VARIATION EFFECT OF FIBER COMPOSITION AND

DIRECTION TOWARD COMPOSITE MECHANICAL

PROPERTIES, FIBERGLASS FIBER WITH POLISTER

MATRIX MATERIAL

PUBLICATION ARTICLE

Submitted as a Partial Fulfillment of the Requirements for Getting Bachelor Degree of Engineering in Automotive Department

Arranged by:

Roberto Agus Mainaki

D 200 102 016

MECHANICAL ENGINEERING DEPARTMENT

INTERNATIONAL PROGRAM

IN AUTOMOTIVE/MOTORCYCLE ENGINEERING

MUHAMMADIYAH UNIVERSITY OF SURAKARTA

VARIATION EFFECT OF FIBER COMPOSITION AND DIRECTION TOWARD COMPOSITE MECHANICAL PROPERTIES, FIBERGLASS FIBER WITH POLISTER

MATRIX MATERIAL

Ir. Pramuko IP, MT.

Mechanical Engineering Department of Muhammadiyah University of Surakarta Jln. A. Yani Pabelan-Kartasura. Tromol Pos I Telp. (0271) 715448 Surakarta

Wijianto, ST.M.Eng.Sc

Mechanical Engineering Department of Muhammadiyah University of Surakarta Jln. A. Yani Pabelan-Kartasura. Tromol Pos I Telp. (0271) 715448 Surakarta

Roberto Agus Mainaki

Automotive Engineering Department of Muhammadiyah University of Surakarta Jln. A. Yani Pabelan, Kartasura, Tromol Pos I, Telp. (0271) 715448 Surakarta

Email: [email protected]

ABSTRACT

With the development of technology, it is found, new technology in modification motorcycle body, so a lot of people utilize composite for making motorcycle body with the performance they want.

It is easy to make body of motorcycle in willingness. There are three materials in the modifications motorcycle body (catalyst, resin and fiberglass). Fiberglass is a light material, and it is very strong. Though the character of its strength rather lowers that carbon fiber and less stiff, the material which is usually fragile, and the standard material is cheaper. Missal strength and weight character of body is also to make more than metal, and it is easy to make with the press. The purpose of the research is to know the strength of different fibers, from random fiber, woven fiber, and one direction fiber.

Testing is done by differentiating three fibers (random fiber, woven fiber, and one direction fiber) with catalyst composite and the same resin. Every fiber tests with impact test that is based ASTM D - 256, bending test based on ASTM D - 790 and tensile test that is based on ASTM D - 638.

The composition of a catalyst 4.76 % of a resin used, and use of composite volume faction 37.1 %.Analysis is done after getting result data of testing. The result from each testing has a different result. Numbers of height of impact test are gotten from one direction fiber 0.82 J/mm2, flexure stress is gotten from woven fiber 29.89 MPa, tensile strength is gotten from woven fiber 66 MPa, and elastic modulus from woven fiber 142.268 kg/mm2. The strength to hold is a strength and character as tenacity, strength, hardness etc, it can be considered by data which are gotten from the results of the test.

Background

excellence in the ratio of strength to weight,

encourage the use of composite as an

ingredient of a substitute for material metal

commonly used in a variety of products.

Composite materials made from two

or more different materials. First is the

matrix, which serves as a glue to keep the

fibers together. Both are fiber, which serves

as a composite reinforcement of unification.

One type of composites that can be easily

formed is a hybrid composite. Hybrid

composites formed by two or more

reinforcements, so the modification that the

arrangement and composition, it will be easy

to achieve mechanical properties.

In this study the authors will conduct

a research differences fiber, random fibers,

woven fibers, the composition of the

mixture catalyst and similar resin. Then the

next is analyze the result after test and will

be compared between each fiber glass.

Problem Statement

The problem statement that can be

drawn from the problem above is how the

differences in fiber can influence the

mechanical properties of motorcycle body

modification on impact strength, bending

stress and tensile strength.

Objectives

in the composite manufacturing.

3. The specimens are tested in the

impact test, bending test, and tensile

primary load carriers of the material, with

the matrix component transferring the load

from fiber to fiber. Reinforcement of the

matrix material can be achieved in a variety

of ways including particles. Fibers may be

continuous or discontinuous with the matrix

material usually sourced from one of the

many available engineering plastics/

polymers.

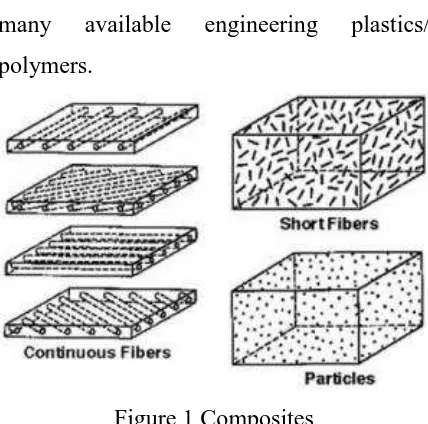

Figure 1 Composites

(

http://www.aid-n.com/what-are-composite-

materials-and-the-function/composite-materials-development/ )

Composites are made up of

individual materials referred to as

constituent materials. There are two

categories of constituent materials: matrix

and reinforcement. At least one portion of

each type is required. The matrix material

surrounds and supports the reinforcement

materials by maintaining their relative

positions. The reinforcements impart their

special mechanical and physical properties

to enhance the matrix properties. A

synergism produces material properties

unavailable from the individual constituent

materials, while the wide variety of matrix

and strengthening materials allows the

designer of the product or structure to

choose an optimum combination.

Catalyst

A catalyst is a substance that

accelerates a reaction by lowering the active

energy. Catalyst can accelerate chemical

reactions and can be accelerated by

increasing the fraction of molecules whose

energy exceeds the energy having active.

Figure 2 catalyst

(http://www.easycomposites.co.uk/products/

polyester-vinylester-resin/mekp-catalyst.aspx)

Without a catalyst, a chemical

reaction may never get a faster time to react.

When a chemical reaction takes the form of

mixture of chemical which changes more

the catalyst itself is not changed and is not

part of the end result.

Figure 3 Comparison of catalysis and

non-catalysis

(http://ch302.cm.utexas.edu/images302/Cata

lyst_effect.png)

Resin 157 BTQN

Resin is a hydrocarbon secretion

many plants, particularly coniferous trees.

Other liquid compounds found in plants is

like sap, latex, or mucus, sometimes are

confused with the terms above, but they are

chemically the same. It can be used for the

production of varnishes, adhesives, glass

mixture, as a source of raw materials for

organic synthesis, a staple of incense and

perfumes. In products such as fragrances are

often called “ambered”, resin can be

fossilized and it becomes amber gemstone.

Figure 4 Resin (butek)

Thermosetting polyester resins and

as with other resin, changes react

exothermically. Excessive use of catalysts

can, therefore, cause charring or ignition

even during the producing process. The

catalyst can also lead to excessive product to

fracture of forming rubber material.

Fiber glass

Fiberglass or glass fiber is often

translated into molten glass is drawn into

thin fiber with straight line around 0,005

mm - 0,01 mm. this fiber can be spun into

yarn or woven into fabric which is then

impregnate with a resin material so that it

becomes a strong and corrosion-resistant for

use as car bodies and ship building. It is also

used as a reinforcing agent for many

polymer products; resulting composite

material known as glass-reinforced plastic

reinforced epoxy (GRE), is called

“fiberglass” in general use.

Figure 5 random fiber glass

Figure 6 Woven fiber glass

Figure 7 unidirectional fiber glass

It should be noted that fiberglass is

not carbon fiber, not glass-reinforced plastic,

although it is similar to both. Carbon fiber

which is made of carbon stands, not as long

as it can be extruded into strands of

fiberglass

Impact Test

Impact strength is an important

criterion to determine the brittleness of

polymeric materials. From this test will be

obtained some data of absorbed energy,

energy activation and can be used to

determine the impact value of specimen,

with (Standard ASTM D 256).

Figure 6 Impact Tool

(1)

Where:

K = Impact value (J/mm2) A = Cross sectional area (mm2) W= Energy (J)

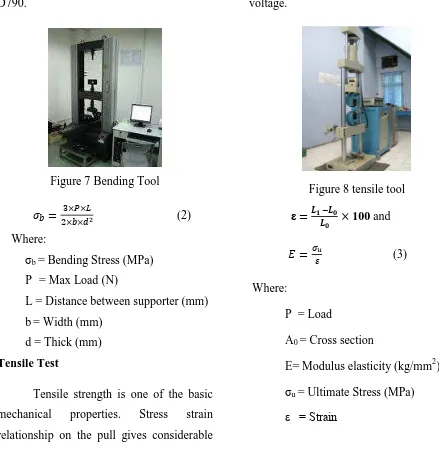

Bending Test

Testing of flexural strength is

intended to determine the resistance of the

polymer loading. In this method the method

used is the three-point bending method. This

test is also intended to determine the

specimen was set in accordance with ASTM

D790.

Figure 7 Bending Tool

(2)

Where:

σb = Bending Stress (MPa)

P = Max Load (N)

L = Distance between supporter (mm)

b = Width (mm)

d = Thick (mm)

Tensile Test

Tensile strength is one of the basic

mechanical properties. Stress strain

relationship on the pull gives considerable

value changes depending on the rate of

voltage.

Figure 8 tensile tool

ε 100 and

(3)

Where:

P = Load

A0 = Cross section

E= Modulus elasticity (kg/mm2)

σu = Ultimate Stress (MPa)

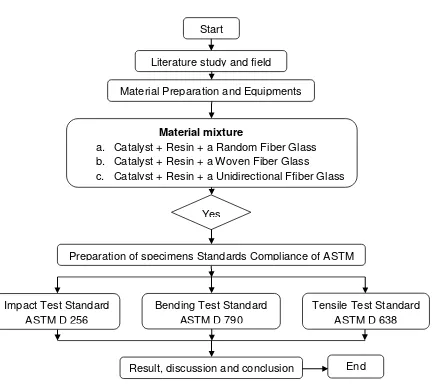

Flow Chart of Research

Figure 9 Flow Chart of Experiment

The test results and analysis

No Fiber Volume Faction (%)

Catalyst (%)

W

(J) 0 0

A (mm2)

K (J/mm2)

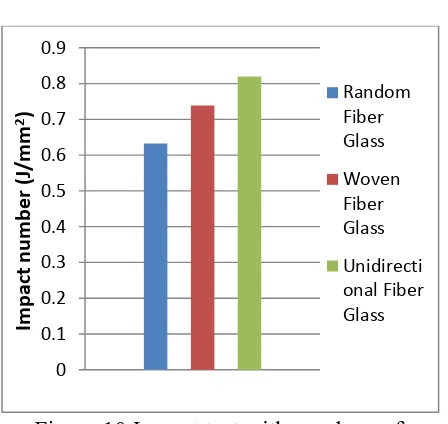

1 Random Fiber Glass 37.1 4.76 12.29 156 146.67 19.46 0.632

2 Woven Fiber Glass 37.1 4.76 14.39 156 145.33 19.46 0.739

3 Unidirectional Fiber

Glass

37.1

4.76 11.77 156 144.33 19.46 0.82

Table 1 Result of Impact Test Start

Result, discussion and conclusion End Preparation of specimens Standards Compliance of ASTM

Material mixture

a. Catalyst + Resin + a Random Fiber Glass b. Catalyst + Resin + a Woven Fiber Glass

c. Catalyst + Resin + a Unidirectional Ffiber Glass Material Preparation and Equipments

Literature study and field

Yes

Bending Test Standard ASTM D 790

Tensile Test Standard ASTM D 638 Impact Test Standard

No Fiber Volume

3 Unidirectional Fiber Glass

37.1 4.76 13.83 2.21 43 29.86 28.334

Table 2 Result of Bending Test

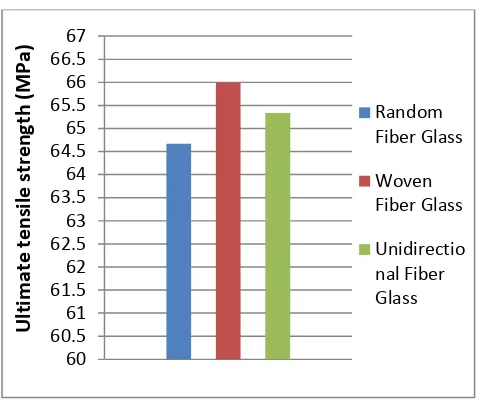

No Fiber Volume

3 Unidirectional Fiber

Glass

37.1

4.76 165 172.63 4.626 65.333 141.170

Table 3 Result of Tensile Test

Impact test

Figure 10 Impact test with numbers of

specimen with different fiber

From the figure 10 show the result of

izod testing in 3 different specimens. The

number of impact is shown with random

fiber glass 0.632 j/mm2 and the value from Woven fiber glass 0.739 j/mm2 and value of unidirectional fiber glass 0.82 j/mm2.

In testing the impact of three

different fibers can determine the strength of

Bending Test

Figure 11 Bending test with numbers of

specimen with different fiber

Bending test was conducted by

fiber used, but for torsion bending test.

Tensile Test

Figure 12 Tensile test with specimen

numbers with different fiber

From the above data in Table 3,

From the result of tensile test with the

different specimens, numbers of stress,

strain is elastic modulus also (Standard

has good tensile strength.

Analysis

High or low strength of the

composite depends on the fiber used,

because the voltage applied to the composite

forwarded to the fiber, so the fiber will

withstand loads up to maximum load.

Therefore, the fiber must have a tensile

stress and modulus of elasticity, higher than

the constituent matrix composites.

Specimens used in the manufacture

of the volume fraction are often used in

communities with 4.76% catalyst

composition of 100 ml of resin and fiber. In

testing the impact unidirectional fiber glass

has better strength 0.0433 j/mm2. And in a

bending test of Woven fiber glass that has a

better strength compared to other fibers

29.89 MPa. Woven fiber glass have a tensile

strength of 66 MPa from the test results of

all specimens can be summed kinds of fiber

strength.

In making uses catalyst, resin, and

fiber. In making resin and catalyst in the

same process, but in this research

differentiate its fiber, from random fiber

glass, Woven fiber glass, and unidirectional

fiber glass. The time is needed to these

variations 75 minutes till dry.

Conclusion

Based on the results of research that has

been conducted, we can take some

conclusions that can be discussed and finally

this research can be concluded:

1. Composite that has the highest

impact strength of

unidirectional fiber glass with a

value of 0.0433 J/mm2. Unidirectional fiber glass has a better

energy absorption than others.

2. From the test results mean maximum

bending highest are woven fiber

glass can withstand bending stress

with good value 29.89 MPa.

3. The composite has the highest tensile

strength of woven glass fiber with a

value of 66 MPa. Woven fiber

glass have a tensile strength that is

better than other fibers.

4. From testing all experiments can be

concluded that Unidirectional fiber

glass better used for variations,

body motorcycle. Because having th

e absorption of energy that better

than the other fibers.

Further Work

2. Preparing the material and tools as

well as possible to make better

result.

3. Hopefully for the next research can

develop this research with other

types of fiber.

REFERENCES

A Review of Engineering Approaches to Design Against Fracture, American Society of

Mechanical Engineers, New York, 1964.

Agus Hariyanto. 2009, Pengaruh fraksi Volume Komposit serat Kenaf dan serat Rayon

Bermatriks Polister terhadap kekuatan Tarik Dan Impact,Jurusan Teknik Mesin, Fakultas

Teknik Universitas Muhammadiyah Surakarta.

High Strain Rate testing “Metals Handbook,” 9th

ed., vol 8, pp. 187-297, American Society for

Metals, Metals Park, Ohio, 1985.

Knott, J. F.: “Fundamental of Fracture Mechanics,” John Wiley And Sons, Inc., New York, 1973.

Plastik berserat kaca (glass-reinforced plastic – GRP), 2004.

http://en.wikipedia.org/wiki/Glass-reinforced_plastic.

Rapid Inexpensive Tests for Determining Fracture Toughness, National Materials Advisory

Board, Nat. Academy of Sciences, Washington, D.C., 1976.

Rolfe, S.T. and J. M. Barsom, “Fracture and Fatigue Control in Structures,” Prantice-Hall, Inc.,

Englewood Cliffis, N. J., 1977.

Sifat mekanik bahan dan hubungan antara respons atau deformasi bahan terhadap bahan yang

diberikan. http://ft.unsada.ac.id/wp-content/uploads/2008/03/bab4-mt.pdf.

Spath, W.: “Impact Testing of Materials.” Thames-Hudson, London 1962.

Tetelman, A. S, and A. J. McEvily, Jr.: “Fracture of Structural Materials,” John Wiley And Sons,

Inc., New York, 1967.