Manajemen dan Rekayasa Struktur C-47

NUMERICAL STUDY OF CARBONATION DEPTH DETECTION OF

CONCRETE DAMAGED FROM ULTRASONIC AXYSIMMETRIC

LOADING USING REFLECTIVE WAVES

IFTA MINKA1,2, TA-PENG CHANG2, DATA IRANATA1

1

Department of Civil Engineering, Institut Teknologi Sepuluh Nopember (ITS), Surabaya, Indonesia, 60111

2

Department of Construction Engineering, National Taiwan University of Science and Technology (NTUST), Taipei, Taiwan, 106

Abstract- Concrete exposed to environment, such as urban and industrial site, were easily

attacked by either aggressive agents or reactive agents. One of the major and unavoidable

concrete deterioration was carbonation. Generally, carbonation depth detection was

measured using chemical phenolphthalein solutions 1%. However, from the previous

experiment conducted by Y. Lo and H. M. Lee (2001), it was known that phenolphthalein

could not give the significant result again.

In this investigation, the numerical analysis conducted using the commercial finite element

software LS-DYNA 970. It is used to simulate the 2-D plate 100 x 200 mm with difference

acoustic impedance (Z) subjected to ultrasonic axysimmetric loading. The signal resulted

from numerical simulations were analyzed using reflective waves. Reflective waves as a

filter to measure the depth of concrete carbonation damaged.

Numerical results show that accuracy of depth detection depends on the impedance (Z)

value of material. Measurement of carbonation depth could be detected with accuracy

under 3%.

Keywords-numerical, carbonation depth, ultrasonic, reflective waves

1. INTRODUCTION

Concrete as a widely used material for

construction must resist from some aggressive

agents or reactive agents. Carbonation of

concrete is one type of concrete deteriorations

which are able to deliver corrosion of

reinforced bars and change the characteristic

Manajemen dan Rekayasa Struktur C-48

traditional detection method of concrete

carbonation was conducted by traditional

measurement using phenolphthalein 1%

solution. From the previous research

conducted by Y. Lo and H. M. Lee (2001) [1],

it was known that the phenolphthalein test did

not indicate a significant result. Moreover, the

carbonation detection using phenolphthalein is

not an in-situ carbonation detection method.

Ultrasonic wave propagation is one of

non-destructive method for concrete damaged

detection. Reflection wave method is one of

ultrasonic method that usually been used as a

tool to identify and detect the thickness/depth

of concrete cracks [2, 3]. Therefore, in this

study, reflection method will be used to

identify the depth/thickness of carbonation

damaged of concrete.

2. METHODOLOGY

Numerical simulation is conducted using

commercial finite element software LS-DYNA

970. Geometry of finite element model is a

concrete element of 100 mm height 200

mm length. It is used to simulate the

carbonation condition of concrete subjected to

ultrasonic loading using 2-D axysimmetric

elements. The element mesh size is 0.0625

0.0625 mm. The material properties

including Young’s Modulus (E), density (ρ) and Poisson’s ratio (ν) of concrete are

presented in Table 1. Hence, simulation model

is presented in Figure 1.

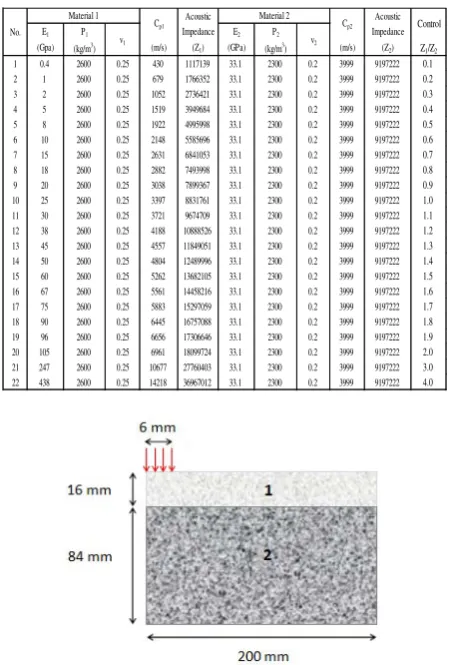

Table 1 Material properties of simulation model

Acoustic Acoustic

E1 P1 Impedance E2 P2 Impedance

(Gpa) (kg/m3) (m/s) (Z

1) (GPa) (kg/m3) (m/s) (Z2) Z1/Z2

1 0.4 2600 0.25 430 1117139 33.1 2300 0.2 3999 9197222 0.1

2 1 2600 0.25 679 1766352 33.1 2300 0.2 3999 9197222 0.2

3 2 2600 0.25 1052 2736421 33.1 2300 0.2 3999 9197222 0.3

4 5 2600 0.25 1519 3949684 33.1 2300 0.2 3999 9197222 0.4

5 8 2600 0.25 1922 4995998 33.1 2300 0.2 3999 9197222 0.5

6 10 2600 0.25 2148 5585696 33.1 2300 0.2 3999 9197222 0.6

7 15 2600 0.25 2631 6841053 33.1 2300 0.2 3999 9197222 0.7

8 18 2600 0.25 2882 7493998 33.1 2300 0.2 3999 9197222 0.8

9 20 2600 0.25 3038 7899367 33.1 2300 0.2 3999 9197222 0.9

10 25 2600 0.25 3397 8831761 33.1 2300 0.2 3999 9197222 1.0

11 30 2600 0.25 3721 9674709 33.1 2300 0.2 3999 9197222 1.1

12 38 2600 0.25 4188 10888526 33.1 2300 0.2 3999 9197222 1.2

13 45 2600 0.25 4557 11849051 33.1 2300 0.2 3999 9197222 1.3

14 50 2600 0.25 4804 12489996 33.1 2300 0.2 3999 9197222 1.4

15 60 2600 0.25 5262 13682105 33.1 2300 0.2 3999 9197222 1.5

16 67 2600 0.25 5561 14458216 33.1 2300 0.2 3999 9197222 1.6

17 75 2600 0.25 5883 15297059 33.1 2300 0.2 3999 9197222 1.7

18 90 2600 0.25 6445 16757088 33.1 2300 0.2 3999 9197222 1.8

19 96 2600 0.25 6656 17306646 33.1 2300 0.2 3999 9197222 1.9

20 105 2600 0.25 6961 18099724 33.1 2300 0.2 3999 9197222 2.0

21 247 2600 0.25 10677 27760403 33.1 2300 0.2 3999 9197222 3.0

22 438 2600 0.25 14218 36967012 33.1 2300 0.2 3999 9197222 4.0

Control

Figure 1 Model of numerical simulation with the thickness of carbonation is 16 mm

The basic procedure of this research is

determining the depth (thickness) of

carbonation damaged from the ultrasonic

signals products.

The thickness was calculated using reflected

wave method based on the value of internal

P-wave velocity, Cp, as presented in the

following expression [4]:

(2-1)

where T is thickness (m), Cp is the P-wave

(m/s), t1 and t2 are the occurring times

correspond to the amplitude A1 and A2,

Manajemen dan Rekayasa Struktur C-49

travels was obtained using similar equation as

(2-1), presented in the following equation:

(2-2)

Figure 2 Time travels from first layer and second layer of carbonated concrete

Figure 2 above shows that t1 and t2 are time

traveling at first layer, while t3 is time

traveling at second layer.

3. RESULTS

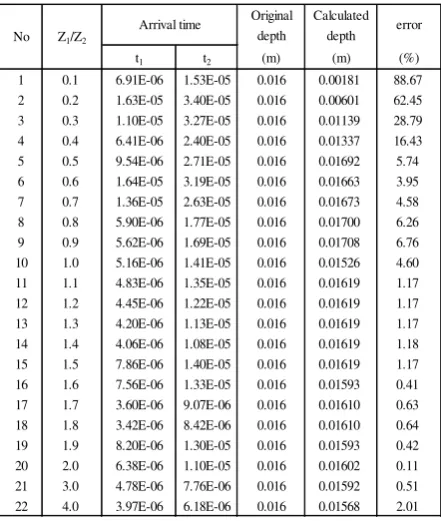

Numerical simulations using ultrasonic

loading were conducted on carbonated and

un-carbonated concrete model to obtain

signals and carbonation damage (i.e. thickness)

of concrete. Figure 3 shows the signals output

from LS DYNA. Detection of carbonation

thickness was shown in Table 2.

0 1E-005 2E-005 3E-005 4E-005

Time (s)

(a) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005

Time (s)

(b) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005

Time (s)

(c) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005

Time (s)

(d) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005

Manajemen dan Rekayasa Struktur C-50

0 1E-005 2E-005 3E-005 4E-005

Time (s)

(f) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005

Time (s)

(g) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005

Time (s)

(h) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005

Time (s)

(i) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005

Time (s)

(j) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005

Time (s)

(k) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005

Time (s)

(l) Results of numerical simulation with Z1/Z2

Manajemen dan Rekayasa Struktur C-51

0 1E-005 2E-005 3E-005 4E-005

Time (s)

(n) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005 Time (s)

(o) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005

Time (s)

(p) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005

Time (s)

(q) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005 Time (s)

(r) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005 Time (s)

(s) Results of numerical simulation with Z1/Z2

0 1E-005 2E-005 3E-005 4E-005 Time (s)

(t) Results of numerical simulation with Z1/Z2

Manajemen dan Rekayasa Struktur C-52

0 1E-005 2E-005 3E-005 4E-005 Time (s)

(v) Results of numerical simulation with Z1/Z2

Figure 3 Results of numerical simulation from LS-DYNA

Table 2 Results of carbonation depth detection using reflected wave theory

= 4.0

Original Calculated depth depth t1 t2 (m) (m) (%) 1 0.1 6.91E-06 1.53E-05 0.016 0.00181 88.67 2 0.2 1.63E-05 3.40E-05 0.016 0.00601 62.45 3 0.3 1.10E-05 3.27E-05 0.016 0.01139 28.79 4 0.4 6.41E-06 2.40E-05 0.016 0.01337 16.43 5 0.5 9.54E-06 2.71E-05 0.016 0.01692 5.74 6 0.6 1.64E-05 3.19E-05 0.016 0.01663 3.95 7 0.7 1.36E-05 2.63E-05 0.016 0.01673 4.58 8 0.8 5.90E-06 1.77E-05 0.016 0.01700 6.26 9 0.9 5.62E-06 1.69E-05 0.016 0.01708 6.76 10 1.0 5.16E-06 1.41E-05 0.016 0.01526 4.60 11 1.1 4.83E-06 1.35E-05 0.016 0.01619 1.17 12 1.2 4.45E-06 1.22E-05 0.016 0.01619 1.17 13 1.3 4.20E-06 1.13E-05 0.016 0.01619 1.17 14 1.4 4.06E-06 1.08E-05 0.016 0.01619 1.18 15 1.5 7.86E-06 1.40E-05 0.016 0.01619 1.17 16 1.6 7.56E-06 1.33E-05 0.016 0.01593 0.41 17 1.7 3.60E-06 9.07E-06 0.016 0.01610 0.63 18 1.8 3.42E-06 8.42E-06 0.016 0.01610 0.64 19 1.9 8.20E-06 1.30E-05 0.016 0.01593 0.42 20 2.0 6.38E-06 1.10E-05 0.016 0.01602 0.11 21 3.0 4.78E-06 7.76E-06 0.016 0.01592 0.51 22 4.0 3.97E-06 6.18E-06 0.016 0.01568 2.01 No Z1/Z2 Arrival time error

4. DISCUSSIONS

Results of signal from numerical simulation

using ultrasonic loading could be seen in

Figure 4 and calculation of depth could be

seen in Table 2. Figure 4 showed the resulting

signal from different variations ratio of

acoustic impedance (Z). In the analysis of

depth detection, the highest first peak of each

resulting signal could be neglected, if

necessary. This condition is caused by that

peak did not contain any information of

reflected wave from surface that could be used

to detect the depth of carbonation damaged. In

reality, this peak comes from sensor that was

used along detection. Even in the geophysics

science, this highest first peak is a direct wave

which is come from geophone [5]. Therefore,

this peak could be neglected also in this

detection.

According to Table 2, it was known that

accurate detection could be obtained at

material with ratio of acoustic impedance

(Z1/Z2) higher than 1.1. Accurate detection in

this study is detection which has an error of

detection less than 3%. From Table 2, it was

shown that double layer of carbonation model

could be detected in the range of acoustic

impedance ratio (Z1/Z2) of 1.1 – 4.0. This

condition occurred because of acoustic

impedance has big influence on the reflection

and refraction/transmission of waveform. In

the acoustic impedance theory, if Z2 becomes

very smaller than Z1, Areflection approaches and

Arefraction/transmission approaches zero. It means

that the compressive wave and refraction will

not occur [4]. In other words, attenuation from

another signals occurred before the real

Manajemen dan Rekayasa Struktur C-53

5. CONCLUSIONS

1. Reflected wave theory could be applied to

identify the thickness/depth of concrete

damaged from ultrasonic testing with an

error of detection under 3%.

2. Detection of carbonation damaged using

reflected wave is accurate in material

with ratio of acoustic impedance (Z)

higher than 1.1.

REFERENCES

[1] Lo, Y., H. M. Lee (2001), Curing Effects

on Carbonation of Concrete Using a

Phenolphthalein Indicator and

Fourier-Transform Infrared Spectroscopy,

Journal of Building and Environment,

Pergamon.

[2] Morishige, H. and Tanaka, S (2004),

Non-Destructive Inspection of Concrete

Structures Using Ultrasonic Sensor, SICE

Annual Conference in Sapporo, Hokkaido

Institute of Technology, Japan.

[3] Islam, Muhammed Mazharul.

Yamamoto, Hiroya. Tanaka, Shogo,

(2006), Non-Destructive Inspection of

Multiple Concrete Cracks Using

Ultrasonic Sensor, SICE-ICASE

International Joint Conference, Bexco,

Busan, Korea, Oct. 18-21.

[4] Boggess, Albert, (2001),A First Course in

Wavelets with Fourier Analysis, New

Jersey, Prentice-Hall.

[5] Sansalone, M. J and Streett, W. B., (1997),

Impact Echo: Nondestructive Evaluation

of Concrete and Masonry, Ithaca, New