PROCEEDINGS OF THE FIRST INTERNATIONAL SYMPOSIUM OF

INDONESIAN WOOD RESEARCH SOCIETY

“Contribution of Scientific Profession Society on the Development of

Wood Science and Technology in Indonesia”

2

nd–

3

rdNovember, 2009

IPB INTERNATIONAL CONVENTION CENTER

BOGOR, INDONESIA

Supported by

Directorate General of Higher Education

Ministry of National Education

Edited by

Wahyu Dwianto

Ari Kusumaningtyas

Cover Design by

Teguh Darmawan

Published by

Indonesia Wood Research Society

Scientific Committee

Research Institute for Sustainable Humanosphere

Kyoto University

Uji, Kyoto 611-0011, Japan

Korean Wood Research Society

Prof. Nam-Hun Kim

Insttute of Forest Science

Department of Wood Science and Engineering

College of Forest and Environmental Sciences

Kangwon National University

Chunchon 200-701, Korea

Published by

Wood Quality Enhancement

Fixation of Agathis and Gmelina Densified Woods at Radial Direction and

Observation of their Anatomical Structure -

Atmawi Darwis,

Imam Wahyudi and

Wahyu Dwianto

Physical and Mechanical Properties of Randu and Angsana Impregnated with

Polystyrene - Rudi Hartono, Sucahyo, Yusuf Sudo Hadi and Jasni

Wood Constructions

Acacia mangium

Shear Modulus Based on ASTM D198-05a (2008) and Modulus of

Elasticity Curve - Indah Sulistyawati, Naresworo Nugroho, Surjono Surjokusumo and

Yusuf Sudo Hadi

The Reliability of LVL-CFB Shearwall Structure Due to Pseudo Dynamic Cyclic Load -

Maryoko Hadi

Bamboo Connection Design (An advanced Research) -

Gina Bachtiar, Naresworo

Nugroho and FM. Farida

Possibility of Javanese Traditional House Reconstruction Using Laminated Veneer

Lumber (LVL) - Yulianto P. Prihatmaji

Wood Composites

Biocomposites of Polypropylene or Polylactic Acid Reinforced with Sisal or Bamboo

Micro Fibers -

Subyakto, Euis Hermiati, Dede Heri Yuli Yanto, Nanang Masruchin,

Fitria, Kurnia Wiji Prasetiyo and Ismadi

Static Bending Strength of Meranti Merah (

Shorea

spp) LVL Bonded by PVAc - Isna

Yuniar Wardhani

Termite Resistance of Oriented Strands Board (OSB) Made of Small Diameter Fast

Growing Species -

Arif Nuryawan, Bud Diman Gea, Muh.Yusram Massijaya and

Yusuf Sudo Hadi

The Properties of Oil Palm Fronds Cement-Bonded Board - Dede Hermawan

Effects of Some Factors on Veneer Volume Recovery - Benoni Kewilaa

Wood Entomology and Preservation

Distribution and Identification of Subterranean Termites of

Macrotermes gilvus

Hagen in Dungus Iwul Sanctuary, Bogor, Indonesia - Niken Subekti

Identification of Wood Destroying Beetles Attacking Log and Timber -

Ira

Taskirawati, Astuti Arif and Ayu Astrianingsih R.

Wood Quality Enhancement - The First International Symposium of IWRS 79

Physical and Mechanical Properties of Randu and Angsana

Impregnated with Polystyrene

Rudi Hartono

1, Sucahyo

2, Yusuf Sudo Hadi

2and Jasni

31

Department of Forest Product Technology, Faculty of Agriculture,

North Sumatera University, Jl. Tridharma Ujung No. 1 Kampus USU,

Medan, North Sumatera 20155, Indonesia

2

Department of Forest Product Technology, Faculty of Forestry

Bogor Agriculture University

3

Forest Product Research and Development Centre

Forestry Research and Development Agency (FORDA)

Ministry of Forestry

Abstract

The aim of this research was to know the physical and mechanical properties of Randu (Ceiba pentandra

Gaertn) and Angsana (Pterocarpus indicus) polystyrene. Clear specimens were used with dimension 2 x 2 x 30 cm with MC 7 %. Replication of wood sample was three. Samples were divided into 3 treatments; there were control, soaked and vacuum-pressured. Three of each species were soaked by styrene monomer liquid for 3 days. The others were put in tank and given treatment by vacuum at 600 mm Hg for 30 minutes, then Pressured at 10 kg/cm2 for 30

minutes. After that, woods were wrapped by aluminum foil and dried with temperature 60oC for 24 hours to make

polymerize, then conditioned in the room for 2 weeks.

The result showed that average of polymer loading by soaking on Randu wood and vacuum-pressure were 32.20% and 92.43%, respectively. While by soaked on Angsana wood and vacuum-pressure were 22.20% and 68.71%, respectively. There were increasing in density, stability of dimension, hardness, modulus of elasticity (MOE), modulus of rupture (MOR) and compression parallel to grain.

Key words : Polystyrene, Randu, Angsana, physical and mechanical properties.

Introduction

Industrial Plantation Forest has being developed for additional supply of log in Indonesia, and fast growing species were dominantly planted. . These species have a great contribution, not only improvement of damage forest productivity, but also to balance of supply and demand for wood industry. The disadvantage of fast growing species has inferior physical and mechanical properties and more susceptible attacked by biodeterioration than the ordinary structural wood.

Many methods that can use to improve wood qualities. One method is modifying wood properties with impregnation particular chemical agents into the wood, such as polystyrene. Some researchers mentioned that polystyrene can improve the physical, mechanical properties and also the wood durability.

Lawniczak (1993) mentioned that polystyrene impregnated wood produced by a thermal polymerization process has been used on an industrial scale in Poland. Lawniczak and Kozlowski (1993) stated that polystyrene bamboo with 20 % weight gain increased MOR 60 % in dry condition and 300 % in wet condition, decreased two third water adsorption, and more resistant to fungal attack. Furthermore Lawniczak (1995) studied another research, the inner part of coconut wood was impregnated with polystyrene using heat as catalyst, and the products had equal properties with outer part of coconut wood and more resistant to fungal attack.

Wood Quality Enhancement - The First International Symposium of IWRS 80 Impregnation of polystyrene is possible to improve wood of fast growing species, such as to Randu and Angsana Wood. The purpose of this research was to know the physical and mechanical properties of the polystyrene wood.

Methods

Wood Preparation

The wood species were used for physical and mechanical test were Randu (Ceiba pentandra Gaertn) and Angsana (Pterocarpus indicus). The small clear specimens sized 2 cm x 2 cm x 30 cm were used for the test.

Samples were divided into three treatments; there were control, soaked and vacuum-pressure. Three of each species were soaked by styrene monomer liquid for 3 days. The others were put in tank and given treatment by vacuum at 600 mm Hg for 30 minutes, then Pressure at 10 kg/cm2 for 30 minutes. After that, woods were wrapped by

aluminum foil and dried with temperature 60oC for 24 hours to make polymerize, then conditioned in the room for 2

weeks.

Physical Properties Test

Some physical properties test were moisture content, density and polymer loading. The formula of physical properties test were

Some mechanical properties test were modulus of rupture (MOR) and modulus of elasticity (MOE), hardness and compression parallel to grain. The formula of mechanical properties test :

1. Modulus of Rupture (MOR) = (3 PL)/(2 bh2) kg/cm2

After polymerization process with heat, the average of polymer loading of Randu woods could be described as follows, soaking and vacuum-pressure were 32.20 % and 92.43 %, respectively. While average of polymer loading of Angsana woods, soaking and vacuum-pressure were 22.20 % and 68.71 %, respectively.

Wood Quality Enhancement - The First International Symposium of IWRS 81 Table 1. Average of physical properties of Randu and Angsana.

Variable Polymer Loading hydrophobic properties. Therefore, the moisture content in the wood decreased due to increasing polystyrene in wood. Furthermore, impregnation of polystyrene caused increasing of density, both on randu and angsana woods.

Impregnated Polystyrene into Randu was higher than Angsana, because density of randu is lower (0.2 g/cm3) then Angsana (0.4 g/cm3). Generally wood with low density has big pore, thin cell walls, big lumen, and also low

extractive content. They could make more permeable (Pandit, 1996)

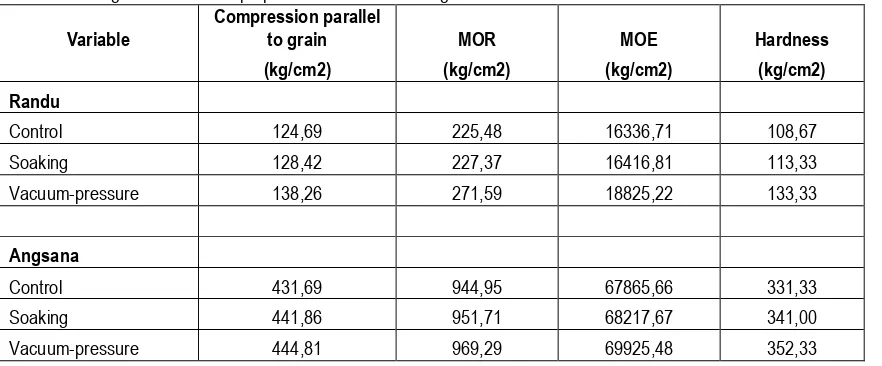

Mechanical Properties Polystyrene Wood

Average of mechanical properties of this research i.e. MOE, MOR, hardness, MOR, MOE and compression parallel to grain shown in Table 2.

Table 2. Average of mechanical properties of Randu and Angsana

Variable polystyrene enter into wood, then made bonding with wood structure. Therefore, wood strength will increase.

Conclusions

From discussions above, it could be concluded that:

1. Wood with low density is easier to be entered polystyrene than high density. 2. Impregnation polystyrene could increase physical and mechanical properties.

3. Vacuum-pressure treatment force polystyrene enters to woods, those cause vacuum-pressure treatment is

Wood Quality Enhancement - The First International Symposium of IWRS 82

References

Bakraji, E.H., N. Salman, and H. Al-Kassiri. 2000. Gamma-radiation-induced wood–plastic composites from Syrian tree species. Journal of Radiation Physics and Chemistry 61 (2001) 137–141

Baysal, E., M.K. Yalinkilic, M.Altinok, A. Sonmez, H. Peker and M. Colak (2006). Some physical, biological, mechanical, and fire properties of wood polymer composite (WPC) pretreated with boric acid and borax mixture. Journal Construction and Building Materials (article in Press)

Lawniczak, M. 1993. Method of production of the composite bamboo polystyrene elaborated in Poland. Presented at International Bamboo Festival and First National Bamboo Convention, Bandung, Indonesia, 25-28 November 1993.

Lawniczak, M and R. Kozlowski. 1993. Chosen properties of composite bamboo polystyrene. Presented at International Bamboo Festival and First National Bamboo Convention, Bandung, Indonesia, 25-28 November 1993.

Lawniczak, M. 1995. Effect of the density of Cocos nucifera wood on the quality of produced wood polystyrene composite. Folia Forestalia Polonica, Seria B, Zeszyst 25, p. 29-41.