Metallurgy and Materials Engineering Department

University of Indonesia

2007

Corrosion Resistant Steel

(Stainless Steel)

Dr.-Ing. Bambang Suharno

Dr. Ir. Sri Harjanto

Kuliah Baja Paduan & Super Alloy

University of Indonesia

Metallurgy and Materials Engineering Department UI

Stainless Steel, Why Stainless?

Stainless steels =

Cr containing

steel alloys

Cr content is

min. 10.5% and

max 30%

Cr makes the steel

'stainless'

=

improved corrosion resistance,

due to a

chromium oxide film

that is formed on the

steel

surface

This extremely thin layer is

also

self-repairing

in the

presence of oxygen

and damage by abrasion,

cutting or machining is

quickly repaired

C : < 0.03 % - 1,2%

0

Cor

ro

si

on Rat

e

(

m

m/

year)

% Chromium

5

10

0

0.1

0.2

University of IndonesiaChromium Oxide Film

Fig. 1 - In any normal oxidising environment a protective coating

of

passive chromium rich oxide film

is

automatically formed

on

stainless steel.

Fig. 2 - When

scratched, damaged or machined

this protective film

is denuded exposing the steel to the atmosphere.

Fig. 3 - The protective coating is

quickly restored

through the rapid

self-repairing quality

of the chromium rich film.

University of Indonesia

Pasivitas Pada Stainless Steels

Pasivitas dikarenakan

oleh adanya lapisan

oksida yang bersifat

self-repairing

dengan

karakteristik :

Kompak

, lapisan

kontinyu memerlukan ~

11wt% Cr.

Pasivitas

meningkat

dengan meningkatnya

Cr hingga ~17wt%

Umumnya stainless

steels mengandung

17-18wt% Cr

Pada Duplex SS Cr 22-27%

Ketahanan korosi

tergantung pada

kestabilan lapisan oksida

Untuk lingkungan yang

berbeda dioptimalkan oleh

alloying

dengan unsur lain

Contoh; Ni, Mo, N,

Cu

University of Indonesia

Metallurgy and Materials Engineering Department UI

Produk Stainless Steel

Wrought Product

Long Product: Pipa,

Batangan, Profil

Flat Product: Lembaran,

sheet, Pelat

Casting Product

Impeller, Flange, Valve

University of Indonesia

Metallurgy and Materials Engineering Department UI

Pengelompokan Stainless Steels

Berdasarkan

mikrostruktur

Stainless steels (SS)

dapat dikelompokkan atas:

•

Feritik

SS

•

Austenitik

SS

•

Duplex

(Feritik-Austenitik) SS

•

Martensitik

SS

•

Precipitation Hardening

(PH) SS

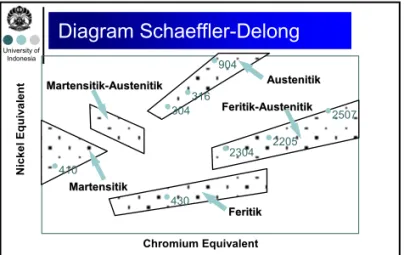

Mikrostruktur stainless steels (sangat tergantung dari

komposisi) dapat diprediksi menggunakan diagram

Schaeffler-Delong

University of IndonesiaSchaefler Diagram

University of IndonesiaUniversity of Indonesia

Metallurgy and Materials Engineering Department UI

Diagram Schaeffler-Delong

Chromium Equivalent = %Cr + 1.5%Si + %Mo

Nickel Equivalent = %Ni + 30(%C + %N) + 0.5(%Mn + %Cu + %Co)

Feritik

Feritik

Feritik

Feritik

-

-

Austenitik

Austenitik

Martensitik

Martensitik

Martensitik

Martensitik

-

-

Austenitik

Austenitik

Austenitik

Austenitik

Chromium Equivalent

Ni

ckel

Equiv

a

le

nt

•

430

•

410

•

304

•

316

•

904

•

2304

•

2205

•

2507

University of IndonesiaMetallurgy and Materials Engineering Department UI

Classification of Stainless Steel

University of Indonesia

Strength and Ductility of

Stainless Steel

University ofIndonesia

University of Indonesia

Metallurgy and Materials Engineering Department UI

Family

of SS

University of Indonesia

Metallurgy and Materials Engineering Department UI

Effect of Alloying Elements

Unsur paduan berkontribusi terhadap

pembentukan fasa

ferrite-austenite

Ferrite stabilizer (misal: Cr, Mo, W, V)

Austenite stabilizer (misal: C, Cu, Ni, Mn, N)

pembentukan

fasa kedua (precipitate)

yang melibatkan

unsur Cr, Mo, W, Cu, N

Sigma phase

Chi phase

Sangat penting untuk mengetahui pengaruh elemen

paduan terhadap ‘complex metallurgical system”

University of Indonesia

Effect of Alloying on SS Properties

-√ -X X X Cold Workability √ -√ -X -√ X -X X Weldability -√ -√ -√ -X X Machinability √ -√ -X √ √ -High Temperature Resistance

√ -√ √ √ √ √ -√ √ Mechanical Properties -√ -√ -X √ √ -Corrosion Resistance Ti or Nb Se Mo Cu P Si Mn S Ni Cr C Property University of Indonesia

Effect of Carbon

Iron + carbon =

increasing the hardness

and

strength

of iron.

In austenitic and ferritic stainless steels

a high carbon content is

undesirable

,

especially for

welding

Æ

carbide precipitation

University of Indonesia

Metallurgy and Materials Engineering Department UI

Effect of Chromium

Chrom :

To increase

resistance to oxidation

.

This resistance increases as

more chromium is added

.

Duplex Stainless Steel

Cr =

ferrite former

and

sigma phase

(carbide former)

Cr > 22%

increase in

pitting and crevice

corrosion resistance

Cr < 27 % in order to

retain

ductility, toughness and corrosion resistance

University of Indonesia

Metallurgy and Materials Engineering Department UI

Effect of Chromium on oxidation

resistance

University of Indonesia

Effect of Nickel

Ni =

austenite former

(austenite promoting element)

To

balance

the microstructure to

ferrite/ austenite

ratio

Affects the

corrosion

and

mechanical

properties

Excessive Ni:

increase in austenite content

Promoting a greater conc. of

ferrite stabilizer element

(Cr, Mo) in the remaining ferrite

(not change to the

precipitation of sigma phase)

University of Indonesia

Effect of Mo and N

Molybdenum (Mo):

Strong

ferrite former

, similar effect as Cr does on

properties

when added to austenitic stainless steels

improves

resistance to pitting and crevice

corrosion

especially in

Cl and S

containing environments

Nitrogen (N):

N =

austenite forming

element

increasing the

austenite stability

Yield strength

is greatly improved without sensitization

(e.g. carbon)

University of Indonesia

Metallurgy and Materials Engineering Department UI

Effect of Mn and Cu

Manganese (Mn):

to

improve hot working properties

and

increase strength

,

toughness

and

hardenability

.

Mn = austenite forming element

used as a substitute for nickel

in Austenitic SS

e.g. AISI 202 as a substitute for AISI 304

Copper (Cu):

Cu = normally present as

a residual element

in a few alloys to

produce precipitation hardening properties

or to

enhance corrosion resistance

University of Indonesia

Metallurgy and Materials Engineering Department UI

Effect of W

W =

minor elements

improving

corrosion resistance

The addition of W causes

easy to form inter metallic phase compare with W-free

duplex SS

W =

like Cr and Mo promotes

sigma phase

formation

promote of

Chi phase

University of Indonesia

Properties of Stainless Steel

Low Low Low Low Martensitic Low Low High Medium Ferritic High Medium Low Medium Duplex Very High Very High Very High Very High Austenitic Weldability Low Temperature Resistance3 High Temperature Resistance Ductility Alloy Group Age Harden Medium Medium Yes Precipitation Hardening Quench & Temper Medium Medium Yes Martensitic No Medium Medium Yes Ferritic No Very High Medium Yes Duplex By Cold Work High Very High Generally No Austenitic Hardenable Corrosion Resistance2 Work Hardening Rate Magnetic Response1 Alloy Group University of Indonesia

University of Indonesia

Metallurgy and Materials Engineering Department UI

Metallurgy and Materials Engineering Department

University of Indonesia

2007

Mekanisme Penggetasan

(Brittleness) pada Stainless Steel

University of Indonesia

Mekanisme Penggetasan pada

Stainless Steel

Stainless Steel peka terhadap

Embrittlement

(Kehilangan ductility/

toughness)

Penyebab

:

Sensitasi

475°C Embrittlement (350°C

-550°C).

Sigma Phasa (

σ

phase)

University of Indonesia

Sensitasi pada Stainless Steel

Austenitic SS peka terhadap

intergranular

corrosion

jk berada pada temp

480–815

OC

Umumnya akibat:

Welding

Service condition

Terjadi karena terbentuk endapan

M

23C

6(Cr

3Fe)

23C

6pada batas butir

Pencegahan

:

Kurangi Kadar C (0.015 – 0.02%), substitusi

dengan N

University of Indonesia

Metallurgy and Materials Engineering Department UI

475°C Embrittlement

Paduan dengan Cr tinggi, cenderung untuk

Brittle

,

terutama jika ditahan atau pendinginan lambat pada

400 – 550

OC

475°C Embrittlement

menyebabkan

:

UTS, Hardness naik

Ductility turun

Ketangguhan turun

Corrosion resistance turun

Penyebab

475°C Embrittlement:

Terbentuk second phase (carbides, nitrides,

oxides, phosphides)

Pembentukan Fe3Cr, FeCr, FeCr3, mirip sigma

phase hanya saja pada temp rendah

Kecenderungan Brittle

jika:

Kandungan Cr tinggi

Kandungan Carbide former tinggi (Mo, V, Ti, Nb)

Pengerjaan pada temp 475

OC

University of Indonesia

Metallurgy and Materials Engineering Department UI

Sigma Phasa (

σ

) Embrittlement

Pembentukan

FeCr Intermetallic

yang

keras, brittle (68 HRC)

Terbentuk jika temperatur proses sekitar

565 – 980

OC

dan berlangsung lama, hal ini

dapat menyebabkan fracture

Semua elemen paduan

penstabil ferrite

dapat men promote pembentukan sigma

phase

Cr yang tinggi mem promote sigma

phase

C yang tinggi pembentukan sigma phase

dikurangi sebab terbentuk Cr-Carbide

University of Indonesia