PRELIMINARY DESIGN OF PRECIPITATED SILICA PLANT FROM SULPHURIC ACID AND SODIUM SILICATE

WITH CAPACITY OF 40,000 TON/YEARS

By:

MR.ISMAAE YUSOH D500112010

Supervisor:

Dr. Ir. Ahmad M. Fuadi, MT Kun Harismah Ph. D

CHEMICAL ENGINEERING DEPARTMENT FACULTY OF ENGINEERING

APPROVAL

Title : Preliminary of Precipitated Silica Plant from Sulphuric Acid and Sodium Silicate with Capacity of 40,000

Head of Chemical Engineering,

STATEMENT LETTER

I declare that this final report is original. There are no previous researches

that have been submitted in order to get bachelor degree. As I know, there are no

statements from other researchers, except the statements that are listed in the

bibliography.

In the future, if there is a lie on my statements then I will be fully

responsible.

Surakarta, July 2015

ACKNOWLEDGEMENT

The author says thank to Allah SWT who gives His blessing, so the author

has been able finish the final a project “Preliminary of Precipitated Silica Plant from Sulphuric Acid and Sodium Silicate with Capacity of 40,000 ton/years”.

In arranging the report, the author have get supports from several parties.

Because of that, the author wants to say thank to:

1. Allah SWT who has given me His mercy and His blessing.

2. Baba (บาบอ), Mama (มาม่า), Kakak Bede (แบเดร์), Beheng (แบเฮง), Tetoh Dah

(แตเตาะ), Besi’ (แบเซะ), Beding (แบดิง), Bema’ (แบมะ) and brother Hanan (ฮา

นาน) who always gives a support to the writer.

3. Mr. Dr. Ir. Ahmad M Fuadi, MT as supervisor I.

4. Mrs. Kun Harismah Ph.D as supervisor II.

5. Linda Fatmawati as a partner of Our Final Project

6. Nurdeeyah Thank you for all the support.

7. Arbideen and Masoleah thank you for standing by me.

Finally, the writer hopes that this final project report will give benefit for

all researchers, writers, and reader. Aamiin

Surakarata, June 2015

ABSTRACT

In Indonesia, precipitated silica plant is an industry that can provide a good opportunity for the country. Indonesia has not been able to meet the needs of precipitated silica, so that Indonesia imports from other countries. From 2005 to 2012 Indonesia has exported 89,801.806 tons of precipitated silica, and the capacity for imports are 111,362.3 tons, so the precipitated silica plant is designing of 40,000 tons/year. Precipitated silica (SiO2) is the

oxidation of non-metallic compounds. it has a solid powder form, white, odorless, insoluble in water, and has a crystalline structure. The process of manufacturing of precipitated silica using silicate acidification uses CSTR reactor (continuous stirrer tank reactor). It operates at a temperature of 90°C and at a pressure of 1 atm. This reactor proceeds in the liquid phase, irreversible, and non-adiabatic. The product of the reactor are separated in rotary vacuum filter, and then the result is a cake of SiO2. It is dried with

dryer.

MOTTO

Pray on time, surely GOD will always help us.

Ibu Aminah Yusoh

Just be a good person

Mr.Dr. Muhammad Asmee Abubaka

ความภูมิใจสูงสุดในชีวิตคือการประสบความส าเร็จ ในสิ่งที่คนรอบข้างเชื่อว่าคุณไม่มีวันท าได้

(A great pleasure in life is doing what people say you cannot do.)

Hamidah Yusoh

Always thing that time is important thing that will make us get better and successful

We thing when we dream, and we try to do it, Insya allah it will become true Muhammad Yusoh

"Don't limit yourself. Many people

Limit themselves to what they

Think they can do. You can go as far

As your mind lets you.

What you believe, remember, you can archive."

Zeal is a volcano, the peak of which the grass of indecisiveness does not grow.

(The spirit is a volcano that on it, the doubts grass never grows)

"Be you. Find you.

DEDICATION

This work is dedicated for:

My mom is the one who give a spirit for me, advise me, and also give me a direction so that I can finish this final report.

(I LOVE YOU MOM)

Baba is my idol. Even he is hard but I know that he did for me. (I LOVE YOU BABA)

For my baba and mama. Thank you for your praying. Thanks for your money. I will replace it later.

My partner Linda Fatmawati. When I am down, you are the one who always give me a spirit. Thanks

TABLE OF CONTENTS

TABLE OF CONTENTS ... viii

LIST OF TABLE ... xi

1.5Properties of Physical and Chemical Raw Materials and Products ... 6

1.6The General Process Review ... 9

CHAPTER II PROCESS DESCRIPTION ... 10

2.1The Specification of Raw Materials and Products…... 10

2.2The Process Concept ... 10

2.3The Thermodynamic Review ... 11

2.4The Flowchart ... 12

2.5The Process Stages ... 12

2.6The Flowchart of Material Balance and Heat Balance ... 14

2.7The Plant Layout and Equipment ... 18

CHAPTER III THE SPESIFICATION OF THE EQUIPMENT ... 23

3.1Tank of Sodium Silicate (T-01) and Tank of H2SO4 (T-02) ... 23

CHAPTER IV PROCESS SUPPORT UNIT AND LABORATORY ... 32

4.1Process Support Unit... 32

CHAPTER V MANAGEMENT ... 56

5.1Company ... 56

5.2Organizational Structure ... 57

5.3Employee Welfare ... 65

5.4Health and Safety ... 65

5.5Production Management ... 66

5.6Production Plan ... 64

5.7Production Control ... 67

CHAPTER VI ECONOMICAL ANALYSIS ... 70

6.1Basic Calculation ... 70

6.3General Expenses ... 74

6.4Feasibility Analysis ... 74

6.5The Result of Calculation ... 76

CHAPTER VII CONCLUSION ... 81

BIBLIOGRAPHY ... 82

LIST OF TABLE

Table 1.1 The export data and import data precipitated silica... 2

Table 1.2 The existing capacity of precipitated silicaplant... 3

Table 2.1 The data of reaction formation of precipitated silica... 11

Table 2.2 The component of material flow... 14

Table 2.3 The material balance mixer (M-01)... 15

Table 2.4 The material balance of reactor 1 (R-01)... 15

Table 2.5 The material balance of reactor 2 (R-02)... 15

Table 2.6 The material balance, rotary drum filter (RDF-01)... 15

Table 2.7 The material balance, rotary dryer (RD-01)... 16

Table 2.8 The total of material balance... 16

Table 2.9 The heat balance of mixer (M-01)... 16

Table 2.10 The heat balance of reactor (R-01)... 17

Table 2.11 The heat balance of reactor (R-02)... 17

Table 2.12 The heat balance of rotary drum filter (RDF-01)... 17

Table 2.13 The heat balance of rotary dryer (RD-01)... 17

Table 2.14 The heat balance around heat exchanger (HE-01)... 17

Table 2.15 Building precipitated silica... 20

Table 3.1 The needs of electricity for process... 50

Table 5.1 Schedule for each group... 63

Table 5.2 Positions and requirements... 63

Table 5.3 Data of the number of process employee... 64

Table 6.1 Cost index chemical plant year 1990-2010... 71

Table 6.2 Physical plant cost... 76

Table 6.3 Fixed capital cost... 77

Table 6.4 Working capital investment... 77

Table 6.5 Manufacturing cost... 77

Table 6.6 General expense... 78

Table 6.7 Fixed cost... 79

Table 6.8 Variable cost... 79

xiii

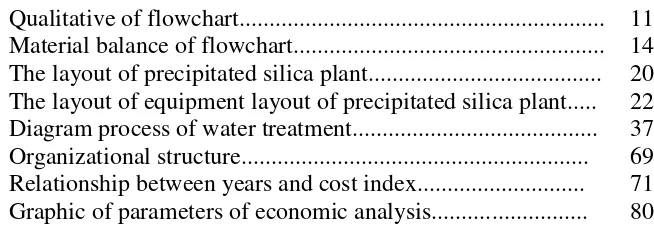

LIST OF FIGURE

Figure 2.1 Qualitative of flowchart... 11

Figure 2.2 Material balance of flowchart... 14

Figure 2.3 The layout of precipitated silica plant... 20

Figure 2.4 The layout of equipment layout of precipitated silica plant... 22

Figure 4.1 Diagram process of water treatment... 37

Figure 5.1 Organizational structure... 69

Figure 6.1 Relationship between years and cost index... 71