261

Effect of Increased Ratio of Mol Pereaktan and Ratio Enzyme

Rhizomuccor Meihei to Yield Coco Dilaurylamide

Lidyana Reihan1, Hellen Fransiska2 , Eka Kurniasih3

1,2,3Politeknik Negeri Lhokseumawe, Indonesia [email protected], [email protected]

Abstract - In Indonesia the demand for household needs is increasing, for example, such as cleaning products with surfactant base material

that serves as a dirt binder. The problem that arises today is that most petroleum-based surfactants (petrochemical surfactants), while the raw materials are classified as resource consumable and environmentally unfriendly because this type of material is not easy to decompose. Therefore, along with the development of technology, surfactants can now be produced with alternative raw materials derived from natural resources that are environmentally friendly and sustainable because it is a renewable natural resources. The advantages of making surfactants from natural raw materials are easily degraded, lower production costs, lower energy requirements and free from aromatic hydrocarbons.

Coco dilaurylamide is one of the alkanolamide surfactants that act as a stabilizer and a foam developer. Coco dilaurylamide is the name given to surfactants obtained from methyl laurate (C11H23COOCH3) reactions with diethanolamine using pure coconut raw material (VCO) in an

esterification reaction, wherein the VCO contains high lauric acid. The surfactant synthesis of pure coconut oil (VCO) was carried out through the esterification stage at 650C using a H2SO4 (10% v/v) catalyst for 2 hours. After esterification stage, followed by amidation stage using

Rhizomucor meihei enzyme biocatalyst with ratio 0,1%, 0,2%, 0,3%, 0,4%, 0,5% (w/w) and mole ratio methyl laurate Diethanolamine 1: 1, 1: 2, 1: 3, 1: 4, 1: 5 (w/v) at 500C for 4 hours. From the result of research of statistical data of variance analysis (ANAVA) it is known that the increase of mole ratio of pereaktan and the increase of Rhizomucor meihei enzyme ratio significantly influence the yield of coco dilaurylamide. Coco dilaurylamide with the highest yield has a pH value of 10, specific gravity (SG)1.08 and a boiling point of 850C.

Keywords : Coco dilaurilamide, Rhizomucor meihei, Aromatic hydrocarbon, Petrolem

INTRODUCTION

Imports of surfactants in Indonesia are increasing every year in line with the development of cleaning industry, cosmetic industry, food industry, textile industry and paint industry.

Coco dilaurylamide is a fatty amide groupcompound and is a non-ionic surfactant widely used as a material for making shampoos, bath foams, latex feeders, rust inhibitors, household cleaning products and liquid detergents. Raw material for surfactant coco dilaurylamide is methyl laurate with diethanolamine derived from vegetable oil.

One of the most widely used surfactants is coco dilaurylamide. The use of this surfactant aims to improve the stability of the emulsion by lowering the surface tension, between the oil phase and the liquid phase.

Coco dilaurylamide produced by the enzyme Rhizomuccor meihei lipase enzyme is safer to use when compared to coco dilaurylamide (chemical reaction). Therefore, in this study, the analysis of acid numbers using the titration method to determine the highest yield of coco dilaurylamide amidation reaction. In this research used 2 (two) independent variable that is ratio of enzyme Rhizomuccor meihei (% w/ w) and ratio of methyl lauric mole: diethanolamine (w / v). The optimum condition of the reaction is the result of the interaction of two independent variables.

RESEARCH METHODOLOGY Material

The materials used for the esterification process are VCO, methanol, H2SO4. While the ingredients used for the

enzymatic amidation process are methyl laurate from VCO, diethanolamine and Rhizomucor meihei biocatalyst.

.Esterification of Pure Coconut Oil (VCO)

Diluted 65 ml of methanol with 200 ml VCO using H2SO4 (10% w/v) catalyst in the flask. Adjusted operating temperature at 650C. Then separated methyl laurate with

glycerol using separating funnel, then added NaOH into methyl laurate to neutralize pH. Reaction is done for 2 hours. Then added H2O to methyl ester to purify methyl laurate from

glycerol.

Amylate Enzymatic Methyl Laurate

262 . It is known that n-hexane has a low toxicity for lipase enzyme activity when compared to other organic solvents. After methyl laurate and n-hexan have been mixed, then the diethanolamine is added according to the specified mole ratio. Further heated by adding Rhizomucor meihei enzyme biocatalyst into the three-neck flask. Stirring scale 3 for 4 hours

.

Product Purification

Purification is done by screening to separate crude coco dilaurylamide with enzyme. The soluble coco dilaurylamide in n-hexane is further distilled at a temperature

of 69°C to evaporate the solvent. Coco solvent-free dilaurylamide then analyzed the final acid number to determine the yield of the product. The yield of coco dilaurylamide product is calculated based on the difference between the initial acid number (raw material) and the final product acid number divided by the initial acid number. (Kaptriyani, 2008).

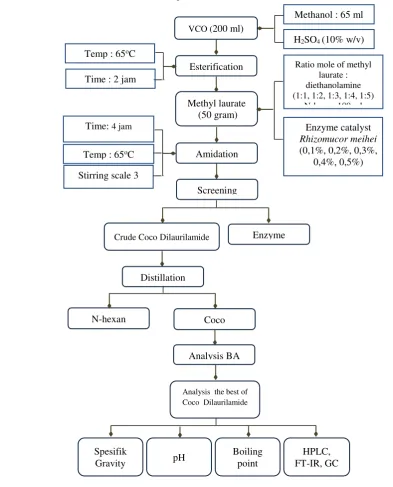

Figure 1. Flow Diagram of Research Analysis BA

Analysis the best of Coco Dilaurilamide

Distillation

N-hexan Coco

Screening

Crude Coco Dilaurilamide Enzyme Methyl laurate

(50 gram)

Amidation reaction Time: 4 jam

Temp : 65oC

: 55oC

Ratio mole of methyl laurate : diethanolamine (1:1, 1:2, 1:3, 1:4, 1:5)

N-hexan 100 ml

Enzyme catalyst Rhizomucor meihei (0,1%, 0,2%, 0,3%,

0,4%, 0,5%) Stirring scale 3

VCO (200 ml)

Methanol : 65 ml

H2SO4 (10% w/v)

Esterification Temp : 65oC

Time : 2 jam

Spesifik

Gravity pH

Boiling point

263 RESULTS AND DISCUSSION

Coco dilaurilamide acts as a stabilizer and a foaming agent According to Holmberg, (2011) states the use of diethanolamide in shampoo formulas can prevent the occurrence of excessive oil removal process in the hair and the resulting product does not cause pain in the eyes, so it is suitable for use as a soap product and shampoo on baby. Therefore dilaurilamide can be used in shampoo and soap products.

The n-hexan solvent used in the synthesis of coco dilaurylamide aims to dissolve methyl laurate to dietanolamine. Based on a study by Rahman, (2003) that n-hexan, benzene and heptane are solvents which give good results in alkanolamide synthesis and n-hexane has inert properties so as not to reduce the product mixture. Therefore, in the synthesis of dilaurylamide the solvent used is n-hexan 1:2 to methyl laurate (w / v).

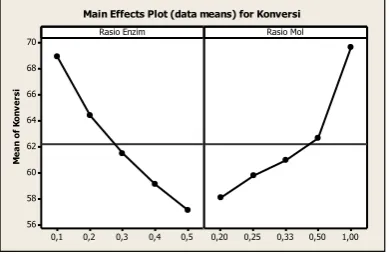

1. Relation of Pereaktan Mole Ratio and Enzyme Ratio to Coco Dilaurylamide Yield

Research on the synthesis of coco dilaurylamide using Rhizomucor meihei enzyme was performed at 5 levels of biocatalyst ratio in percent weight (w / w) ie 0.1%; 0.2%; 0.3%; 0.4%; and 0.5% and 0% (non-enzyme) as the reaction control.

Experiments without the use of enzymes are aimed at knowing the magnitude of the effect that lipase can have on the reaction. The amidation reaction lasts for 4 hours at 50 ° C with a mole ratio of 1: 1, 1: 2, 1: 3, 1: 4, and 1: 5 between

Main Effects Plot (data means) for Konversi

Figure 2. Effect of Increase of Pereaktan Mol Ratio and Enzyme Ratio to Yield Coco Dilaurylamide

Rasio Mol Interaction Plot (data means) for Konversi

Figure 3. Interactional Interaction Charts Against Yield Coco Dilaurylamide

Based on figure 2 and figure 3 above can be seen the effect of increasing the ratio of methyl lauric mole: diethanolamine to yield coco dilaurylamide, the effect of increased enzyme ratio to yield of coco dilaurylamide and interaction factor to yield of coco dilauryamide:

Effect of Mole Ratio Against Yield Coco Dilaurylamide Examining the effect of mole ratio to yield of coco dilaurylamide will be tested hypothesis.

Hypothesis:

H0 : α1 = α2 = α3 = 0

(Increased mole ratio has no effect on yield of coco dilaurylamide)

H0 at least one αi ≠ 0 i = 1, 2, 3

(Increased mole ratio effect on yield of coco dilaurylamide) From the statistical output, F mole ratios of 299.59 and P by 0.000. The conclusion is to reject the initial hypothesis that the increase in the mole ratio has no effect on the yield of coco dilaurylamide. Hence the accepted alternative hypothesis which states the increase in the mole ratio affects the yield of coco dilaurylamide.

Effect of Enzyme Ratio on Coco dilaurylamide Yield Examining the effect of enzyme ratio to yield coco dilaurylamide will be tested hypothesis.

Hypothesis:H0 : β1 = β2 = β3 = 0

(Increased enzyme ratio has no effect on yield of coco dilaurylamide)

H0: at least one βj ≠ 0 j = 1, 2, 3 (Increased enzyme ratio effect on yield of coco dilaurylamide)

From the statistical output, the enzyme F ratio was 322.06 and P by 0.000. The conclusion is to reject the initial hypothesis that increased enzyme ratio has no effect on yield of coco dilaurylamide. Hence the accepted alternative hypothesis which states increase in enzyme ratio effect on yield coco dilaurilamide.

Interaction Factor Against Yield Coco dilaurilamide Examining the interaction effect between factors to yield coco dilaurylamide will be tested hypothesis.

Hypothesis:

H0: (αβ) ij = 0 for all i, j

264 H1: (αβ) ij ≠ 0

(Interaction between factors affect the yield of coco dilaurylamide)

From the statistical output, the mole ratio to the enzyme ratio is 16.52 and P is 0.000. The conclusion is that there is influence of mole ratio interaction to enzyme ratio significantly to coco dilaurylamide yield.

Figure 4. HPLC Analysis Results

The yield of coco dilaurylamide was confirmed using product component analysis using HPLC and obtained yield coco dilaurylamide at optimum condition of 98.76% with the remaining ester of 1.23%.

Coco dilaurilamide produced still remains the ester, this is because the raw material of methyl laurate ester content is still low. The results of ester content on raw materials were confirmed using Chromosografi Gas (GC) analysis. Here are the results of ester content using Chromosografi Gas analysis (GC):

Figure 5. Results of GC Chomotographic Analysis (GC)

From Gc analysis results can be seen that the ester content in methyl laurate is 2.2686%, the resulting ester content is still low but monoglyceride, digliserida has formed the performance of enzymes to break the bonds become esters become shorter. So dilaurilamida formation process does not require a long time and free fatty acid content has been reduced so as not to interfere with dilaurilamida product. This is one of the advantages of coco dilaurylamide synthesis using methyl lauric ester as raw

material for making coco dilaurylamide. The remaining residual tiglyceride is 1.3031%, indicating the remaining tiglyceride that has not formed into esters.

2.Characteristic of Coco Dilaurylamide Product

Based on the results of characteristic analysis, the best product of coco dilaurylamide found in the highest% acid drop rate can be seen in the following table:

Table 1. Results of product characteristics analysis

Parameter Dilaurylamide

(Synthesis)

Commercial

Boiling point 85oC 239 – 244 oC

pH 10 10

SG 1,08 0,98 – 0,99

From the analysis above characteristics can be seen that coco dilaurilamida and specific gravity produced boiling point has not approached the commercial product, this is because the product coco dilaurilamida has not undergone a purification process to separate coco dilaurilamide with ester methyl laurate which is not formed into coco dilaurilamida so that required process further purification to obtain a pure dilaurilamide product. As for the resulting pH has been in accordance with commercial products.

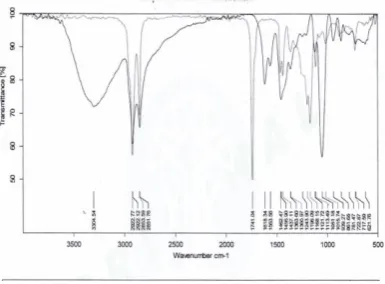

Figure 6. Results of FT-IR Analysis

From the FT-IR analysis it is known that the coco dilaurylamide wave number of methyl laurate is at 1563.56cm-1 C = O and 1456,90 cm-1 C-N bonds. The results of this study coincide with Kurniasih, (2008) the number of dietanolamide waves in 1627.24 cm-1 bonds C = O and 1419,87 cm-1 bonds C-N

265 CONCLUSION

Based on the results of the research and statistical analysis of variance (ANAVA) a significant influence on yield was given by increasing the ratio of methyl lauric mole: diethanolamine and increased Rhizomucor meihei enzyme ratio. Characteristics of coco dilaurylamide with the highest yield were: pH 10, specific graffiti (SG) 0.918 and boiling point 85 oC and FT-IR analysis showed coco dilaurylamide formed on wave 1563.56 cm-1 C = O and 1456,90 cm- 1 CN bond.

Thank-you note

To Dikti who has funded this research and Basic Chemical & Analysis Laboratory and Unit Process Laboratory which has provided facilities in this research.

REFERENCES

1. Arbianti, Rita., Tania S.Utami. 2008. Pemanfaatan Biji Wijen Sebagai Sumber Enzim Lipase Untuk Reaksi esterifikasi Gliserol-Asam Laurat Pada Pembuatan Agen Pengemulsi. Prosiding Seminar Nasional Rekayasa Kimia dan Proses. ISSN : 1411-4216

2. Arfah, Muh, Mappiratu dan Razak AR. 2015. Optikasi Reaksi Esterifikasi Asam Lurat Dengan Methanol Menggunakan Katalis Asam Sulfat Pekat. Jurnal vol. 4 No. 1, Maret 2015 : 46-48. Jurusan Kimia, Universitas Tadulako.

3. Fatarina, Ery dan Bambang Pramudono. 2009. Pembuatan Surfaktan Polyoxyethylene Dari Minyak Sawit: Pengaruh Rasio Mono-digliserida Dan Polyethylenglykol. Jurnal Vol. 12 No. 3, Juni 2009, Hal. 175-182. Jurusan Teknik Kimia, Semarang.

4. Holmberg, K. 2001. Natural Surfactants, Colloid & Interface Science, 6 : 148 – 159.

5. Kurniasih, Eka. 2008. Pemanfaatan Asam Lemak Sawit Destilat Sebagai Bahan Baku Dietanolamida Menggunakan Enzim Lipase (Rhizomucor meihei). Jurusan Teknik Kimia, Medan.

6. Kurniasih, Eka dan Tjahjono Herawan. 2013. Optimasi Reaksi Amidasi Enzimatis Dietanolamida Menggunakan Rhizomucor meihei. Jurusan Teknik Kimia, Lhokseumawe.

7. Kaptriyani, Marina. 2008. Pemanfaatan Gliserol Hasil Samping Pabrik Biodiesel dan Destilat Asam Lemak Sawit Sebagai Emulsifier Monopalmitat Secara Enzimatis. Tesis. Universitas Sumatera Utara

8. Probowati, Astri, Paradigma Cario Geovani dan Diyono Ikhsan. 2012. Pembuatan Surfaktan Dari Minyak Kelapa Murni (VCO) Melalui Proses Amidasi Dengan Katalis NaOH. Jurnal Vol. 1 No. 1, Tahun

2012, Halaman xx-xx. Jurusan Teknologi Kimia dan Industri, Semarang.

9. Rahman, A. M.B., Yap. C.l. K., Dzulkefly, dan Rahman, A. 2003. Synthesis of Palm Oil Alkanolamide Using Lipase. Journal of Oleo Science (JOS) Vol 52 No. 2, hal 65-72

10. Reetz. 2002. Lipase Sebagai Biokatalis. Current Opinion in Chemical Biology 6:145-150

(http://www.geocities.com//Jurnal Ilmiah, diakses