The Influence of Palm Fiber on Shear Strength

of Liquefiable Sand

Yelvi

1, Handi Sudardja

2, Istiatun

3Civil Engineering Department, State Polytechnic of Jakarta, Indonesia 1E-mail: yelvich@gmail.com

2E-mail: handi_sudardja@yahoo.co.id 3E-mail: Iis.distia18@gmail.com

Abtsract - The research of shear strength values on sand that potentially liquefied by using palm fibers as reinforcement is randomly distributed using Direct Shear Test. The sand investigated is the sand that potentially liquefied according to the Tsuchida graph (1970) with a relative density of 40%. The influence of the palm fibers content (0.25%, 0.5%, and 0.75%) and the length of palm fibers (2 cm, 4 cm, and 6 cm) against the investigated shear strength values. The test result showed that the addition of the palm fibers and the length of palm fibers was not directly proportional to increase from the angel of internal friction values. 0.5% palm fibers content and the length of palm fibers 4 cm provide the highest increase to angel friction value is 34.25% compared with sand without palm fibers. This suggests that increased levels of palm fibers and length of palm fibers up to given time cause the amount of sand matrix available to hold fibers insufficient to provide an effective bond between sand and fibers. In terms of soil cohesion, the addition of palm fibers and length of palm fibers decreases the value of cohesion, although cohesion decreases, but the shear strength value continues to increase, because the increase in sangel friction is greater than the decrease in soil cohesion

Keywords : palm fibers, length, shear strength

I. INTRODUCTION

The sand or coarse-grained soils is a non-cohesive soil type (cohesionless soil), it’s having loose coarse properties (loose), this is indicated with coarse soil will be separated when dried and only attached to wet conditions caused by pull force of the surface. The non-cohesive soil does not have a boundary of plastic and non-plastic, because this type of soil is not plastic for all water content values. But in some condition, non-cohesive soils with sufficiently high water content may be as a viscous liquid [5]. Parameter of this soil shear strength lies in the cohesion value (c) and the angel of internal friction (). In general, sand in solid conditions tends to have good properties For certain condition above when in a condition of loose and saturated water, can have a low shear strength when there is cyclic loads such as earthquakes. In this condition, the sand layer loses or decreases its shear strength. In order to increase the shear strength, the sand improved by giving reinforced done using fiber inclusions in the soil mass in a designated pattern (ie, a systemically soil reinforcement) or mixing discrete fibers randomly by filling the soil (ie, randomly soils reinforcement). The fibers used are derived from natural fibers and synthetic fibers.

Palm Fibers are a natural fiber derived from palm trees that grow throughout very well in the mainland of Indonesia, especially at an altitude of 400 to 1000 meters above sea level. Indonesia has a lot of palm trees, but unfortunately palm fibers have not been fully utilized, there are still many palm fibers that are burned by the farmers or left unutilized. The Palm fibers have a flexible and non-fragile characteristic, highly resistant to puddle of acid including puddle salt of seawater. In addition, the palm fibers are not easily decayed either in the open area (weather resistant) or embedded in the ground.

optimum if added palm fibers without a combination of palm fibers and bagasse ash. Jamaloeddin, et al. (2010) [6] found that significant increases in deviator voltage failure and soil to shear strength parameters (C and U) was due to the addition of palm fibers. The effect of the palm fibers on the sandy soil to the shear strength of the soil was investigated by Ahmad et al. (2010) [2] with palm fibers content (0.25% and 0.5%) and length of palm fibers (15 mm, 30 mm, and 45 mm). Palm fibers at 0.5% palm fibers content and length 30 mm can increase internal shear angular as 25%. Omid Azadegan et al (2012) [9] conducted a laboratory study on palm fibers to strengthened clay against bulging, cracking and strength behavior. Jili Que and Dongxue Zhao (2015) [6] do the stabilization of clay with sheath of palm fibers.

Research on strengthened using fiber on clay has been widely done, opposite to the sand is still bit studied. Studies on sand need to do more given the risks posed by liquefaction events that generally occur to granular soils with uniform grains and high groundwater levels. Therefore in this paper will be presented the results of research on the strengthening of soil using palm fibers on the sand that potentially occur liquefaction. The test is performed under static and dynamic loads, and which will be discussed now is the effect of static loads to the sand shear strength using the Direct Shear Test.

II. RESEARCH METHOD A. Materials of Reaserch Sand

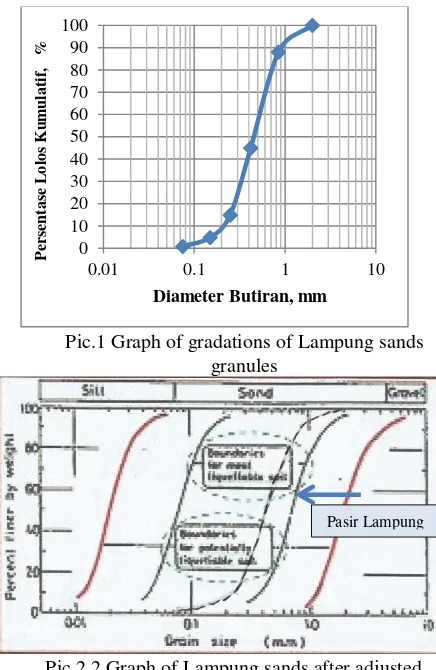

The soil used in this research is sand from Lampung with disturbed soil condition (undisturbed sample). Testing of filter analysis according to ASTM 1989, D 422-63 is done first to get gradations of granules. The results of screening analysis can be seen in Figure 2.1. The resulting granules distribution obtained is plotted on the Tsuchida graph (1970) [12]. The results show that the sand of Lampung is entering the area that is potentially liquefied. The curvature of the graph should be adjusted to the Tsuchida chart, so that the gradation of No. Sieves 20, 40, and 60, should be added and subtracted. The adjusted graph can be seen in Figure 2.2.

Pic.1 Graph of gradations of Lampung sands granules

Pic 2.2 Graph of Lampung sands after adjusted Based on graph of Lampung sands after adjusted and classified using unified classification system, the sands used include poorly graded sand soils (SP). Then on the sands tested specific gravity and the relative density of 40% determined so that the index obtained properties of the soil as shown in Table 2.1

TABLE 2.1.

being tested are cut to lengths of 20 mm, 40 mm, and 0.5%, and 0.75%. against the dry weight of the sand. The Direct Shear test will be applied to the test object. The weight of the sand to be tested is obtained by multiplying the weight of the soil dry contents by the volume of the mold. The content of the palm fibers to be used is adjusted to the percentage of the palm fibers. Then the sand mixed with palm fibers in accordance with predetermined levels. The mixing process is done by mixing palm fibers randomly and then the specimen is tested.

b. Testing Stage

The specimen is weighed (adjusted to the volume of mold), then input of the sliding box of the test cell locked by two bolts on the top and bottom mounted pore stones. The test specimen is loaded with normal load and horizontal load. The first normal load is attempted to raise the tension in the specimen at least the geostatic voltage in the field. The speed of the horizontal shift taken is 0.50 mm / min. The locking bolts are loaded, then attached to the other two holes, the rotation is given so that the upper and lower slide boxes are ± 0.5 mm apart. the shift is done until the load watch on the last three readings respectively shows a constant value. Shear and load watches are reading every 30 second until collapse occurs. For the second specimen, the normal load is twice the first normal load. The third test object is given a normal load three times the first normal load.

III. ANALISYS AND RESULTS 3.1. Direct Shear Test Results

The result of direct shear test on sand of Lampung (SP)without mixed of palm fibers (0%) obtained the angel of internal friction value () of 30.77o and cohesion value (c) is 0.0232 kg cm2. The result of direct shear testing on sand can be seen in Table 3.1.

TABEL 3.1

.RESULT OF DIRECT SHEAR TEST ON SAND

Palm and Angle of Internal Friction

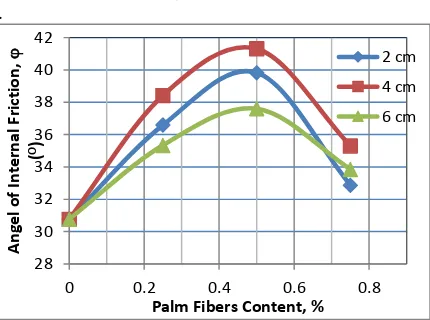

From Table 3.1, created graph of Correlation between Length of Palm Fibers and Angle of Internal friction values presented in Figure 3.2.

.

Fig. 3.2 Curve of Corelation Between Length of Palm Fibers and Angel of Internal Friction

Figure 3.2 shows that increasing length of palm fibers will increase the angel of internal friction va

The maximum shear angular value is 41.31% at 4 cm. When compared with the shaer angular of sand without palm fibers are increasing 34.25%. From the graph can be seen that the angel of internal friction increases in the increasing size of the palm fibers from 20 mm to 40 mm, and decreases from the palm fibers length of 60 mm. At the same volume, increasing length of palm fibers in constant fibers caused the friction between the grains of soil is obstructed the palm fibers. If the fiber length is shorter, the randomly distributed palm fibers will make of network element in the soil. The created and Angle of Internal Friction

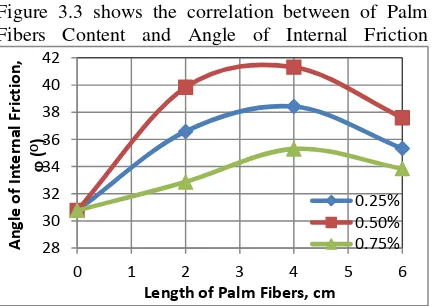

Figure 3.3 shows the correlation between of Palm Fibers Content and Angle of Internal Friction

Fig. 3.3 Curve of Correlation between Palm Fibers Content and Angle of Internal Friction

The correlation between the palm fiber content and angel of internal friction gives the same conclusion as the length of the palm fibers. Increase value of angel of internal friction is not linear with addition of palm fiber content. At the time of the palm fibers content of 0.75% the value of internal friction angular decreases in each size of the palm fibers. Addition of palm fiber content evaluated at the same volume, the addition of palm fibers content resulted in replacing grains. The content of 0.5% palm fibers gives optimum result of s shear strength value.

This is caused of palm fibers on the sand grains are replaced by palm fibers. Increasing of palm fibers content, amount to sand matrix available to hold the fiber is not effective to provide for sand and palm fibers. The 0.5% palm fibers content gives optimum result of increase in friction angular value 34.25%.

C. Correlation between Length of Palm Fibers and Cohesion Value

Based on Table 3.1 can be seen that cohesion values of Lampung sand is very small ie 0.0232 kg / cm2. The effect of cohesion values with the length of palm fibers can be seen in Figure 3.5

Fig. 3.4 Curve of Correlation between Length of Palm Fibers Content and Cohesion value

Figure 3.4 shows that increasing length of palm fibers does not significantly affect to the value of soil cohesion. This suggests that the soil cohesion is determined by the attraction force between the soil grains. The addition of palm fibers did not affect the length of palm fibers because palm fibers with slippery surface do not arise tensile strength between the palm fibers and sand.

D. Correlation between Palm Fibers Content and Soil Cohesion

The correlation between Palm Fibers Content and Soil Cohesion can be seen on Picture 3.5

Fig. 3.5 Curve of Correlation between Palm Fibers Content and Cohesion value

The addition of palm fibers causes decrease of soil cohesion values, and the smallest cohesion value is 0.5% from palm fibers content. The addition of palm fibers causes reduced of soil grains percentage so the tensile strength between the grains and soil is reduced .

E. Correlation between Palm Fibers Content and Soil Shear Strength

of the shear strength as shown in Table 3.2. and Figure 3.6.

TABEL 3.2

CORRELATION OF PALM FIBERS CONTENT AND LENGTH WITH SOIL SHEAR STRENGTH

Fig. 3.6 Curve of Correlation of Palm Fibers Content and length with Angel of Internal Friction

Based on Figure 3.6 can be seen shape of curve obtained from the correlation between the fiber content and length of the shear strength is same with internal shear angular curve. In this case increasing between the granules and palm fibers. So the angel of internal friction of the soil is not only affected by the soil density, but also by the shear resistance provided by the palm fibers. So the more fiber percentage of the palm fibers on the soil, the shear resistance is increasing until a certain palm fiber content and length. However, palm fibers do not cause tensile strength between palm fibers and granular of soil which determines the value of soil cohesion.

IV. CONCLUSIONS

1. The use of palm fibers as a reinforcement in the soil can increase of internal friction angle to 34.25%.

2. The increase of maximum internal friction angle occurs at the content of the palm fiber is 0.5 % Standards, Section 4, Volume 04.08

2. Ahmad F, Bateni F, Azmi M.(2010) “Performance evaluation of silty sand reinforced with fibers”. Geotext Geomembr 2010;28:93–9.

3. Ankita S., Srividhya. S.(2017)., ”Experimental study on strength Characteristics of palm fiber Reinforced soil stabilize using Bagasse ash” International Journal of Civil Engineering and Technology (IJCIET) Volume 8, Issue 4, April 2017, pp. 2027–2035.

4. Ardiany.B.C, (2006), “Analisis pengaruh pencampuran ijuk terhadap kuat dukung tanah berbutir halus pada alas pondasi dengan metode vesic”, skripsi pada UGM Yogyakarta tidak diterbitkan.

5. Bowles. J.E. 1991, Sifat-sifat Fisis danGeoteknis Tanah (Mekanika Tanah). Edisi Kedua. Erlangga Jakarta.

6. Jamellodin Z, Talib Z, Kolop R, Noor N.(2010) “The effect of oil palm fibre on strength behaviour of soil.” In: 3rd SANREM conf, kota kinabalu, Malaysia; 3– 5 August,2010.

7. Jili Que dan Dongxue Zhao (2015),” Stabilising the cohesive soil with palm fibre sheath strip”, Journal Road Materials and Pavement Design,Volume 17, 2016 - Issue 1 8. Marandi,1S.M,.Bagheripour1M.H,1R.Rahgo

zar, and 2H. Zare (2008) “Strength and Ductility of Randomly Distributed Palm Fibers Reinforced Silty-Sand”, SoilsAmerican Journal of Applied Sciences 5 (3): 209-220, 2008.

9. Omid azadegan, E.Akbari,Kaffash, M.J.Yaghoubi, G.R.Pourebrahim (2012), “Laboratory study of the swelling cracking and mechanical characteristics of the palm fiber reinforcement clay”, EJGE vol (17).. 10. Sudarmadji Ibnu dan Eko Sumardiono.

LOGIKA, Volume 8, No.9. ISSN: 1410-2315. pp. 44-56.

11. Suroso. P, Samang. L, Tjaronge. W, Ramli. M, (2013), “Palm fibers influence the compressive strength and CBR on soil cement”, Proceedings of the 7th International Conference on Asian and Pacific Coasts (APAC 2013) Bali, Indonesia.