Postharvest disinfestation heat treatments: response of fruit

and fruit fly larvae to different heating media

Krista C. Shellie *, Robert L. Mangan

United States Department of Agriculture,Agricultural Research Ser6ice,Crop Quality and Fruit Insect Research Unit, 2301S.International Boule6ard,Weslaco,TX78596, USA

Received 24 March 2000; accepted 28 July 2000

Abstract

The surface heat transfer efficiency of three heating media (water, and forced air with and without a water vapor-pressure deficit) was compared using four commodities: mango, papaya, grapefruit, and orange. Forced vapor-saturated-air (VFA), and water (HW) transferred heat most efficiently to the fruit surface. Thermal stress to the fruit was greatest during heating in VFA. Thermal diffusivity of fruit corresponded to fruit density, and was highest for papaya and mango. Differences in the oxygen (O2) and carbon dioxide (CO2) concentration inside grapefruit were

apparent among those exposed to an identical heat dose in HW, forced water vapor-pressure deficit air (MFA), or a forced, vapor-pressure deficit atmosphere of 1 kPa O2 with 20 kPa CO2(MFCA). The altered atmosphere that

developed inside fruit during heating in HW or MFCA was shown to enhance efficacy of heat as a disinfestation treatment. Results from this research suggest that heating in an atmosphere that inhibits fruit respiration does not in itself predispose a fruit to injury. The water vapor pressure of the atmosphere used to heat a commodity influences the thermal stress delivered to that commodity during heating. Forced, water vapor-pressure-deficit atmospheres with altered levels of O2 and or CO2 have commercial potential for providing quicker, less severe heat disinfestation

treatments. Published by Elsevier Science B.V.

Keywords: Qquarantine; Fruit fly; Vapor pressure; Respiration; Heat tolerance; Controlled atmosphere; Hot water; Forced air; Anastrepha

www.elsevier.com/locate/postharvbio

1. Introduction

The marketing of fresh horticultural commodi-ties can be disrupted by the presence on the commodity of insects recognized as pests. Produce

harvested from growing regions where insect pests may be present must be disinfested before it can be marketed in a geographic location that has a legislated restriction for that particular insect. Heat is one option that can be used commercially as a postharvest commodity treatment to rid fresh produce of unwanted insects. Hot water immer-sion or high temperature forced air (schedules T102-a, or T103-c-1) can be used to disinfest * Corresponding author: Fax: +1-956-5656652.

E-mail address: [email protected] (K.C. Shel-lie).

mangoes of Anastrepha fruit flies prior to impor-tation into the US (US Department of Agricul-ture, 1998). The treatment schedules for hot water and high temperature forced air provide the same level of quarantine security against a similar pest, yet the high temperature forced air schedule re-quires a more severe heat dose. For example, when hot water is used to heat a 700 g mango, insect control is achieved after 90 min of immer-sion in 46°C water. After 90 min of immerimmer-sion, the center of a 700 g mango heats to 45°C. However, if the same sized mango is heated by high temperature forced air at 50°C, insect control is not achieved until the center of the fruit reaches 48°C (110 min). The more severe heat dose (longer exposure and or higher temperature) re-quired to disinfest mangoes using air suggests that insect tolerance to heat can be lowered by heating a commodity in water.

The medium used to heat a commodity may also influence its tolerance to heat. Many com-modities do not tolerate immersion in hot water, yet the same commodity may tolerate an exposure to heated air at a higher temperature for a longer duration. For example, grapefruit were damaged after immersion for 4.5 h in water at 43.5°C (Miller et al., 1988), even though no damage was observed in grapefruit heated for 5 – 7 h in air at 46°C (McGuire and Reeder, 1992; Shellie and Mangan, 1996). The vapor pressure of the heated air has been shown to alter a commodity’s toler-ance to heat. Jones (1939) was the first to demon-strate the importance of water vapor-pressure during heating in air by lowering the relative humidity of the heated air from 100 to 60%, which resulted in the elimination of visual internal damage symptoms in heated papaya fruit. Hall-man et al. (1990), McGuire and Reeder (1992) and Shellie and Mangan (1996) have also demon-strated that grapefruit tolerate heating with forced air at 46°C for 195-min longer when the heated air is not saturated with water vapor.

The greater heat transfer efficiency of water does not entirely explain the disparity in insect and commodity tolerance to different heating me-dia. For example, McGuire (1991) and Hayes (1994) simulated identical heat transfer efficiencies to deliver identical heat doses via water or air,

and observed damage to grapefruit only when they were heated in water. Inhibition of fruit respiration has been hypothesized as predisposing a fruit to injury during heating (Jones, 1939; Hayes, 1994). However, the mechanism of action by which the heating media alters the commodity and insect tolerance to heat remains in question. The objective of this research was to identify some physical and physiological explanations as to why a more severe heat dose is required for insect control when commodities are heated in air. The specific objectives were to: (1) compare heat transfer efficiencies of water, forced vapor-satu-rated air, and forced vapor-pressure-deficit air; and (2) explore the hypothesis that immersion in hot water alters the concentration of O2and CO2

inside a heated commodity, and that this modified atmosphere lowers the tolerance of fruit fly larvae to heat.

2. Materials and methods

2.1. Heat transfer: commodity and heating medium

Mango (Mangifera indica), grapefruit (Citrus

paradisi ), orange (Citrus sinensis) and papaya

(Carica papaya) fruit of similar weight were

Fruit heated by VFA, or MFA were placed into a treatment chamber similar to that described by Gaffney (1990). The bin (perforated bottom, solid sides) containing the fruit was placed over the air vent inside the chamber so that heated air was forced over the surface of the fruit in a vertical direction. Air speed inside the treatment chamber was maintained at 2 m s−1. The chamber was

equipped with a chilled mirror type hygrometer and a steam generator. Dewpoint temperature inside the chamber was automatically maintained relative to fruit surface temperature using com-puter software that continuously regulated the injection of steam into the treatment chamber. During VFA treatments, a vapor-saturated condi-tion was obtained inside the treatment chamber by maintaining the dewpoint temperature of the chamber air equal to the temperature of the coolest fruit surface. A water vapor-pressure-deficit condition was obtained inside the

treat-ment chamber for MFA treatments by

continuously maintaining the dewpoint tempera-ture of the chamber air 2°C cooler than the coolest fruit surface. The fruit surface remained dry during MFA treatments.

Fruit were weighed and numbered prior to each heat treatment. Fruit density was calculated by dividing the weight of the fruit by the amount of water it displaced (ml) when immersed in a 1000 ml graduated cylinder. Three, 36-gauge (0.13 mm) Type T copper constantan thermocouples were inserted into each fruit. One thermocouple was attached to the fruit surface, a second thermocou-ple was inserted 2 mm deep into the fruit. A third thermocouple was placed 16 mm deep into the fruit by inserting it through a 1.9-mm (outside diameter) plastic tube with a 20-gauge stainless steel pipetting needle. The temperature reading from the third thermocouple was used to deter-mine when to terminate the heat treatment. Each thermocouple was anchored in place with hot glue at the point of insertion on the fruit exterior. The temperature recording region of all thermocouples was free of hot glue. Temperatures were recorded every 60 s throughout the duration of each heat treatment. Exposure to each heating medium was replicated four times.

2.2. Heating medium: fruit internal atmosphere and lar6al mortality

Physiologically mature ‘Rio Red’ grapefruit were harvested from a grove in Weslaco, TX 1 day prior to treatment, and stored overnight at 23°C. The fruit were not washed or waxed prior to treatment. Grapefruit were artificially infested by placing 25, late third instar Anastrepha ludens

(Loew) larvae into the fruit center, as described by Mangan and Ingle (1994) and Shellie et al. (1997). All larvae used in these experiments were ob-tained from an experimental colony, originally founded in 1953 with material from Mexico, and maintained at the USDA – ARS laboratory in Weslaco, TX. Larvae were reared on a standard fruit fly diet of rehydrated carrot powder and torula yeast in a room maintained at 26.792°C. The third instars used in this research were re-moved from the rearing medium at age 8 or 9 days.

An identical heat dose was delivered to infested grapefruit via HW, MFA, or forced, water vapor-pressure-deficit 1 kPa (1%) O2with 20 kPa (20%)

CO2 (balance nitrogen) (hereafter referred to as

MFCA for moist, forced, controlled atmosphere). Graduated temperature-controlled water baths were used to deliver the HW treatment. Computer control was used to simulate the surface tempera-ture of fruit during exposure to MFA or MFCA in the water baths. Simulation of the surface temperature of the fruit during MFA or MFCA treatments in the water baths provided an isother-mal heat dose via all three heating media. The temperature of the circulating water bath was controlled to 90.02°C by a computer-driven tem-perature control system (Water Troll, J.J. Gaffney, USDA – ARS Gainesville, FL). The wa-ter baths consisted of a series of four stainless steel baths (11 l capacity), each equipped with an electric stirrer motor with shaft and propeller, a 1000 Watt electrical resistance heater and a Hart 1006 precision thermometer.

The MFCA treatments were conducted inside a gas-tight, horizontal flow chamber as described by Shellie et al. (1997). Gas velocity inside the cham-ber was maintained at 2 m s−1. A chilled mirror

dewpoint temperature of the chamber 2°C below the coolest fruit surface. Humidity was introduced into the chamber by computer-controlled injec-tion of water through no.12 Baumac™ nozzles. An atmosphere of air or 1 kPa O2 with 20 kPa

CO2 (balance nitrogen) was maintained inside the

chamber during heating. Oxygen and CO2

con-centration was quantified in an HP 5890 gas chromatograph equipped with an Alltech CTR 1 column and thermal conductivity detector. The altered atmosphere was established initially by flushing with nitrogen, and then the required amount of air, CO2, or nitrogen was introduced

using needle valve rotameters (Dakota Instru-ments, Monsey, NY) and compressed gas cylinders.

The temperature of the heating medium and the center of each heat-treated fruit was logged at 60 s intervals using 36-gauge (0.13 mm) Type T copper constantan thermocouples. The concentra-tion of O2 and CO2 inside each heat-treated fruit

was monitored at 30 min intervals by manually extracting gas from the fruit interior (Shellie et al., 1997). A 22 gauge, 15.2 cm long Luer lock needle was inserted into the center of each heat-treated fruit. The Luer lock end of the needle was fitted with a Luer air lock. Needles extended through a rubber septum embedded in the outside wall of the heat chamber, and the Luer air lock was attached to the chamber exterior. A gas-tight, glass sampling syringe was attached to the air lock, and used to extract a 1 ml gas sample from the fruit interior.

The grapefruit were heated in graduated tem-perature water baths, or the forced atmosphere chamber for either 2 or 4.5 h. Equal numbers of artificially infested grapefruit in each replication were either heated or left unheated. Larval mor-tality in heated fruit was adjusted for natural mortality in unheated controls. Due to larvae and fruit availability, a different number of replicates were completed for each time dose and heating media. The 2 and 4.5 h exposures to forced air were replicated eight and 11 times with two heated fruit per replication, resulting in a total of 800 and 550 treated larvae (50 and 25 larvae per fruit). The 2 and 4.5 h exposures to forced, 1 kPa O2 with 20 kPa CO2 were replicated nine and

eight times with two heated fruit per replication, resulting in a total of 450 and 400 treated larvae. The 2 and 4.5 h immersions in graduated temper-ature water baths were replicated ten and four times with three and five fruit, respectively per replication, resulting in a total of 1500 and 500 treated larvae (50 and 25 larvae per fruit).

Late third instar larvae were heated in rearing diet to evaluate the efficacy of atmospheric alter-ations during heating independent of grapefruit. Twenty-five larvae were placed into cups contain-ing 6 g of rearcontain-ing diet. Ten cups were exposed for 2 h to forced, vapor-pressure-deficit air or forced, 1 kPa O2 with 20 kPa CO2 at 44°C. Air speed,

temperature recording, and dewpoint control in-side the treatment chamber were the same as described previously. An equal number of cups were either heated or left unheated, and larval mortality in heated cups was adjusted for natural mortality in unheated controls. Heating in air or 1 kPa O2 with 20 kPa CO2 was repeated twice,

resulting in a total of 500 treated larvae in each atmosphere.

Larvae were removed from heat-treated and non heat-treated fruit or diet 24 h after comple-tion of each heat treatment, and larvae were observed until they either died (brown and desic-cated) or pupated. Adjusted mortality data was expressed as a percentage by dividing the adjusted number of dead larvae by the number of larvae that were treated and multiplying this by 100. Mortality after 2 or 4.5 h treatments was indepen-dently analyzed in an analyses of variance with heating medium as the main effect (GLM proce-dure, SAS® Institute Inc., Cary, NC, USA).

3. Results

3.1. Heat transfer: commodity and heating medium

The average temperature of each heating medium was 48.690.2, 48.190.1, and 47.59

maintained equal to the coolest fruit surface), whereas it increased from 50 to a maximum of 90% during MFA treatments (chamber dewpoint temperature maintained 2°C cooler than the coolest fruit surface). The surface of the fruit heated with VFA was wet after treatment, whereas the fruit surface remained dry after heat-ing with MFA.

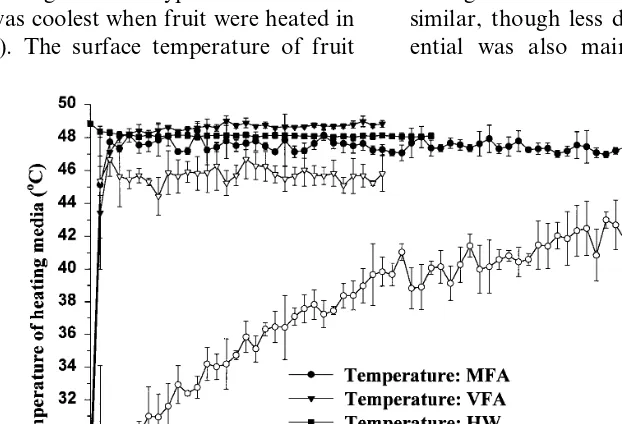

Heat was transferred into the fruit fastest dur-ing VFA heatdur-ing (Fig. 2). It took 62, 72, or 116 min, for the slowest heating type of fruit to reach an average temperature of 46°C, 1.6 cm deep into the fruit. Papaya and mango fruit heated more rapidly than orange and grapefruit (Fig. 2), even though they weighed 50 g more than the citrus fruit and had a higher density than the other fruits (Table 1). Mango and papaya fruit had an average density of 1.03 and 0.91 g ml−1

, respec-tively, and heated about 20 min faster than or-anges (0.88 g ml−1) and grapefruit (0.80 g ml−1).

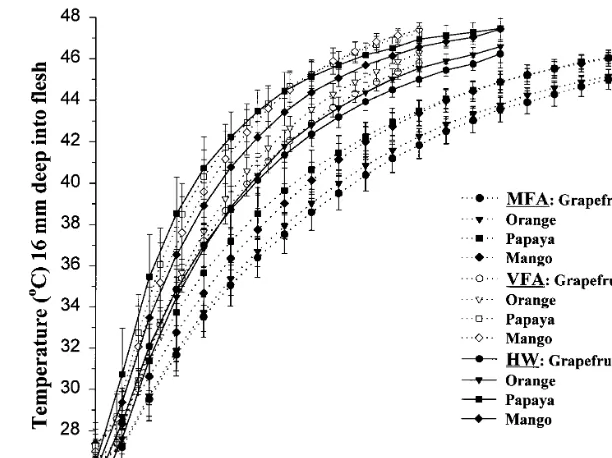

The temperature of the fruit surface during heating varied according to heating medium, but was similar among all fruit types. Fruit surface temperature was coolest when fruit were heated in MFA (Fig. 3). The surface temperature of fruit

heated with VFA or heated in HW reached 46°C, or 96% of the temperature of the heating medium, within 5 min of exposure. In contrast, the surface temperature of fruit heated in MFA reached 39°C, or 81% of the temperature of the heating medium, within 5 min of exposure. During heat-ing in VFA, the surface temperature of the fruit exceeded the temperature of the heating medium after 20 minutes of exposure, and remained

1.0°C hotter throughout the entire 62 min treatment. However, the surface temperature of fruit heated in MFA remained cooler than the temperature of the heating medium throughout the entire 116 min treatment. The surface temper-ature of fruit immersed in HW was similar to the temperature of the water when the treatment was terminated.

The relationship between temperatures at the fruit surface and 2 mm below the fruit surface also varied by heating medium (Fig. 3). A temper-ature differential between the hotter fruit surface and 2 mm deep into the fruit was maintained throughout the entire time of exposure to VFA. A similar, though less dramatic, temperature differ-ential was also maintained between the hotter

Fig. 2. Average temperature 16 mm deep into grapefruit (circle), orange (triangle), papaya (square), or mango (diamond) during exposure to 48°C in forced vapor-pressure-deficit air (MFA) (closed symbol, dotted line), forced vapor-saturated air (VFA) (open symbol, dotted line), or water (HW) (closed symbol, solid line) until the average temperature of the slowest heating type of fruit reached 46°C. Standard errors based upon mean of four replications with three of each fruit type per replication.

fruit surface and 2 mm below the fruit surface for the first 60 min of exposure to HW or MFA. However, after about 60 min of exposure to HW or MFA, this temperature differential dissipated, and the temperature of the fruit surface actually became cooler than 2 mm below the fruit surface.

3.2. Heating medium: fruit internal atmosphere and lar6al mortality

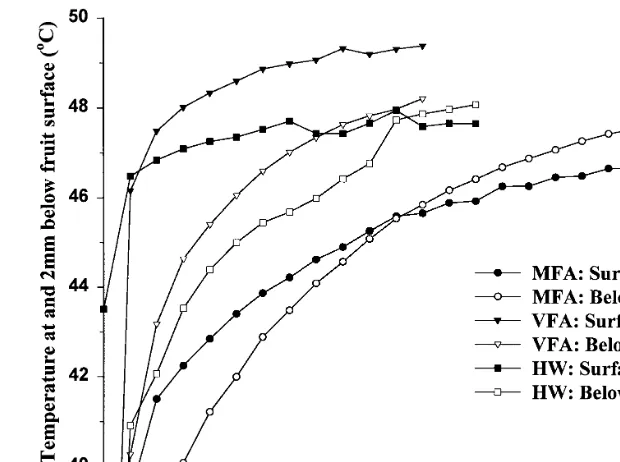

Isothermal heat doses were delivered to the center of grapefruit using three different heating media: MFA, MFCA (1 kPa O2with 20 kPa CO2)

or HW (Fig. 4). The temperature at the center of the fruit reached 41°C and a maximum of 45°C, respectively, after 2 and 4.5 h of heating. Upon termination of the heat treatments, the tempera-ture of the fruit center was cooled to 30°C within 200 min. The range among center temperatures of heated fruit reached a maximum after 30 min of exposure, and then declined. Variability among fruit center temperatures was greatest during heat-ing in water.

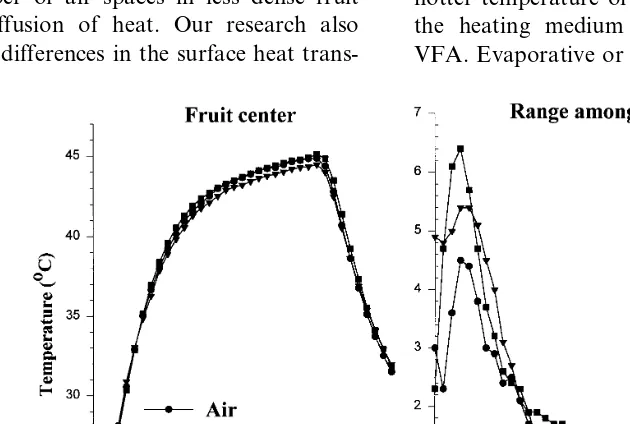

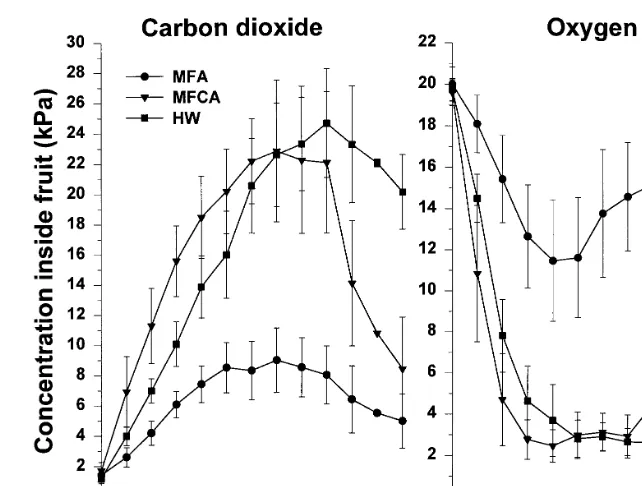

The concentrations of O2 and CO2 inside the

grapefruit were different after 1 h of exposure to the isothermal heat dose (Fig. 5). Prior to heating, the internal atmosphere of all grapefruit con-tained 19.890.2 kPa O2 and 1.590.3 kPa CO2.

After 1 h of heating, (when the fruit center tem-perature was 35°C) the concentration of O2inside

the grapefruit immersed in water or heated in MFCA declined to below 10 kPa and the

concen-Table 1

Average weight and density of papaya, mango, grapefruit, and orange heated in 48°C water, or forced air that was or was not vapor-saturated until the center of the coolest type of fruit reached 46°Ca

Fruit Weight (g)

Fruit Type Density (g ml−1)

Papaya 352.2a 0.91b

335.0a 1.03a

Mango

302.1b

Grapefruit 0.80c

Orange 287.8b 0.88b

aMean separation in columns by Duncan’s multiple range

Fig. 3. Average temperature of the fruit surface (solid symbol) and 2 mm below the fruit surface (open symbol) during heating in vapor-pressure-deficit air (MFA) (circle), vapor-saturated air (VFA) (triangle), or water (HW) (square). Values represent average of 12 fruit (grapefruit, orange, papaya, and mango) over four treatment replications.

tration of CO2 increased to 7 or 11 kPa,

respec-tively. In contrast, the internal concentration of O2and CO2after 1 h of heating in MFA was 15.4

and 4.2 kPa, respectively. A maximum decrease in O2 and increase in CO2 was reached after 3 h of

heating, when the grapefruit center temperature had reached 44°C. Fruit heated in water or trolled atmosphere contained similar internal con-centrations of O2 and CO2 (3 and 21 kPa,

respectively) after 3 h of heating, and remained at about that level until the treatment was termi-nated. The change in internal concentrations of O2 (13 kPa) and CO2(8 kPa) were of less

magni-tude when fruit were heated for 3 h in MFA. The concentrations of O2 and CO2 inside fruit heated

by MFA or MFCA returned close to pre-heat treatment levels within 90 min after heating, whereas fruit heated by HW remained altered at 5 and 20 kPa, respectively.

Larval mortality was highest when artificially infested grapefruit were heated in MFCA or in HW (Table 2). No larvae survived 4.5 h of heat-ing in MFCA or HW, yet 10% of larvae survived 4.5 h of heating in MFA. After 2 h of heating in

MFCA, 21 vs 8% of larvae were killed, respec-tively. Larval mortality was higher after a 2 h isothermal exposure to MFCA than a similar exposure to MFA (88 vs 12%, respectively).

Table 2

Average adjusted percent mortality of late third instar

Anastrepha ludens larvae heated in grapefruit or diet to an identical temperature in air, controlled atmospherea, or waterb

Artificially infested Diet grapefruit (6 g per cup)

Exposure: 2 h 4.5 h 2 h @ 44°C

8.3a 89.8a 11.7a

Hot air

20.7b

Hot CAa 100.0b 88.1b

100.0b NEc

16.1a,b

Hot water

a1 kPa O

2with 20 kPa CO2(balance nitrogen).

bMean separation in columns by Duncan’s multiple range

test,P50.05 (superscript, bold letters).

4. Discussion

The rate at which heat is conducted into a fruit can be predicted by knowing the surface heat transfer coefficient of the heating medium and the thermal diffusivity of the fruit (Hayes, 1994). The surface heat transfer coefficient couples the rate of heat flow through the fruit surface to the differ-ence between the surface temperature and that of the ambient temperature. Once heat has been transferred into a fruit, it travels by conduction at a rate influenced by the thermal diffusivity of the fruit. Therefore, for any given thermal diffusivity, the efficiency by which heat is transferred from a heating medium to the fruit surface drives the rate at which the center of a fruit heats. We have demonstrated, in this research, that the water vapor pressure of the air during forced air heating influences the surface heat transfer coefficient, and suggest that the thermal diffusivity of the fruit is associated with fruit density. Presumably, the greater number of air spaces in less dense fruit slows the diffusion of heat. Our research also suggests that differences in the surface heat

trans-fer coefficient had a greater relative influence on the rate of heating at the fruit center than differ-ences in fruit thermal diffusivity.

Many researchers have demonstrated that heat-ing in MFA is less damagheat-ing to the fruit than HW or VFA. Hayes (1994) assumed a similar surface heat transfer coefficient for heating in VFA and MFA, and concluded that thermal stress by either method would be similar. He also demonstrated a linear, positive relationship between air speed and the surface heat transfer coefficient. By maintain-ing similar air speed and ambient temperature and only altering vapor pressure, we have demon-strated a difference in surface heat transfer effi-ciency between VFA and MFA, and we have shown that thermal stress is greater in VFA. The faster heating rate for VFA compared to MFA suggests that water vapor pressure influences the efficiency by which heat is transferred to the fruit surface. Perhaps the latent heat of condensation, alluded to by Hayes (1994), is responsible for the hotter temperature of the fruit surface relative to the heating medium when fruit is exposed to VFA. Evaporative or transpirative cooling during

Fig. 4. Average temperature of the center and range among fruit center temperatures of grapefruit heated in vapor-pressure-deficit air (MFA) (circle), vapor-pressure-deficit 1 kPa O2with 20 kPa CO2(MFCA) (triangle), or water (HW) (square). The temperature

Fig. 5. Concentration of CO2and O2extracted from the interior of grapefruit exposed to an identical heat dose in

vapor-pressure-deficit air (MFA) (circle), vapor-pressure-vapor-pressure-deficit 1 kPa O2with 20 kPa CO2(MFCA) (triangle), or water (HW) (square). Standard

errors for MFA or MFCA are based upon the average of two fruit over 11 treatment replications, and five fruit over four treatment replications for HW.

exposure to MFA may contribute to the cooler temperature of the fruit surface relative to the heating medium. The cooler temperature of the fruit surface relative to the fruit interior after 60 min in MFA lends additional support for surface cooling.

Jones (1939) and Hayes (1994) hypothesized that inhibition of respiration during heating predisposes a fruit to injury. They postulated that HW caused greater damage to fruit because the water inhibited gas exchange and fruit respiration. Our data demonstrate dramatic differences in the concentra-tion of O2and CO2inside grapefruit when they are

exposed to an isothermal heat dose delivered via water or MFA. We also demonstrated that this altered atmosphere inside the fruit enhanced the efficacy of heat as a disinfestation treatment. En-hanced efficacy of heating in MFCA was also reported by Neven and Mitcham (1996) for codling moth (Cydia pomonellaL.). Our research and that of Shellie et al. (1997) does not support the hypoth-esis that inhibition of respiration during heating

predisposes fruit to injury. Shellie et al. (1997) showed that grapefruit tolerated exposure to MFCA (1 kPa of O2, balance nitrogen) at 46°C for

up to 210 min. The sustained elevation of CO2

concentration inside grapefruit that were heated in water after termination of the heat treatment sug-gests that heating in water is more stressful to grapefruit than heating in a MFCA that simulates identical alteration of respiratory gases. Our data suggest that inhibition of fruit respiration per se

does not predispose fruit to injury during heating.

5. Conclusions

inside the fruit during immersion in hot water may impose an additional stress and may alter the tolerance of fruit fly larvae to heat. Atmospheric modification during heating in a rapidly circulated gas can enhance treatment efficacy, providing quicker, less severe disinfestation heat treatments. Results from this research also demonstrate that the vapor pressure of the atmosphere used to heat a commodity has an important influence on the heating rate and surface temperature of a com-modity. The heating rate is slower, but commod-ity tolerance is enhanced when a water vapor – pressure-deficit is maintained in the heat-ing medium, and the surface of the commodity remains dry. Applications from this research are especially appropriate for the many commodities that cannot tolerate immersion in hot water.

Acknowledgements

We thank Sam J. Ingle, Eli Moreno, Julie de Leon, and Karen Robacker for their assistance in conducting this research.

References

Gaffney, J.J.,1990. Warm air/vapor heat research facility for heating fruits for insect quarantine treatments. Amer. Soc. of Agr. Eng. Paper No. 906615. St. Joseph, MI.

Hallman, G.J., Gaffney, J.J., Sharp, J.L., 1990. Vapor heat treatment for grapefruit infested with Caribbean fruit fly (Diptera: Tephritidae). J. Econ. Entomol. 83, 1475 – 1478. Hayes, C.F., 1994. Modeling heat and cold transfer. In: Paull, R., Armstrong, J.W. (Eds.), Insect Pests and Fresh Horti-cultural Products. CAB International, Wallingford, U.K, pp. 237 – 248.

Jones, W.W., 1939. The influence of relative humidity on the respiration of papaya at high temperatures. Proc. Amer. Soc. Hort. Sci. 37, 119 – 124.

Mangan, R.L., Ingle, S.J., 1994. Forced hot air quarantine treatment for grapefruit infested with Mexican fruit fly. J. Econ. Entomol. 87, 1574 – 1579.

McGuire, R.G., 1991. Market quality of grapefruit after heat quarantine treatments. HortScience 26, 1393 – 1395. McGuire, R.G., Reeder, W.F., 1992. Predicting market quality

of grapefruit after hot-air quarantine treatment. J. Amer. Soc. Hort. Sci. 117, 90 – 95.

Miller, W.R., McDonald, R.E., Hatton, T.T., Ismail, M., 1988. Phytotoxicity to grapefruit exposed to hot water immersion treatment. Proc. Fla. State Hort. Soc. 101, 192 – 195.

Neven, L.G., Mitcham, E.J., 1996. CATTS (Controlled atmo-sphere/temperature treatment system): a novel tool for the development of quarantine treatments. Amer. Entomol. Spring, 56 – 59.

Shellie, K.C., Mangan, R.L., 1996. Tolerance of red-fleshed grapefruit to a constant or stepped temperature, forced-air quarantine heat treatment. Postharvest Biol. Technol. 7, 151 – 159.

Shellie, K.C., Mangan, R.L., Ingle, S.J., 1997. Tolerance of grapefruit and Mexican fruit fly larvae to heated controlled atmospheres. Postharvest Biol. Technol. 10, 179 – 186. US, Department of Agriculture, 1998. Plant Protection and

Quarantine Treatment Manual. US Dept. Agr., Animal Plant Health Inspection Serv, Hyattsville, MD.