Effects of hot air conditioning of ‘Kensington’ mango fruit

on the response to hot water treatment

Keryl K. Jacobi

a,*, Elspeth A. MacRae

b, Suzan E. Hetherington

caQueensland Horticulture Institute,Gatton Research Station,Locked Mail Bag7M/S437,Gatton,4343.Queensland,Australia bPosthar6est Science Group,HortResearch,Mt Albert Research Centre,Pri6ate Bag92 169,Auckland,New Zealand

cSchool of Land and Food,The Uni6ersity of Queensland,St Lucia,4072.Queensland,Australia

Received 6 March 2000; accepted 19 August 2000

Abstract

Hot air conditioning treatments of mature ‘Kensington’ mango fruit (Mangifera indica Linn.) were optimised by incubating fruit at temperatures from 22 to 42°C for 4 – 16 h, prior to a hot water treatment (HWT) of 45°C for 30 min or 47°C for 15 min, before ripening at 22°C. Hot water injuries were reduced, and in some cases, eliminated, by conditioning the fruit at 40°C for 8 h. The conditioning temperature was more important than the duration of the HWT in injury alleviation. Conditioning at 40°C prior to HWT accelerated the ripening of fruit, increased weight loss, reduced fruit firmness, increased brix and lowered titratable acidity compared to untreated fruit and fruit receiving other heat treatments. These treated fruit were also more resistant to postharvest diseases. © 2000 Elsevier Science B.V. All rights reserved.

Keywords:Heat treatments; Thermotolerance; Mango;Mangifera indica; Postharvest storage; Fruit; Ripening

www.elsevier.com/locate/postharvbio

1. Introduction

Conditioning ‘Kensington’ mango fruit at 40°C increases heat tolerance through a reduction or elimination of heat injuries (Jacobi et al., 1995, 1996). Previously, Joyce and Shorter (1994) had demonstrated that the severity of cavitation and retention of starchy regions within heat-damaged mesocarp of ‘Kensington’ fruit, could be reduced by a slow 7-h heating of the fruit to a 37°C core

temperature. These authors maintained fruit at 37°C for 5 12 h prior to a HWT of 47°C core temperature held for 25 min. For avocado (Woolf et al., 1995) and tomato (Hakim et al., 1996) temperatures in the range 25 – 46°C applied for 0.5 – 72 h have also proved effective in raising fruit heat tolerance.

In previous research reported by Jacobi et al. (1996), injuries to fruit not conditioned before HWT, included accentuated lenticel spotting, ex-ternal and inex-ternal cavities and starchy layers beneath the skin. A conditioning treatment of 40°C for 8 – 12 h was found to minimise these heat injuries to the fruit. This paper reports on the * Corresponding author. Tel.:+61-7-54623223; fax:+

61-7-54623223.

E-mail address:[email protected] (K.K. Jacobi).

potential to achieve different levels of heat toler-ance in ‘Kensington’ fruit using a range of condi-tioning treatments and HWT. The optimum conditions for the development of fruit heat toler-ance were also determined.

2. Materials and methods

2.1. Plant material and common procedures

Mango fruit (Mangifera indica Linn. cv Kens-ington) were harvested and desapped in the field. Maturity was assessed in the field on a sample of ten fruit that were similar in size and skin colour to those selected for the experiments using the mango picking guide (Holmes et al., 1990). The total solids (TS) levels of the fruit were deter-mined in the laboratory according to AOAC methods (AOAC, 1984). Upon arrival at the labo-ratory, fruit were immediately transferred to 23°C for sorting and evaluation of initial skin colour.

Uniform unblemished fruit of size 380 – 440 g were selected for each treatment. All conditioning treatments were carried out in a darkened cham-ber (Jacobi et al., 1996). Fruit core temperature was raised to the required conditioning tempera-ture during the first 2 h within the chamber and subsequently maintained at this temperature for the duration. Immediately after conditioning, fruit were transferred from the chamber directly to the bath for hot water treatment (HWT). After HWT, fruit were stored at 22°C together with untreated (control) fruit.

2.2. Experiment1:optimum temperature for 8 h to generate heat tolerance

Green ‘Kensington’ mangoes were obtained from a commercial orchard near Eumundi (26°28%S, 152°58%E) around 0700 h on the 6th February 1995 and transferred to the Brisbane laboratory within about 1h. Fruit were randomly distributed to each treatment (14 fruit/treatment). Treatments were: (1) untreated (control) fruit were held continuously at 22°C; (2) conditioning for 8 h at 22°C followed immediately by a HWT, where the fruit core temperature was raised to

47°C and held for 15 min using 48°C water, total HWT time was 90 min; (3) conditioning for 8 h at 30°C followed immediately by HWT as described above in (2), total HWT time was 85 min; (4) conditioning for 8 h at 38°C followed immediately by HWT as described above in (2), total HWT time was 75 min; (5) conditioning for 8 h at 40°C followed immediately by HWT as described above in (2), total HWT time was 65 min; and (6) conditioning for 8 h at 42°C followed immediately by HWT as described above in (2), total HWT time was 60 min.

All evaluations were made 4 days after HWT, when the maximum differences between treat-ments occurred. Fruit weight loss, skin colour (objective and subjective), and the incidences and severities of external and internal injuries were measured as described by Jacobi et al. (1996). Fruit firmness was measured in Newtons (N) us-ing an Instron Universal Testus-ing machine.

2.3. Experiment 2:increased heat tolerance deri6ed from conditioning treatments

Green ‘Kensington’ mangoes were obtained from an orchard near Kandanga (26° 23%S, 152° 41%E) around 0600 h on the 7th February 1996 and transferred to the Brisbane laboratory within 3 h. Each treatment had ten fruit assigned to: (1) untreated (control) fruit were held continuously at 22°C; (2) conditioning for 8 h at 22°C followed immediately by a hot water treatment (HWT) where the fruit core temperature was raised to 47°C and held for 15 min using 48°C water, total HWT time was 110 min. This HWT time was then used as the standardised time for the remaining treatments described below; (3) to (6) condition-ing for 8 h at 30, 38, 40 or 42°C followed immedi-ately by HWT as described above in (2). The standardised HWT time was 110 min.

cali-brated, using distilled water, for measurement at 20°C. Titratable acidity was measured on each fruit from an accurately weighed sample of de-canted juice free of pulp residue (usually a volume of 1 – 5 ml) diluted to 40 ml using distilled water. Each sample was titrated against 0.1 M sodium hydroxide to pH 8.2 using a Mettler DL20 com-pact titrator. Results were expressed as percentage anhydrous citric acid. The two major diseases were anthracnose (Colletotrichum gloeosporioides (Penz.) Penz. and Sacc.) and stem end rot (Doth -iorella dominicana Petrak and Cif., Lasiodiplodia theobromae Griff. and Maubl.). The severity of disease was assessed 4 days after treatment ac-cording to the percentage skin area affected by either one or both diseases per fruit, and then the percentage scores were related to a 5-point scale where 0=0% skin area affected; 1=1 – 5%; 2 (mild)=6 – 15%; 3 (moderate)=16 – 30%; and 4 (severe)=31 – 100% skin area affected.

Data were examined by analysis of variance using the QDPI BALF.9106 software package. The analysis examined the effect of conditioning treatment, with variation between fruit within treatments being used as the error term. Graphs of variables against conditioning temperature were assessed before deciding whether it would be useful to partition the temperature portion of the treatment effect into polynomial components. However, these graphs did not indicate any useful relationships. Instead pairwise comparisons be-tween means were made using the protected least significant difference procedure. All testing was carried out at P=0.05.

3. Results

3.1. Experiment1:optimum temperature for 8 h to generate heat tolerance

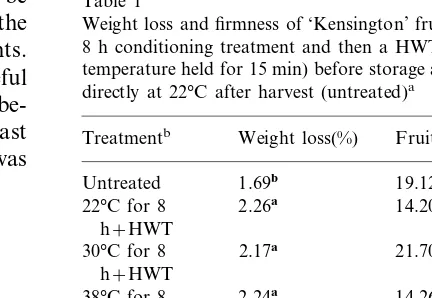

The average internal pulp colour rating of fruit was 4 and total solids level 15.3% (90.24), indi-cating that fruit were commercially mature. There were no differences in weight loss between fruit conditioned at the different temperatures, but un-treated fruit (1.7%) lost significantly less weight than treated fruit (from 2.17 to 2.29%) (Table 1).

Skin colour, reflectance, chroma and hue angle values before or after HWT (data not shown) did not differ. Conditioning treatments, except for 30°C, decreased fruit firmness by 25 – 40% com-pared to untreated fruit (19.1 N) 4 days after HWT (Table 1). Fruit conditioned at 30°C (21.7 N) were the firmest, followed by untreated fruit (19.1 N). There were no significant differences from the other conditioning treatments.

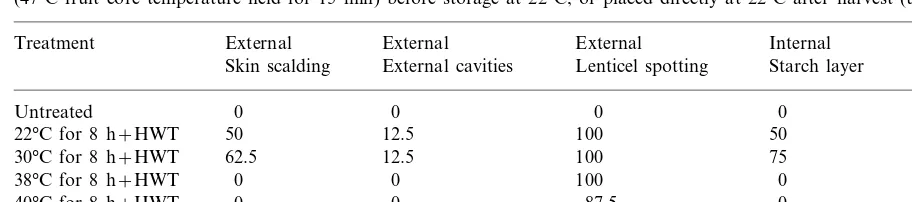

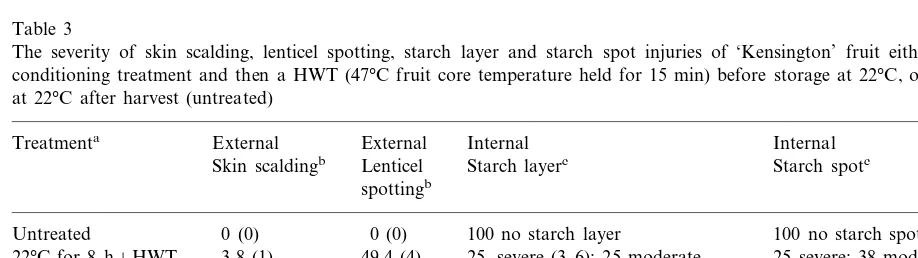

Untreated fruit (Tables 2 and 3) had no exter-nal or interexter-nal injuries, and there were no exterexter-nal injuries on any fruit for 24 h after HWT (data not shown). Fruit conditioned at 38 – 42°C did not show skin scalding. However, fruit conditioned at 30°C before being heated to 47°C core tempera-ture for 15 min had the highest incidence and severity of skin scalding followed by fruit condi-tioned at 22°C (Tables 2 and 3). Cavitation only occurred in fruit from these two treatments (Table 2). All conditioned fruit displayed lenticel spotting 4 days after HWT, that decreased with increasing conditioning temperature, especially above 40°C (Tables 2 and 3). Fruit conditioned at 40 and 42°C had the lowest incidences and severities of lenticel spotting.

Table 1

Weight loss and firmness of ‘Kensington’ fruit either given an 8 h conditioning treatment and then a HWT (47°C fruit core temperature held for 15 min) before storage at 22°C, or placed directly at 22°C after harvest (untreated)a

Fruit firmness(N)

aMeans within a column not followed by a bold superscript

common letter are significantly different (PB0.05).

bAll measurements were made after 4 days of storage at

22°C; values presented are the means of 14 fruit.

Table 2

The incidence of external and internal injuries of ‘Kensington’ fruit either given an 8 h conditioning treatment and then a HWT (47°C fruit core temperature held for 15 min) before storage at 22°C, or placed directly at 22°C after harvest (untreated)a

Treatment External External External Internal Internal

External cavities Lenticel spotting Starch layer

Skin scalding Starch layer

0 0

Untreated 0 0 0

12.5 100

50 50

22°C for 8 h+HWT 62.5

62.5

30°C for 8 h+HWT 12.5 100 75 87.5

0

38°C for 8 h+HWT 0 100 0 12.5

0 87.5

0 0

40°C for 8 h+HWT 0

0 62.5 0 25

42°C for 8 h+HWT 0

aAll measurements were made after 4 days of storage at 22°C; values presented are the percentages of fruit showing injury from

a total of eight fruit.

Fruit conditioned at 38 – 42°C did not have starch layers (Tables 2 and 3), while fruit condi-tioned at 30°C prior to HWT had the highest incidence and severity, followed by fruit condi-tioned at 22°C. Fruit condicondi-tioned at 40°C prior to HWT were the only heated fruit not to possess starch spots (Tables 2 and 3).

3.2. Experiment2:increased heat tolerance deri6ed from conditioning treatments

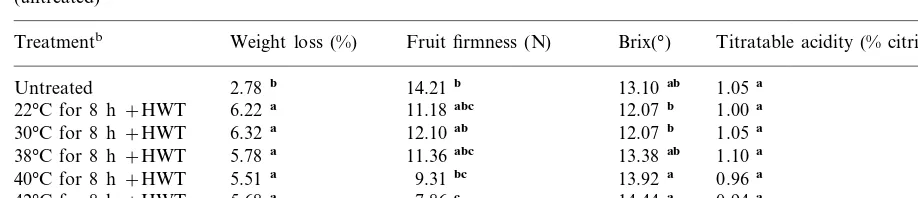

The average internal pulp colour rating for fruit was 4 and total solids level 15.7% (90.31), indi-cating that fruit were commercially mature. Un-treated fruit had significantly lower weight loss (2.8%) than the other treatments and there were no significant differences in weight loss between fruit conditioned at the different temperatures (Table 4). There were no significant differences between treatments in skin colour rating, reflec-tance (brightness), chroma (colour intensity) and hue angle (skin yellowness) before and 4 days after treatment (data not shown). Four days after transfer to 22°C, the untreated fruit were firmer, but not significantly firmer than fruit conditioned at 22, 30, or 38°C (Table 4). There was a trend towards increased fruit softness with higher condi-tioning temperature (30 – 42°C). Fruit conditioned at 42°C prior to HWT and then stored at 22°C for 4 days had the highest brix levels (14.44°), but this was not significantly different from untreated

fruit or fruit conditioned at 38 – 42°C (Table 4). Titratable acidity tended to decrease with increas-ing conditionincreas-ing temperature (Table 4).

4. Discussion

4.1. Optimum conditioning treatments for heat injury reduction

Conditioning ‘Kensington’ mango fruit at 40°C for 8 h provided a ‘window of opportunity’ for reduction, and in some instances, elimination of, hot water injuries in both experiments. In Experi-ment 2, this conditioning treatExperi-ment prior to HWT alleviated external and internal injuries (Tables 5 and 6), despite the duration of the HWT being longer through standardisation of the immersion time. These results demonstrated that the condi-tioning temperature is a more important factor in injury alleviation than the duration of the HWT. It was shown that conditioning fruit at 22 or 30°C was not as effective as the 40°C temperature in reducing injuries (Tables 2, 3, 5 – 7) and this corre-lates with the findings of Jacobi et al. (1995, 1996). Joyce and Shorter (1994) conditioned ‘Kensington’ mangoes for 7 – 19 h at 37°C before a HWT of fruit core temperature of 47°C held for 25 min. In this study, conditioning was found to reduce heat injuries, but did not completely

elimi-nate them. A possible reason for the different responses obtained with the same mango variety is a difference in the method of application of the conditioning treatments. In the experiments in this paper, the fruit core was elevated from 22 to 40°C within a 2 h period. The procedure outlined by Joyce and Shorter (1994) indicated that the elevation of fruit core temperature to 37°C oc-curred over a 7 h period with fruit individually wrapped in plastic cling wrap for the conditioning period. Therefore, for ‘Kensington’ fruit, increas-ing the fruit core temperature rapidly was more effective in reducing heat injuries than a gradual increase in temperature over a number of hours.

4.2. Effect of conditioning on fruit ripening

Conditioning fruit at 40°C accelerated the ripening of ‘Kensington’ mango fruit in both ex-periments, as reflected in the increased weight loss and the higher total soluble solids and lower titratable acidity levels within the mesocarp of the fruit compared to other untreated and heat-treated fruit (Tables 1 and 4). Generally, the more ripe fruit had the lowest levels of injuries.

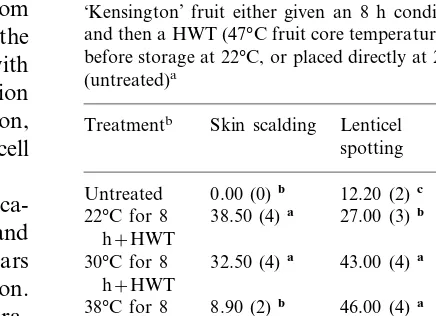

There-Table 3

The severity of skin scalding, lenticel spotting, starch layer and starch spot injuries of ‘Kensington’ fruit either given an 8 h conditioning treatment and then a HWT (47°C fruit core temperature held for 15 min) before storage at 22°C, or placed directly at 22°C after harvest (untreated)

External

Treatmenta External Internal Internal

Skin scaldingb Lenticel Starch layerc Starch spotc

spottingb

0 (0) 100 no starch spot

0 (0)

Untreated 100 no starch layer

3.8 (1) 49.4 (4)

22°C for 8 h+HWT 25, severe (3–6); 25 moderate 25 severe; 38 moderate; 37 no (1–3); 50, no starch layer starch spot

38.8 (4) 76, moderate (1–3); 24 no starch 10 (2)

30°C for 8 h+HWT 25 severe; 63 moderate; 12 no

starch spot layer

38°C for 8 h+HWT 0 (0) 33.1 (4) 100 no starch layer 12.5 mild; 87.5 no starch spot 0 (0) 16.9 (3) 100 no starch layer 100 no starch spot

40°C for 8 h+HWT

25 mild; 75 no starch spot 0 (0) 100 no starch layer

42°C for 8 h+HWT 5.6 (1)

aAll measurements were made after 4 days of storage at 22°C.

bFor skin scalding and lenticel spotting, the values presented are the mean percentage skin area affected of eight fruit, as well as

the severity rating in parentheses.

cFor starch layer and starch spot, the values presented are the percentages of fruit showing a particular severity rating from a

Table 4

Weight loss, firmness, mesocarp brix and titratable acidity levels of ‘Kensington’ fruit either given an 8 h conditioning treatment and then a HWT (47°C fruit core temperature held for 15 min) before storage at 22°C, or placed directly at 22°C after harvest (untreated)a

Fruit firmness (N)

Treatmentb Weight loss (%) Brix(°) Titratable acidity (% citric acid)

14.21b

Untreated 13.10ab

2.78b

1.05a 22°C for 8 h+HWT 6.22a

11.18abc

12.07b

1.00a

30°C for 8 h+HWT 12.10ab

6.32a

12.07b

1.05a 11.36abc

13.38ab 5.78a

1.10a 38°C for 8 h+HWT

5.51a

40°C for 8 h+HWT 9.31bc

13.92a

0.96a 7.86c

14.44a

42°C for 8 h+HWT 0.94a

5.68a

1.34 0.54

0.20 0.09

SEMc

aMeans within a column not followed by a common bold superscript letter are significantly different(PB0.05). bAll measurements were made after 4 days of storage at 22°C; values presented are the means of ten fruit. cStandard error of mean.

fore, the advancement in ripening may play a key role in the protective mechanism established within fruit cells to heat stress.

Weight loss of all fruit conditioned prior to HWT was significantly higher than that of un-treated fruit in both experiments. However, the temperature of the conditioning treatment in the range 22 – 42°C did not influence weight loss (Ta-bles 1 and 4). Increased weight loss following conditioning of fruit has been reported to occur in mango fruit and other fruit species. ‘Keitt’ and ‘Tommy Atkins’ mangoes intermittently warmed at 34°C for 1 or 2 days prior to HWT of 46 to 46.5°C for up to 12 min lost more weight than fruit not warmed prior to HWT (Nyanjage et al., 1998). Apples conditioned for 4 days at 38°C (Klein and Lurie, 1990; Lurie et al., 1996) lost about 0.5% of their weight, as water, each day. Similarly, an increase in weight loss occurs in ‘Hass’ avocados heated in air at 25 – 46°C for up to 24 h (Woolf et al., 1996), and in ‘Vibelco’ tomato fruit heated at either 35, 37 or 39°C for 72 h (Hakim et al., 1996). Fruit lost weight linearly with increasing temperature and duration of the heat treatment.

The increased weight loss associated with con-ditioning could be due to either increased respira-tion associated with accelerated ripening or increased transpiration, or both processes. In-creased fruit respiration with a heat treatment at 38°C for 3 or 4 days has been recorded for apples (Lurie and Klein, 1990) and tomatoes (Lurie and

Klein, 1992). However, for ‘Keitt’ mango fruit, the respiration rates of unheated and fruit condi-tioned at 38°C for 24 – 48 h were similar (McCol-lum et al., 1993). In contrast, the respiration rates of tomatoes heated at 33°C for 12 days (Ogura et al., 1976), or 35°C for 3 days (Inaba and Chachin, 1988) or 37°C for 3 days (Cheng et al., 1988) and papayas heated at 49°C for 70 min (Paull and Chen, 1990) declined after these respective treat-ments. The reason for the disparity in respiration response between fruit types may be related to a combination of factors, as suggested by Lurie (1998), including the time and temperature of the heat exposure, the preharvest environmental con-ditions and fruit physiological age. Therefore, the possibility that conditioning at 40°C increased the respiration rate of ‘Kensington’ mangoes requires further verification.

Table 5

The incidence of external and internal injuries of ‘Kensington’ fruit either given an 8 h conditioning treatment and then a HWT (47°C fruit core temperature held for 15 min) before storage at 22°C, or placed directly at 22°C after harvest (untreated)

Internal External

Treatmenta

External cavities Lenticel spotting Starch layer Starch spot Skin scalding

0 100

Untreated 0 0 0

22°C for 8 h+HWT 100 20 70 100 100

aAll measurements were made after 4 days of storage at 22°C; values presented are the percentages of fruit showing injury from

a total of ten fruit.

softer than fruit not warmed prior to HWT (Nyanjage et al., 1998). These results are in con-trast to reports of retarded rates of softening of fruit following heat treatment, as papaya (Paull and Chen, 1990), tomatoes (Ogura et al., 1976; Picton and Grierson, 1988), apples (Porritt and Lidster, 1978; Lurie and Klein, 1990; Sams et al., 1993; Conway et al., 1994), plums (Tsuji et al., 1984) and avocados (Eaks, 1978) softened more slowly when heated at temperatures ranging from 30 to 49°C for up to 4 days. It is likely that the increase in mango fruit softness associated with conditioning treatments is related to the duration and temperature of the hot water immersion, which leads to an increase in the activity of cell wall enzymes.

TSS (brix) and titratable acidity provide indica-tors of ripening within the mango mesocarp and reflect the conversion of starch reserves to sugars and organic acids which are used in respiration. In Experiment 2, fruit conditioned at tempera-tures of 38°C and above, particularly at 40°C, had higher brix and lower titratable acidity levels 4 days after treatment with HWT (Table 4). These results indicate that fruit conditioned at tempera-tures of 38°C or higher were riper than either untreated fruit or fruit conditioned at lower tem-peratures. In addition to conditioning tempera-tures of 40°C and higher promoting an increase in brix levels, the duration of the conditioning treat-ment at 40°C was important. The longer the conditioning treatment the higher the brix level.

Increased TSS and decreased titratable acidity levels within heat-conditioned fruit have been re-ported for a range of fruit types including ‘Keitt’ mango following a treatment of 3892°C for 48 h (McCollum et al., 1993; Burdon et al., 1994); ‘Keitt’ and ‘Tommy Atkins’ mangoes

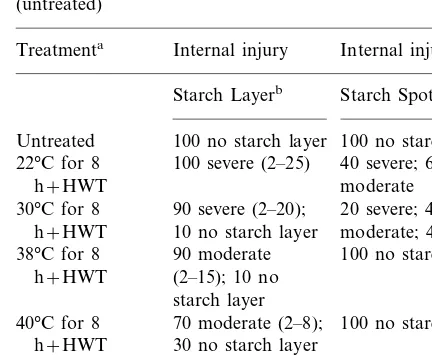

intermit-Table 6

The severity of skin scalding, lenticel spotting and disease for ‘Kensington’ fruit either given an 8 h conditioning treatment and then a HWT (47°C fruit core temperature held for 15 min) before storage at 22°C, or placed directly at 22°C after harvest (untreated)a

Lenticel Disease Skin scalding

Treatmentb

spotting

Untreated 0.00 (0)b

12.20 (2)c

aAll measurements were made after 4 days of storage at

22°C; values presented are the mean percentage skin area affected of 10 fruit, as well as the severity rating in parenthe-ses.

bMeans within a column not followed by a common letter

are significantly different (PB0.05).

Table 7

The severity of starch layer and starch spot injuries in ‘Kens-ington’ fruit either given an 8 h conditioning treatment and then a HWT (47°C fruit core temperature held for 15 min) before storage at 22°C, or placed directly at 22°C after harvest (untreated)

Internal injury Treatmenta Internal injury

Starch Layerb Starch Spot

Untreated 100 no starch layer 100 no starch spot 100 severe (2–25) 40 severe; 60 22°C for 8

h+HWT moderate

90 severe (2–20);

30°C for 8 20 severe; 40

10 no starch layer moderate; 40 mild h+HWT

90 moderate

38°C for 8 100 no starch spot

h+HWT (2–15); 10 no starch layer

40°C for 8 70 moderate (2–8); 100 no starch spot 30 no starch layer

h+HWT

42°C for 8 90 moderate 10 mild; 90 no starch spot h+HWT (2–15); 10 no

starch layer

aAll measurements were made after 4 days of storage at

22°C; values presented are the percentages of fruit showing a particular severity rating from a total of ten fruit.

bStarch layer thickness is presented in parentheses and

expressed in mm.

duced injury was the treatment that accelerated the greatest level of fruit ripening.

4.3. Protecti6e effect of sugars against heat stress

The probable role of soluble sugars in protect-ing cellular membranes from temperature ex-tremes and desiccation has been studied by Leprince et al. (1992) and Ingram and Bartels (1996) and a mechanism for the action of sugars has been proposed by Back et al. (1979). It is proposed that sugars stabilise proteins from heat denaturation through effects on water structure and the degree of hydrophobic interactions ex-erted between molecules. An alternative theory is that sugars tend to form a metastable state char-acterised by high viscosity, which provides greater stability to chemical reactions, and biomembranes under stress (Leopold, 1986; Roos, 1993). There-fore, from what is currently known about the probable roles of soluble sugars, it is possible that conditioning treatments applied to ‘Kensington’ fruit, which accelerated sugar accumulation in fruit, may have caused cellular changes resulting in the protection of membrane integrity during HWT. This was measured as a reduced level of heat-induced injuries.

4.4. Effect of conditioning temperature on injury incidence and se6erity and disease

Conditioning at 40°C was the most effective treatment in eliminating skin scalding in both experiments (Tables 2 and 3), and these results are in agreement with the findings of Jacobi et al. (1995, 1996). Conditioning at 42°C was also effec-tive in reducing the severity of skin scalding in both experiments (Tables 2, 3, 5 and 6). Fruit conditioned at 22 and 30°C had the highest inci-dence and severity of skin scalding of all treated fruit. Therefore, the temperature of the condition-ing treatment is critical in increascondition-ing the heat tolerance of the fruit to skin injury.

Preharvest factors affected the occurrence of lenticel spotting, since this injury was pre-existing in the untreated fruit of Experiment 2. HWT increased the severity of lenticel spotting, and this result correlates with the findings of Spalding et al. (1988) who reported lenticel darkening on tently warmed at 34°C for 1 or 2 days prior to

water-in-‘Tommy Atkins’ and ‘Keitt’ mango fruit as a result of immersion in 46°C water for 90 – 120 min. In Experiment 1, conditioning fruit at a temperature of 40°C or higher alleviated severity of lenticel spotting severity (Table 3), but did not eliminate the lenticel damage. However, conflict-ing trends arose between the experiments of this study with respect to the influence of conditioning temperature on the severity of lenticel spotting. In Experiment 1, the incidence and severity of lenticel spotting decreased with increasing condi-tioning temperature (Tables 2 and 3), while in Experiment 2, the fruit treated at the lower tem-perature of 22°C were less severely injured (Table 6). One difference between the fruit used in these two experiments is that fruit for Experiment 1 had no lenticel spotting before HWT, whereas fruit in Experiment 2 had 100% incidence and a severity level of 2 lenticel spotting. Therefore, a preharvest level of lenticel spotting complicated the ranking of fruit response to the conditioning treatment.

The appearance of cavities within fruit was influenced by conditioning temperature in both experiments. Fruit conditioned at 40°C for 8 h showed no cavitation in Experiment 1 (Table 2). However, in Experiment 2, all conditioned fruit contained cavities, with the fruit conditioned at 40°C having the lowest incidence of cavitation (Table 5). Therefore, 40°C was still the most effective temperature in reducing the occurrence of cavitation.

Conditioning at 40°C was the most effective treatment in eliminating both starch layer and starch spot injuries in both experiments. The con-ditioning temperature was critical for increasing fruit heat tolerance, since the lower temperatures of 22 and 30°C were not as effective in preventing occurrence of starch layer and starch spot (Tables 2, 3, 5 and 6) as were the higher temperatures. Conditioning the fruit at 42°C appeared to exceed a physiological limit, since in Experiment 1, starch spot injury appeared within fruit treated at this temperature, but not within fruit treated at 40°C (Tables 2 and 3). These results are in agreement with those of Joyce and Shorter (1994) who found that conditioning ‘Kensington’ fruit at 37°C for 7 h prior to HWT reduced the inhibition of starch breakdown injury in the mesocarp. However,

these authors did not identify the temperature that optimises fruit heat tolerance. The effective-ness of a 38 – 40°C conditioning treatment in re-ducing the appearance of starch layers and starch spots in heat-treated fruit may be directly corre-lated with the synthesis of HSPs in the mango mesocarp. Certain HSPs have been proposed to protect proteins through a chaperone-like func-tion or by removing heat-denatured proteins in the cell (Howarth and Ougham, 1993). In ‘Kens-ington’ fruit conditioned at 40°C, synthesis of HSPs may have protected the enzymes involved in starch degradation, such as alpha-amylase, against heat-induced inactivation. Starch degrada-tion would then have proceeded normally and to completion in all cells in conditioned fruit follow-ing HWT.

hot water dips of 30 min at 40°C or 2 min at 46, 48 or 50°C also reduced decay in ‘Daniella’ toma-toes (Lurie et al., 1997b). There may be several reasons for the success of the 40°C conditioning treatment in reducing disease severity in ‘Kensing-ton’ fruit. Firstly, the conditioning treatment may have reduced the number of viable spores on the fruit surface. For anthracnose, the appressoria become more melanized at temperatures above 30°C (Nyanjage et al., 1998). Secondly, the num-ber of viable spores may have been reduced. A reduction in the numbers of viableColletotrichum gloeosporioides spores on Valencia oranges oc-curred when fruit were conditioned at 30°C for 24 h (Williams et al., 1994). Additionally, the en-hanced rate of water loss from fruit during the conditioning treatment may have been a further obstruction to the development of anthracnose in storage, because germination of the fungi and appressorial formation increase at relative humid-ity around 100% (Dodd et al., 1997). Therefore, for ‘Kensington’ mango, the conditioning temper-ature of 40°C, which was optimum for reducing heat injury, was also very effective in conferring fruit resistance to postharvest fungal invasions.

5. Final conclusions

The 40°C conditioning temperature held for a duration of 8 h was optimal for conferring heat tolerance to ‘Kensington’ fruit. Conditioning tem-perature was found to be the major contributing factor to alleviate heat-induced damage in ‘Kens-ington’ mango fruit, the duration of the HWT did not alter fruit response patterns. Conditioning treatments, particularly at 40°C, were found to accelerate fruit ripening, and it is proposed that the elevated sugar levels in tissues assist fruit to withstand heat stress when immersed in hot water to raise the fruit core temperature to 47°C for 15 min. External and internal injuries were either promoted or inhibited within the one conditioning temperature, that is, the responses were segre-gated, in the range of 38 – 40°C.

This knowledge has practical implications for the commercial mango industry. It has now been demonstrated that ‘Kensington’ fruit can be

artifi-cially conditioned prior to HWT protocols re-quired for disinfestation without injuries occurring to render the fruit unmarketable. The conditioning treatment of 40°C for 8 h can be recommended for fruit to ensure that the heat tolerance of fruit destined to be heat-treated and exported will be increased so that a uniform re-sponse to the heat disinfestation treatment can be expected.

References

AOAC, 1984. Official Methods of Analysis. Association of Official Analytical Chemists: Arlington, Virginia, p 416. Back, J.F., Oakenfull, D., Smith, M.B., 1979. Increased

ther-mal stability of proteins in the presence of sugars and polyols. Biochem. 18, 5191 – 5196.

Burdon, J.N., Dori, S., Lomaniec, E., Marinansky, R., Pesis, E., 1994. Effect of pre-storage treatments on mango fruit ripening. Ann. Appl. Biol. 125, 581 – 587.

Cheng, T.S., Floros, J.D., Shewfelt, R.L., Chang, C.J., 1988. The effect of high-temperature stress on ripening of toma-toes (Lycopersicon esculentum). J. Plant Physiol. 132, 459 – 464.

Conway, W.S., Sams, C.E., Wang, C.Y., Abbott, J.A., 1994. Additive effects of postharvest calcium and heat treatment on reducing decay and maintaining quality in apples. J. Am. Soc. Hortic. Sci. 119, 49 – 53.

Dodd, J.C., Prusky, D., Jeffires, P., 1997. Fruit diseases. In: Litz, R.E. (Ed.), The Mango: Botany, Production and Uses. CAB International, Wallingford, Oxon, United Kingdom, pp. 257 – 280.

Eaks, I., 1978. Ripening, respiration, and ethylene production of ‘Hass’ avocado fruits at 20 to 40°C. J. Am. Soc. Hortic. Sci. 103, 576 – 578.

Hakim, A., Kaukovirta., E., Pehu, E., Voipio, I., 1996. Quali-ties of heat treated tomatoes after storage. Acta Hortic. 429, 473 – 479.

Holmes, R., Campbell, T., Ledger, S., 1990. Mango Picking Guide — ‘Kensington Pride, Q190030. Queensland De-partment of Primary Industries, Brisbane.

Howarth, C.J., Ougham, H.J., 1993. Gene expression under temperature stress. New Phytol. 125, 1 – 26.

Inaba, M., Chachin, K., 1988. Influence of and recovery from high temperature stress on harvested mature green toma-toes. HortScience 23, 190 – 192.

Ingram, J., Bartels, D., 1996. The molecular basis of dehydra-tion tolerance in plants. Ann.Rev. Plant Physiol.and Plant Molec. Biol. 47, 377 – 403.

Jacobi, K., Giles, J., MacRae, E., Wegrzyn, T., 1995. Condi-tioning ‘Kensington’ mango with hot air alleviates hot water disinfestation injuries. HortScience 30, 562 – 565. Jacobi, K.K., Wong, L.S., Giles, J.E., 1996. Conditioning with

(Mangifera indica Linn.) by hot water disinfestation treat-ment. Aust. J. Exper. Agric. 36, 507 – 512.

Joyce, D.C., Shorter, A.J., 1994. High-temperature condition-ing reduces hot water treatment injury of ‘Kenscondition-ington Pride’ mango fruit. HortScience 29, 1047 – 1051.

Klein, J.D., Lurie, S., 1990. Prestorage heat treatment as a means of improving poststorage quality of apples. J. Am. Soc. Hortic. Sci. 115, 265 – 269.

Lay-Yee, M., Ball, S., Forbes, S.K., Woolf, A.B., 1997. Hot-water treatment for insect disinfestation and reduction of chilling injury of ‘Fuyu persimmon. Postharvest Biol. Technol. 10, 81 – 87.

Leopold, C.A., 1986. Membranes, Metabolism, and Dry Or-ganisms. Comstock Publishing Associates, Ithaca, New York, USA.

Leprince, O., van der Werf, A., Deltour, R., Lambers, H., 1992. Respiratory pathways in germinating maize radicles correlated with desiccation tolerance and soluble sugars. Physiol. Plant. 85, 581 – 588.

Lurie, S., 1998. Postharvest heat treatments. Postharvest Biol.Technol. 14, 257 – 269.

Lurie, S., Klein, J.D., 1990. Heat treatment of ripening apples: differential effects on physiology and biochemistry. Phys-iol. Plant. 78, 181 – 186.

Lurie, S., Klein, J.D., 1992. Ripening characteristics of toma-toes at 12°C and 2°C following a prestorage heat treat-ment. Scientia Hortic. 51, 55 – 64.

Lurie, S., Handros, A., Fallik, E., Shapira, R., 1996. Re-versible inhibition of tomato fruit gene expression at high temperature. Plant Physiol. 110, 1207 – 1214.

Lurie, S., Fallik, E., Handros, A., Shapira, R., 1997a. The possible involvement of peroxidase in resistance to Botrytis cinerea in heat treated tomato fruit. Physiol. Molec. Plant Pathol. 50, 141 – 149.

Lurie, S., Laamim, M., Lapsker, Z., Fallik, E., 1997b. Heat treatments to decrease chilling injury in tomato fruit. Ef-fects on lipids, pericarp lesions and fungal growth. Physiol. Plant. 100, 297 – 302.

McCollum, T.G., Daquino, S., McDonald, R.E., 1993. Heat treatment inhibits mango chilling injury. HortScience 28, 197 – 198.

Nyanjage, M.O., Wainwright, H., Bishop, C.F.H., 1998. The effects of hot-water treatments in combination with cooling

and/or storage on the physiology and disease of mango fruits (Mangifera indicaLinn.). J. Hortic. Sci. Biotechnol. 73, 589 – 597.

Ogura, N., Hayashi, R., Ogishima, T., Abe, Y., Nakagawa, H., Takehana, H., 1976. Ethylene production by tomato fruits at various temperatures and effect of ethylene treat-ment on the fruits. J. Agric. Chem. Soc. Japan. 50, 519 – 523.

Paull, R.E., Chen, N.J., 1990. Heat shock response in field-grown, ripening papaya fruit. J. Am. Soc. Hortic. Sci. 115, 623 – 631.

Picton, S., Grierson, D., 1988. Inhibition of expression of tomato-ripening genes at high temperature. Plant Cell En-viron. 11, 265 – 272.

Porritt, S.W., Lidster, P.D., 1978. The effect of pre-storage heating on ripening and senescence of apples during cold storage. J. Am. Soc.Hortic. Sci. 103, 584 – 587.

Roos, Y., 1993. Melting and glass transitions of low molecular weight carbohydrates. Carbohydrate Res. 238, 39 – 48. Sams, C.E., Conway, W.S., Abbott, J.A., Lewis, R.J.,

Ben-Shalom, N., 1993. Firmness and decay of apples following postharvest pressure infiltration of calcium and heat treat-ment. J. Am. Soc. Hortic. Sci. 118, 623 – 627.

Spalding, D.H., King, J.R., Sharp, J.L., 1988. Quality and decay of mangos treated with hot water for quarantine control of fruit fly. Trop. Sci. 28, 95 – 101.

Tsuji, M., Harakawa, H., Komiyama, Y., 1984. Changes in shelf life and quality of plum fruit during storage at high temperatures. J. Japan. Soc. Hortic. Sci. 52, 469 – 473. Williams, M.H., Brown, M.A., Vesk, M., Brady, C., 1994.

Effect of postharvest heat treatments on fruit quality, surface structure, and fungal disease in Valencia oranges. Aust. J. Exper. Agric. 34, 1183 – 1190.

Woolf, A.B., Watkins, C.B., Bowen, J.H., Lay-Yee, M., Main-donald, J.H., Ferguson, I.B., 1995. Reducing external chill-ing injury in stored ‘Hass’ avocados with dry heat treatments. J. Am. Soc. Hortic. Sci. 120, 1050 – 1056. Woolf, A.B., Ball, S., Watkins, C.B., Spooner, K.J., Bowen,

J.H., Lay-Yee, M., Ferguson, I.B., 1996. Post-harvest re-sponses of Hass avocados to high temperature treatments — An overview from New Zealand. Sth African Growers Assoc.Yearbook 19, 8 – 10.