engineeringand

proactive maintenince strategy,';Production planning andtontol,

vol.S7 stem Safety, vol. 79, no. 3, pp. 301 -8,

2003.

tZ, no.2,pp. 176_g7, ZOO|.F. C. Badia, M. D. Berrade, A. C. Clemente, "Optimal inspection

and

tS2J T. Singer, ;Are you using all the features of your CMMS? Following preventive maintenanceof

unitswith

revealed andunrevealed

thisT-stepplancanhelpuncovernewbenefits," planEngineering,vol fulures," Reliability Engineering and System Safety, vol.78, no. 2,pp.

53. no. l, pp 324,lggi.

157'63'2002.

t53l A. W.

Labib, "world-class rnaintenance usinga

computerizedU. Gurler and A. Kaya, "A maintenance policy for a system with

multi-

maintenance management systert', Journat of euality in Mointmancestate componentsi an approximate solution," Reliability

Engineering

Engineeing, vol. 4, no. 1, pp. 66-75, 1998.andSystemSafety, vol.76,no. 2,pp.

117-27,29O2.

t54l L.

Swanson, "Computeriiid maintenance manag€menr sysrems: aS. Motta'

D.

Brandao, andE' A.

Colosimo, "Determinationof

studyof

syslem -<lesign and use", Produetion and Inventary preventive maintenance periodicities of standby devices,"Reliability

ManagementJournal,vol.38,no.2,pp. ll-15,1997.EngineeringandSystemSafety,

vo1.76,no.2,pp.149-54,2002. I55l

K.

Jones, and S. Collins, "Compuierized maintenance management\1. K.

Salameh andR.

E..Ghattas, "Optimal just-in+imebuffer

system",PropertyMenagement,rrol. 14,no.4,pp.33-7,1gg6.in-ventorY for regular preventive maintenance," International

Journal t56] l.

F{. Wictrteri, 'Opt-i.;"ing maintenance'i.rnctionby

ensuringo-fProduction Economics. vol.74, no. 1, pp.

157-61,2001.

effective managementofyouriomputerized maintenance *unugr-"nt 1'' Tsai, K. Wang, and H' Teng,."Optimizing preventivemaintenance

systems', I\EE , .frtcan bon|ermce (24-27 Septenber), Steltibusch,for

mechanical components using genetic algorithms",Retiability

usl,pp.Tgg-95,i996.EngineeringandSystenSafety,vol.T4,no.

l,pp.89-97,2001..

t57l

M.

A.^Burhanuddin, "An Apptication ofDecision Making Grid to

T'

Dohi'N'

Kaio' and S. osaki, "Optimal periodicmaintenance

Improve Maintenance Strategiisin

Small and Medium Industries,,,sfategy under an intermittently used environment,, IEE

Transaction,

pioc. the /d

IEEECoiyer"rr"

on

Industial

Electronic &.vol.33, no.

l2,pp.103746,2001.

Apptication,pp.455_60,2007.

?78-97?- l 9765.0-6

Proceedings of The 1" Makassar Inremational Conference on Elecuical Engineering and Informarics

Hasanuddin Universiry, Makassar, Indonesia November 13,14, 2008

t58]

K. E. McKone and E,E Weiss, "Guidelines for implementing predictive maintenance", vol. I l, no, Z, pp. t0g-24,2002.[59]

C. Clru, J. Proth, and P Wolff, "Preditive maintenance: the one-unit replacement model," fnturnational Journal of Production Economics,vol. 54, no. 3, pp. 285-9j, 1998.

t60l

D.

N

Murthy and E. Asgharizadeh, "Optimal decision making inmaintenance service operation,'o European Journal

of

OperationalResearch, vol. I16, no. 2, pp. Z5g-73, l ggg.

[61]

H. H. Martin, "Contracting out maintenance and a plan for futureresearch," Journal of Quality in Maintenfrnce Engineering, vol. 3, no.2, pp. 8l-90, 1997.

162]

P. S. Buczkowski, M, E. Hrtmann, and V. G. Kulkami, "Outsourcing prioritized warranty repairs", International Journalaf fuality

& Reltability iufanagement, vol. ZZ,no. T, pp. 699-714, 2005.[63]

K. Pun, K. chin, M. chow, and H,i. w.

Law, "Aneft'ectiveness-centered approach to maintenanco management: a cass sfudy," Journal of Quality in maintenance Engineering, vol. 8, no. 4, pp. 346-69,2002.

[64] D. N. P.

Murthy,A.

Atrens, andJ. A.

Eccleston, "strategicmaintenance managsment,"

Journal

quality in

Matntenance Engineering, vol. 8, no.4, pp.ZB7-305, Z}Aid.[65] F. I.

Khan andM. M.

Haddara, "Risk based maintenance: aquantitative approach

for

maintenance/inspection scheduling andplanningn" Journal of Loss Prevention in the Process Industrres, vol.

16, no. 6, pp. 536-73, 2003

[66]

T. L. Saafy, The Analytic Hierarchy Process, McGraw-Hill, New York,I 980.

t67l

M. Bevilacqua and M. Braglia, "The analytic hierarchy process appliedto maintenance strategy selection," Reliability Engineering and System

Safbty, vol. 70, no. l, pp. T1-83, 2000.

t68] A. W.

Labib, "World class maintenance usinga

computerizedmaintenance management systemo', Joltrnal of Quality in Maintenance Engineering, vol.4o no. l, pp. 66-?5, lg9B.

169l

B. Al-Najjar and I. Alsyouf, "selecting the most efficient maintenance approach using fuzzy multiple criteria decision making," International Journal of Production Economfcs, vol. 84, no. l, 85-100, 2003.I70]

E. Triantaphyllou, B" Kovalerchuk, L. J. Mann, and G. M. Knapp,"Determining the most important criteria

in

maintenance decision making" , Jottrnal af Quality in Maintenance Engineering, vo[. 3, no. l,pp" l6-28, 1997.

[71] L.

Swanson,"An

information processing rnodelof

maintenancemanagement," International Journal of Production Econonucs, vol, 83,

no. l, pp. 45-64,2003.

l72l

D. Sherwin, "Review overall model for maintenance rnanagement",Reliability Engineering and System safety, vol. 6, no. 4, pp. l jg-64,

2000.

[73]

C- Pieri, M.R Klein and M. Milaness, "A data and knowledge-basedsystem

for

supportingthe

maintenanceof

chemical plant," International Journal of Production Economlcs, vol. 79, no. 2, pp.143-59,2002.

t741

H. D. Goel, J. Grievink, and M.p.C weijnen, "Intsgrated optimalreliable design, production, and maintenancs planning for multipurpose

process plants", Computers & Chemieal Engineering, vofl-

fi*

pp. 1543-55,2003.

t75]

L. A. Zadeh, "Fu?&y Logic", IEEE Computer Society, VoI-li-93,1988.

t76l

C.K.

Mechefske andZ.

Wang, "Using fuzzy lingusmicn

optimum maintenance

and

condition monitoring Mechanical Systems and Signal Processing, val. 15, no. 6,m-2001.

1771

[78]

lTel

180l

t8

ll

P. Bruns, "Optimal maintenance strategies for systems

st&

A. C. Marquez, A. S. Heguedas, "Models for maintenance

J. H"

Chiang, andJ.

Yuan, "Optimal maintenancepory

Y.

Lam,"An

optimal maintenance modelfor

a

cotwodi vol. 77. m" repair options and without assuming bounded cosB',

f;q

Joarnal of Operational Researc&, vol. 139, no.l pp. 14G65.

W*

a study for repairable systems and finite time periods", Engineering and System Safety, vol. 75, no. 3, pp.367-77.

Markovian system under periodic inspection," Reliability

and System Safety, vol. 71, no. 2, pp. 165-72,2001. secondhand-new or outdated-updated system," European

Operational Research, vol. I 19, no. 3, pp. 739-52, 1999,

Z"

Rochdi,B.

Driss, andT.

Mohammed, "InternationaXmaintenance modeling using Petri nets", Retiability Enginffii

System Sofety, vol. 65, no. 2, pp. I 19-24, 1999.

182]

S, Apeland, and P. A. Scarf, "A fully subjectivc approach tsinspection maintenance," European Journal of Operational

vol. 148, ilo. 2,pp.410-25,2003.

[83]

L, L. Ho and A, F. Silva, "Unbiased estimators for a systernfu

time

to

failure and percentilesin a

Weibull regressionInternational Journal of Quality & Reliability Management,

d-3, pp. 323-39,2006.[84]

T. Chen, and E. Popova, "Maintenance policies with warranty," Reliability Engineering and System Safety,6l-9,2002.

t85]

J. Barata, C. C. Soares,M.

Marseguerra, and E. Zio, '"Simodeling of repairable multi-component deteriorating systems

condition' maintenance optimization," Reliability Enginwiry

System Sofbty,voi. 76, no.3, 256-64,2002.

[86]

R. Sarker andA.

Haqueo "optimizationof

maintenance mc.provisioning policy using simulation," Applied Mathematical vol.24, no. 10, pp,751-60,2000.

[87]

N. T. Balakrishnan,"A

simulation model for maintenance pProceetlings Annual Reliability and Maintainability Syntposh,tn

pp.109-l 8, 1992.

l88l

R. W. Peters, Maintenence Benchmarking and Best Pracriw,Graw Hilt, USA, 20A6,

158

![Fig. t Maintenance Techniques Classification [1]](https://thumb-ap.123doks.com/thumbv2/123dok/666947.81949/5.595.69.532.70.475/fig-t-maintenance-techniques-classification.webp)

![Fig. 3 Maintenance Decisions Out ;:;,'!.:l',r.-t.i.:,...:,:;.'-ii|- -+-i_]i1i+!-.::.::;[gg]](https://thumb-ap.123doks.com/thumbv2/123dok/666947.81949/8.595.56.345.87.735/fig-maintenance-decisions-out-l-r-ii-gg.webp)