Biofiltrasi Menggunakan Kultur

Saccharomyces Cerevisiae ATCC

9763 dan Ragi

Kering Instan dengan Media Komposit Karbon aktif dan Onggok untuk

Mengurangi gas ammonia pada Industri Karet

Winda Marthalia dan Devi Oktiani

Balai Riset dan Standardisasi Industri Bandar Lampung

Jl. By Pass Soekarno Hatta KM.1 Rajabasa Bandar Lampung Indonesia Telp. 0721-706353 e-mail: winda_agawa@yahoo.com

ABSTRAK

Penelitian ini bertujuan untuk memberikan alternatif penyelesaian permasalahan bau amonia pada industri karet. Biofiltrasi dalam skala laboratorium menggunakan Saccharomyces cerevisiae ATCC 9763 dan khamir kering instan menggunakan media campuran karbon aktif dan onggok (limbah padat industri tapioka) digunakan untuk menurunkan kadar amonia di udara. Penelitian ini mempelajari pengaruh jumlah inokulum terhadap efektivitas penurunan kadar amonia. Penelitian in membandingkan antara penggunaan isolat Saccharomyces cerevisiae ATCC 9763dan ragi kering instan yang mengandung Saccharomyces cerevisiae yang ada di pasaran. Dilakukan pengujian terhadap kadar amonia udara setelah proses biofiltrasi. Dilakukan penjerapan udara yang telah melewati kolom biofiltrasi menggunakan larutan asam sulfat dan selanjutnya dilakukan pengukuran kadar amonia pada larutan penjerap menggunakan metoda indofenol secara spektrofotometri. Hasil penelitian menunjukkan bahwa semakin banyak jumlah inokulum ragi yang digunakan maka semakin efektif penurunan amonia. Ragi kering instan lebih efektif dibandingkan dengan kultur

Saccharomyces cerevisiae ATCC 9763.Saccharomyces cerevisiae baik dalam bentuk kultur murni maupun dalam bentuk instan dapat menurunkan kadar amonia di udara.

BiofiltrationwithCultureof Saccharomyces cerevisiae ATCC 9763 andInstant

Dried Yeast withComposite Media ofActivated Carbon andTapioca Solid Waste

for ReductionofAmmonia Gas in Rubber Industry

Winda Marthalia and Devi Oktiani

Balai Riset dan Standardisasi Industri Bandar Lampung

Jl. By Pass Soekarno Hatta KM.1 Rajabasa Bandar Lampung Indonesia Telp. 0721-706353 e-mail: winda_agawa@yahoo.com

ABSTRACT

The objective of this research is to give the alternative solution related to ammonia gas odor in rubber industry. Biofiltration in laboratory scale with the culture of Saccharomyces cerevisiae ATCC 9763 and instant dried yeast with activated carbon and tapioca solid waste as media applied for the reduction of ammonia content in air. This research analyzed the effect of yeast inoculums volume on ammonia reduction. This research compared culture of Saccharomyces cerevisiae ATCC 9763 and instant dried yeast of Saccharomyces cerevisiae which commonly sold in the market. Ammonia gas in outlet from biofiltration process was absorbed in sulfuric acid solution, and ammonia content was analyzed based on indophenol method using spectrophotometry. The result indicated that the number of yeast increases the effectiveness of ammonia reduction. The instant dried yeast is more effective than culture of Saccharomyces cerevisiae ATCC 9763. Saccharomyces cerevisiae in culture formula and instant dried yeast can be used for lowering ammonia content in the air.

INTRODUCTION

Indonesia is one of the natural rubber production and exporting country. Indonesia produces

natural rubber intermediate products includes ribbed smoked sheets (RSS), air dried sheets (ADS),

block rubber, crepe rubber, crumb rubber, and concentrated rubber latex. The production process of

these products causes water and air pollution. The air pollution, especially the ammonia (NH3) odor,

arises from the production process and waste water. The manufacturing and storage process emit

various gases, vapors, fumes, and aerosols due to the leaching out of chemicals and high

temperature vulcanization (Jagadaleetal., 2015).

There are two variety of rubber sheet, RSS and ADS, its production process causes odor. The

main difference of ADS and RSS is in the drying process, ADS exploits air, while RSS uses smokes

(Dasetal., 2016). The main environment problem in the rubber sheet industry is the smoke from

fuel wood burning which caused by the presence of hazardous components such as polycyclic

aromatic hydrocarbons, while in the rubber latex industry, the waste water and the odor arises from

ammonia used for latex preservation (Tekasakul & Tekasakul, 2006). In rubber glove industry the

problem is the wastewater which is treated in the same way in rubber latex industry. The latex is

usually treated with 0.2% or 0.7% ammonia solution. The ammonia solution added to the rubber

latex is the source of a strong ammonia smell (Tekasakul & Tekasakul, 2006).

Ammonia is a colorless, toxic, reactive, and corrosive gas with a prickly odor. Ammonia

vapor is an irritant to the eyes and the respiratory tract, and acute exposure to high concentration

can cause death (Ganduetal., 2015).Previous studies about ammonia in air concerned about its odor,

environmental acidification, and pollution of ground and surface water because of its high

deposition velocity (Nanda etal., 2012). Ammonia, quantitatively, is the largest emission from

agricultural operations (Anejaetal., 2008). According to the ministry of environment’s regulation,

the ammonia content in air should be less than 2 ppm (KLH, 1996). The traditional methods for

treatment of ammonia are based on physical and chemical processes. Recently, biological process

has received much attention (Gandu etal., 2015). When ammonia is discharged into open

atmosphere, the odor mitigated within short distance through dispersion and dilution (Joshi etal.,

2000).

A biofilter is a column filled with the porous and humid packing material and indigenous

microorganisms or inoculated microorganisms that are able to degrade pollutants to the filter bed

media (Chetpattananondh etal., 2005). Biofilter is widely used for odor and air pollution treatment,

with high flow rates and pollutant concentration less than 1000 ppm (Zhuetal.,2016). Air pollutants

In gas biofiltration, the contaminated gas pass through biofilter, the pollutants are transported

into the biofilm where they are utilized by microbes as a carbon source, or an energy source, or

both. The organic contaminants are converted to odorless compounds such as CO2, water vapor, and

organic biomass (Chan, 2006). Biofiltration is classified into open or closed and vertical or

horizontal by gas flow direction (Chen & Hoff, 2009). This research was applied in laboratory

scale vertical open biofilter. The success of biofilter used for controlling odors is based on

absorption and regeneration process (Chen & Hoff, 2009). Odor gasses, passing through a biofilter,

are absorbed on the surface of the biofilter medium particles.

The performance of biofiltration depends on the medium that provide the optimal

environment conditions for the growth or living of microbial population. A good filter material

should have a large surface area, high water retention capacity without becoming saturated, low

bulk density, high porosity, structural integrity, and a buffer capacity towards acidification and high

contaminant loads (Chan, 2006).

The quality of the filter media has been reported as one of the key factors in biofilter

performance. Composite based media has been extensively used because of its cheap price and has

several microbial communities for degrading various pollutants (Pagans, Font, & Sanchez, 2007).

The choice and preparation of a proper inoculums to obtain a healthy population of

microorganisms is a fundamental for successful biofilter operation (Chan, 2006). When treating a

gas mixture with many components, different microbial species are active, and it is difficult to

anticipate the biofilter treatment result. Microorganisms with various substrates will convert the

easily degradable compounds at the inlet of the filter. The contaminants must be biodegradable and

non-toxic for the microbes. The highly soluble organic compounds with simple bond structures are

easy to remove compare to inorganic compounds (Chan, 2006).

The following are previous studies about biofiltration. The bacteria used in biofiltration, in

example Nitrosomonas europea(Chung, Ho, & Tseng, 2007), Nitrosomonas sp., Pseudomonas sp.,

Nitrosomonassp. for biofiltration (Kimet al., 2015), Planctomycetes for biofiltration (Keuter, 2011),

Thiobacillus sp. (Kim etal., 2003), active sludge (Lebreroetal., 2011), gas phase compost biofilter

(Maiaetal., 2012). Various media and packing bed used in biofiltration in example, ceramic beads

and molasses with bacterial consortium (Pseudomonas sp., Nitrosomonas sp., Nitrobacter sp.)

(Muter etal., 2014), microbial soil in biofiltration (Nelson & Bohn, 2011). The industrial waste

which contains organics and nutrients can be used as media or substrate, as an example commercial

The application of biofiltration in industry: the application of ammonia gas reduction in

livestock farm (Jinanan & Leungprasert, 2015), the application of biofiltration in cattle manure and

rice husk mixture (Kavyashree, Ramya, Sanjay, Chandan, Shilpa, & Rashmi, 2015), the biofilter

packed with mixed of top soil and rubber leaves at crumb rubber industry (Yanietal., 2012).

Previous studies about yeast in biofiltration, yeast for metal removal (Fogarty, 1998),

Saccharomyces cerevisiae for metal removal(Norris & Kelly, 1977), yeast biofilter and abattoir

wastewater (Rabahetal., 2011).

The biological treatment techniques for odor control have gained popularity in comparison to

traditional physical and chemical removal methods (Gopal etal., 2014). Biological treatment is an

attractive alternative for low concentration gas streams because of its low energy consumption,

relatively moderate operating cost, and minimal by-products generation (Kumaretal., 2011).

Biofiltration is advantageous because it does not require large amounts of energy during operations

and produce a relatively low toxicity waste stream (Kumar etal., 2013).

MATERIALS AND METHODS

Materials

Biofilter media was powder activated carbon and cassava solid waste. Cassava solid waste was

collected from the tapioca industry.

This experiment compared two different yeast, culture of Saccharomyces cerevisiaeATCC 9763

and instant dried yeast of Saccharomyces cerevisiaethat sold in the market and commonly used in

bakery.

Ammonia gas in this experiment was generated from Ammonia glacial 85% produced by

MERCK.

The chemical materials for analysis of ammonia content in biofilter gas outlet and chamber

included sodium nitropruside (Na2Fe(CN)5NO.2H2O 2%, sodium hydroxide 6.75M, sodium

hypochlorite 3.7%, phenol (C6H5OH) 45% v/v, buffer (50 gr Na3PO4.12H2O and 74 mL, NaOH

6.75 M diluted to 1000 mL), ammonia stock solution (3.18 gr NH4Cl diluted to 1000 mL with

distilled water). The air sampler absorbent made from sulfuric acid, the 3 mL sulfuric acid 97%

diluted to 1000 mL. The material based on SNI 19-7119.1-2005 (Badan Standardisasi Nasional,

Glassware, analytical laboratory equipment, and experiment tools

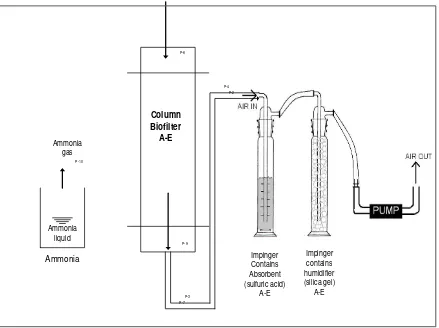

Biofilter columns made of polyvinyl chloride (PVC) pipe, 3 cm in diameter, and 20 cm in

height. The columns or pipes are opened in the upper end so that it is possible to come into constant

with the air contaminated with ammonia which represented the environment air. The lower end of

the columns or pipes are closed with the small hole which enough for the hose connecting the gas

outlet with the impinge air sampler.

Impinge air sampler, a set consists of 5 individual air samplers, each air sampler includes

pump 0.5, flow regulator, rotameter impinge for absorbent, and impinge for humidifier. Range of

air sampler was 0.5 – 3 L/minutes.

Glassware for analytical testing included erlenmeyer flask, pipette, volumetric flask,

magnetic stirrer, and petri dishes. UV visible spectrophotometer is needed for measure ammonia

content.

Methods

Starter yeast culture yeast preparation

This experiment compared two different yeasts: Saccharomyces cerevisiaeATCC 9763 and instant

dried yeast. Preparation Saccharomyces: 1 ose Saccharomyces cerevisiaeATCC 9763culture added

to 100 mL potato dextrose broth (PDB) media, incubated for 24 hours in 25°C. Preparation of

instant dried yeast: 1 gram of instant dried yeast added to 100 mL potato dextrose broth (PDB)

media, incubated for 24 hours in 25°C.

Calculated the colony number of yeast

1 mL starter yeast mixed with 9 mL Buffered Peptone Water (BPW) and then diluted to 10-9 times.

1 mL of each diluted culture transferred to 20 mL potato dextrose agar (PDA) media and then

incubated for 2 x 24 hours in temperature 25°C. The colony number of yeast calculated with

counting chamber.

The composit of media and yeast

There are four volume variations of Saccharomyces cerevisiae ATCC 9763 culture and instant dried

waste added to each sample (four variations and two types of Saccharomyces cerevisiae), then

incubated for 12 hours. Activated carbon is added to each sample and then homogenized. The

composite is transferred into biofilter column.

The Analysis of ammonia content

Ammonia concentration from the outlet gas biofilter was measured by indophenol testing

method based on SNI 19-7119.1-2005 (Badan Standardisasi Nasional, 2005).

Experimental Design

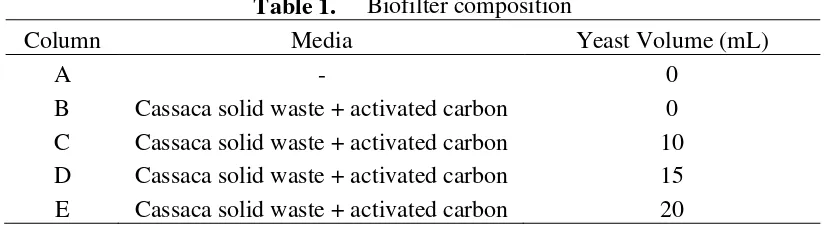

The objective of this experiment is to measure the outlet gas from 4 different composition of

biofilter with four volume variations of yeast. There are five biofilter columns (A-E) with different

biofilter composition.

Table 1. Biofilter composition

Column Media Yeast Volume (mL)

A - 0

B Cassaca solid waste + activated carbon 0

C Cassaca solid waste + activated carbon 10

D Cassaca solid waste + activated carbon 15

E Cassaca solid waste + activated carbon 20

Column A, column without media and bacteria, represents the air in the environment

without biofiltration, the contaminated ammonia air. The biofiltration process was operated for 90

minutes simultaneously for A-E in a chamber. Five impinge air sampler connected to biofilter gas

outlet (Figure 1), one impinger for each biofilter column. Ammonia in chamber generated from

liquid ammonia solution. Gas outlet was absorbed with sulfuric acid in impinge. The ammonia

absorbed was measured with indophenol methods based on SNI 19-7119.1-2005.

RESULT AND DISCUSSION

This research investigated the effect of microbial colony number which represents as

inoculums yeast volume on ammonia removal. The target of the biofiltration was that gas outlet

contains low ammonia, less than 2 ppm. The ammonia content of air in the chamber was

conditioned between 3-4 ppm by generating ammonia gas form liquid ammonia, this number

represents the common ammonia content in process and storage room rubber industry.

The experiment design included 5 biofilter columns: 1 column without biofiter (media)

which represents air without biofiltration process, and four columns which different in inoculums

bacteria volume (0 mL, 10 mL, 15 mL, and 20 mL). The media in this biofilter was 10 gram

activated carbon and 10 gram of cassava waste. The reason of choosing cassava waste as media was

because it contains carbon and nutrient for yeast and it is a natural mateial, low price resource,

available in a big quantity.

The air flow was set in 1 L/ minute based on the National Standard method of ambient air

sampling (SNI 19-7119.1-2005). The 1 L/minute represents the outdoor wind velocity which

mitigates air in outdoor environment or ambient air.

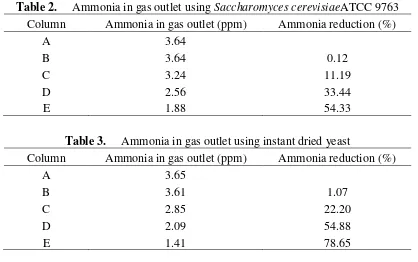

The finding indicates that the volume of inoculum bacteria has an effect on ammonia

absorption (Table 2). The ammonia concentration decreases as the additional volume of yeast. The

Table 2. Ammonia in gas outlet using Saccharomyces cerevisiaeATCC 9763

Column Ammonia in gas outlet (ppm) Ammonia reduction (%)

A 3.64

B 3.64 0.12

C 3.24 11.19

D 2.56 33.44

E 1.88 54.33

Table 3. Ammonia in gas outlet using instant dried yeast

Column Ammonia in gas outlet (ppm) Ammonia reduction (%)

A 3.65

B 3.61 1.07

C 2.85 22.20

D 2.09 54.88

E 1.41 78.65

Table 4. The number of yeast colony in biofilter after biofiltration process

Column Saccharomyces CerevisiaeATCC 9763 Instant Dried Yeast

B 1.59 x 108 1.72 x 108

C 1.62 x 109 1.84 x 109

D 2.40 x 109 2.70 x 109

E 3.10 x 109 3.21 x 109

In this biofilter system, the effectiveness of ammonia removal is affected by number or

volume yeast added, while activated carbon has no significant effect on ammonia removal. There is

no significant difference between ammonia content in experiment A and experiment B. The

function of cassava solid waste in this system is not as ammonia absorber, but as carbon source and

nutrient for bacteria and as water absorbent for maintaining moisture content, as water content has

effect on biofilter effectiveness.

The chamber temperature in this experiment was 35°C, it represents the natural temperature

of room in rubber industry, this experiment held on optimum temperature. The instant dried yeast

can be applied in the biofilter, especially in the warm tropical country without temperature

conditioning. The biofiltration in this experiment effectively reduced the ammonia content below 2

ppm. The Saccharomyces cerevisiaeATCC 9763 was not effective for reducing ammonia compared

to instant dried yeast, maybe because it cannot grow optimally in the experiment temperature 35°C,

while the instant dried yeast is processed to be applied in the warm temperature.

Biofiltration with instant dry yeast and the composite media of activated carbon and cassava

solid waste can be used for ammonia gas removal. The instant dried yeast is more applicable for the

biofilter system than Saccharomyces cerevisiae ATCC 9763culture.

REFERENCES

Aneja , V. P., Blunden, J., Roelle, P. A., Schlesinger, W. H., Knighton, R., Niyogi, D., et al. (2008).

Workshop on agricultural air quality: state of the science. Atmospheric Environment 42,

3195-3208.

Badan Standardisasi Nasional. (2005). Standar Nasional Indonesia (SNI) 19-7119.1-2005.. Udara

ambien- Bagian 1: Cara Uji kadar amoniak (NH3) dengan metoda indofenol menggunakan spektrofotometer. Jakarta: Badan Standardisasi Nasional.

Chan, A. A. (2006). Biofiltration of odours gas emissions (Doctoral Thesis). Lulea, Sweden: Lulea

University of technology.

Chen, L., & Hoff, S. (2009). Mitigating odors from agriculture facilities: a review of literature

concerning biofilters. American Society of Agricultural and Biological Engineers, 751-766.

Chetpattananondh, P., Nitipavachon, Y., & Bunyakan, C. (2005). Biofiltration of air contaminated

with methanol and toluene. Journal of Science and Technology 27(3), 761-773.

Chung, Y.-C., Ho, K.-L., & Tseng, C.-P. (2007). Two - stage biofilter for effective NH3 removal

from waste gases containing high concentration of H2S. Journal of the Air & Waste

Management Association 57(3), 337 - 347.

Das, D., Saha, A., & Bhattacharjee, H. (2016). Rubber processing is detrimental to environment: a

case study. International Journal of Scientific & Engineering Research 7(7), 369-376.

Fogarty, R. V. (1998). Toxicity and Biosorbtion of Metals by Saccharomyces cereviseae,

Amorphtheca resinae, and Azolla filiculoides (Master Thesis). Dublin 9, Ireland: School of Biological Sciences Dublin City University .

Gandu, B., Rao, G., Kranti K, & Sawmy, Y. (2015). Ammonia odours removal by gasphase

biofilter through nitrification and Anammox proceses. Journal of Chemical and

Pharmaceutical Research 7(10), 763-766.

Gopal, B., Rao, A., Devi, V., Rao, Y., & Babu, B. (2014). Biofilter for the purification of air

contaminated with tryethylamine (TEA). International Journal of Advanced Research,

295-302.

Jagadale, S. C., Rajkumar, K., Chavan, R. P., & Shinde, D. N. (2015). Environmental concern of

pollution in rubber industry. International Journal of Resesarch in Engineering and

Jinanan, J., & Leungprasert, S. (2015). Feasibility study of low cost biofilter to control ammonia

from livestock farms. International Journal of Research in Chemical, Metallurgical, and

Civil Engineering 2(1), 1-8.

Joshi, J. A., Hogan, J. A., Cowan, R. M., Strom , P. F., & Finstein , M. F. (2000). Biological

removal of gaseous ammonia in biofilters: space travel and earth-based applications. Journal

of

Kavyashree, B., Ramya, N., Sanjay, U. A., Chandan, K., Shilpa, B., & Rashmi, M. (2015).

Ammonia gas removal using biofilter. International Advanced Research Journal in Science,

Engineering, and Technology 2(7), 110 - 114.

Keuter, S. (2011). Characterization of nitrifying bacteria in marine recirculation aquaculture

systems with regard to process optimization (Dissertation). Hamburg: Departement Biologie der Universitat Hamburg.

Kim, B., Kim, J., Kim, D., & Park, J. (2015). Analysis of biofilter and microbial community change

under thetreatment of ammonia and toluene. International Conference on Biotechnology &

Environment Engineering (ICBNE '15) (pp. 32-33). Bangkok, Thailand: International Academy of Art, Science, and Technology.

Kim, C.-W., Park, J.-S., Cho, S.-K., Oh, K.-J., Kim, Y.-S., & Kim, D. (2003). Removal of hydrogen

sulfide, ammonia,and benzena by fluidized bed reactor and biofilter. Journal of

Microbiology and Biotechnology 13(2), 301-304.

Kumar, K. V., Sridevi, V., Harsha, N., Lakshmi, M. C., & Rani, K. (2013). Biofiltration and its

application in treatment of air and water polutants- a review. International Journal of

Application or Innovation in Engineering & Management 2(9), 226-231.

Kumar, T. P., Rahul, Kumar, M. A., & Chandrajit, B. (2011). Review paper. Biofiltration of volatile

Organic Compounds (VOCs)- an averview. Reearch Journal of Chemical Sciences 1(8),

83-92.

Kumar, V. R., Sukumaran, V., Achuthan, C., Joseph, V., Philip, R., & Singh, I. B. (2013).

Molecular characterization of the nitrifying bacterial consortia employed for the activation

of bioreactors used in brackish and marine aquaculture systems. International

Biodeterioration & Biodegradation 78, 74-81.

Lebrero, R., Rodriguez, E., Garcia-Encina, P., & Munoz, R. (2011). A comparative assessment of

biofiltration and activated sludge for odour abatement. Journal of Hazardous Materials,

622-630.

Maia, G., Day V, G., Gates, R., Taraba, J., & Coyne, M. (2012). Moisture effects on greenhouse

gases generation in nitrifying gas-phase compost biofilters. Water Research, 3023 - 3031.

Muter, O., Mihallova, A., Berzins, A., Shvirksts, K., Patmalnieks, A., Strikauska, S., et al. (2014). Optimization of nitrification process by a bacterial consortium in the submerged biofiltration

Nanda, S., Sarangi, P. K., & Abraham, J. (2012). Microbial biofiltration technology for odour

abatement: an introductory review. Journal of Soil Science and Environmental Management

3(2), 28-35.

Nanda, S., Sarangi, P. K., & Abraham, J. (2012). MIcrobial biofiltration technology for odour

abatement: ann introductory review. Journal of Soil Science and Environmental

Management 3(2), 28-35.

Nelson , M., & Bohn, H. (2011). Soil-based biofiltration for air purification: potentials for

environmental and space life support application . Journal of Environmental Protection 2,

1084 - 1094.

Norris, P., & Kelly, D. (1977). Accumulation of cadmium and cobalt by Saccharomyces cerevisiae.

Journal of General Microbiology (99), 317-324.

Pagans, E., Font, X., & Sanchez, A. (2005). Biofiltration for ammonia removal from composting

exhaust gas. Chemical Engineering Journal 113, 105-110.

Pagans, E., Font, X., & Sanchez, A. (2005). Biofiltration for ammonia removal from composting

exhaust gas. Chemical Engineering Journal, 105 - 110.

Pagans, E., Font, X., & Sanchez, A. (2007). Coupling composting and biofiltration for ammonia

and volatile organic compounds removal. Biosystems Engineering, 281-284.

Rabah, A. B., Ibrahim , M. L., Ijah, U. J., & Manga, S. B. (2011). Assessment of the efficient of a

yeast biofilter in the treatment of abattoir wastewater. African Journal of Biotechnologi,

9347-9352.

Rattanapan, C., & Ounsaneha, W. (2012). Removal of hydrogen sulfide gas using biofiltration -

Tekasakul , P., & Tekasakul, S. (2006). Environmental problems related to natural rubber

production in Thailand. Journal of Aerosol Research 21(2), 122-129.

Yani, M., Nurcahyani, P. R., & Rahayuningsih, M. (2013). Ammonia removal by biofiltration technique packed with coral and granulated activated carbon (GAC) inoculated with

enriched nitrifying bacteria. Jurnal Teknologi Industri pertanian 23(1), 22-29.

Yani, M., Purwoko, Ismayana, A., Nurcahyani, P. R., & Pahlevi, D. (2012). Penghilangan bau amoniak dari tempat penumpukan leum pada industri karet remah dengan menggunakan

teknik biofilter. Jurnal Ilmu Pertanian Indonesia 17(1), 58 -64.

Zhu, Y., Li, S., Luo, Y., Ma, H., & Wang, Y. (2016). A biofilter for treating toluene vapors: