See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/257942463

Supplier selection using revised multi-segment

goal programming model

Article in International Journal of Advanced Manufacturing Technology · February 2014 DOI: 10.1007/s00170-013-5368-0

CITATIONS

7

READS

92

2 authors, including:

Some of the authors of this publication are also working on these related projects:

Inverse Center Location Problem on a Tree View project

Incomplete Hub Location Problems View project Hossein Karimi

University of Bojnord

33PUBLICATIONS 126CITATIONS

SEE PROFILE

All content following this page was uploaded by Hossein Karimi on 23 February 2015.

1 23

The International Journal of

Advanced Manufacturing Technology

ISSN 0268-3768

Volume 70

Combined 5-8

Int J Adv Manuf Technol (2014)

70:1227-1234

DOI 10.1007/s00170-013-5368-0

Supplier selection using revised

multi-segment goal programming model

1 23

Your article is protected by copyright and

all rights are held exclusively by

Springer-Verlag London. This e-offprint is for personal

use only and shall not be self-archived

ORIGINAL ARTICLE

Supplier selection using revised multi-segment

goal programming model

Hossein Karimi&Alireza Rezaeinia

Received: 5 November 2011 / Accepted: 27 September 2013 /Published online: 18 October 2013 #Springer-Verlag London 2013

Abstract Selecting the best supplier has been turned into a strategic subject in the competitive market, in the recent years. Supplier selection is one of the significant multiple criteria decision-making problems, which is studied in this paper. This research applies the multi-segment goal programming formula-tion, which considers different positions in the goal program-ming. This new kind of goal programming is revised in this investigation. The advantage of the proposed method is that it allows decision makers to set multiple aspiration levels for the coefficient of variables. Hence, the decision makers obtain more revenue and match with the reality of their problems. Unlike the multi-segment goal programming proposed in the literature, the revised formulation is linearized in the current study. The supplier selection problem is solved by this new formulation in a special circumstance. Finally, some concluding notes are remarked.

Keywords Supplier selection . Goal programming . Multiple

aspiration levels . Revised multi-segment goal programming

1 Introduction

Goal programming (GP) is a kind of multiple objective pro-gramming, which is the progeny of multi-criteria decision making (MCDM). In this research, the methodology known as GP has been inspired from [1]. Further developments are provided for instance by [2–6]. GP lets decision makers

(DMs) fix their aspiration levels for each goal. The objective of GP is to minimize the undesirable deviations between the

achievement of goals and their aspiration levels. In a charac-teristic manner, GP can be expressed as follows:

minX

ith objective, respectively, andF is a feasible set. Also,N is the number of criteria.

Based on this formulation, researchers proposed many formulations for GP, which had different attitudes. We intro-duced some of these models, which have been frequently applied by different researchers.

Ignizio proposed weighted GP (WGP) and lexicographic GP (LGP) [7]. These formulations are the following in order:

min X

are the positive and negative deviations between theith objective and its goal, respectively;

αiandβiare the positive weights to the deviations.

min X

placed in the rth level. The other variables are defined in WGP.

H. Karimi (*)

Department of Industrial Engineering, K. N. Toosi University of Technology, No. 17, Pardis St., Molla Sadra St.,

Vanak Sq., Tehran, Iran e-mail: [email protected]

A. Rezaeinia

Project Planning and Control, National Iranian Oil Company, Pars Economic Special Zone, Assaluyeh, Iran

e-mail: [email protected]

Int J Adv Manuf Technol (2014) 70:1227–1234 DOI 10.1007/s00170-013-5368-0

Flavell presented min–max or Chebyshev GP (MGP),

min-imizing the maximum deviation [8]. This method is provided as follows: maximum value of the deviation. The aforementioned formu-lations have numerousdi+anddi

−

variables. Hence, Li pro-posed a new approach as follows [4]:

minX

giis the negative deviation.

Romero et al. provided a combinatorial formulation relied on WGP and MGP [9]. This formulation structure can be presented as follows: unwanted deviation variables and maximum deviation, re-spectively. Forλ=0, we can achieve the MGP; forλ=1, the WGP is achieved; and for the other values of this parameter belonging to the interval (0, 1), intermediate solutions are provided by the weighted combination of WGP and MGP.

Chang proposed mixed binary GP (MBGP), which in-volved the achievement of goals [10]. This formulation ex-presses as follows: Chang declared in some cases that there might be a situa-tion where the DMs would like to make a decision on the problem, with the goal that can be achieved from some spe-cific aspiration levels [11]. Therefore, the multi-choice GP (MCGP) problem can be expressed as follows:

min X binary serial number. Other variables have been defined in the preceding paragraphs. The revised MCGP is presented in [12]. The author improved the model and linearized it. In addition, it is applied for multi-period, multi-stage inventory controlled supply chain problem [13]. MCGP with utility function, con-sidered for goals, is also introduced lately [14]. Additionally, a new GP called multi-coefficient GP is introduced recently [15]. It can be used for group pricing discrimination problems. The model of this type is mixed integer nonlinear program-ming. Lately, a new multi-aspiration goal programming (MAGP) model is proposed to join in the multi-segment GP (MSGP) and MCGP in order to solve the problems [16].

Also, Liao proposed a new GP model called as MSGP [17], which is considered in this paper. A manager's objective of an organization may include some of the following: intensifying market share, obtaining difference profits, portioning the product price, and so on, in different markets. In fact, the incompleteness of the attainable information and conflicts of organizational resource force DMs to build a reliable mathe-matical model for portraying their preference. The objectives are so different in organizations, which they cannot be com-bined into a single proper goal, but the DMs attempt to set a goal to get the acceptable solutions in solving the problem of a multi-segment aspiration level. DMs would be interested to minimize the deviations between the achievements of the goal and their aspiration levels of variable coefficients of decision. However, this formulation can be described as follows:

min X

decision representing the multi-segment aspiration levels of

1228 Int J Adv Manuf Technol (2014) 70:1227–1234

jth segment ofith goal inith decision variable. Therefore, in this model, the aspiration contribution level should be defined only for one decision variable in each goal. In addition, other binary variables should be added for solving MSGP problem that if there have been many segments in each market, multi-plicity of extra binary variables would be difficult to solve the problem. Therefore, we propose a conceptual model consid-ering more than one coefficient for decision variables in each goal for segmentation and linearize the formulation with a new idea.

The rest of the paper is arranged as follows: Section2 introduces the revised multi-segment goal programming (RMSGP) formulation. In Section3, we apply the displayed method to the supplier selection in an Iranian company. Fi-nally, Section4presents the conclusion and future researches.

2 Revised multi-segment goal programming framework

Based on the MSGP method introduced by [17], an aspiration contribution level should be defined only for one decision variable in each goal. Unlike the mentioned MSGP, the revised MSGP allows the decision maker to set multi-aspiration levels for each decision variable in each goal. RMSGP suggests a conceptual model for multi-choice in variables of aspiration levels that it analyzes coefficients of decision variables. Hence, decision maker can decide more effectively with achieving a set of compromising solutions and minimizing the deviations between the achievement of goals and their aspiration levels.

The general model is as follows:

min X

are the positive and negative deviations correlated toith goal;wiis the weight for normal-ization of the deviations (e.g.,wi¼g1i).Sijkrepresents thekth segment ofjth variable inith goal of the coefficients.Xijkis their decision variable;Yjis decision variable ofjth factor in deciding (e.g., supplier in the supplier selection problem);gi is the aspiration level of the goal; hij is the number of seg-ments forjth variable inith goal.

The differences between this revised model and the first model of MSGP are summarized in Table1.

The following cases express the advantages of RMSGP: (1) considering segmentation of all decision variables; (2) the segmentation is distributed to one or more than one coeffi-cient, not only to one of coefficients; (3) this model can be solved for more than four segmentations, while MSGP cannot be formulated easily; (4) changing the mixed integer program-ming to the linear programprogram-ming; and (5) selecting one or more than one coefficient for each decision variable with consider-ing their percentage. Hence, usconsider-ing RMSGP, the formulation can significantly describe the real-world problem.

In the next section, we apply our proposed formulation to an important MCDM problem. In addition, the model is described fluently to introduce RMSGP further.

3 Application of the MSGP model to the supplier selection problem

In this section, we present the literature review and our proposed method for supplier selection, respectively. Supplier selection belongs to the multi-criteria decision-making problem. There-fore, decision-making techniques and criteria are two significant elements in this problem. We review the literature about this problem and its solution methods. One of the first researchers in this field was Dickson [18]. He recognized 23 different criteria for this problem focused on a questionnaire, which was sent to some companies in North America. These criteria contain deliv-ery time, production capacity, warranty situation, product quality, performance, claims policy, production facilities, net price, and technical capabilities. Moore and Fearon [19] provided a review, which concentrated on industrial applications of computer-assisted supplier selection models. Evans proposed that price, quality, and delivery are the most important criteria for evaluat-ing suppliers in the industrial market [20]. Shipley proposed

Table 1 Differences between

MSGP and RMSGP Model Number of variables

segmented in each goal Extra variables

Extra constraints

Class Selecting coefficient

MSGP One Binary 0 Nonlinear One

RMSGP One or more than one Positive M×N Linear One or more than one with considering their proportion

Int J Adv Manuf Technol (2014) 70:1227–1234 1229

three criteria including quality, price, and delivery lead time for supplier selection [21]. Ellram mentioned that the firm needed to consider the product-offering price, quality, delivery time, and service quality in supplier selection problem [22]. Weber et al. arranged the literature on supplier selection in some groups by reviewing many articles [23]. Moreover, de Boer et al. reviewed the decision methods published in the literature for supporting the supplier selection process [24]. Pi and Low proposed quality, on-time delivery, price, and service for supplier evaluation using Taguchi loss functions [25]. Aissaoui et al. [26] have presented another literature review according to the purchasing process. They have focused on the classification of single and multiple items and periods. Saen emphasized on the ordinal data [27]. However, with the widespread use of manufacturing philoso-phies such as just in time (JIT), the emphasis has shifted to the simultaneous consideration of cardinal and ordinal data in the supplier selection process. He proposed a new pair of assurance region-imprecise data envelopment analysis for selecting the best suppliers in the presence of both weight restrictions and impre-cise data. Liao and Kao integrated the Taguchi loss function, analytical hierarchy process, and multi-choice GP model for solving the supplier selection problem [28]. Their method allowed decision makers to fix multiple aspiration levels for the decision criteria. Ho et al. [29] published another review paper in supplier selection method with multiple criteria decision-making approaches. Amin et al. applied quantified SWOT in the context of supplier selection for the first time [30]. They proposed a fuzzy linear programming model to determine how much should be purchased from each supplier. Vinodh et al. used fuzzy analytic network process approach for the supplier selection process [31]. Yücenur et al. proposed a model for choosing the global supplier by analytical hierarchy process and analytical network process depending upon linguis-tic variable weight [32].

Our approach is relevant to represent a method in the previ-ous section. Supplier selection is a multi-criteria problem, which consists of both tangible and intangible factors. In order to select the best suppliers, it is essential to make a trade-off between some of conflicting tangible and intangible factors. Therefore, making a dependable mathematical model can be useful for better decision making on the management of problems.

An Iranian thermal system production company wants to select a suitable supplier to purchase the input components.

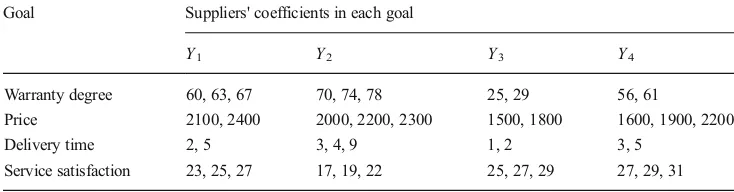

The company has to evaluate suppliers with their different aspiration levels in order to make optimal options. Their suppliers cause some segmentation for the company goals. Therefore, to cope with this problem, we proposed RMSGP, which is the unique method that can consider this problem situation. The following four goals have been defined for supplier selection and segmentations of supplier's coefficients in each goal (presented in Table2):

Goal 1. Warranty degree goal with satisfaction level 80,

Goal 2. Price goal with satisfaction level 2200,

Goal 3. Delivery time goal with satisfaction level 2, and

Goal 4. Service satisfaction goal with satisfaction level 50.

In this study, suppliers suggested two or three aspiration levels for different goals. For example, (Y1, Y2) suppliers

exposed (60, 63, 67; 70, 74, 78) aspiration levels for warranty degree goal, respectively.

To deal with this problem, a new constraint should be added to the RMSGP model indicating the selection concept. This constraint is as follows:

X

j¼1

M

Yj¼1:

In this constraint, it should be considered to be M=4, because there are four suppliers. This constraint ensures that the model selects only one supplier.

In basis of RMSGP model, this problem can be solved using LINGO 8 to achieve the best supplier. The optimal solutions are as (Y1,Y2,Y3,Y4)=(1, 0, 0, 0). The problem

results display that the supplier Y1is the best selection. In

addition,Xi1kvalues are the following:

X111¼0;X112¼0;X113 ¼1; X211¼0:67;X212 ¼0:33;

X311¼ 1;X312¼ 0 ; X411 ¼0;X412¼ 0;X413¼ 1:

The segmentation is distributed to one coefficient in different aspiration levels like the first, third, and fourth goals and is divided into more than one coefficient forX21kvalues between 0 and 1. In this optimal solution, the aspiration levels for the second decision variable (i.e., first supplier) on the first, second, third, and fourth goals are 67, (1407+792), 2, and 27, respec-tively. To normalize the deviation, each deviation is divided by

Table 2 Segmentations of

sup-plier's coefficients in each goal Goal Suppliers' coefficients in each goal

Y1 Y2 Y3 Y4

Warranty degree 60, 63, 67 70, 74, 78 25, 29 56, 61

Price 2100, 2400 2000, 2200, 2300 1500, 1800 1600, 1900, 2200

Delivery time 2, 5 3, 4, 9 1, 2 3, 5

Service satisfaction 23, 25, 27 17, 19, 22 25, 27, 29 27, 29, 31

1230 Int J Adv Manuf Technol (2014) 70:1227–1234

its goal value. Therefore, we can add together the proportion of the deviations. The minimum proportion of deviation from the goals is 0.62 in this case. In respect to this result, we suggest that this thermal system production company that selects the

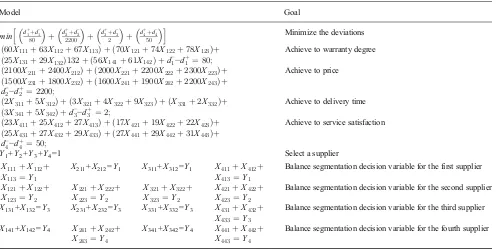

first supplier can be suitable to achieve its goals. It is better for the company to choose the third aspiration level of this supplier to abut onto warranty degree. To achieve the price goal, the company should accept 67 and 33 % of the first and second Table 3 RMSGP model formulation

Model Goal

h i Minimize the deviations

60X111þ63X112þ67X113

ð Þ þð70X121þ74X122þ78X123Þþ

ð25X131þ29X132Þ132þð56X141þ61X142Þ þd

−

1−dþ1 ¼80;

Achieve to warranty degree

2100X211þ2400X212

Achieve to delivery time

23X411þ25X412þ27X413

Achieve to service satisfaction

Y1+Y2+Y3+Y4=1 Select a supplier

X111þX112þ

X113¼Y1

X211+X212=Y1 X311+X312=Y1 X411þX412þ

X413¼Y1

Balance segmentation decision variable for the first supplier

X121þX122þ

Balance segmentation decision variable for the second supplier

X131+X132=Y3 X231+X232=Y3 X331+X332=Y3 X431þX432þ

X433¼Y3

Balance segmentation decision variable for the third supplier

X141+X142=Y4 X241þX242þ

X243¼Y4

X341+X342=Y4 X441þX442þ

X443¼Y4

Balance segmentation decision variable for the fourth supplier

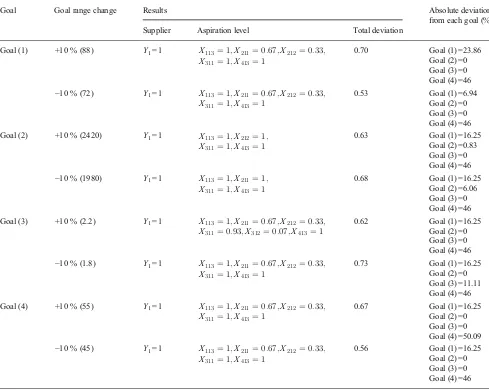

Table 4 Sensitivity analysis results for aspiration level changes

Range change of aspiration levels (%)

Results Absolute deviation

from each goal (%) Selected

supplier

Selected aspiration level Total deviation

Int J Adv Manuf Technol (2014) 70:1227–1234 1231

aspiration levels of this supplier. In addition, this compa-ny had better select the first and third aspiration levels of

the first supplier to obtain delivery time and service sat-isfaction, respectively.

Table 5 Sensitivity analysis results in goal value changes

Goal Goal range change Results Absolute deviation

from each goal (%)

Supplier Aspiration level Total deviation

Goal (1) +10 % (88) Y1=1 X113¼1;X211¼0:67;X212¼0:33;

X311¼1;X413¼1

0.70 Goal (1)=23.86

Goal (2)=0 Goal (3)=0 Goal (4)=46

−10 % (72) Y1=1 X113¼1;X211¼0:67;X212¼0:33;

X311¼1;X413¼1

0.53 Goal (1)=6.94

Goal (2)=0 Goal (3)=0 Goal (4)=46 Goal (2) +10 % (2420) Y1=1 X113¼1;X212¼1;

X311¼1;X413¼1

0.63 Goal (1)=16.25

Goal (2)=0.83 Goal (3)=0 Goal (4)=46

−10 % (1980) Y1=1 X113¼1;X211¼1;

X311¼1;X413¼1

0.68 Goal (1)=16.25

Goal (2)=6.06 Goal (3)=0 Goal (4)=46 Goal (3) +10 % (2.2) Y1=1 X113¼1;X211¼0:67;X212¼0:33;

X311¼0:93;X312¼0:07;X413¼1

0.62 Goal (1)=16.25

Goal (2)=0 Goal (3)=0 Goal (4)=46

−10 % (1.8) Y1=1 X113¼1;X211¼0:67;X212¼0:33;

X311¼1;X413¼1

0.73 Goal (1)=16.25

Goal (2)=0 Goal (3)=11.11 Goal (4)=46 Goal (4) +10 % (55) Y1=1 X113¼1;X211¼0:67;X212¼0:33;

X311¼1;X413¼1

0.67 Goal (1)=16.25

Goal (2)=0 Goal (3)=0 Goal (4)=50.09 −10 % (45) Y1=1 X113¼1;X211¼0:67;X212¼0:33;

X311¼1;X413¼1

0.56 Goal (1)=16.25

Goal (2)=0 Goal (3)=0 Goal (4)=46

Fig. 1 Results of sensitivity analysis by varying the goal value

1232 Int J Adv Manuf Technol (2014) 70:1227–1234

The whole formulation of this problem is described in Table3.

In order to know how the change in value from +10 to−10 % in the all aspiration levels affects the deviation from the goals and the total deviation, sensitivity analysis of aspiration level is run. In Table4, the sensitivity analysis results are shown. As it can be seen from this table, in all aspiration levels, an increase of 10 % will cause an 8.36 % lower change in warranty degree, 5 % higher change in price, 10 % higher change in delivery time, and 6.60 % lower change in service satisfaction. In contrast, in all aspiration levels, a decrease of 10 % will cause an 8.38, 1.82, and 5.40 % higher change in warranty degree, price, and service satisfaction, respectively. No change in the delivery time will be happened by a 10 % decrease of all aspiration levels. An increase of 5 % of all aspiration levels will lead to a 4.19 % lower change in warranty degree, 0.23 % higher change, 5 % higher change in delivery time, and 2.70 % lower change in service satisfaction. In contrast, in all aspiration levels, a decrease of 5 % will lead to a 4.19 and 2.70 % higher change in warranty degree and service satisfaction, respectively. This reduction will cause no change in price and delivery time. We see in Table4 that in the all aspiration levels, increasing causes lower total deviation, but the supplier selected in all of them is the same.

In order to analyze how the different value of each goal affects the deviation from the goals and the total deviation. We change each goal from +10 to−10 % for sensitivity analysis of goal value. In Table5, the sensitivity analysis results are summarized. As can be seen in Table5, the warranty degree increase of 10 % will lead to a 0.08 higher change in the total deviation. In contrast, this goal decrease of 10 % will cause a 0.09 lower change in the total deviation. The prices grow, and a decrease of 10 % will cause a 0.01 and 0.06 higher changes in the objective function of the RMSGP, respectively. The 10 % increase of delivery time will lead to no change in the total deviation. This goal reduction of 10 % will cause a 0.11 higher change in the total deviation. The service satisfaction growth and reduction of 10 % will cause a 0.05 and 0.0.6 lower and higher change in the total deviation, respectively. The results of sensitivity analysis of goal change are shown in Fig.1.

It has been inferred from this figure that a 10 % reduction of the warranty degree does not create any impact on the decision made, which has been revealed by the model without change on this goal. However, this reduction causes the lowest change in the total deviation among all studied changes. The 10 % reduction of warranty degree leads to a 9.31 % lower change in warranty degree and no change in the other goals.

4 Conclusion

Drawing and optimizing efficient supply chain network make available competitive benefits to buyers and companies.

Moreover, supplier selection, the procedure of selecting suit-able suppliers who are proficient to provide the buyer with the accurate quality products or services at the appropriate price and at the optimal time and quantities, is one of the most significant activities for determining an efficient supply chain. On the other hand, this is a hard problem since supplier selection is considered as a multi-objective decision-making problem. Hence, in this paper, with concentration to the GP techniques, a revised MSGP model is proposed to improve MSGP model. This approach is being different from MSGP model to consider multi-aspiration levels for each decision variable in each goal. Four different suppliers that make thermal products are selected by using RMSGP method. This result represents that selective supplier provides better perfor-mance levels at the suppliers' different inputs. As for the future researches, we recommend a new solution methodology based on multi-choice goal programming which can be developed for the different segments, and the efficiency of the model according to this solution methodology can be examined.

Acknowledgments The authors would like to thank the anonymous referees for their valuable contributions, which led to improvements in this paper. Moreover, the second author has been partially supported by the National Iranian Oil Company (NIOC).

References

1. Charnes A, Cooper WW (1957) Management models and industrial applications of linear programming. Manag Sci 4(1):38–91 2. Lee SM (1972) Goal programming for decision analysis. Auerbach,

Philadelphia, p 387

3. Ignizio JP (1985) Introduction to linear goal programming. Sage, Beverly Hills

4. Li HL (1996) An efficient method for solving linear goal program-ming problems. J Opt Theory Appl 90(2):465–469

5. Tamiz M, Jones D, Romero C (1998) Goal programming for decision making: an overview of the current state-of-the-art. Eur J Oper Res 111(3):569–581

6. Romero C (2001) Extended lexicographic goal programming: a unifying approach. Omega 29(1):63–71

7. Ignizio JP (1976) Goal programming and extensions (vol. 26). Lex-ington Books, LexLex-ington, MA

8. Flavell RB (1976) A new goal programming formulation. Omega 4(6):731–732

9. Romero C, Tamiz M, Jones DF (1998) Goal programming, compro-mise programming and reference point method formulations: link-ages and utility interpretations. J Oper Res Soc 49(9):986–991 10. Chang CT (2004) On the mixed binary goal programming problems.

Appl Math Comput 159(3):759–768

11. Chang CT (2007) Multi-choice goal programming. Omega 35(4): 389–396

12. Chang CT (2008) Revised multi-choice goal programming. Appl Math Model 32(12):2587–2595

13. Paksoy T, Chang CT (2010) Revised multi-choice goal programming for multi-period, multi-stage inventory controlled supply chain model with popup stores in Guerrilla marketing. Appl Math Model 34(11): 3586–3598

Int J Adv Manuf Technol (2014) 70:1227–1234 1233

14. Chang CT (2011) Multi-choice goal programming with utility func-tions. Eur J Oper Res 215(2):439–445

15. Chang CT, Chen HM, Zhuang ZY (2012) Multi-coefficients goal programming. Comput Ind Eng 62(2):616–623

16. Karimi H, Attarpour M (2012) Multi-aspiration goal programming formulation. Int J Industr Eng 19(12):456–463

17. Liao CN (2009) Formulating the multi-segment goal programming. Comput Ind Eng 56(1):138–141

18. Dickson GW (1966) An analysis of vendor selection systems and decisions. J purchasing 2(1):5–17

19. Moore DL, Fearon HE (1973) Computer-assisted decision-making in purchasing. J Purchasing 9(4):5–25

20. Evans RH (1980) Choice criteria revisited. J Mark 44:55–56 21. Shipley DD (1985) Resellers' supplier selection criteria for different

consumer products. Eur J Mark 19(7):26–36

22. Ellram LM (1990) The supplier selection decision in strategic part-nerships. J Purchas Mat Manag 26(4):8–14

23. Weber CA, Current JR, Benton WC (1991) Vendor selection criteria and methods. Eur J Oper Res 50(1):2–18

24. de Boer L, Labro E, Morlacchi P (2001) A review of methods supporting supplier selection. Eur J Purchas Supp Manag 7(2):75–89

25. Pi WN, Low C (2005) Supplier evaluation and selection using Taguchi loss functions. Int J Adv Manuf Technol 26(1–2):155–160 26. Aissaoui N, Haouari M, Hassini E (2007) Supplier selection and order

lot sizing modeling: a review. Comput Oper Res 34(12):3516–3540 27. Saen RF (2008) Supplier selection by the new AR-IDEA model. Int J

Adv Manuf Technol 39(11–12):1061–1070

28. Liao CN, Kao HP (2010) Supplier selection model using Taguchi loss function, analytical hierarchy process and multi-choice goal programming. Comput Ind Eng 58(4):571–577

29. Ho W, Xu X, Dey PK (2010) Multi-criteria decision making ap-proaches for supplier evaluation and selection: a literature review. Eur J Oper Res 202(1):16–24

30. Amin SH, Razmi J, Zhang G (2011) Supplier selection and order allocation based on fuzzy SWOT analysis and fuzzy linear program-ming. Expert Syst Appl 38(1):334–342

31. Vinodh S, Anesh Ramiya R, Gautham SG (2011) Application of fuzzy analytic network process for supplier selection in a manufacturing organisation. Expert Syst Appl 38(1):272–280

32. Yücenur GN, Vayvay Ö, Demirel NÇ (2011) Supplier selection problem in global supply chains by AHP and ANP approaches under fuzzy environment. Int J Adv Manuf Technol 56(5–8):823–833

1234 Int J Adv Manuf Technol (2014) 70:1227–1234