UNIVERSITI TEKNIKAL MALAYSIA MELAKA

MECHANICAL AND THERMAL PROPERTIES OF PURE NICKEL

AS AN ALTERNATIVE AUTOMOTIVE BODY MATERIAL

This report submitted in accordance with requirement of the Universiti Teknikal Malaysia Melaka (UTeM) for the Bachelor Degree of Manufacturing Engineering

(Engineering Materials) with Honours

By

GAN BEE GEOK

DECLARATION

I hereby, declared this report entitled “Mechanical and thermal properties of pure nickel as an alternative automotive body material” is the results of my own research

except as cited in references.

Signature :

Author’s Name : GAN BEE GEOK

APPROVAL

This report is submitted to the Faculty of Manufacturing Engineering of UTeM as a partial fulfillment of the requirements for the degree of Bachelor of Manufacturing Engineering (Engineering Materials) with Honours. The member of the supervisory committee is as follow:

………

ABSTRACT

ABSTRAK

DEDICATION

ACKNOWLEDGEMENT

TABLE OF CONTENTS

1.5 Organization of Report 3

2. LITERATURE REVIEW 5

2.1. Introduction 5

2.2. Nickel 5

2.2.1. Commercially Pure Nickel 8

2.2.2. Corrosion properties of Pure Nickel 11

2.2.3. The applications of Nickel 11

2.2.4. Health Effects of Nickel 12

2.3. Current Automotive Body Material 13

2.3.1. Steel 15

2.3.1.1. High Strength Steel 15

2.4. Alternative Material for Automotive Body Materials 17

2.4.1. Aluminium 17

2.4.2. Magnesium and its Alloys 19

2.4.2.1. Common Magnesium Alloys 19

2.4.3. Polymers and Composites 20

2.4.4. Comparison Cost and Hardness of Pure Nickel and Current

Automotive Body Materials 21

3. METHODOLOGY 23

3.4.1. Test Specimen Condition 26

3.4.2. Procedure 27

3.5. Mechanical Testing 27

3.5.1. Tensile Test 28

3.5.1.1. Test Machine 28

3.5.1.2. Test Sample 29

3.5.1.3. Test Method for Tensile Test 29

3.5.2. Hardness Test 30

3.5.2.1. Test Machine 30

3.5.2.2. Test Sample 31

3.5.2.3. Test Procedure 32

3.6. Corrosion Test 32

3.6.1. Test Equipment and Specimen 32

3.6.2. Test Method 33

3.7. Crystallographic Analysis 33

3.8. Composition Analysis 34

3.8.1. Scanning Electron Microscope 34

3.9. Summary 35

4. RESULTS & DISCUSSIONS 36

4.1. Introduction 36

4.2. Mechanical Testing 36

4.2.1. Hardness Analysis 37

4.2.2. Tensile Analysis 38

4.3. Corrosion Test 42

4.4. Composition Analysis 45

4.4.1. Energy Dispersive X ray Analysis 45

4.5. Crystallographic Analysis 46

4.5.1. X-Ray Diffraction Analysis 46

4.6. Summary of Mechanical Properties and Chemical Properties of

Pure Nickel in Different Annealing Temperature 51 4.7. Comparison mechanical properties of both of Annealed Pure Nickel

and Current Automotive Body Material. 52

4.7.1. Corrosion Resistance of Automotive Body Materials 52

5. CONCLUSION AND FUTURE WORK 54

C. Yield Strength Finding 63

LIST OF TABLES

TITLE PAGE

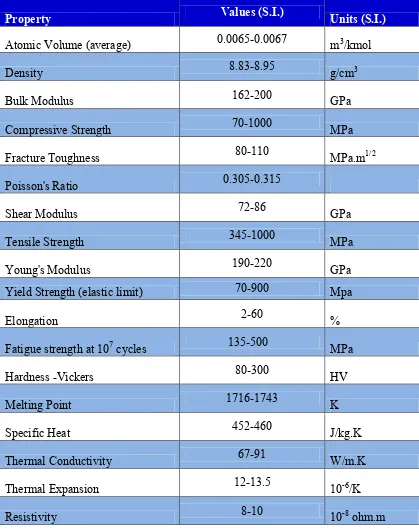

Table 2.1 Chemical, Mechanical and Thermal Properties of Nickel 7

Table 2.2 Chemical Composition of Nickel Alloy 8

Table 2.3 Room Temperature Mechanical Properties and Physical Properties of Commercially Pure Nickel and Low Alloy Nickel

9

Table 2.4 Description and Major Applications of Commercially Pure Nickel

10

Table 2.5 Results Of Atmospheric Corrosion And Pitting Of Nickel-Base Alloy of 20-Year Exposure 24.4m From Ocean At

Table 2.7 Material Properties of Various Steels 16

Table 2.8 Automotive Aluminium alloys in Current Use 18

Table 2.9 Common Automotive Magnesium Alloys 19

Table 3.1 Number of Samples 26

Table 3.2 Annealing Condition of Pure Nickel 27

Table 3.3 The Dimensions of the Specimen 29

Table 4.1 Hardness Result of Pure Nickel with Different Annealing Temperature

37

Table 4.2 Ultimate Tensile Strength, Young Modulus and Yield Strength of Pure Nickel in Different Annealed Temperature

39

Table 4.3 Results of Corrosion Analysis by using Tafel Extrapolation Technique

Table 4.4 Theoretical XRD Lattice Parameter of Pure Nickel 47 Table 4.5 Comparison between Theoretical and Experimental of

Interplanar Spacing of Non-heat treated Pure Nickel.

47

Table 4.6 XRD Lattice Parameters Comparison 48

Table 4.7 The Grain Size Range of Non- heat Treated and Annealed Pure Nickel

48

Table 4.8 Mechanical and Chemical Properties of Pure Nickel at Different Annealed Temperature for 1 Hour

51

LIST OF FIGURE

TITLE PAGE

Figure 2.1 Nickel in Various Form 6

Figure 2.2 The Galvanic Series of Metals 11

Figure 2.3 Graph of Price Against Hardness Between Pure Nickel and Current Automotive Materials

21

Figure 3.1 Flow Chart of Methodology 24

Figure 3.2 Image of diamond cutter 25

Figure 3.3 Image of horizontal band saw 25

Figure 3.4 Image of CWF-1300 Furnace 27

Figure 3.5 Image of Universal Testing Machine 28

Figure 3.6 Image of tensile testing specimens dimension and shape 29 Figure 3.7 Micro Vickers Hardness Testing Machine 30 Figure 3.8 Image of Metkon FinoPress Automatic Mounting Press 31

Figure 3.9 Buehler Grinder and Polisher 31

Figure 3.10 Buehler grinder polisher 31

Figure 3.11 The EuroCell 32

Figure 3.12 Image of X-Ray X-Ray Diffractormeters 33 Figure 3.13 Image of Scanning Electron Microscopy 34

Figure 4.1 Indentation of Diamond Pyramid Indenter with A 90° Angle Between Opposite Faces. Image Is Magnified At 50x

37

Figure 4.2 Graph of Hardness against Annealing Temperature 38 Figure 4.3 Graph of Ultimate Tensile Strength against Different

Annealing

39

Figure 4.4 Graph of Yield Strength against Different Annealing Temperature of Pure Nickel

Figure 4.5 Graph of Young’s Modulus in Different Annealing Temperature of Pure Nickel

40

Figure 4.6 Graph of Tensile Stress against Elongation of Pure Nickel In Different Annealing Temperature

41

Figure 4.7 Tafel graph for non- heat treated and 300°C pure nickel 42 Figure 4.8 Tafel graph for 500°C and 700°C annealed pure nickel 43 Figure 4.9 Graph of Corrosion Rate against the Different Annealing

Temperature

44

Figure 4.10 Data Obtained from EDX for Non Heat Treated and Annealed Pure Nickel

45

Figure 4.11 Results Obtained from X -Ray Diffraction 46 Figure 4.12 Intensity of Non- heat Treated and Different Annealed

Temperature of Pure Nickel

LIST OF ABBREVIATIONS

ASTM - American Society for Testing Material CFRP - Carbon Fiber Reinforce Polymer ECAP - Equal- Channel Angular Pressing

EDX - Energy Dispersive X-Ray

FCC - Face Centered Cubic

FKP - Falkuti Kejuruteraan Pembuatan

GMT - Glass Mat Thermoplastic

HSS - High Strength Steel

HV - Vickers Hardness

SEM - Scanning Electron Microscopy

UTEM - Universiti Technikal Malaysia Melaka

UTM - Universal Testing Machine

UTS - Ultimate Tensile Strength

CHAPTER 1

INTRODUCTION

1.1 Introduction

1.2 Problem Statement

Due to the increasing demand of high quality exterior panels, better functional properties and lower weight in the automotive industry, the researches on different materials have been conducted to alternate the existing automotive body material. One of the changes is due to the weight deduction. Therefore, automotive body materials change from steel to aluminium. The weight of the steel is higher than aluminium but the cost of the steel is lower than aluminium. This is due to the weight of the automotive body will affect the energy consumption of the automotive. Therefore, researches on lightweight material have been conducted to achieve fuel efficiency. Cui, X.T.et al,(2007)stated that approximately 40% of the weights of the

1.3 Objectives

The objectives of this project are:

To study the mechanical properties and corrosion test of pure nickel at

This project involves the study of different annealing conditions for pure nickel of their mechanical properties and thermal properties. Apply pure nickel as an alternative automotive body by study the mechanical and chemical properties of pure nickel at different annealing temperature .This project consists of the comparison between pure nickel and current automotive body material. An experiment on mechanical and chemical studies with thermal effect of pure nickel has to be conducted. Thermal properties will be studied by doing annealing in different temperature. Mechanical studies include tensile and hardness test. Chemical study include corrosion test was carried out to obtain the corrosion rate of pure nickel in different annealing temperature.

1.5 Organization of the Report

The whole report is divided into six major parts, which is known as Introduction, Literature Review, Methodology, Results, Discussion, and Conclusion and future work.

Basically, each of the content of each chapter is;

Chapter 1 : Introduction

the project with material properties and techniques involved to study the suitable alternative material for automotive body.

Chapter 2: Literature Review

In this chapter, any information which is related to the project is studied and summarized. The source of the information can be from journals, books, internet, articles and etc. Based on the information from past studies and research, it will guide a correct path for the success of the project.

Chapter 3 : Methodology

It describes overview of the research methods to conduct the various experiments. It provide the details of introduce the test to be conduct; the function of the machine and the details of the specimens and the parameter to be used for the experiments.

Chapter 4: Results

It states all the results such as tables, figures and graphs when research carrying out. All the important findings will be presented in a comprehensive way. It also analyzes the results statistically.

Chapter 5: Discussion

Discuss the results obtain and compare with the current automotive body material. Besides, comparison of finding between theoretically and practically practices.

Chapter 6 : Conclusion

CHAPTER 2

LITERATURE REVIEW

2.1. Introduction

This chapter consists of information related to the study of pure nickel, current automotive body materials and comparison properties between pure nickel and current automotive body material. This chapter introduces the history of current automotive materials and the changes occurring. Besides, this chapter discuss about the mechanical and chemical properties of pure nickel with respect to thermal effect. Also the possibility of replacing the current automotive body materials proposed based on the work done by others.

2.2. Nickel

resistance. Nickel is reacting with all acids except concentrated nitric acid. Nickel is not influenced by alkaline. It is a conductor of heat and electricity. The chemical, mechanical and thermal properties of nickel are shown in Table 2.1. Figure 2.1 show the difference size and various forms of nickel.

Table 2.1: Chemical, mechanical and thermal properties of nickel CES EduPack, (2009).

Property Values (S.I.) Units (S.I.)

Atomic Volume (average) 0.0065-0.0067 m3/kmol

Density 8.83-8.95 g/cm3

Bulk Modulus 162-200 GPa

Compressive Strength 70-1000 MPa

Fracture Toughness 80-110 MPa.m1/2

Poisson's Ratio 0.305-0.315

Shear Modulus 72-86 GPa

Tensile Strength 345-1000 MPa

Young's Modulus 190-220 GPa

Yield Strength (elastic limit) 70-900 Mpa

Elongation 2-60 %

Fatigue strength at 107 cycles 135-500 MPa

Hardness -Vickers 80-300 HV

Melting Point 1716-1743 K

Specific Heat 452-460 J/kg.K

Thermal Conductivity 67-91 W/m.K

Thermal Expansion 12-13.5 10-6/K