UNIVERSITI TEKNIKAL MALAYSIA MELAKA

COMPARISON STUDY OF PRESS PART QUALITY

INSPECTION SYSTEM: CHECKING FIXTURE AND FARO ARM

LASER SCANNER

This report submitted in accordance with requirement of the Universiti Teknikal Malaysia Melaka (UTeM) for the Bachelor Degree of Manufacturing Engineering

(Manufacturing Design) with Honours.

by

NURUL WAHIDA BT HANAPIAH

(Mengandungi maklumat TERHAD yang telah ditentukan oleh organisasi/badan di mana penyelidikan dijalankan) UNIVERSITI TEKNIKAL MALAYSIA MELAKA

BORANG PENGESAHAN STATUS LAPORAN PSM

JUDUL: Comparison Study of Press Part Quality Inspection System: Checking Fixture and Faro Arm Laser Scanner

SESI PENGAJIAN: 2009/2010 (Semester 2)

Saya Nurul Wahida Bt Hanapiah,

mengaku membenarkan tesis (PSM) ini disimpan di Perpustakaan Universiti Teknikal Malaysia Melaka (UTeM) dengan syarat-syarat kegunaan seperti berikut:

1. Tesis adalah hak milik Universiti Teknikal Malaysia Melaka dan penulis.

2. Perpustakaan Universiti Teknikal Malaysia Melaka dibenarkan membuat salinan untuk tujuan pengajian sahaja dengan izin penulis.

3. Perpustakaan dibenarkan membuat salinan tesis ini sebagai bahan pertukaran antara institusi pengajian tinggi. atau kepentingan Malaysia yang termaktub di dalam AKTA RAHSIA RASMI 1972)

DECLARATION

I hereby, declared this report entitled “Comparison Study of Press Part Quality Inspection System: Checking Fixture and Faro Arm Laser Scanner” is the results of my own research except as cited in references.

Signature :

Author’s Name : Nurul Wahida Bt Hanapiah

APPROVAL

This report is submitted to the Faculty of Manufacturing Engineering of UTeM as a partial fulfillment of the requirement for the degree of Bachelor of Manufacturing Engineering (Manufacturing Design) with Honours. The member of the supervisory committee is as follow:

ABSTRACT

ABSTRAK

DEDICATION

ACKNOWLEDGEMENT

First and foremost, gratefully wishes to the Almighty, Allah S.W.T for all His blessing.

This opportunity has been taken to express sincere appreciation and gratitude to respective supervisor, Mr. Wahyono Sapto Widodo, for constructive guidance, consistent encouragement, and fulfilling aspiration in completing this project. Also for his kindness, patient, and supporting, I wish him thanks a lot. Same goes PSM examiner and panels, Mr. Tajul Ariffin Bin Abdullah and Mr Saifudin Hafiz Bin Yahaya for guidance and patient.

Also this chance has been taken to wish thank to the entire technician at the UTeM Rapid Prototyping Laboratory for took valuable time to teach and give a proper training technique to understanding about 3D scanner machines and how to operate this machines and teach something that very useful in manufacturing design.

TABLE OF CONTENT

2.4.2 Types of Portable Coordinate Measuring Machine 11

2.4.3 Advantages Using 3D Scanner 14

2.4.4 The Disadvantages 15

2.5 Scanning Characteristics 15

2.5.1 3D Scanning Concept 16

2.7 3D Scanning Times 18

2.10 Introduction to Scanning 23

2.10.1 Scan Quality 23

2.10.2 Scanner Types 23

2.10.3 Arm-mounted Scanners 24

2.11 Preparing To Scan 24

2.11.1 Determining the Intended Use of the Scan 25

2.11.2 Whether to Generate ordered or Unordered 25

2.11.3 Scanning Examples 25

2.11.4 Scanning For Geomagic Qualify 26

2.12 Collecting data with the Faro Scan Arm 26

2.13 Software 27

2.13.1 Geomagic Software 28

2.13.2 The creation of the CAD model 28

2.14 Current Quality Inspection in Press Part Industry 29

3. CHAPTER 3 33

3.1 Introduction 33

3.2 Summary of Project Flow Chart 35

3.2.1 Faro Arm Laser Scanner Identification 35

3.2.2 Project Mission 36

3.2.3 Literature Review 36

3.2.4 Methodology Approaches 37

3.2.5 Selection of the Product for the Project Analysis 37

3.2.7 Scanning the Product 38

3.2.8 Scanning Time taken 39

3.2.9 Analysis 40

4. CHAPTER 4 44

4.1 Setup Experiment 44

4.1.1 Preparation of the Product 44

4.1.2 Calibration 45

4.1.3 Scanning Data 45

4.1.4 Software 46

4.2 Product and Drawing 47

4.3 Preparation of the Product 48

4.3.1 Cleaning Process 48

4.3.2 Coating Process 48

4.4 Setup and Calibration Machine 49

4.5 Scanning Process 51

4.6 Editing Process using GEOMAGIC STUDIO Software 53

4.6.1 Starting GEOMAGIC STUDIO 54

4.6.2 Point Phase Fundamentals 56

4.6.3 Polygon Phase Fundamentals 65

4.6.4 Polygon Phase Advanced 74

4.7 Faro Arm 3D Scanned Result 78

4.8 Measuring Process using GEOMAGIC QUALIFY Software 78

5. CHAPTER 5 83

5.1 Dimensional Accuracy Analysis 83

5.1.1 Analysis Scan Data Dimensional Accuracy by Faro Arm Laser 83 Scanner

5.2 Shape Analysis 89

5.3 Time Analysis 90 5.4 Comparison between Faro Arm Laser Scanner and Manual Checking 92

Fixture

6. CHAPTER 6 95

6.1 Conclusion 95

6.2 Recommendation 96

REFERENCES 97

LIST OF TABLE

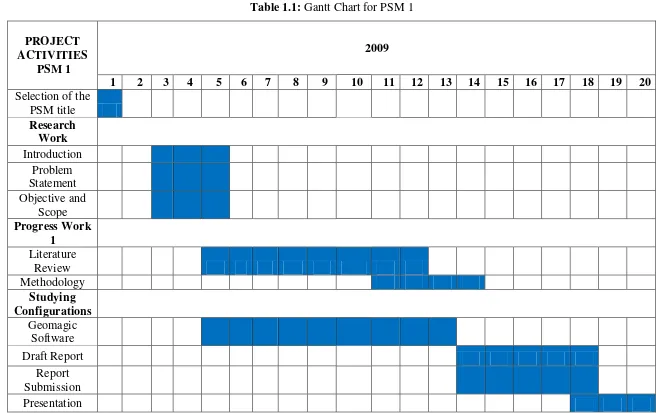

1.1 Gantt chart for PSM 1 4

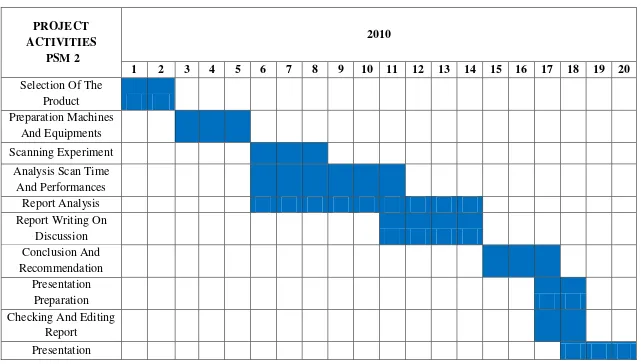

1.2 Gantt chart for PSM 2 5

2.1 Portable CMM Faro Arm 11

2.2 Capability Criteria of 3D Scanner 18

3.1 The Example Table Sheet for Time Taken During the 3D Scanning 39 Process “Product (A) Scanning Time Taken”

4.1 Tabs Available In the Main Application Window 55

5.1 Tabular Result from the Comparison Dimension of Product 85 5.2 Overall Tabular Result from the Comparison Dimension of Product 88 5.3 The Shape Analysis of Real Product Compare with Scan product for 90

Faro Arm

LIST OF FIGURES

2.1 Faro Arm Laser Scanner 10

2.2 Portable CMM specification 13

2.3 Illustration of Typical Manufacturing Product Cycle 16

2.4 3D Scanning Process Time 19

2.5 The Standard Scanning Process versus Time Diagram 20

2.6 The Scanning Operation Diagram 21

2.7 Data Processing Flow 22

2.8 FARO Laser Scan Arm. 24

2.9 An example part mounted for scanning (left) and the same part as 26 scanned (right)

2.10 Generation of the CAD models: patch layout. 28

2.11 Wheel Caster 30

2.12 Checking Fixture 30

2.13 The Function of Checking Fixture 30

2.14 Example design of checking fixture 31

2.15 Example of checking fixture for car’s front bumper 31

2.16 Components of jig and fixture 32

3.1 Flow Chart of the Project 34

3.2 The Flow Chart of the Procedure in Scanning Process 38

3.3 Geomagic Basic Work Flow 41

3.4 Inspection Technique 42

3.5 Check Sheet Part Manual 43

4.1 Isometric View 47

4.2 SKD-S2 Developer and Caster Wheel after Coating Process 48

4.4 Connection to Faro Arm Machine 49

4.5 Starting Plug-In GEOMAGIC STUDIO Software 50

4.6 Movement of the Faro Arm Machine on the GEOMAGIC STUDIO 50 Software

4.7 Faro Arm Machine in the lab UTeM 51

4.8 Caster Wheel after Coating Process 51

4.9 Guideline of the Laser Range and Scanning Process 52

4.10 Button Scan 52

4.11 Basic Studio Workflow 53

4.12 Window Layout 54

4.13 Main Application Window 54

4.14 Open File into the GEOMAGIC STUDIO 56

4.15 Display manager 57

4.16 Zoom in Top View 57

4.17 Outliers Points 58

4.18 Deleted Points 58

4.19 Disconnected Components 59

4.20 With Noise 60

4.27 Polygon Phase Fundamentals 65

4.34 Partial Boundary 71

4.35 Decimate Polygon 72

4.36 Reverse Selection 73

4.37 Olive Green Surface 74

4.44 Cross section and the point of the product 80

4.45 Cross Section for the Product to Measure the Part Dimension 81

4.46 2D Dimension View 82

5.1 The Section to Be Measured 84

5.2 Graph Comparison Dimension for section 1 86

5.3 Graph Comparison Dimension for section 2 86

5.4 Graph Comparison Dimension for section 4 87

5.5 Graph Comparison Dimension for section 5 87

5.6 Graph Dimension Comparison Analysis of Actual Dimension and Scan 88 Dimension Data

LIST OF ABBREAVIATIONS

UTeM - Universiti Teknikal Malaysia Melaka

RP - Rapid Prototyping

CAD - Computer Aided Design CAE - Computer Aided Engineering CAM - Computer Aided Manufacturing STL - Standard Template Library

CHAPTER 1

electronic, metal fabrication, plastics and press industries. Based on the research title, quality investigation was carried out to collect and record related quality checking results of Faro arm laser scanner equipmentIn this project study will be using press part component such as a caster that are produce in press part industries. The experimental results in this project are among the data that recorded in the reference. A press is a process of changing a shape of sheet metal using a force according to the shape of dies which this process is widely used in industrial practice. Mostly, all product manufactured are necessary an inspection process in order to conform the quality of the product. Many kind of inspection method are using such as visual inspection and through a conformance gauge. At manufacturing practice, a quality conformation on the part manufactured using press method is inspected through a special tool called checking fixture. This tool is designed and fabricated for locating, holding and then checking a certain points on part.

manufacturing industries are using power generated checking fixture which is combine with pneumatic devices and controlled through a program generated via MATLAB or visual basic program. It is usually to inspect the attribute data of product such as light brightness and sound. For example is a manufacturer of digital cameras. Nowadays, there are many research and experimental work that have been done in the quality inspection field but the most effective parameter still cannot define. Consequently, in this project study will analysis and doing experiment investigate of the application Faro Arm Laser Scanner in quality inspection field whether it is suitable to use in press part industries or not.

1.2 Problem Statement

Although many knew about the capability of a products are manufactured through a press machine. The problems that always occur are in quality inspection system where checking process of the product is needed in order to meet the specification and dimension that are required. Therefore, the application of Faro Arm Laser Scanner and checking fixture need to be identified in term of the problem in real time and capability limitation for both equipment, so that in the future the information from the experimental work can be further extended or to be used for analysis to validate the result.

1.3 Objective of the Project

Objectives are very important as guidelines to the aims of the project purpose. It based on the problem statement that occurs to the find the better solution of the problems. The objectives of this project study will be:

ii. To study the application of the Faro Arm Laser Scanner as a quality inspection tool for press part components.

1.4 Scope and Key Assumptions

Few scopes and guidelines are listed to ensure the project is conducted within its intended boundary. This is to ensure the project is heading to the right direction to achieve its intended objectives. The first scope of this project is to find out the various researches that related with project study. All the information and data collected will be approach in this project report. Secondly, the scope of this project is to do experiment process by using Faro Arm Laser Scanner and checking fixtures equipment. In this experiment process, need to know how to use and apply both of equipment in quality inspection system.

1.5 Gantt Chart

1.6 Summary

CHAPTER 2

LITERATURE REVIEW

2.1 Introduction

This chapter will be describing about the most important elements that generated idea of the latest technology or method use that is already occurs before. This chapter also describes the researches that have been done by others in Faro Arm Laser Scanner and checking fixture. The methods of test, collecting data and assessment of Faro Arm Laser Scanner and checking fixture that had been used by others also will be described in this chapter. It is also summarized the equipments and techniques which will be used to measure the quality conformation on the part manufactured using press method.

Faro Arm Laser Scanner can be studied and analyzed in this project by taking some of the example and guidance from other research. When someone has already completed do the research about Faro Arm Laser Scanner technology that is very useful for the future work, once the result of the research need to be upgrades, so literature review is the medium that can be able to get best information of recent technology or method use for this Faro Arm Laser Scanner research.

2.2 Introduction of 3D Scanner