DAFTAR PUSTAKA

1. Cotton, F.Albert., Wilkinson,G., (1989), Kimia Anorganik Dasar, Penerbit Universitas Indonesia, Jakarta, 477-482

2. Mehtar,S., Wiid I., Todorov,S.D.,(2008),The Antimicrobial Activity of Copper and Copper Alloys Against Nonsomical Pathogens and Mycobacterium Tubercolosis Isolated from Helthcare Facilities in the Western Cap: an in vitro study, J. Hosp. Infect 68(1),45-51

3. Lee,W.,Li,S,E.,Lee,C.H.,Eds.,(2001), A chelating resin containing 1-(2-thioazolylazo)-2-naphtol as the functional group; synthesis and sorption behaviour for trace metal ions, Microchemical Journal, 70,195-203

4. Memon Q.S.,Bhanger,I.M.,Hasany,S.M.,Eds.,(2007).,The Efficacy of Nitrosonaphtol Functionalized XAD-16 Resin For The Preconcentration/ Sorption of Ni(II) and Cu(II) Ions,Elsevier Talanta,72,1738-1745

5. Burguera,J.L.,(1989), Flow Injection Atomic Spectrometry, Marcel Dekker,Inc, New York, 1-6

6. Cortina,N.M.,(1997), Kinetic Studies on Heavy Metal Ion Removal by Impregnated Resin Containing di-(2,4,4,-Trimethylpenyl) Phosphinic Acid, 167-183

7. Ensafi,Ali.A; Kayamian,Taghi,Karbasi,Eds.,(2003),On Line Preconcentration System for Lead (II) Determination in Wast Water by Atomic Absorption Spectrometry Using Active Carbon Loaded with Pyrogallol Red, Analytical Science, 19, 952-956

8. Dr.B.Saha,M.D.G.,and Mr.R.J.Gill Bailey,the Removal of Chromium (VI) Ion From Aqueous Solutions Using Solvent Impregnated Resin

11. Akerkar,V.G.,Karalkar,N.B.,Sharma,R.K.,Eds.,(1998),Synthesis and properties of new chelating resin with a spacer containing α-Nitroso-β-Naphtol as the functional group, Elsevier Science B.V., 46, 1461-1467

12. Fang,Z.L.,(1993),Flow Injection Separation and Preconcentration,VCH Publishers,Inc.,New York,10,169-215

13. Adamson,Arthur.W.,Alice P.,(1997), Physical Chemistry of Surfaces,6th edition,John wiley and Sons,New York

LAMPIRAN A

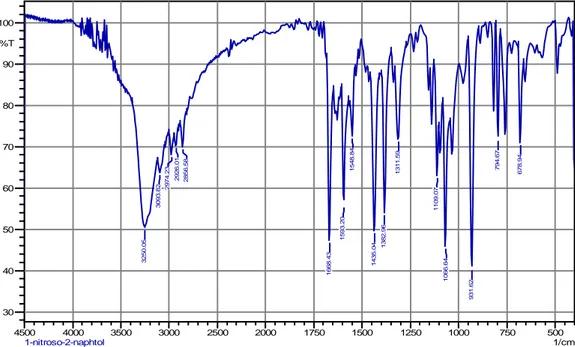

Hasil FTIR NITROSONAPHTOL

500 750 1000 1250 1500 1750 2000 2500 3000 3500 4000 4500 1/cm 30 40 50 60 70 80 90 100 %T 3250. 05 3093. 82 2974 .23 2 926. 01 2856. 58 1668. 43 1593. 20 1548. 84 1435. 04 1382 .96 1311. 59 110 9. 07 1066. 6 4 931. 62 794. 67 678. 94 1-nitroso-2-naphtol

Gambar A.1 Spektrum FTIR Nitrosonaphtol

ν

(cm

-1)

%T

794,67 71,998 931,62 40,702 1066,64 45,884 1109,07 62,983 1311,59 71,824 1382,96 54,055 1435,04 49,701 1548,84 72,503 1593,20 55,929 1668,43 47,406 2856,58 69,926 2926,01 70,173 2974,23 68,112 3093,82 63,667 3250,05 50,445LAMPIRAN B

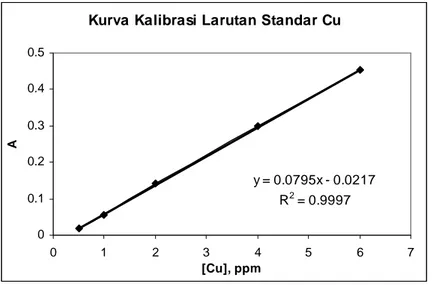

Pembuatan Kurva Kalibrasi Larutan Standar Cu

2+[Cu],ppm A1 A2 A3 A 0,5 0,0174 0,0163 0,0171 0,0170 1 0,0528 0,0552 0,0561 0,0547 2 0,1405 0,1417 0,1403 0,1409 4 0,2961 0,2993 0,3035 0,2996 6 0,4558 0,4523 0,4490 0,4524

Tabel B.1 Korelasi konsentrasi larutan standar cu terhadap absorban

Kurva Kalibrasi Larutan Standar Cu

y = 0.0795x - 0.0217 R2 = 0.9997 0 0.1 0.2 0.3 0.4 0.5 0 1 2 3 4 5 6 7 [Cu], ppm A

Gambar B.1 Kurva kalibrasi Larutan Standar

Persamaan garis

y

=

0

,

0795

x

−

0

,

0127

selanjutnya dipakai dalam perhitungan untuk

LAMPIRAN C

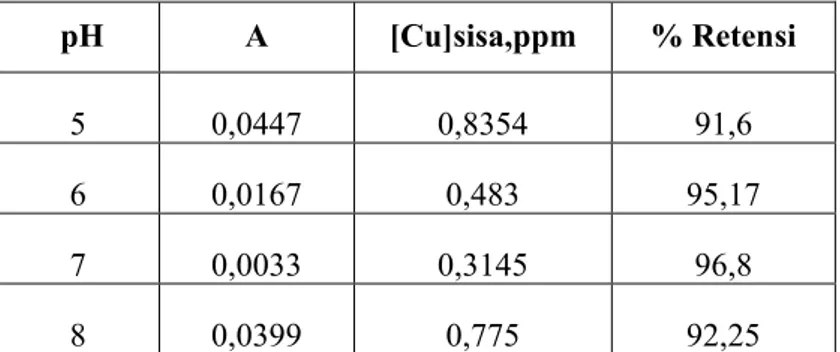

Penentuan pH optimum

pH A [Cu]sisa,ppm % Retensi 5 0,0447 0,8354 91,6 6 0,0167 0,483 95,17 7 0,0033 0,3145 96,8 8 0,0399 0,775 92,25Tabel C.1 Pengaruh pH terhadap retensi ion logam Cu2+

pH optimum terbentuknya kompleks dengan ion logam Cu2+t pH 7

0127

,

0

x

0795

,

0

y

=

−

awal sisa awal sisa[Cu]

]

Cu

[

[Cu]

Retensi

%

ppm

0,3145

[Cu]

3145

,

0

0217

,

0

07948

,

0

0033

,

0

−

=

=

=

−

=

x

x

96,8%

%

100

10

0,3145

-10

=

=

x

LAMPIRAN D

Pengaruh Waktu Kontak

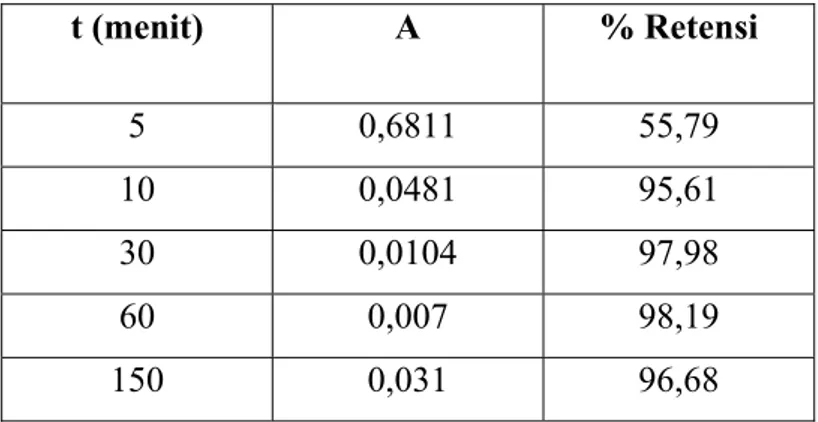

Tabel D.1 Pengaruh waktu kontak terhadap retensi ion Cu2+

t (menit)

A

% Retensi

5 0,6811

55,79

10 0,0481

95,61

30 0,0104

97,98

60 0,007

98,19

150 0,031 96,68

Dengan waktu kontak 60 menit memberikan absorbansi sebesar 0,007

awal sisa awal sisa

[Cu]

]

Cu

[

[Cu]

Retensi

%

ppm

0,361

[Cu]

361

,

0

0217

,

0

07948

,

0

007

,

0

−

=

=

=

−

=

x

x

%

98,19

%

100

10

0,361

-10

=

=

x

LAMPIRAN E

Penentuan Kapasitas Retensi

Tabel E.1 Pengaruh konsentrasi Cu2+ terhadap kapasitas retensi

[Cu],

ppm

[Cu]sisa,ppm

mg Cu teretensi

mg Cu teretensi/ g resin

2 0,3107 0,00338

0,337

4 0,5208 0,06958

0,6958

6 0,8025 0,1039

1,039

8 2,605 0,1078

1,078

0,0421

A

ppm

6

[Cu]

=

→

=

mg

0,12

L

0,02

L

mg

6

ppm

6

=

x

=

0217

,

0

07948

,

0

0421

,

0

=

x

−

8025

,

0

=

x

mg 0,0161 L 0,02 L mg 0,8025 ppm 0,8025 ppm 0,8025 [Cu]sisa = = = xmg

0,0161

-mg

0,12

terserap

yang

Cu

mg

2+=

=

0,1039

mg

resin g terserap yang Cu mg penyerapan Kapasitas 2+ =resin

g

/

Cu

mg

1,039

g

0,1

mg

0,1039

=

2+=

LAMPIRAN F

Perhitungan Presisi Pengukuran

F.1.

Pengaruh konsentrasi eluen

Tabel F.1 Tabel korelasi [HNO3] terhadap tinggi puncak

[eluen],M

Tinggi puncak (AU)

0,5 121,39

1 105,34

2 133,14

3 122,2

Pengaruh konsentrasi larutan asam nitrat

0 20 40 60 80 100 120 140 160 1 2 3 4 [asam ],M Ti ng gi p un c a k

F.2.

Pengaruh volume eluen

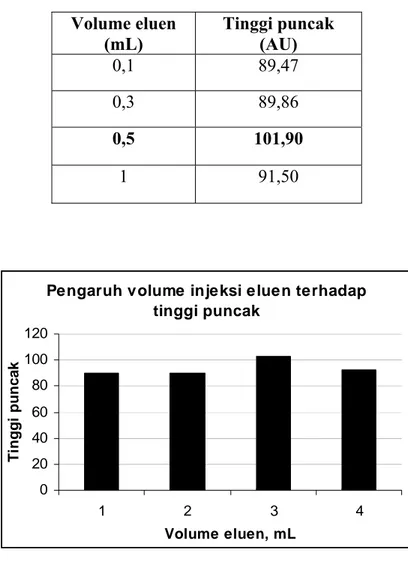

Tabel F.2 Kurva korelasi antara volume HNO3 terhadap tinggi puncak

Volume eluen

(mL)

Tinggi puncak

(AU)

0,1 89,47

0,3 89,86

0,5 101,90

1 91,50

Pengaruh volume injeksi eluen terhadap tinggi puncak 0 20 40 60 80 100 120 1 2 3 4 Volume eluen, mL Ti nggi punc a k

F.3. Kebolehulangan

Tabel F.3 Kebolehulangan pengukuran

Puncak Xi Xi-

![Tabel E.1 Pengaruh konsentrasi Cu 2+ terhadap kapasitas retensi [Cu],](https://thumb-ap.123doks.com/thumbv2/123dok/2581493.2236879/8.892.193.771.283.454/tabel-e-pengaruh-konsentrasi-cu-kapasitas-retensi-cu.webp)

![Tabel F.1 Tabel korelasi [HNO 3 ] terhadap tinggi puncak [eluen],M Tinggi puncak (AU)](https://thumb-ap.123doks.com/thumbv2/123dok/2581493.2236879/9.892.296.657.309.812/tabel-tabel-korelasi-terhadap-tinggi-puncak-tinggi-puncak.webp)