ASSESSMENT OF CURRENT HYGIENIC

MANUFACTURING PRACTICES AND EVALUTION OF

ADDITIONAL FOOD PRESERVATIVES EFFECT

IN NAM PRIK MUSHROOM

BERLIAN PURNAMA SARI

DEPARTMENT OF FOOD SCIENCE AND TECHNOLOGY

FACULTY OF AGRICULTURAL ENGINEERING AND TECHNOLOGY

BOGOR AGRICULTURAL UNIVERSITY

STATEMENT LETTER OF MANUSCRIPT AND SOURCE

OF INFORMATION

I declare the truth that this manuscript entitled Assessment of Current Hygienic Manufacturing Practices and Evaluation of Additional Food Preservatives Effect in Nam Prik Mushroom is my own work with guidance of the advisors and has not been submitted in any form at any college, except Bogor Agricultural University and Prince of Songkla University. Sources of information derived or quoted from published and unpublished works of other authors mentioned in the text and listed in the list of references at the end of this manuscript.

ABSTRACT

BERLIAN PURNAMA SARI. Assessment of Current Hygienic Manufacturing Practices and Evalution of Additional Food Preservatives Effect in Nam Prik Mushroom. Supervised by DEDI FARDIAZ (Bogor Agricultural University); BENCHAMAPORN PIMPA, SOMWANG SONGSAENG, PARAMEE NOONIM (Prince of Songkla University, Suratthani Campus, Thailand).

Nam Prik Mushroom is ready-to-eat food product in Thailand which made from edible mushroom Schizophyllum commune with curry paste. It is produced by Chaiyo Farm, one of Thailand small-medium enterprise. Current hygienic and manufacturing practices in Chaiyo Farm and effectiveness of combination chemical food preservatives, propyl-paraben and calcium propionate, of Nam Prik Mushroom’s shelf life was assessed. Assessment of manufacturing practices at Chaiyo Farm resulted in total conformity of 25.83% based on Thailand Primary Good Manufacturing Practices. Propyl-paraben and calcium propionate did not influence pH, color, and water activity of Nam Prik Mushroom. The effectiveness combination of propyl-paraben and calcium propionate to extend the shelf life Nam Prik Mushroom was not proven. Either non-preserved or preserved Nam Prik Mushroom could not be accepted organically after 3 days storage at room temperature.

Keywords:

Manuscript

In the partial fulfillment of requirement for degree of Bachelor of Agricultural Technology

at

Departement of Food Science and Technology

ASSESSMENT OF CURRENT HYGIENIC

MANUFACTURING PRACTICES AND EVALUTION OF

ADDITIONAL FOOD PRESERVATIVES EFFECT

IN NAM PRIK MUSHROOM

BERLIAN PURNAMA SARI

DEPARTMENT OF FOOD SCIENCE AND TECHNOLOGY

FACULTY OF AGRICULTURAL ENGINEERING AND TECHNOLOGY

BOGOR AGRICULTURAL UNIVERSITY

PREFACE

Praise to The Lord for His mercy, bless, and love throughout the study in food science and finished this manuscript for partial fulfillment of bachelor degree.

1. In particular, I want to appreciate Mama, Papi, Mama Yan, Mama Yanti, Abang Yudha, Kokoh Opan, Cera, Julian, and all my family for their continuing encouragement.

2. I would like to grateful thank and deeply indebted to Prof. Dr. Ir. Dedi Fardiaz, MSc, my academic advisor in IPB; Assist. Prof. Dr. Benchamaporn Pimpa, Dr. Somwang Songsaeng, Dr. Paramee Noonim, my research advisors in Prince of Songkla University Suratthani-Thailand; for the welcome, advices, encouragement, valuable times, and for my report correction.

3. Grateful thank to Department of Food Science and Technology Bogor Agricultural University-Prince of Songkla University Suratthani, who had provide the student exchange program.

4. I am deeply thanks to Dr. Dra. Suliantari, MSi and Dr. Ir. Yadi Haryadi, MSc; for giving their valuable times and help to be my final examiner. 5. I would like to thank to Prof. Dr. Ir. Ratih Dewanti-Hariyadi, MSc; for

giving support and advices.

6. I am heartfelt thank to P’Boo and the gank for helping me in my research and the wonderful time together.

7. I am thanks to Ajarn Sutida, Ajarn Russel, P’ Pipe, and Ryan for caring and supporting me during stayed in Thailand.

8. I am deeply thanks to Brian, who had accompanied me in Thailand and gave me support every time.

9. Unforgetful, May, Tang, Pi, Dia, Tick, Mayae, Coy, Kim, Bird, and all my PSU friends, big thanks for the unforgettable moment that we had.

10.I am very thanks to Anela, Doni, and “Pitung & Kumpeni” Ririd, Astro, Sarlub, Nurhad for helping and supporting me until now. Also, thanks a lot to all my lovely friends ITP46, Sri Rahayu I lovers, Kosan Bidadari, and others.

Thank you very much!

TABLE OF CONTENT

LIST OF TABLE vi

LIST OF FIGURE vi

LIST OF APPENDIX vi

1. INTRODUCTION 1

1.1. Background 1

1.2. Research Objectives 2

2a. MATERIALS AND METHODS 3

Assessment of Current Hygienic and Manufacturing Practices 3

3a. RESULT AND DISCUSSION 5

Current Hygienic and Manufacturing Practices in Chaiyo Farm 5

4a. CONCLUSION & RECOMMENDATION 11

4a.1. Conclusion 11

4a.2. Recommendation 11

2b. MATERIALS AND METHODS 13

2b.1. Product Preservation Using Propyl-paraben and Calcium Propionate 13

2b.2. Analysis 13

2b.2.1. Sample Collection 13

2b.2.2. Physicochemical Analysis 14

2b.2.3. Microbiological Analysis 14

3b. RESULT AND DISCUSSION 17

Product Evaluation 17

4b. CONCLUSION & RECOMMENDATION 21

4b.1. Conclusion 21

4b.2. Recommendation 21

REFERENCES 23

APPENDIX 27

LIST OF TABLE

1 Percentage Conformity and Non-conformity of Chaiyo Farm GMP based on

Thai Primary GMP 5

LIST OF FIGURE

1 Chaiyo Farm’s Nam Prik Hed 1 2 Schizophyllum commune 2

LIST OF APPENDIX

1 Nam Prik Hed making process 27

2 Assessment checklist and corrective actions of Nam Prik Hed

production plant 28

3 Chaiyo Farm’s production building and manufacturing practices 34

4 Effect of preservative on physicochemical Nam Prik Hed 35 5 Total aerobic plate and total yeast & molds of Nam Prik Hed 35

6 Total aerobic plate count in PCA mediun 36

7 Total yeast and mold in MEA medium 36

8 Microbiological quality of processing plant, laminar flow, and packaging 37

9 Personal observation results 38

10 Hazard analysis 39

1. INTRODUCTION

1.1. Background

Nam Prik Mushroom is a ready-to-eat product that made from California fungi with chilli or curry paste. People eat Nam Prik Mushroom together with rice. Chaiyo Farm, one of Thailand small-medium enterprise, produces Nam Prik Mushroom in type of flavor, curry and chili paste. Texture of this food is soft and moist. After packaging, producer stores the product in a refrigerator. See Nam Prik Mushroom of Chaiyo Farm on Figure 1.

Producer displays Nam Prik Mushroom in a booth located on roadside, in front of Chaiyo Farm’s mushroom farm. One cup of Nam Prik Mushroom weighed is about 50 grams. Shelf life of Nam Prik Mushroom that Chaiyo Farm produced is only 3-4 days in refrigerator. This shelf life can be obtained when washing raw mushroom was being a part of Nam Prik Mushroom making process and product stored in a refrigerator.

California fungi (Schizophyllum commune) is shell-shaped (1-5 cm), thin, small, usually in groups. On upper surface, it has grey-brown to flesh-colored becoming white with dryness, downy-wolly. On lower surface, it appear as gilled, hymenium covering fan-like arranged (See figure 2). Schizophyllum commune is included in edible mushroom category. Initially, it was eaten in Assam, Congo, Peru, and Thailand, and used as chewing gum in Hong Kong, Indonesia, and Malaysia (Schimdt, 2006). In Chaiyo Farm, Schizophyllum commune is collected from their own farm not far from the production area.

Good Manufacturing Practices (GMP’s) means all production steps which

include: procedures, start from location, building, sanitation facilities, production equipment, material, processing, final product, laboratory, employee, packaging, labeling, storage and maintenance to prevent food contamination from food safety hazard (Indonesia Ditjen PPHP, 2009). It also control product quality standard in line to their specification and produce the product consistently (WHO,1997).

According to notification from the Thailand Ministry of Public Health

Thailand (NO 342) B.E. 2012, the requirements for implementation of GMP consist of: 1) location and building; 2) tools, machinery, and production equipments; 3) control of production process; 4) sanitation; 5) cleaning and maintenance; 6) personnel and employee hygiene. Chaiyo Farm shall implement

GMP’s to increase traditional producer’s revenue. Prior to implementation,

preliminary assessment of current manufacturing practices in Chaiyo Farm shall be carried out.

Propyl-paraben and calcium propionate are two food grade chemical compounds that act as food preservative. These food preservatives possibly can increase the shelf life of Nam Prik Mushroom because both of them are able to work at neutral pH. Propyl-paraben is stable at a broad pH range and heat stable during cooking process (Msagati, 2012). It is used at 100 to 1000 ppm (0.01 to 0.1%) in food (Ray,2005). Calcium propionate is able to work at higher pH values. Gram-negative bacteria are inhibited by propionate. However, it is not good to against yeast (Tucker, 2007). The maximum level to use it is 0.3% if it is used alone (Smith & Hong-Shum, 2011).

1.2. Research Objectives

This research aimed to assess current hygienic and manufacturing practices in the factory before GMP implemented in Chaiyo Farm. It was also carried out to measure an effect of additional propyl-paraben and calcium propionate in Nam Prik Mushroom.On the Insert tab, the galleries include items that are designed to coordinate with the overall look of your document. You can use these galleries to insert tables, headers, footers, lists, cover pages, and other document building blocks. When you create pictures, charts, or diagrams, they also coordinate with your current document look. You can easily change the formatting of selected text in the document text by choosing a look for the selected text from the Quick Styles gallery on the Home tab. You can also format text directly by using the other controls on the Home tab.

2a. MATERIALS AND METHODS

Assessment of current hygienic and manufacturing practices was carried out in November 17th 2013. Study location was in Chaiyo Farm, Suratthani, Thailand.

Assessment of Current Hygienic and Manufacturing Practices

This step aimed to provide information on the current hygienic and manufacturing practices adopted in the factory before the implementation of GMP. Assessment was carried out by an assessment checklist (see Appendix 2). Assessment checklist was prepared based on Primary GMP Thailand Guideline (Thailand Ministry of Public Health, 2012). A total of 35 Good Manufacturing Practices aspects based on the basic requirements was checked at the factory. There were three checklist points in assessment checklist, such as conformity (when the requirements were fully obeyed), non-conformity (when the requirements were partially obeyed or not obeyed), and not applicable. No-applicable points were not calculated in determining the percentage of conformity and non-conformity (Dias et.al., 2012).

3a. RESULT AND DISCUSSION

Current Hygienic and Manufacturing Practices in Chaiyo Farm

Chaiyo Farm has not fully implemented Primary GMP yet in processing of their product. From the assessment results, Chaiyo Farm production building reached 25.83% conformity based on Thailand basic requirements of Primary GMP (Table 1). Non-conformity of Chaiyo Farm’s production building and required corrective action are shown in Appendix 2. Limitation from this part was

researcher asked by producer and advisor’s assistant to participate in production

process. It aimed to accelerate Nam Prik Mushroom making process.

Table 1. Percentage Conformity and Non-conformity of Chaiyo Farm GMP based on Thai Primary GMP. Location and production buildings (10 aspects) 10 90 Tools, machinery, and production equipment

(3 aspects) 100 0

Control of production process (4 aspects) 20 80

Sanitation (5 aspects) 0 100

Cleaning and maintenance (3 aspects) 0 100

Personnel and employee hygiene (8 aspects) 25 75

AVERAGE 25.83 74.17

3a.1. Location and production buildings

Conformity of Chaiyo Farm’s manufacturing practices of Location and

Production Buildings assessed aspects (10%) was adequately lighting and

ventilation in production area for supporting employee’s performance. As much as

90% from 10 points assessed aspects was not complied with Thai Primary GMP.

See appendix 3 to know Chaiyo Farm’s production building and manufacturing

practices.

Chaiyo Farm’s processing area was a kitchen of processor’s house and

connected to residential areas. Everyone and pets could enter production building. There were birds, a cat, and a dog inside of production building in the production area. Near the production area, researcher found unused materials, such as washing machine, trash can, chairs, packaging materials, dish of pet, shoes rack,

and etc. Outside building’s floor was covered by any mosses. Building was right

beside a yard (soil). It also was near the road. It was exposed directly onto the road. There was no full-wall to cover it. Drained pipeline connected to public sewage pipelines was less good. Internal pipeline was not provided. The sanitation program was carried out at once per day after product processing.

mosses of the outside building’s floor, the yard, can be sources of contaminants. Location near the road and the wall not covered fully led production area exposed to high amount of dust. Inappropriate drained pipeline and unavailable internal pipeline can cause a puddle around production building. Sanitation program before production process will prevent any contamination to final product (Winarno & Surono, 2004).

Producer shall move unused materials (bird cages, chairs, shoes racks, food dogs, etc) from the processing area to other places. Processing building should be move to other area that not exposed of dust too much. Producer can build a new building or rent a house specially for product processing. A new building should be built for production area particularly (separated from residence). The sanitation program in the building shall be carried out before and after product processing. The production area shall be covered by full wall with adequate window, ventilation, and also give a door to enter the production area. Internal pipeline shall be built and extended to public sewage system. Producer also shall renovate drained pipeline (Thailand Ministry of Public Health, 2012).

Production lines and product flow should be designed to have an one direction or linear flow from raw materials to finished product (for example: from receiving, to storage, to preparation to, packaging). It aims to prevent cross contamination (CFIS, 2013).

3a.2. Tool, machines, and production equipment

Tool, machines, and production equipment aspects of Chaiyo Farm were about 100% complied Thai Primary GMP. Material of production equipments was appropriated. It was made from non-hazardous material, such as stainless steel. Tables and surface area were built by ceramics. It made easy to clean the equipments. Tools and equipments design were suitable for cooking process of Nam Prik Mushroom.

However, producer should change old equipment to the new one if frying pan had uneven surface. Contamination may be occurred from food residue which is left in it while inappropriate cleaning carried out. Tools and equipments shall be used only for production process. Producer shall use different tools and equipments for household purposes (Thailand Ministry of Public Health, 2012; Winarno & Surono, 2004).

3a.3. Control of Production Process

As much as 20% of Chaiyo Farm’s production process control was in line with Thai Primary GMP. Vessels for packaging and transportation of ingredients in food production were suitable. A cardboard was used for packaging vessel, whereas a large plastic bowl was used for transportation ingredients.

(without clean spoon). Packaging that used did not have sealed. Water used in the processing was not cleaned.

Washing or cleaning step is necessary to remove any contaminants of raw materials, such as soil (US FDA, 1996). Hand washing before handling production process prevent cross contamination from food handler to raw materials or final product. Less sanitation and inappropriate place for storing packaging cannot assure hygiene of packaging. Insect, rodent, and other pest can also contaminate packaging in storing place. High amount of dust will bring any contaminants to final product. Storing final product with raw materials and taking food sample by hand will cause the cross contamination of final product. Packaging without sealed can be open during transportation. It will enhance the risk of contamination to Nam Prik Mushroom during transportation to storing place or selling place.

There are several ways to minimize water absorption and reduce initial microbial load of mushroom, without disappearing washing step. Food handler can add soaking or blanching steps in the production process after washing step. Soaking step can be carried out with adding citric acid solution.

Citric acid is commonly used as acidulant in food and beverage industry. It is used not only as acidulant, but also as preservative (Hui & Khachatourians, 1995). Treatment with solution of 40 g/l citric acid for 10 minutes can be used to reduce initial microbial load. Adding citric acid in soaking water does not influence the taste of mushroom product.

Blanching process can decrease the amount of microbial, prevent enzymatic browning, induces contraction in size and air leaking. Blanching time of 150 seconds gave minimum volumetric shrinkage and weight loss. Enzymatic activity was not detected on this time. Fresh mushroom that has obtained this process can also be stored in the freeze temperature. (Vullioud et.al., 2011).

Producer should make an SSOP and SOP for her employee to make sure good sanitation and right procedures. A special place to store packaging material must be provided. Production and storage area shall be clean and sanitized every day. Cooling process should be carried out in enclosed area. Producer should provide a special refrigerator for storing final product. Food handler shall use a clean spoon to test the organoleptic of final product. Packaging should be changed to other type of packaging that has a sealed (Thailand Ministry of Public Health, 2012; Winarno & Surono, 2004).

3a.4. Sanitation

Chaiyo Farm’s sanitation did not comply with Thai Primary GMP as much

as 100%. Water used in the factory did not obtain any treatments or cleaning process. There was a trash can, but trash elimination system was not proper. Trash would be thrown per 3 days or more, depending on the amount of trash in can. Sanitation of toilet was inappropriate. Sink for hand washing was not available. There was no schedule for cleaning and sanitizing toilet. Waste water flowed to public sewage without going through internal pipeline.

ensure sanitation toilet. Waste water flowed without internal pipeline will litter the yard surface.

Producer shall be clean and treated according to government standards. Trash shall be thrown to laystall at least once per day. A cleaning and sanitizing schedule for toilet is needed. Producer shall provide a fully equipped hand washing sink in the production area, such as flowing water, hand dryer/ tissue, liquid soap, disinfectant dilution, and trash can with cover. Internal pipeline shall be built (Thailand Ministry of Public Health, 2012; Winarno & Surono, 2004).

3a.5. Cleaning and Maintenance

Cleaning and maintenance of Chaiyo Farm was not complied with Thai Primary GMP as much as 100% of 3 assessed aspects. The cleaning program was only done once per day after production process. There was no assessment and maintenance of tools and equipments. Producer stored chemical agent for cleaning production area in near the sink for cleaning raw materials, inside production area. Cleaning before starting production reduces dust or soil in the production building. Dust and soil are the source of microbial and its spore contamination. Assessment and maintenance of tools and equipments aims to maintain they work in good performance at all times. Chemical agent stored in production area has a risk to contaminate raw materials or food product.

The processor shall be clean production building before and after production process. The producer should provide the special equipment for cleaning production area that not used on other areas. The producer shall make a schedule for food handler to inspect and maintenance the tools and equipments. It shall be provide a special place for storing chemical agents that isolated from production area (Thailand Ministry of Public Health, 2012; Winarno & Surono, 2004).

3a.6. Personnel and employee hygiene

Chaiyo Farm’s personnel and employee hygiene was complied with Thai Primary MGP as much as 25% of 8 assessed aspects. Worker and personnel that enter production area were not infected any communicable or contagious disease. The owner always asked to the worker about her health. If she was sick or had contagious disease, she was not permitted to handle all the production process. She had to take a rest until she felt better. During that time, the owner took over the responsibility of food handler. Food handler did not wear jewelry while working and keep their hands and nails healthy and clean at all times.

As much as 75% of 8 personnel and employee hygiene assessed aspects were not conformed of the regulation. Food handler did not change her clothe with clean and proper clothe when she would enter production area. Food handler did not worn shoes. Food handler did not wash her hand after handling other things. There was no a SSOP to wash hands. Food handler did not use head covering at all times in the production area. Personnel smoking in the production area was still found. Visitor or other personnel could enter to production area without a specific rule.

way. Good hand washing procedure will decrease the risk of contamination from employee. Head covering has function to prevent hair falled into food product. Personnel or visitor with inappropriate behavior and without the specific rule when entering production area, increase the risk of contamination either physical or chemical.

4a. CONCLUSION & RECOMMENDATION

4a.1. Conclusion

Assessment of hygienic and manufacturing practices at Chaiyo Farm resulted in total conformity of 25.83% based on Thailand Primary Good Manufacturing Practices. Tools, machinery, and production equipment in the factory had complied with the regulation as much as 100%.

4a.2. Recommendation

2b. MATERIALS AND METHODS

This study was conducted in December 2nd until December 13th 2013. The study location was Chaiyo Farm, Suratthani, Thailand. All the samples that collected from Chaiyo Farm were analyzed in the laboratory of Food Technology, Faculty of Science and Industrial Technology, Prince of Songkla University, Suratthani and Hat Yai Campus, Thailand. Methodology used in the study consist of assessment, product preparation, sample collection, physicochemical analysis, microbiological analysis, and statistical analysis (Simon et.al., 2005). Physicochemical and microbiological were carried out per 3 storage days at room temperature (29oC).

2b.1. Product Preservation Using Propyl-paraben and Calcium Propionate

Three plastics of Schizophyllum commune (each plastic contains 1 kg mushroom) were taken out from refrigerator in mushroom farm office when production process would be started. Each mushroom was sliced to be a small piece. If rotten part of mushroom was founded, it was separated. Sorted mushroom was roasted for 10 minutes directly without washing process. When the time was attained, roasted mushroom was put in clean large bowl.

Afterwards, food handler prepared curry paste. Ingredients used in this process were salt, sugar, dried shrimp, garlic, onion, black pepper, green chili, dried red chili, lemon grass, turmeric, galingale, galangal, fish sauce, monosodium glutamate (MSG), and soy oil. All ingredients were crushed using a blender until smooth texture obtained.

Curry paste was fried with soybean oil until its color change and releasing delicious smell. Roasted mushroom was added in that frying pan. Stir-frying process was carried out for 30 minutes. A half of frying mushroom (1500 gram) was picked and cooled for 20 minutes in large plate. The rest of mushroom in the frying pan was added food preservatives, 750 ppm of propyl-paraben and 1500 ppm of calcium propionate. Prior to adding food preservatives into mushroom, it was diluted in 20 ml water. Frying was continued for 10 minutes. Fried mushroom with preservatives was picked and cooled for 20 minutes.

Cooled curry mushroom was packed into a small packaging that made from polyetilen (PE). It consisted of a cup and a cover. After packaging process was done, it already became curry Nam Prik Mushroom product. See appendix 1 to know curry Nam Prik Mushroom making process.

2b.2. Analysis

2b.2.1. Sample Collection

2b.2.2. Physicochemical Analysis

2b.2.2.1. Measurement of pH value

This value was measured by pH-meter Docu-pH+ meter®, model Sartorius. Before used, the calibration was carried out by buffered-water with pH value 4, 7, and 10. Each sample was weighed 1 gram and put into test tube. As much as 10 ml distilled water (1/10 w/w) was added, then mixed by spoon (Hocaoglu et.al., 2012). The measurement was carried out in 3 replicates.

2b.2.2.2. Water Activity

Every sample was measured for 5 times. The analysis was carried out by AquaLab® Model Series 3, Serial No. 01107060B. One time measurement used approximately 5 grams of sample. It put into a small plastic container and was placed to the instrument chamber. The measurement was conducted in five replicates (Aishah & Rosli, 2013).

2b.2.2.3. Color

Approximately 25 grams of sample at random was put into quartz pot. It was measured using MiniScan XE PLUS® Model No.45/0-L, Serial No. 7097.

This instrument defined colour numerically in terms of its lightness or “L” value

(black = 0, white = 100), “a” value (greenness 0 to -100, redness 0 to +100) and

“b” value (blueness 0 to -100, yellowness 0 to +100). Illuminant D65 and 10 Observer were used in the active view option. To measure the colour of product, took several spoon of it, placed on a glass cup, then click “Start” on the desktop of computer. The measurement was carried out as much as ten replicates for each sample (Kim et.al., 2005).

2b.2.3. Microbiological Analysis

2b.2.3.1. Media & Chemical

These analysis need several media and chemical: a. Butterfield’s Phospate-Buffered Dilution Water

Stock Phosphate Buffer Solution: As much as 34 g potassium dihydrogen phosphate, KH2PO4, was dissolved in 500 ml distilled water. The value of pH

solution should be adjusted to 7.2 with 1 N NaOH, and diluted to 1 liter. As much as 1.25 ml stock phosphate buffer solution was added. Volume of this solution brings to 1 liter with distilled water. Solution was dispensed in bottle that will provide 99 ml and/or 9 ml. Then, it was sterilized by autoclave at 121oC for 15 minutes (FDA, 2001).

b. Malt Extract Agar (MEA) Medium

Media that used in this study was ready-to-use media, Difco MEA. c. Plate Count Agar (PCA) Medium

d. Ringer Rinse Solution

To prepare Ringer solution, as much as 2.15 g sodium chloride, 0.075 g potassium chloride, 0.12 g calcium chloride, 0.5 g sodium thiosulfate were dissolved in distilled water up to 1 liter. The solution was sterilized in autoclave for 15 minutes, at 121oC (Askar & Treptow, 1993).

e. Alcohol 70% for sterilization hand of researcher. 2b.2.3.2. Preparation sample of final product

The microbial tests were carried out are total aerobic bacteria (Plate Count Agar) and total yeasts & molds (Malt Extract Agar). A cup of sample (30 grams) was taken and mixed it with sterile spoons or other utensils before withdrawing the analytical unit from a sample. As much as 25 grams sample was weighed aseptically. It put into sealed plastic bag. Dilution water (buffered-phospate water) 225 ml was added into plastic bag, then it stomached by hand. This became the 1:10 dilution. As much as 1 ml of the blended 1:10 dilution was added into a 9 ml dilution blank to make the 1:100 dilutions. This procedure was repeated to prepare serial dilutions of 1:1000. Then, it was shaken 25 times before used (Andrews et.al., 2003).

2b.2.3.3. Total Aerobic Plate Count ( FDA BAM Method: Aerobic Plate Count)

Dilutions were shaken. Each dilution was pipetted 1 ml into marked petri dishes. It was made duplicates of each dilution. Plate Count Agar 12-15 ml was poured to each plate. Sample dilutions and agar media was mixed uniformly. Let agar solidify. Solidified petri dishes was inverted and incubated promptly for 48 ± 2 h at 35°. Counts plates containing 25-250 colonies.

where:

N = Number of colonies per ml or g of product

∑ C = Sum of all colonies on all plates counted n1 = Number of plates in first dilution counted

n2 = Number of plates in second dilution counted

d = Dilution from which the first counts were obtained, (Maturin et.al., 2001). 2b.2.3.4. Total Yeasts and Molds (FDA BAM Method: Yeasts, Molds and

Mycotoxins Method)

Spread-plate method. Dilutions were shaken. Aseptically, as much as 0.1 ml of each dilution was pipetted on pre-poured solidified MEA agar plates. Inoculum was spread with a sterile bent glass rod. Each dilution was plated in duplicate. Plates were incubated in the dark (inside a cupboard on PSU Suratthani Laboratory) at 25°C for 5 days. Count plates containing 10-150 colonies.

where:

N = Number of colonies per ml or g of product (cfu/g)

n1 = Number of plates in first dilution counted

n2 = Number of plates in second dilution counted

d = Dilution from which the first counts were obtained, (Tournas et.al., 2001).

2b.2.3.5. Culture Settling Plate Technique

To measure the microbiological air quality of Chaiyo Farm processing area and laminar flow, media PCA and MEA were exposed on the air, in the processing area and laminar flow for 15 minutes. Then it was incubated as same as final product procedures. To calculate the number of microbial (total aerobic bacteria or total yeast & mold), formula below was used:

N = Caverage x 1 x 60 min x 168 hours x 1

15 min 1 hour 1 week plate wide (cm2) where:

N = Number of colonies per ml or g of product (cfu/week/cm2)

Caverage = Average of all colonies on two plates, (Salustiano et.al., 2003;

Obadina et.al., 2009). 2b.2.3.6. Rinsing Test

It used rinse method to determine microbiological quality of packaging. As much as 20 ml Ringer rinse solution was added to a packaging cup and recap it aseptically. The cup was shaken for 10 minutes. It was taken 1 ml of the rinse solution and put into a plate. It was carried out in two replicates. Desired medium (PCA and MEA) was poured into the plate as much as 15 ml. PCA plates were incubated promptly for 48 ± 2 h at 35°, whereas MEA plates were incubated in the dark at 25°C for 5 days.

To calculate the number of microbial (total aerobic bacteria or total yeast & mold), formula below was used:

N = Caverage x rinse solution volume

where:

N = Number of colonies per cup (cfu/cup)

Caverage = Average of all colonies on two plates, (Askar & Treptow,

1993).

2b.2.3.7. Personal observation

3b. RESULT AND DISCUSSION

Product Evaluation

3b.1. Physicochemical (See appendix 4)

3b.1.1. Color

There was no change significantly in color parameters (L*, a*, b*) of both non-preserved and preserved curry mushrom color during storage. A mean of color parameter L* value (lightness) of NP and P were 37.28 and 37.07. The mean of color parameter a* value (redness) NP and P were 9.50 and 9.66.

These results are in agreement with Batt and Tortello (2014). Addition of preservative will not affect the color of food product due to the nature of propyl- paraben and calcium propionate are colorless in solution.

3b.1.2. pH value

Non-preserved and preserved mushroom had no different pH value significantly on 0 storage day. While the product stored in packaging, proteolysis process might had happened. In food product that contains high protein, increasing of free amino acids content and ammonia in line with proteolysis. Proteolysis occurs may be due to action of Pseudomonas spp (Jaye et.al., 1962; in Mexis et.al., 2012). As a result of protein metabolism, pH value increased day after day (Fung & Crozier-Dodson, 2008). Their finding was similar to proteolysis of curry Nam Prik Mushroom. The increasing of pH value can be observed from the initial pH of non-preserved curry mushroom product, 5.98 to 6.7 after 3 days storage and 6.7 to 7.55 after more 3 days storage. For preserved curry mushroom, the increasing pH value after 6 days storage was slightly than 3 days storage. It was possibly caused by human error when prepared samples or cross-contamination during packaging process.

3b.1.3. Water activity

Adding preservatives did not affect the changes of water activity significantly on 0 storage day and during storage. Non-preserved mushroom had a mean of water activity as much as 0.948, whereas preserved mushroom had 0.938. It is in agreement with Davidson, 2002. He said preservatives do not significantly affect water activity.

3b.2. Microbiological (See appendix 5)

The microbiological analysis was carried out at 12 hours after the sample was taken from the seller. The results for microbiological analysis during storage from 2nd December 2013 until 13th December 2013 were showed in Appendix 5. 3b.2.1. Total Aerobic Count and Total Yeast & Mold

All results of total aerobic plate count were spreaders (See appendix 6). These spreaders were contamination by yeast colonies. Possibly, preservatives

(Obadina et.al., 2010). A number of yeasts and molds increased significantly on 3 days storage for both of samples (See appendix 7).

Calcium propionate is more effective to inhibit molds, little effective to inhibit bacteria, and no activity to against yeasts at pH 4.5, 6.0 or slightly higher for some foods (Furia, 1972). Besides, propyl paraben is more effective to against bacteria at pH 6.8 to 7.0 (Davidson et.al., 2005).

Microbiological quality of packaging product and the air of laminar flow had total aerobic plate count less than 1 cfu/cup and 1 cfu/week/cm2. The air in production plant had total aerobic plate count as much as 11 x 102 cfu/week/cm2 (see appendix 8). Total yeast and mold of the production plant air was spreader. Microbiological quality of production plant air, either total aerobic bacteria or total yeast & mold, was higher than 3 x 101 cfu/week/cm2- American Public Health Association (APHA) standards (Salustioano et.al., 2003).

From microbiological quality of packaging, the air of laminar flow and production plant; recontamination of final product could happen after cooking process. It was liked cooling final product in a room which has inappropriate air condition and inappropriate wrapping technique of final product. To prevent recontamination, producer should implement good handling and sanitary conditions. It also can reduce high initial microbial load of raw materials (Bates et.al., 2001). Fully covered production plant is necessary as well.

pH is very important factor affecting chemical preservatives activity such as weak organic acid. Weak organic acid activity is influenced by undissociated molecule or protonated form. Reduction pH of food can increase in the propotion of undissoated molecule (Davidson, 2002; Rico-Munoz & Davidson, 1983 in Davidson, 2002). Curry mushroom products, either non-preserved or preserved, had pH value on range 5.80-6.03 on 0 day storage. According to Marin et.al.(2002), 0,3 % calcium propionate did not perform inhibiting mold growth rate at pH 6.0. However at pH 4.5, calcium propionate activity was most effective to inhibit xerophilic molds at any aW level.

Propyl paraben defend inhibiting activity at a wide range of pH values. Up to pH 8.5, it maintains molecule to retain undissoated. One of factors affecting its activity is product composition. Food containing high fat will decrease propyl paraben activity due to it soluble in lipid phase. On the other word, it reduces the availability of propyl paraben to against microorganisms in water phase (Davidson, 2002; Davidson et.al., 2005; Lou &Yousef, 1999). It possibly decreased propyl paraben activity in curry paste mushroom product. Curry paste mushroom was added 5 tablespoons soybean oil while it was made.

3b.2.2. Personal Observation (See appendix 9)

Preservatives cannot optimally inhibited microorganisms on the product that contained high microbial load. Therefore, either product aroma of preserved or non-preserved curry mushroom decreased slightly and gave off-odor. Preserved and non-preserved curry mushroom cannot be accepted since 3 days storage.

4b. CONCLUSION & RECOMMENDATION

4b.1. Conclusion

Propyl-paraben and calcium propionate did not influence pH, color, and water activity of Nam Prik Mushroom. The effectiveness combination of propyl-paraben and calcium propionate to extend the shelf life of curry mushroom was not proven. Either non-preserved or preserved Nam Prik Mushroom could not be accepted organically after 3 days storage at room temperature (29oC).

4b.2. Recommendation

REFERENCES

Aishah, M.S., W.I. Wan Rosli. 2013. Effect of different drying techniques on the nutritional values of oyster mushroom (Pleurotus sajor-caju). Sains Malaysiana 42(7)(2013):937-941.

Andrews, Wallace H., Thomas S. Hammack. 2003. Bacteriological analytical manual chapter 1: food sampling and preparation of sample homogenate [internet]. [referred on August 16th 2013]. Available in:. www.fda.gov/Food/FoodScienceResearch/LaboratoryMethods/ucm063335.ht m.

Askar, Ahmed, Hans Treptow. 1993. Quality Assurance in Tropical Fruit Processing. Berlin: Springer-Verlag Berlin Heiderberg.

Bates, R.P., J.R. Morris, P.G. Crandall. 2001. Principles and Practices of Small-and-Medium Scale Fruit Juice Processing. Rome: FAO.

Batt, Carl A., Mary Lou Tortorello. 2014. Encyclopedia of Food Microbiology. London: Academic Press. ISBN: 978-0-12-384730-0.

Brennan, Martine H., T. Ronan Gormley. 1998. Extending the shelf life of fresh sliced mushrooms. Ballsbridge: Teagasc.

[CFIS] Canadian Food Assessment System. 2013. Food Retail and Foodservices Code. Canada: Alberta Health and Wellness.

Davidson, P. Michael. 2002. Control of Foodborne Microorganisms. Edited by Vijay K. Juneja & John N. Sofos. New York: Marcel Dekker, Inc.

Davidson, P. Michael, , John N. Sofos, A.L. Branen. 2005. Antimicrobials in Food, Third Edition. Edited by P. Michael Davidson, John N. Sofos, A.L. Branen. Boca Raton: CRC Press, Taylor & Francis Group.

Dias, Maria Angelica Costa, Anderson S. Sant’Ana, Adriano G. Cruz, Jose de

Assis F. Faria, Carlos Augusto Fernandes de Oliveira, Evandro Bona. 2012. On the implementation of good manufacturing practices in a small processing unity of mozzarella cheese in Brazil. Food Control 24 (2012) 199-205. doi: 10.1016/j.foodcont.2011.09.028.

[FDA] Food and Drug Administration. 2001. Bacteriological analytical manual: buffered-phosphatewater [internet]. [referred on August 15th 2013]. Available in : www.fda.gov/Food/FoodScienceResearch/LaboratoryMethods/ucm0612-08.htm.

Fung, Daniel Y. C., Beth Ann Crozier-Dodson. 2008. Tempeh, a mold modified indigenous fermented food. in Handbook of Fermented Functional Foods, Second Edition. editor: Edward R. Farnworth. Boca Raton: CRC Press.

Furia, T.E. 1972. CRC Handbook of Food Additives 2nd Edition Volume I. Danvers: CRC Press LLC.

Hui, Y.H., George G. Khachatourians. 1995. Food Biotechnology: microorganisms. Canada: Wiley-VCH.

Hocaoglu, Ash, Ahmet Sukru Demirci, Tuncay Gumus, Mehmet Dermici. 2012. Effects of gamma irradiation on chemical, microbial quality, and shelf life of shrimp. Radiation Physics and Chemistry 81 (2012) 1923-1929.

Commodities. New York: Kluwer Academic/ Plenum Publishers. eISBN: 0-306-48676-8.

[Indonesia Ditjen PPHP] Indonesia Direktorat Jenderal Pengolahan dan Pemasaran Hasil Pertanian. 2009. Guideline of Good Manufacturing Practices of Agricultural Product. Jakarta: Direktorat Mutu dan Standarisasi, Departemen Pertanian.

Jaye, M., Kittaka, R. S., Ordal, Z. J. 1962. The effect of temperature and packaging material on the storage life and bacterial flora of ground beef. Food Technology, 16, 95-98.

Kim, Ki Myong, Jung A Ko, Jin Sil Lee, Hyun Jin Park, Miford A. Hanna. 2005. Effect of modified atmosphere packaging on the shelf-life of coated whole and sliced mushrooms. LWT 39 (2006) 364-371.

Lohano, Dileep Kumar, Saghir Ahmed Sheikh, Muhammad Shahnawaz. 2010. Effect of chemical preservatives on the shelf life of bread at various temperatures. Pakistan Journal of Nutrition 9 (3): 279-283, 2010. ISSN: 1680-5194.

Lou, Y., A.E. Yousef. 1999. Listeria, Listeriosis, and Food Safety; Second Edition, Revised, and Expanded. Edited by Elliot T. Ryser & Elmer H. Marth. New York: Marcel Dekker, Inc.

Marin, S., M.E. Guynot, P. Neira, M. Bernado, V. Sanchis, A.J. Ramos. 2002. Risk assessment of the use of sub-optimal levels of weak-acid preservatives in the control of mould growth on bakery products. International Journal of Food Microbiology 79 (2002) 203-211.

Maturin, Larry, James T. Peeler. 2001. Bacteriological analytical manual chapter 3 aerobic plate count [internet]. [referred on August 13th 2013]. Available in:.www.fda.gov/Food/FoodScienceResearch/LaboratoryMethods/ucm063346 .htm.

Mexis, S.F., E. Chouliara, M.G. Kontominas. 2012. Shelf life extension of ground chicken meat using an oxygen absorber and a citrus extract. LWT- Food Science and Technology 49 (2012) 21-27. doi: 10.1016/j/lwt.2012.04.012. Msagati, Titus A. M. 2012. Chemistry of Food Additives and Preservatives. John

Willey & Sons Ltd. antimicrobial activity of phenolic antioxidants. Journal Food Science 48:1284-1288, 1983.

Saranraj, P., M. Geetha. 2012. Microbial Spoilage of Bakery Products and Its Control by Preservatives. International Journal of Pharmaceutical & Biological Archives 2012; 3(1):38-48. ISSN: 0976-3333

Schimdt, Olaf. 2006. Wood and Tree Fungi; Biology, Damage, Protection, and Use. Heidelberg: Springer.

Simon, Ana, Elena Gonzales-Fandos, Vanesa Tobar. 2005. The sensory and microbiological quality of fresh sliced mushroom (Agaricus bisporus L.) packaged in modified atmospheres. International Journal of Food Science and Technology 2005, 40, 943-952. doi: 10.1111/j.1365-2621.2005.01028.x. Smith, Jim, Lily Hong-Shum. 2011. Food Additives Data Book. Great Britain:

Blackwell Publishing Ltd. 0-632-06395-5.

Thailand Ministry of Public Health. 2012. RE: Manufacturing Procedures, Production Equipment and Appliance, and Food Storage of Pre-packaged Processed Foods. Thailand Ministry of Public Health, (NO 342) B.E. 2012. Tournas, Valerie, Michael E. Stack, Philip B. Mislivec, Herbet A. Koch, Ruth

Bandler. Bacteriological analytical manual chapter 18 yeasts, molds and mycotoxins [internet]. [referred on August 13th 2013]. Available in:. www.fda.gov/Food/FoodScienceResearch/LaboratoryMethods/ucm071435.ht m.

Tucker, Gary S. 2007. Food Biodeterioration and Preservation. Blackwell Publishing.

[US FDA] United States of America Food and Drug Administration. 1996. 21 CFR (Code of Federal Regulations) part 110, current good manufacturing practices in manufacturing, packing, or holding human food [internet]. [referred on November 13th 2013]. Available in:. www.access-data.fda.gov/scripts/cdrh/cfdocs/cfcr/CFRSearch.cfm?CFRPart=110.

Vullioud, M.B., R. Rusalen, A. De Michelis. 2011. Blanching process of oyster mushrooms (Pleurotus ostreatus) and its effect on parameters of technological interest in Argentina. Micología Aplicada International, vol. 23, núm. 2, 2011, pp. 47-53, Colegio de Postgraduados México. ISSN: 1534-2581.

[WHO] World Healt Organization. 1997. A WHO guide to good manufacturing practice (GMP) requirements. Geneva: WHO.

MBRIO Press.

Wholefoods Market. 2013. Winter holiday menu 2013, heating instructions [internet]. [reffered on January 21th 2015]. Available in: www.wholefoodsmarket.com/sites/default/files/media/Stores/A-C/CIR/Holiday _13_Heating%20Instructions.pdf.

Winarno, F.G. 2012. HACCP and Its Implementation in Food Industry. Bogor: MBRIO Press.

APPENDIX

Appendix 1. Nam Prik Mushroom making process

Mushroom from refrigerator

Sorting

Roasting (10 minutes)

Stir-frying (30 minutes) Curry paste Soy oil

Cooling (20 minutes) Food preservative added,

Frying continued (10 minutes), Cooling (20

minutes)

Packaging

Preserved Nam Prik Mushroom

Packaging

Appendix 2. Assessment checklist and corrective actions of Nam Prik Mushroom production plant.

No. Assessed

Aspects

The Requirements C NC NA Corrective Actions

1. Location and production buildings

1.1. Buildings and their surrounding locations shall be clean and free from accumulated, unused materials, including those which may attract animals, insects, and/or pathogenic microorganisms.

There were chairs, washing machine, food dog, shoes racks, trash can.

Producer shall move unused materials from the processing area to other place.

1.2. Buildings shall be located away from areas that are exposed to high amounts of dust.

Location of processing building/area was near roadway.

Processing building should be move to other area that not exposed of dust too much. 1.3. Buildings shall not be located near any repugnant areas. Building was right

beside a yard (soil).

There were any mosses around outside public sewage pipelines. In the case that food production buildings are located in unsuitable areas and do not adhere to phrases 1.1.1‐ 1.1.4, there shall be standard measures in place to protect food products from, and eliminate insects and other carriers of infection and dust, as well as other sources of contamination.

Drained pipeline connected to public sewage pipelines was less good.

Renovate drained pipeline

1.5. The production building and surrounding area shall be clean and maintain in good sanitation.

The sanitation program was carried out at once per day after product processing

The sanitation program shall be carried out before and after product processing

1.6. Buildings and production areas shall maintain in good sanitation by eliminating all unused or irrelevant materials from production areas.

There were bird cages, chairs, shoes racks, food dogs, etc.

These materials shall be move from production areas.

1.7. Production areas shall be isolated from residential areas. Production area was a kitchen of producer’s house.

Producer shall build a new building, special for production area.

1.8. All production areas shall have adequate lighting and ventilation for employees to be able to work to their

No. Assessed Aspects

The Requirements C NC NA Corrective Actions

highest potential.

1.9. Internal pipeline shall be provided to remove all waste water from manufacturing processes to the public sewage system.

Internal pipeline was not provided.

Internal pipeline shall be built and extended to public sewage system.

1.10. Protective measures shall be provided ensuring that no animals or insects pass through the production area or come in contact with food products.

There was no

The production area shall be covered by full wall with adequate window, lighting, considering contamination may be occurred and ease and thoroughness all over of cleaning for equipment, tools and install area.

√

2.2. Production vessels or equipment which come into contact with food shall be made of non‐ hazardous materials, cause no harm to consumers and be easy to clean.

√

2.3. Tables and surfaces used during food production shall be made of non‐ rusting materials, be easy to clean, not react with food products and not be harmful to consumers’ health. Specifically, the production area should have tables and surfaces of suitable height for ease of cleaning, to If food additives will be used, it is necessary to follow the notification from the Thailand Ministry of Public Health, Re: Food Additives.

Washing raw mushroom step was removed from production process.

No. Assessed Aspects

The Requirements C NC NA Corrective Actions

3.2. Every step involving raw materials and production ingredients including receiving, transferring, preparation, production, packaging, and transportation shall be controlled in good sanitation.

Food processor did not wash her hands before

Producer should make an SSOP and SOP for her employee to wash her hands before and after working in preparation, production, and packaging process.

There is a special place to store packaging material.

Production and storage area shall be clean and sanitized every day.

3.3 Vessels for packaging and transportation of ingredients in food production shall be suitable and shall not contaminate food products.

√

3.4. Water to be used in food production and processing shall be clean and of good quality as defined by the Thailand heading content food products shall be complied with the notification from the Thailand Ministry of Public Health, Re: Ice and Drinking Water and their Sanitary Utilization.

√

3.6. Production, storage, transfer, and transportation methods of food products shall protect food products from

Product was stored in refrigerator with other foods and raw materials.

Processor took the final product for

Cooling process should be carried out in enclosed area.

Producer should provide a special refrigerator for storing final product.

Food handler shall use a clean spoon to test the organoleptic of final product.

No. Assessed Aspects

The Requirements C NC NA Corrective Actions

sensory testing by her hands.

Packaging that used did not have sealed.

changed to other types of packaging that has a sealed.

4 Sanitation 4.1. Any water used in the factory shall be clean and treated according to government standards.

There were no cleaning and treatment for any water used in the factory.

Producer shall be clean and treated according to government standards. 4.2. Adequate amounts of lidded trash cans and proper trash

elimination systems for all types of trash must be available.

Trash elimination system was not proper.

Trash shall be thrown to a laystall or recycle as soon as possible.

4.3. There must be an adequate number of toilets and sinks proportional to the number of workers, and these facilities must be maintained in sanitary conditions. It should be regularly ensured that all sinks and toilets are in proper working order. Sinks for hand washing shall be fully equipped. Toilets shall be isolated from production areas and should not be directly exposed to production areas.

Sanitation of toilet was inappropriate.

Sink for hand washing was not available.

There was no schedule for cleaning and

A cleaning and sanitizing schedule for toilet is needed.

4.4. Adequate amounts of fully equipped hand washing sinks in the production area must be provided.

There was no hand washing sink at all.

- Producer shall provide a fully equipped hand washing sink (with hand dryer/ tissue, liquid soap). 4.5. Proper and effective sewage systems for waste water well as

dirt gutters for waste material which will not contaminate any part of the food production process or food products, must be instated.

Waste water flowed to public sewage without going through internal pipeline.

The cleaning program was only done once per day after production process.

The processor shall be clean production building before and after production process.

5.2. Tools, machinery and production equipment shall be inspected and maintained for efficient use at all times.

There was no assessment and maintenance of tools and equipments

The producer shall make a schedule for food handler to inspect and maintenance the tools and equipments. 5.3. Chemical agents for washing and/or chemicals for

production shall be stored and used under safe conditions

The producer store chemical agent for

No. Assessed Aspects

The Requirements C NC NA Corrective Actions

and be isolated from production areas. Additionally, they must all have clear, correct labeling.

cleaning production area in near the sink inside production area.

chemical agents that isolated from production area.

6 Personnel and employee hygiene

6.1. Workers and personnel in production areas shall not be infected with any communicable or contagious disease as prescribed in the Ministerial regulation, or have any wound which may contaminate equipment or food products.

√

6.2. Wear clean and proper clothes, suitable for work. If a coat is worn, it shall also be clean.

Food handler did not clean and proper clothe for food handler every day.

A SSOP for changing production facility, or place shoes in sanitizing chemical before entering the production facility to prevent contaminants from entering the facility.

Food handler did not worn shoes.

Producer shall provide shoes to be worn in the production facility.

6.4. Shall not wear jewelry while working and keep their hands and nails healthy and clean at all times.

√

6.5. Shall keep clean nails and wash their hands and nails before work and after any kind of contamination.

- Food handler did not

6.6. Shall wear a hat, head covering, or hairnet at all times in the production facility.

Food handler did not use head covering at all times in the production area.

Head covering shall provide and use while food handler is in the production area. 6.7. All workers and personnel shall be warned against and

prevented from expressing inappropriate behavior in the production facility. Such behavior includes smoking and spitting.

Personnel who smoking in production area was still found.

No. Assessed Aspects

The Requirements C NC NA Corrective Actions

6.8. All workers and personnel not involved with food production shall adhere to procedures like food handlers when in the production facility.

Visitor or other personnel can enter to production area without a specific rule.

The producer shall implement a rule (SOP) for all workers/ personnel/ visitors that want to enter the production area.

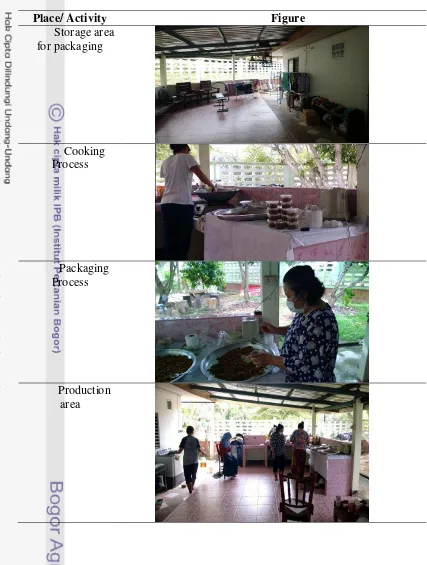

Appendix 3. Chaiyo Farm’s production building and manufacturing practices.

Place/ Activity Figure

Storage area for packaging

Cooking Process

Packaging Process

Appendix 4. Effect of preservative on physicochemical Nam Prik Mushroom.

Appendix 6. Total aerobic plate count on PCA medium.

Sample Storage Periode at 29oC (days)

0 3 6

Preservative

Non-preservative

Appendix 7. Total yeast and mold in MEA medium.

Sample Storage Periode at 29oC (days)

0 3 6

Preservative

Appendix 8. Microbiological quality of processing plant, laminar flow, and packaging.

Place MEA PCA

Processing Plant of Chaiyo Farm

Packaging Product

Appendix 9. Personal observation results. Storage

Periode at 29oC (days)

Preserved Non-preserved Information

0

Red arrow showed mold appearance. Blue arrow

showed the slime on mushroom surface.

3

Appendix 10. Hazard Analysis.

No. Process Step Hazard Hazard Source Hazard Potential Significance Preventive Action

Chance Severity

1 Receiving raw California fungi

B: L. monocytogenes, TPC, S. aureus

C: aflatoxin Medium High S Apply specification

P: soil Medium Low NS

3 Receiving ingredients and packaging

B: -

C: banned food ingredient Supplier was not supervised

5 Storing spices B: TPC, mould Bacteria and mould growth as consequence from prior contamination

High Medium S SSOP implementation

C: aflatoxin Medium High S

10 Mixing raw materials and ingredient

B: - C: - P: -

11 Heat treatment B: L. monocytogenes, S. aureus, yeast

Heat treatment failed High High S Heat treatment use exact time and temperature

C: - P: -

12 Cooling B: S. aureus,yeast, mold Recontamination from the air and environment

High High S Cooling final product in enclosed and sanitized area C: -

P: -

13 Packing/ Labeling B: pathogen Air, food handler Low Medium NS SSOP implementation C: -

P: -

14 Storing final product B: S.aureus Recontamination from food handler at packing process and storing at room temperature

High High S Refrigeration

C: Staphylococcus enterotoxin P: -

15 Distribution B: pathogen Recontamination when packaging is open accidentally

Medium Medium NS - SOP implementation

- Changing packaging material

Appendix 11. Critical Control Point Determination

AUTHOR BIOGRAPHY

Berlian Purnama Sari was born in Banjarmasin, on December 1st 1990. She is the third child of Maskun Effendi Hasim and Normawati. She became a student in 3 Senior High School Jakarta. Since 2009, she was registered as a bachelor degree student in Food Science and Technology Department, Faculty of Agricultural Technology, Bogor Agricultural University (IPB), West Java- Indonesia.