Effect of combined application of heat treatments and

plastic packaging on keeping quality of ‘Oroblanco’ fruit

(

Citrus grandis

L.

×

C

.

paradisi

Macf.)

Victor Rodov

a,*, Tayfun Agar

b, Jacob Peretz

a, Beatrice Nafussi

a,

Jong Jin Kim

c, Shimshon Ben-Yehoshua

aaDepartment of Posthar6est Science of Fresh Produce,Agricultural Research Organization,The Volcani Center,P.O.Box6,

Bet Dagan50250,Israel

bDepartment of Horticulture,Uni6ersity of Cukuro6a,01330Adana,Turkey

cThe Research Institute of Agricultural Resources De6elopment,Konkuk Uni6ersity,Seoul143-701,South Korea Received 16 December 1999; accepted 28 May 2000

Abstract

Combinations of various heat treatments with individual fruit sealing, packaging in polyethylene liners or waxing were tested as means to control pathological and physiological spoilage of ‘Oroblanco’ fruit (Citrus grandisL.×C. paradisiMacf.). The following heat treatments were used: curing at 36°C for 72 h, hot water dip at 52°C for 2 min or ‘hot drench brushing’ at 52, 56 or 60°C for 10 s. The standard packinghouse treatment included waxing with addition of thiabendazole (TBZ) and 2,4-D isopropyl ester. The fruit was stored for 2 weeks at 1°C (simulated low-temperature quarantine treatment), followed by 12 – 13 weeks at 11°C (simulated sea transportation to Japan) and 1 additional week at 20°C (simulated retail shelf-life period). The lowest weight loss and the highest firmness were observed with individually sealed fruit. Polyethylene liners were usually more efficient for weight loss control than waxing. However, the liner packaging enhanced the risk of postharvest disease development, if not accompanied by appropriate decay-controlling measures. Applying TBZ, hot water dip or curing controlled the development of postharvest pathogens, especially that ofPenicilliummolds. In another trial, both hot drench brushing at 56 or 60°C and hot water dip reduced decay incidence. Hot drench brushing at 60°C and hot water dip slowed fruit softening and reduced buttons abscission. In addition, the hot drench brushing at 60°C significantly delayed the loss of ‘Oroblanco’ green rind color, especially at the stylar and stem ends of the fruit. The hot dip at 52°C inhibited yellowing only when combined with individual seal-packaging. © 2000 Elsevier Science B.V. All rights reserved.

Keywords: ‘Oroblanco’ citrus; Citrus grandisL.×C. paradisiMacf.; Heat treatment; Curing; Hot water dip; Plastic packaging; Waxing; Fruit senescence; Peel color; Firmness; Hot drench brushing

www.elsevier.com/locate/postharvbio

* Corresponding author. Tel.: +972-3-9683609; fax: +972-3-9683622.

E-mail address:[email protected] (V. Rodov).

1. Introduction

‘Oroblanco’ citrus, known also under the com-mercial name ‘Sweety’, is a triploid pummelo-grapefruit hybrid. This variety retains green rind color far longer than grapefruit and has notice-ably sweeter flavor related to higher sugar con-tent, lower acidity and lack of bitterness (Soost and Cameron, 1981).

Export of ‘Oroblanco’ to Japan requires a low-temperature quarantine treatment against the Mediterranean fruit fly. The marine transporta-tion to the Far East markets can take 8 – 12 weeks. ‘Oroblanco’ fruit spoilage is caused pri-marily by Penicillium digitatum Sacc. and P.

italicum Wehmer (green and blue mold diseases,

respectively), and physiological deterioration, such as loss of typical green rind color, desicca-tion and chilling injury.

Heat treatments are promising non-chemical means to control fruit pathogens. Postharvest cur-ing at 34 – 36°C for 48 – 72 h effectively controls citrus decay and reduces chilling injury symptoms (Ben-Yehoshua et al., 1987; Del Rio et al., 1992). Shrunk seal-packaging in plastic film is essential during curing to reduce water loss from the fruit and thus protect it from high temperature damage (Ben-Yehoshua et al., 1987). However, practical implementation of curing is complicated by its long duration. Application of relatively short-term hot water dips (2 – 3 min at 50 – 53°C) also reduces disease susceptibility and sensitivity to suboptimal storage temperatures of various citrus fruits, including ‘Oroblanco’ (Schirra and Mulas, 1993; Rodov et al., 1995). The ‘hot drench brush-ing’ technique including hot water drench (10 – 30 s at 55 – 64°C) in combination with brushing (Is-raeli patent 116965) is commercially used in Israel with bell peppers (Fallik et al., 1999), mangoes (Prusky et al., 1999), kumquat (Ben-Yehoshua et al., 1998) and several other crops to reduce decay. The objective of the present work was to test various heat treatments in combination with sev-eral methods of weight loss reduction as non-chemical means to control pathological and physiological spoilage of the ‘Oroblanco’ fruit during simulated shipment to Japan. The efficacy of these treatments was compared with chemical treatments currently used in citrus packinghouses.

2. Materials and methods

‘Oroblanco’ fruit were obtained on the day of harvest from the packinghouse in HaSharon val-ley (Israel) before any treatment was applied (un-less specified otherwise) and divided into three lots of 240 fruit each.

The fruit of one lot were dipped in hot water (2 min at 52°C) and after air-drying either individu-ally sealed, or packaged in cartons with perfo-rated polyethylene liners, or waxed with Zivdar water wax (Safe-Pack Co, Kfar Saba, Israel). The 19 m thick Cryovac MD polyolefin (Cryovac Grace Italiana, Milano, Italy) was used for indi-vidual sealing. The liners were made of 30mthick low-density polyethylene (LDPE) and had 20 holes of 5 mm in diameter per liner. The polyethylene-based Zivdar wax did not contain fungicide or growth regulator additives (except for the packinghouse-treated control fruit).

Another lot was subjected to curing at 36°C for 72 h in combination with the same packaging or waxing treatments, as described above. The fruit were individually sealed or liner-packaged before placing into a high-temperature chamber. When curing was combined with waxing, the wax was applied after curing in order to prevent phytotoxic CO2 damage previously reported on waxed fruit

subjected to curing (Ben-Yehoshua et al., 1987). In this case, the fruit were cured within plastic containers covered with non-perforated high-den-sity polyethylene to prevent excessive water loss.

In another experiment, the ‘hot drench brush-ing’ was compared with the hot water dip. The fruit were either dipped at 52°C for 2 min, or treated for 10 s at 52, 56 or 60°C on the prototype ‘hot drench brushing’ machine (Fallik et al., 1999). Control fruit were treated on the same machine at 20°C. After air-drying, the fruit were waxed with Zivdar water wax and stored as de-scribed above, except for 13 weeks storage at 11°C.

Every treatment had four replications, each replication including one carton containing 20 fruit. The experiments were carried out during two successive harvest seasons.

The following parameters were evaluated dur-ing storage: type and incidence of decay, incidence and severity of chilling injury and other physio-logical disorders, weight loss, firmness and elastic-ity. Fruit firmness was determined by compression (Ben-Yehoshua et al., 1983) and expressed as fruit deformation (mm) after application of a load of 49.0 N to the equatorial region of the fruit. Lower deformation values indicated higher fruit firm-ness. The soluble solids concentration (SSC%) in the juice was measured refractometrically. Titrat-able acidity of the juice was determined with 0.1 N NaOH and expressed as molar concentration of hydrogen ion.

Visual rind color evaluation used a four-grade scale (4, green; 3, light-green; 2, greenish-yellow; 1, yellow). The individual fruit color scores from the same replication were summarized by calculat-ing mean indices of the replication. If n1, n2, n3,

and n4 were numbers of fruit which got color

scores of 1, 2, 3 and 4, respectively, the color index for the replication was calculated as follows

color index=(n1+2n2+3n3+4n4) (n1+n2+n3+n4)

.

Rind color was evaluated using the CROMA-METER CR-200 (Minolta, Japan), and recorded as CIE-L*a*b*. Rind yellowing was measured periodically on the same marked areas on fruit surface. Total color difference (DE) was calcu-lated according to the following equation:

DE=[(L−Linit)2+(a−ainit)2+(b−binit)2]1/2,

where, Linit, ainit and binit were the initial color

readings before storage and L, a and b were the color readings on the same spot after certain period of storage. The samples of 15 fruit from each treatment were marked for color difference measurements. Previous studies demonstrated the applicability of DE as a characteristic of leaf yellowing during storage and showed a good cor-relation between DE and chlorophyll changes in watercress leaves (Meir et al., 1992).

Samples of in-package atmosphere (5 ml) were withdrawn from the packages using gas-tight sy-ringes through septa of silicone rubber. Concen-trations of oxygen and carbon dioxide were determined by Packard 7500 gas chromatograph (Packard, Downers Grove, IL) with thermal con-ductivity detector and CTR-I packed column with helium as the carrier gas. External standards were used for data quantification.

The results of the quality evaluation were elab-orated statistically by analysis of variance (ANOVA), and means were separated by Dun-can’s multiple range test.

3. Results

3.1. Combination of weight-loss controlling measures with hot dips or curing

3.1.1. Weight loss

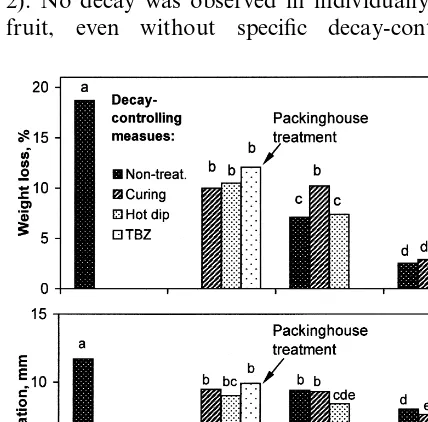

Waxing, individual sealing and use of polyethylene liners significantly inhibited weight loss of fruit during prolonged storage. Individual sealing provided the best weight loss control. Per-forated polyethylene liners were more effective than waxing for weight loss reduction, except for the combination of liners with curing (Fig. 1A). The increase of weight loss from liner-packaged and cured fruit could occur during their 3-day incubation at high temperature due to the pres-ence of perforations in the packaging material.

3.1.2. Firmness

lowest weight loss. A combination of hot water dip with plastic packaging (either sealing or liner) improved firmness of the fruit as compared with non-treated fruit in similar packages (Fig. 1B).

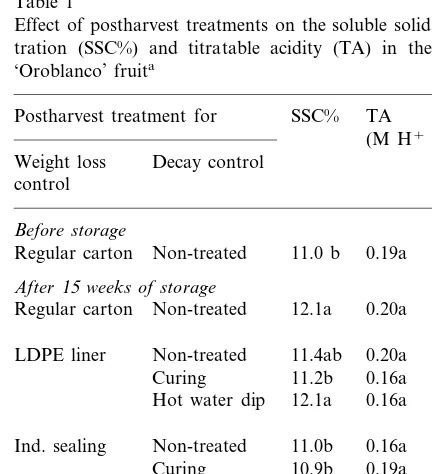

3.1.3. Decay

TBZ, hot water dip or curing minimized the postharvest decay, in particularPenicilliummolds. A low incidence of Alternaria rots was observed in certain fruit subjected to curing. The decay incidence in non-treated control fruit was about 10%. Packaging in perforated polyethylene liners, if not accompanied by one of the decay-con-trolling measures, increased decay incidence (Fig. 2). No decay was observed in individually sealed fruit, even without specific decay-controlling

Fig. 2. Effect of postharvest treatments on decay incidence of ‘Oroblanco’ fruit after storage for 15 weeks, including 2 weeks at 1°C, 12 weeks at 11°C and 1 week at 20°C. The details of decay-controlling measures were as described in Fig. 1. The decay incidence was expressed as percentage of infected fruit related to the total number of fruit subjected to the treatment. Bars labelled with the same letter were not significantly differ-ent by the Duncan’s multiple range test atP=0.05.

Fig. 1. Effect of postharvest treatments on weight loss (A) and firmness (B) of ‘Oroblanco’ fruit after storage for 15 weeks, including 2 weeks at 1°C, 12 weeks at 11°C and 1 week at 20°C. The decay-controlling measures included curing at 36°C for 72 h, hot water dip at 52°C for 2 min, dipping in 1000 ppm TBZ emulsion at room temperature (combined with individual sealing), or addition of 2000 ppm TBZ into wax (regular packinghouse treatment). The fruit received either one of the above-listed treatments, or did not get any treatment aimed specifically at decay control. Firmness is expressed as compres-sion deformation of the fruit after application of a load of 49.0 N. Lower values of deformation indicated higher firmness. Bars labelled with the same letter were not significantly differ-ent by the Duncan’s multiple range test atP=0.05.

treatments. None of the samples, including the non-treated control, showed significant chilling injury.

3.1.4. SSC and acidity

An increase in the SSC% level was observed during storage in some samples, including the non-treated control (Table 1). The phenomenon might be related to general increase in solute concentration due to the water loss and was not observed in individually sealed fruit. There was no statistically significant difference in titratable acidity.

3.1.5. Color

3.2. Hot drench brushing

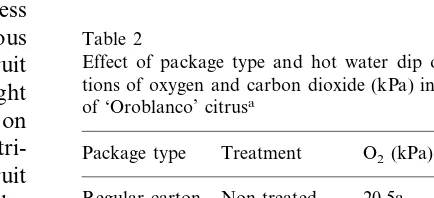

3.2.1. Decay

The reduction in decay incidence of fruit sub-ject to hot drench brushing depended on water temperature. Treatment for 10 s at 52°C did not reduce the decay level as compared with the fruit washed at room temperature. Increasing water temperature to 56 and 60°C significantly reduced the decay incidence, although still it was higher than after 2-min hot water dip at 52°C (Fig. 4A).

3.2.2. Firmness

Hot water dip inhibited fruit softening and maintained firmness. A similar effect was ob-served with ‘hot brushing’ at 60°C but not at a lower temperature (Fig. 4B).

3.2.3. Buttons abscission

Hot water treatments significantly reduced ab-scission of buttons (fruit stem-ends, including pe-duncle and calyx). After 15 weeks of cold storage, the percentage of lost buttons in fruit subjected to ‘hot brushing’ at 60°C and to hot dip at 52°C, was almost equal. However, transfer to shelf life caused additional buttons abscission of in ‘hot-brushed’ fruit, but not in the hot-dipped fruit (Fig. 4C).

3.2.4. Color

Yellowing was significantly slowed by ‘hot brushing’ at 60°C, followed by waxing. This treat-ment provided about 2 weeks delay in rind color change as compared with the control fruit, washed at room temperature and subsequently waxed (Fig. 5). The fruit treated at 60°C retained green patches at the stem and stylar ends (but not on the equator) until the end of the storage pe-riod. Heat treatments at lower temperatures did not consistently inhibit yellowing (data not shown).

4. Discussion

The results demonstrate that combining heat treatments and plastic packaging may protect ‘Oroblanco’ fruit against decay and desiccation similar to chemicals (fungicides+waxing). Since curing and hot water dip showed close efficacy, hot water dip may have certain practical advan-tage as a shorter treatment (Rodov et al., 1995). However, up-scaling of the hot dip method from the laboratory to packinghouse scale demands additional technical solutions to maintain a de-sired treatment regime with large masses of fruit (Rodov et al., 1997). The hot drench brushing technique is compatible with citrus packinghouse operations (Ben-Yehoshua et al., 1998). The treat-ment regime (temperature and duration) for ‘Oroblanco’ fruit requires further optimization in order to reach maximal decay control.

Individual shrink seal-packaging is a superior means to prevent fruit desiccation (Ben-Ye-hoshua, 1990). In cases when individual sealing is not justified economically or technically, plastic Table 1

Effect of postharvest treatments on the soluble solids concen-tration (SSC%) and titratable acidity (TA) in the juice of ‘Oroblanco’ fruita

SSC% TA Postharvest treatment for

(M H+ion) Weight loss Decay control

control

Before storage

Non-treated 11.0 b

Regular carton 0.19a

After15weeks of storage

0.20a Non-treated

Regular carton 12.1a

LDPE liner Non-treated 11.4ab 0.20a Curing 11.2b 0.16a Hot water dip 11.0b

12.1a 0.16a Curing

Waxing

12.1a Hot water dip 0.19a

0.19a 11.6ab Packinghouse

treatment

Fig. 3. Effect of postharvest treatments on rind color changes of ‘Oroblanco’ fruit during 15 weeks of storage, including 2 weeks at 1°C, 12 weeks at 11°C and 1 week at 20°C. The decay-controlling measures and their designation (in parenthesis); curing (Cur), hot water dip (HWt), packinghouse treatment, including addition of 2000 ppm TBZ into wax (PHT), non-treated (NT). Each fruit was evaluated visually at the beginning of the experiment and after 8, 14 and 15 weeks of storage according to the following scale; 4, green, 3, light-green, 2, greenish-yellow, 1, yellow. The color indices were calculated as described in the text. Bars labelled with the same letter were not significantly different by the Duncan’s multiple range test atP=0.05.

liners provide a partial solution more efficient at controlling weight loss than waxing (Albrigo and Miller, 1992; Ben-Yehoshua et al., 1997). How-ever, liners must be combined with an efficient disease control measures to avoid growth of pathogens within the package (Tugwell and Chvyl, 1997; Peretz et al., 1998). The present work showed that heat treatments could provide adequate control of decay of liner-packaged ‘Oroblanco’ fruit.

The improvement of ‘Oroblanco’ fruit firmness by hot water was demonstrated in our previous work (Rodov et al., 1995). Firmness of citrus fruit depends primarily on turgidity and on the weight loss rate. Accordingly, the effect of hot dips on the fruit firmness may be associated with redistri-bution of natural epicuticular wax on the fruit surface, closing numerous microscopic cuticular cracks (Rodov et al., 1997). Indeed, hot water dips do reduce weight loss of citrus fruit, in particular in kumquat (Rodov et al., 1995; Schirra et al., 1995). However, in the present work it was noted that improvement of fruit firmness by hot dips, within either liners or individually sealed packages, was not accompanied by additional weight loss reduction as compared with

non-dipped fruit. In this case, heat may have effected fruit firmness either by inhibiting enzymatic sys-tems involved in softening, or by elicitation of cell wall strengthening processes, such as lignification. Heat treatments delayed rind yellowing, a very important marketing factor in ‘Oroblanco’ citrus. The retention of green color could be attributed in part to inhibition of fruit senescence by heat shock. In individually sealed fruit, slightly ele-vated carbon dioxide level can contribute to

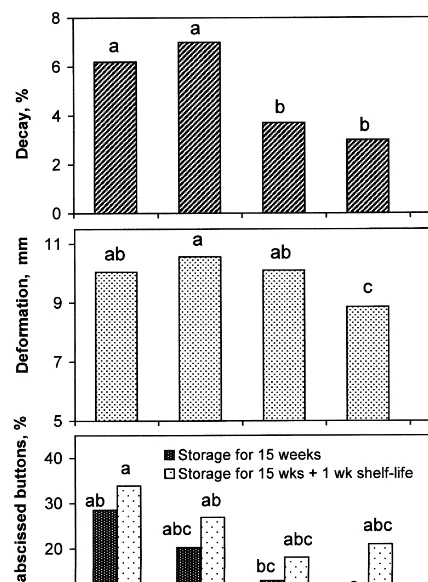

Table 2

Effect of package type and hot water dip on the concentra-tions of oxygen and carbon dioxide (kPa) inside the packages of ‘Oroblanco’ citrusa

Package type Treatment O2(kPa) CO2(kPa)

0.03b 20.5a

Non-treated Regular carton

Non-treated

LDPE liner 20.5a 0.01b

Hot water dip 0.02b

LDPE liner 20.4a

20.2a

Non-treated 0.35a

Individual sealing

20.1a

Hot water dip 0.54a Individual

sealing

Fig. 4. Effect of hot water dip for 2 min. at 52°C and ‘hot brushing’ (HB) for 10 s at 52, 56 or 60°C on decay incidence (A), firmness (B) and abscission of buttons (C) in ‘Oroblanco’ fruit after 16 weeks of storage, including 2 weeks at 1°C, 13 weeks at 11°C and 1 week at 20°C. The decay incidence was expressed as percentage of infected fruit related to the total number of fruit subjected to the treatment. The firmness was expressed as compression deformation after application of a load of 49.0 N. Bars labelled with the same letter were not significantly different by the Duncan’s multiple range test at

P=0.05.

Transfer of heat-treated fruit for 2 weeks to 1°C could prevent protein synthesis and thus hinder the recovery of ethylene producing system.

In addition, heat can exert a direct inactivating effect on chlorophyll-degrading system. The en-zyme chlorophyllase plays an important role in citrus fruit degreening (Amir-Shapira et al., 1987). Hot water treatment inhibits chlorophyllase activ-ity and chlorophyll loss in broccoli heads and delays yellowing (Kazami et al., 1991). Moderate hot water application (30 min at 45 or 46°C) enhance cucumber yellowing, while longer heating (50 or 60 min at 46°C) inhibits the loss of green color, presumably due to chlorophyllase inactiva-tion (Chan and Linse, 1989). Further research is needed to prevent degreening of ‘Oroblanco’ fruit by ‘hot brushing’.

Acknowledgements

Contribution No 422/99 from the Agricultural Research Organization, The Volcani Center, Bet Dagan, Israel. This work was partially supported by the Citrus Marketing Board of Israel and by the scholarship of the Department of

Interna-Fig. 5. Effect of hot drench brushing (HB) at 60°C on rind color changes in ‘Oroblanco’ fruit during simulated shipment to Japan. The control fruit did not receive any heat treatment. Color was recorded periodically on the same areas on the fruit equator and color changes expressed as total color difference (DE) as described in the text. Color changes on the stylar end were evaluated twice, before and after simulated shelf life period at 20°C. Bars indicate confidence intervals of the means of 15 replications atP=0.05.

senescence delay, especially since the CO2

tional Cooperation of the Ministry of Foreign Affairs of Israel given to Tayfun Agar. We are grateful to the authors of hot drench brushing technique (E. Fallik, O. Yekutieli, A. Wiseblum and R. Regev) for providing the opportunity to test the performance of this method with ‘Orob-lanco’ fruit.

References

Albrigo, G.L., Miller, W.M., 1992. Alternative bulk film wrap-ping methods for weight loss control of fresh grapefruit. Proc. Florida State Hort. Soc. 105, 101 – 103.

Amir-Shapira, D., Goldschmidt, E., Altman, A., 1987. Chlorophyll catabolism in senescing plant tissues: in vivo breakdown intermediates suggest different degradative pathways for Citrus fruit and parsley leaves. Proc. Natl. Acad. Sci. USA 84, 1901 – 1905.

Ben-Yehoshua, S., Shapiro, B., Even Chen, Z., Lurie, S., 1983. Mode of action of plastic film in extending life of lemon and bell pepper fruits by alleviation of water stress. Plant Physiol. 73, 87 – 93.

Ben-Yehoshua, S., Shapiro, B., Moran, R., 1987. Individual seal-packaging enables the use of curing at high tempera-tures to reduce decay and heal injury of citrus fruits. HortScience 22, 777 – 783.

Ben-Yehoshua, S., Peretz, J., Rodov, V., Fishman, S., 1997. High humidity packaging extends life of easy peelerCitrus reticulata fruits. In: Manicom, B. (Ed.), 1996 Proceedings of the International Society of Citriculture, vol. 1, pp. 334 – 337.

Ben-Yehoshua, S., Peretz, J., Rodov, V., Nafussi, B., Yeku-tieli, O., Regev, R., Wiseblum, A., 1998. Commercial application of hot water treatments for decay reduction in kumquat (in Hebrew). Alon Hanotea 52, 348 – 352. Ben-Yehoshua, S., 1990. Individual seal-packaging of fruit and

vegetables in plastic film. In: Brody, A. (Ed.), Controlled/

Modified Atmosphere/Vacuum Packaging of Foods. Foods & Nutrition Press, Trumbull, pp. 101 – 107.

Biale, J.B., 1961. Postharvest physiology and chemistry. In: Sinclair, W.B. (Ed.), The Orange, Its Biochemistry and Physiology. University of California, Berkeley, pp. 96 – 130. Briggs, M.S., Woodson, W.R., Handa, A.K., 1988. Biochemi-cal basis of high temperature inhibition of ethylene biosyn-thesis in ripening tomato fruit. Physiol. Plantarum 72, 117 – 125.

Chan, H.T. Jr, Linse, E., 1989. Conditioning cucumbers for quarantine heat treatments. HortScience 24, 985 – 989. Del Rio, M.A., Cuquerella, J., Ragone, M.L., 1992. Effects of

postharvest curing at high temperature on decay and qual-ity of ‘Marsh’ grapefruits and navel oranges. In: Tribulato,

E., Gentile, A., Reforgiato, G. (Eds.), Proceedings of the International Society of Citriculture, vol. 3, pp. 1081 – 1083.

Fallik, E., Grinberg, S., Alkalai, S., Yekutieli, O., Wiseblum, A., Regev, R., Beres, H., Bar-Lev, E., 1999. A unique rapid hot water treatment to improve storage quality of sweet pepper. Postharvest Biol. Technol. 15, 25 – 32. Kazami, D., Sato, T., Nakagawa, H., Ogura, N., 1991. Effect

of pre-storage hot water dipping of broccoli heads on shelf-life and quality during storage. Nippon Nogeikagaku Kaishi/J. Agric. Chem. Soc. Jpn. 65, 19 – 26.

Meir, S., Philosoph-Hadas, S., Gloter, P., Aharoni, N., 1992. Nondestructive assessment of chlorophyll content in water-cress leaves by a tristimulus reflectance colorimeter. Postharvest Biol. Technol. 2, 117 – 124.

Paull, R.E., 1990. Postharvest heat treatments and fruit ripen-ing. Postharvest News Information 1, 355 – 363.

Peretz, J., Rodov, V., Ben-Yehoshua, S., 1998. High humidity packaging extends life of easily peeled citrus cultivars (C.

reticulata). In: Ben-Yehoshua, S. (Ed.), CIPA Proceedings: International Congress for Plastics in Agriculture, Tel Aviv, Israel, March, 1997. Laser Pages Publication, Jerusalem, pp. 617 – 625.

Prusky, D., Fuchs, Y., Kobiler, I., Roth, I., Weksler, A., Shalom, Y., Fallik, E., Zauberman, G., Pesis, E., Aker-man, M., Yekutieli, O., Weisblum, A., Regev, R., Artes, L., 1999. Effect of hot water brushing, prochloraz treat-ment and waxing on the incidence of black spot decay caused byAlternaria alternatain mango fruits. Postharvest Biol. Technol. 15, 165 – 174.

Rodov, V., Ben-Yehoshua, S., Albagli, R., Fang, D.Q., 1995. Reducing chilling injury and decay of stored citrus fruit by hot water dips. Postharvest Biol. Technol. 5, 119 – 127. Rodov, V., Peretz, J., Ben-Yehoshua, S., Agar, T., D’hallewin,

G., 1997. Heat applications as complete or partial substi-tutes for postharvest fungicide treatments of grapefruit and oroblanco fruits. In: Manicom, B. (Ed.), 1996 Proceedings of the International Society of Citriculture, vol. 2, pp. 1153 – 1157.

Schirra, M., Mulas, M., 1993. Keeping quality of ‘Oroblanco’ grapefruit-type as affected by hot dip treatments. Adv. Hort. Sci. 7, 73 – 76.

Schirra, M., Agabbio, M., Continella, G., D’Aquino, S., 1995. Extension of kumquat storage life by postharvest hot dip treatments in water and freshening agent. Adv. Hort. Sci. 9, 83 – 86.

Soost, R.K., Cameron, J.W., 1981. ‘Oroblanco’, a triploid pummelo-grapefruit hybrid. In: Matsumoto, K. (Ed.), Pro-ceedings of the International Society of Citriculture, vol. 1, pp. 59 – 60.

Tugwell, B.L., Chvyl, W.L., 1997. Modified atmosphere pack-aging for citrus. In: Manicom, B. (Ed.), 1996 Proceedings of the International Society of Citriculture, vol. 2, pp. 1150 – 1152.