UNIVERSITI TEKNIKAL MALAYSIA MELAKA

A Comparison of Mechanical Propert ies

bet ween Kenaf Core Fiber and Kenaf Bast

Fiber Reinforced Polyest er Composit es

Thesis submitted in accordance with the partial requirements of the Universiti Teknikal Malaysia Melaka for the Degree of Bachelor

of Engineering (Honours) Manufacturing (Process)

By

Mohamad Ridzwan Bin Ishak

UTeM Library (Pind.1/2005)

SULIT

TERHAD

TIDAK TERHAD

(Mengandungi makl umat yang berdarj ah kesel amat an at au kepent ingan Mal aysia yang t ermakt ub di dalam AKTA RAHSIA RASMI 1972)

(Mengandungi makl umat TERHAD yang t el ah dit ent ukan ol eh organisasi/ badan di mana penyel idikan dij al ankan)

(TANDATANGAN PENULIS)

* Tesis dimaksudkan sebagai t esis bagi Ij azah Dokt or Fal saf ah dan Sarj ana secara penyel idikan, at au disert asi bagi pengaj ian secara kerj a kursus dan penyel idikan, at au Laporan Proj ek Sarj ana Muda (PSM). ** Jika t esis ini SULIT at au TERHAD, sil a l ampirkan surat daripada pihak berkuasa/ organisasi berkenaan dengan menyat akan sekal i sebab dan t empoh t esis ini perl u dikel askan sebagai SULIT at au TERHAD.

BORANG PENGESAHAN STATUS TESIS*

JUDUL: A COMPARISON OF MECHANICAL PROPERTIES BETWEEN KENAF CORE FIBER AND KENAF BAST FIBER REINFORCED POLYESTER COMPOSITE

SESI PENGAJIAN: 2/ 2006-2007

Saya _____________________________________________________________________

mengaku membenarkan t esis (PSM/ Sarj ana/ Dokt or Fal saf ah) ini disimpan di Perpust akaan Universit i Teknikal Mal aysia Mel aka (UTeM) dengan syarat -syarat kegunaan sepert i berikut :

1. Tesis adal ah hak mil ik Universit i Teknikal Mal aysia Mel aka.

2. Perpust akaan Universit i Teknikal Mal aysia Mel aka dibenarkan membuat sal inan unt uk t uj uan pengaj ian sahaj a.

3. Perpust akaan dibenarkan membuat sal inan t esis ini sebagai bahan pert ukaran ant ara inst it usi pengaj ian t inggi.

4. **Sil a t andakan (√)

MOHAMAD RIDZWAN BIN ISHAK

√

APPROVAL

This thesis submitted to the senate of UTeM and has been accepted as partial fulfillment of the requirements for the degree of Bachelor of Manufacturing Engineering (Manufacturing Process). The members of the supervisory committee are as follow:

……… Main Supervisor

(Official Stamp and Date)

……….. Co – Supervisor

DECLARATION

I hereby, declared this thesis entitled “A Comparison of Mechanical Properties between Kenaf Core Fiber and Kenaf Bast Fiber Reinforced Polyester Composites.” is

the results of my own research except as cited in references

Signature : ………

Author’s Name : ………

ABSTRACT

ABSTRAK

Projek ini adalah bertujuan untuk mengkaji perbandingan sifat mekanikal dan mikrostruktur di antara gentian daripada kulit dan empulur pokok kenaf diperkuatkan dengan termoset poliester komposit. Matrik yang akan digunakan adalah matrik daripada jenis polimer termoset iaitu poliester yang diperolehi dari Makmal Polimer universiti. Termoset poliester dicampur dengan pemangkin metil etil keton peroksida (MEKP)

Butanox M50 dengan nisbah berat satu bahagian daripada seratus berat poliester bagi

daripada acuan, panel komposit dibiarkan pada suhu bilik selama 2 minggu bagi memastikan komposit kering sepenuhnya sebelum dipotong mengikut dimensi ukuran piawaian ASTM. Prosedur yang sama telah dijalankan bagi menghasilkan komposit gentian daripada kulit dan empulur kenaf diperkuat poliester dengan pertambahan peratusan berat pengisi bagi kedua-dua gentian. Komposit yang dihasilkan adalah 5%, 10%, 20%, 30%, 40% berat pengisi gentian dan komposit tanpa pengisi. Berdasarkan eksperimen, peratusan maksimum berat gentian kenaf yang boleh diisi adalah sebanyak 40% berdasarkan sifat resapan cecair semulajadi bahan. Ujian mekanikal telah dijalankan dan mendapati gentian daripada kulit kenaf diperkuat poliester memberikan nilai kekuatan tegangan, kelenturan dan hentaman lebih tinggi. Komposisi terbaik bagi menghasilkan nilai kekuatan tertinggi untuk gentian daripada kulit kenaf adalah sekitar 10%-20% manakala gentian daripada empulur kenaf adalah sekitar 5%-20% berat pengisi. Kelembapan gentian didapati mengurangkan sifat mekanikal gentian. Analisis topografi menggunakan Scanning Electron Microscope (SEM) keluaran Syarikat Zeiss,

DEDICATION

ACKNOWLEDGEMENT

TABLE OF CONTENTS

List of Abbreviations, Symbols, Specialized Nomenclature………....…....……xviii

1.

INTRODUCTION

……….11.1 Introduction to Kenaf………...……….1

1.2 Statement of the Purpose………...………4

1.3 Hypotheses………...……….5

2.1.1 Plant Component Partitioning and Composition………..……….8

2.1.1.1 Whole Stalk ……….………..9

2.1.1.2 Bast Fiber……….………...………...10

2.1.1.3 Core Fiber……….………11

2.1.2 Uses of Kenaf………..………….12

2.1.2.1 Traditional Use of Kenaf………..………12

2.1.3 General Properties of Kenaf Fibers……….………….15

2.1.4 Separation of Kenaf Fiber………..………..17

2.1.4.1 Mechanical Separation Method……….17

2.2.4 Manufacturing Techniques……….……..22

2.2.5 Characteristics Influence the Properties of Composites……….………..23

2.2.6 Thermoset Polyester Resin………...25

2.3.2.2 Specimen Shape………32

2.3.2.3 UTM Machine………..33

2.3.2.4 Typical Configuration………..33

2.3.2.5 Three Point Flexural Test……….35

2.3.2.6 Testing calculation………..…….….36

2.3.3 Charpy and Izod Pendulum Impact Test………..37

2.3.3.1 Definition and Purpose………...…..37

2.3.3.2 Specimen Shape………..…..38

2.3.3.3 Impact Machine……….…...39

2.4 Physical Testing………...42

2.4.1 Water Absorption Test……….…42

2.4.1.1 Definition and Purpose……….…………42

2.4.1.2 Specimen Shape……….……..42

2.4.1.3 Tools and Equipment………...42

2.5 Microstructure Observation………...…..43

2.5.1 Definition and Purpose……….43

2.5.2 Scanning Electron Machine (SEM)………..…43

2.5.3 Basic Operating ………...43

2.6 Previous Research on Natural Fiber Composite………..45

2.6.1 High Fiber-Low Matrix Composites: Kenaf Fiber-Polypropylene…...45

2.6.2 Physical and Mechanical Properties of Composite Panels Made. From Kenaf Plant Fibers and Plastics………..46

2.6.3 Kenaf Fiber Reinforced Composite Athletic Wheelchair………..…47

3.

METHODOLOGY

………..………..….503.1 Introduction………..………50

3.2 Process Sequence……….…………51

3.3 Kenaf Fiber Preparations……….53

3.3.1 Separation of Fibers……….…55

3.3.2 Fiber Drying Process………..…….56

3.4 Mould Fabrication………57

3.4.1 Mould Designing………..57

3.4.2 Selection of Mould Material………...………..57

3.4.3 Mould Fabrication………61

3.5 Composite Fabrication………..61

3.5.1 Composite Formulation………61

3.5.2 Preparation of Polyester and Hardener……….62

3.5.3 Formulation/Composition of resin/filler………...62

3.5.4 Fabrication Process……….………..63

3.5.4.1 Casting with Liquid Resin……….………63

3.5.4.2 Cutting of Composite……….…….……..68

3.5.4.3 Notching Process……….………..…69

3.6 Testing and Analysis……….……….…..71

3.6.1 Mechanical Testing………...…….………..71

3.6.1.1 Tensile Tests………..………..71

3.6.1.2 Flexural Tests……….…….…………....72

3.7 Physical Testing……….………..………73

3.7.1 Water Absorption Test……….………73

3.8 Surface Topography of Bast and Core Fibers……….…….74

4.

RESULTS……….

………764.1 Number of Specimens………...………...76

4.2 Final Specimens………...………78

4.3 Overall Specimens……….…..78

4.4 Kenaf Bast Fiber Reinforced Composite for Tensile Specimens………79

4.5 Kenaf Core Fiber Reinforced Composite for Tensile Specimens………...……80

4.6 Surface Topography……….……….…..………81

4.6.1 Observation of Fiber Diameter……….………....81

4.6.2 Observation of Fiber Surface……….………...83

4.6.3 Matrix-Fiber Interfacial Bonding Observation……….84

5.

DISCUSSION

………865.1 Characteristic Influence the Composite Properties……….…86

5.1.1 Large Fiber Particle……….……….………86

5.1.2 Dispersion of the Fiber……….………87

5.1.3 Influence of Fiber Length……….………87

5.1.4 Influence of Fiber Orientation……….……….89

5.1.5 Influence of Fiber Phase……….……….…….89

5.2 Challenges during Preparation of the Specimen …………...……….91

5.3.2.1.2.2 Flexural properties………..109

5.3.2.1.2.3 Impact Properties………111

6.

CONCLUSION

...……….……….1136.1 Conclusion………...……….……….113

6.2 Recommendations……….115

7. REFERENCES

………..………..….1168. APPENDICES

A The detail list of property values for a range of thermoset polyester compounds B Machines involved in the mould fabrication

C Formulation of composite fabrication D Calculation of tensile test

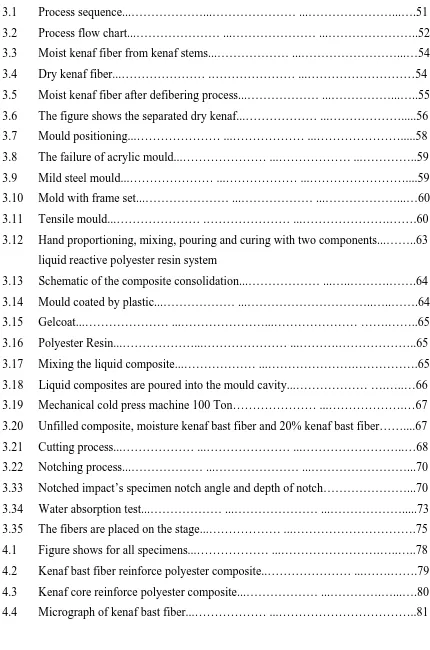

LIST OF FIGURE

1.1 Kenaf Plantatition...……… ...………….……… ...………..…….2

1.2 Kenaf stalks...……… ...……… ...………..……3

2.1 Kenaf stalks with bast and core material...….……… ...………..……..9

2.2 Kenaf bast fiber strands...……… ...………….…… ...………….…...11

2.3 Core fiber material...……… ...………….…… ...……….…...12

2.4 Kenaf Fiber Images...……… ...……….……… ...……….….16

2.5 Schematic of Stick Machine Trash Master...……….……… ...………..….18

2.6 Water retting process...……… ...……….……… ...………..…..19

2.7 Formation of a composite material using fibers and resin...………...….20

2.8 Continuous fiber composites and short fiber composites...……….…..…...20

2.9 Crosslinking of thermoset molecules during curing...………...…...22

2.10 Schematic representations of various geometrical and spatial characteristics of. particles...……… ……….…24

2.11 Reaction A(1) ...……… ...……… ...………...…25

2.12 Reaction A (2) ...……..………… ...……… ...………26

2.13 Reaction B...……… ...……… ...……….………..…..26

2.14 MEKP catalyst ratio...……… ...……… ...………..…29

2.15 Tensile configurations...……… ...……… ...………...31

2.16 Location of tensile and compressive forces during three-point bending...……..33

2.17 Crack propagation and failure during three-point bending...………...34

2.18 Three point bending...……… ...……… ...………...…36

2.19 Schematic striker movement of impact machine...………..38

2.20 Impact machine...……… ...……… ...………..…...39

2.21 Charpy and Izod specimens’ positioning...……… ...………..…40

2.22 Charpy impact strike-specimen configuration...……….……..…41

2.23 SEM component...……… ...……… ...………...…………...…..43

3.1 Process sequence...………...……… ...………...….51

3.2 Process flow chart...……… ...……… ...………..52

3.3 Moist kenaf fiber from kenaf stems...……… ...………...…54

3.4 Dry kenaf fiber...……… .……… ...………54

3.5 Moist kenaf fiber after defibering process...……… ...………...…..55

3.6 The figure shows the separated dry kenaf...……… ...………...56

3.7 Mould positioning...……… ...……… ...………...58

3.8 The failure of acrylic mould...……… ...……… ...…………..59

3.9 Mild steel mould...……… ...……… ...………....59

3.10 Mold with frame set...……… ...……… ...………...…60

3.11 Tensile mould...……… .……… ...……….…….60

3.12 Hand proportioning, mixing, pouring and curing with two components...……..63

liquid reactive polyester resin system 3.13 Schematic of the composite consolidation...……… ...…..……….…….64

3.14 Mould coated by plastic...……… ...………..…..…….64

3.15 Gelcoat...……… ...………...……… …….……..65

3.16 Polyester Resin...………...……… ...……….………..65

3.17 Mixing the liquid composite...……… ...……….……….65

3.18 Liquid composites are poured into the mould cavity...……… ….…..…66

3.19 Mechanical cold press machine 100 Ton……… ...……….…67

3.20 Unfilled composite, moisture kenaf bast fiber and 20% kenaf bast fiber……....67

3.21 Cutting process...……… ...……… ...………..…68

3.22 Notching process...……… ...……… ...………...70

3.33 Notched impact’s specimen notch angle and depth of notch………...70

3.34 Water absorption test...……… ...……… ...………...73

3.35 The fibers are placed on the stage...……… ...……….75

4.1 Figure shows for all specimens...……… ...……….…..…..78

4.2 Kenaf bast fiber reinforce polyester composite..……… ...…….…….79

4.3 Kenaf core reinforce polyester composite...……… ...………….…...….80

4.5 Micrograph of kenaf core fiber...……… ...……….….82

4.6 Micrograph of kenaf bast fiber with 2000 x magnification...………...83

4.7 Micrograph of kenaf core fiber with 335 x magnification...……….…...…83

4.8 SEM fracture surface of kenaf bast fiber reinforce polyester composite……...84

4.9 SEM image of fracture surface of kenaf core fiber with polyester…………..…85

5.1 The non uniform dispersion composite………...………...87

5.2 Matrix-fiber deformation pattern..……… ...………88

5.3 The failure of the composite pallet specimens...……… ...…………..…91

5.4 Failure of unfilled composites...……… ...………...…92

5.5 Graph for tensile Strength vs. Volume Fiber Fraction for Kenaf Bast and...…93

Core Fiber Reinforced Composites. 5.6 Histogram graph for tensile Strength vs. Volume Fiber Fraction for Kenaf.…..95

Bast and Core Fiber Reinforced Composites. 5.7 SEM micrograph for kenaf core fiber.. ...……… ...………..….…….96

5.8 Graph for Stress vs. Strain for 20% fiber volume fraction of kenaf bast……….97

fiber reinforced composites shows the highest value of maximum force and modulus young. 5.9 Graph for Flexural Strength vs. Fiber Volume Fraction for Kenaf Bast and...99

Core Fiber Reinforced Composites 5.10 Histogram graph for Flexural Strength vs. Fiber Volume Fraction for...…...…100

Kenaf Bast and Core Fiber Reinforced Composites. 5.11 Graph for Impact Strength vs. Fiber Volume Fraction for Kenaf Bast and…...102

Core Fiber Reinforced Composites. 5.12 Histogram graph for Impact Strength vs. Fiber Volume Fraction for Kenaf….103 Bast and Core Fiber Reinforced Composites 5.13 Graph for Weigh Gain vs. Fiber Volume Fraction for Kenaf Bast and……...106

Core Fiber Reinforced Composites 5.14 Histogram graph for Weigh Gain vs. Fiber Volume Fraction for Kenaf……...107

reinforced composite

5.16 Flexural strength vs. fiber volume fraction for kenaf core and bast fiber…..…110 reinforced composite

LIST OF

TABLE

2.1 The characteristics of liquid resins for non electrical applications………..……27

2.2 MEKP Catalyst ratio...28

4.1 Number of specimens had been produced………...…….76

5.1 Data of Tensile Testing……….………..…….93

5.2 Table for data of graph Stress vs. Strain………..…….…97

5.3 Data of Flexural Testing………..…….…99

5.4 Data of Notched Charpy Impact Testing………...……..……...102

LIST OF ABBREVIATIONS, SYMBOLS, SPECIALIZED

FRIM - Forest Research Institute of Malaysia PMCs - Polymer–Matrix Composites

M - Mega Pa - Pascal

RHP - Rice Husk Powder

HDPE - High Density Polyethylene

KFRUPE - Kenaf Fiber Reinforced Unsaturated Polyester ASTM - American Standard Testing Material

UP - Unsaturated Polyester

MARDI - Malaysian Agricultural Research and Development Institute

ΔM(t) - % Water absorption Mo - Dry weight

Mt - Wet weight

CHAPTER 1

INTRODUCTION

1.1 Introduction to Kenaf

Kenaf or its scientific name Hibiscus cannabinus L is a warm season annual fiber crop closely related to cotton and jute. Historically, kenaf has been used as a cordage crop to produce twine, rope and sackcloth. Nowadays, there are various new applications for kenaf including paper products, building materials, absorbents and animal feeds. In Malaysia, realizing the diverse possibilities of commercially exploitable derived products from kenaf, the National Kenaf Research and Development Program has been formed in an effort to develop kenaf as a possible new industrial crop for Malaysia. The government has allocated RM12 million for research and further development of the kenaf-based industry under the 9th Malaysia Plan (2006–2010) in recognition of kenaf as a commercially viable crop.