Other uses, including reproduction and distribution, or selling or

licensing copies, or posting to personal, institutional or third party

websites are prohibited.

In most cases authors are permitted to post their version of the

article (e.g. in Word or Tex form) to their personal website or

institutional repository. Authors requiring further information

regarding Elsevier’s archiving and manuscript policies are

encouraged to visit:

a v a i l a b l e a t w w w . s c i e n c e d i r e c t . c o m

j o u r n a l h o m e p a g e : w w w . e l s e v i e r . c o m / l o c a t e / i n d c r o p

Effect of curing time on physical and mechanical properties

of phenolic-treated bamboo strips

U.M.K. Anwar

a,∗, M.T. Paridah

b, H. Hamdan

a, S.M. Sapuan

c, E.S. Bakar

baForest Product Division, Forest Research Institute Malaysia, 52109 Kuala Lumpur, Malaysia

bFaculty of Forestry, Universiti Putra Malaysia, 43400 Serdang, Selangor, Malaysia

cFaculty of Engineering, Universiti Putra Malaysia, 43400 Serdang, Selangor, Malaysia

a r t i c l e

i n f o

Article history:

Received 14 November 2006 Received in revised form 30 April 2008

Accepted 3 May 2008

Keywords: Bamboo strips Impregnation Phenolic resin Pressing time

a b s t r a c t

Effect of pressing time on physical and mechanical properties of phenolic-impregnated bam-boo strips was evaluated. Bambam-boo strips (Gigantochloa scortechinii) were impregnated with low molecular weight phenol formaldehyde (LMwPF) resin. Samples were submerged in LMwPF resin using a vacuum chamber of 750 mmHg for 1 h before it was released within 1.5 h.

Treated strips were dried in an oven with a temperature of 60◦C within 6–9 h. It was hot

pressed at 14 kg m−2and a temperature of 140◦C for 5, 8, 11, 14 and 17 min. The physical

and mechanical properties of the test indicated that the properties of phenolic-treated strips have significantly increased as compared to control samples. Dimensional stability (water absorption, thickness swelling and linear expansion) of the phenolic-treated properties were significantly lower than control after 5-min pressing time. The antishrink efficiency (ASE) of phenolic-treated strips increased when pressing time were extended from 5 to 17 min. The

mean value of modulus of rupture (MOR) for the control samples (177 N mm−2) showed a

significant difference with phenolic-treated strips after 17-min pressing time (224 N mm−2).

However, there is no significant difference in compression parallel to grain. The MOE of

phenolic-treated strips was 21,777 N mm−2and for control was 18,249 N mm−2, whereas the

compression parallel to grain values for phenolic-treated and control samples were 94 and

at 77 N mm−2, respectively.

© 2008 Elsevier B.V. All rights reserved.

1.

Introduction

Bamboo is one of the fastest growing plants that can be used for multipurposes. The modern processing techniques of bam-boo have further extended its use. Bambam-boo is used in splits, strips or round form depending on the application. For being used as constructional material, bamboo culms must be con-verted into bamboo strips to make plybamboo, bamboo mat board and laminated bamboo. The term of strips is defined as squared splits resulted by removing the outer and inner skin of the bamboo splits with a planner. However, bamboo strips

∗Corresponding author. Tel.: +60 3 6279 7390; fax: +60 3 6280 4623.

E-mail address:[email protected](U.M.K. Anwar).

have some inherent properties, such as dimension changes due to varying moisture content, relative humidity, and biotic

and abiotic degradation (Hamdan, 2004; Mansur, 2000; Deka

et al., 2003).Anwar et al. (2005)observed that the shrinkage of strip was significantly higher when the epidermises and inner

layer of bamboo splits were removed. According toAbd. Latif

and Liese (1995)bamboo started to shrink from the very begin-ning of the drying process. Shrinkage generally decreases with age and culms height where the dimensional stability of the top portion of older bamboo is much greater than that of basal of young ones.

In order to enhance the properties of lignocellulose mate-rial, a lot of research has been done especially through resin impregnation. The resin caused significant increase in strength properties of bamboo and exhibited higher dimensional stability when compared to untreated

bam-boo (Deka et al., 2003). Mahlberg et al. (2001) also found a

significant improvement in the mechanical properties and dimensional stability of wood fiber when impregnated with

polypropylene.Gindl et al. (2003)noticed that impregnation of

melamine–formaldehyde (MF) resin into wood could improve a number of its wood properties, such as surface hardness and

weathering resistance. As mentioned byFuruno et al. (2004)

the phenolic resin was penetrated into the cell walls, thereby contributing the enhancement of dimensional stability and decay resistance in the resin-impregnated wood. It has been assumed that the deposition of polymer within the wood cell walls resulted in high decay resistance as well as an

improve-ment in the dimensional stability (Imamura et al., 1998). The

objective of this study is to determine the optimum curing time of phenolic-treated strips and its effect on physical and mechanical properties.

2.

Materials and methods

Strips were obtained from 4-year-old bamboo (Gigantochloa scortechinii) and the moisture content was about 10%.

Speci-men size of 400 mm×20 mm×4 mm was submerged in low

molecular weight phenol formaldehyde (LMwPF) resin in a container and put inside a vacuum chamber set for 750 mmHg. The vacuum pressure was maintained for 1 h before the air in the vacuum chamber was slowly released within 1.5 h.

The samples were dried in an oven maintained at 60◦C for

6–9 h. After being dried, the impregnated bamboo strips were pressed using hot press at different pressing durations of 5, 8,

11, 14 and 17 min. The hot press temperature was set at 140◦C

and pressure of 14 kg cm−2 (Anonymous, 1999; Anwar et al.,

2004). All the samples were stacked in a conditioning

cham-ber with a temperature of 20±2◦C and a relative humidity of

65±3% until they reached equilibrium moisture content.

2.1. Evaluation of physical properties

The water absorption test of the samples was based on weight of the specimens before and after immersion in water for 24 h. The weight of soaked samples was measured immediately after the removal of the excess water with a dry cloth. Same specimens were used for the determination of dimensional stability. The properties were evaluated based on thickness swelling and linear expansion after being soaked in water.

Sixty specimens (25 mm×20 mm×5 mm) were prepared and

the width and thickness of all samples were measured before and after horizontally immersion in water (30 mm below the water surface) for 24 h. Measurements were taken by using digital vernier calipers with a precision of 0.01 mm. Due to the absence of an international standard that can be used as a ref-erence for testing the physical and mechanical properties of bamboo strips, the testing protocol thus follows different stan-dards and methods used by other researchers on similar study. The water absorption and dimensional stability (thickness

swelling, perpendicular to the grain) were evaluated based

on European Standard EN 317 (Anonymous, 1993) with some

modification on the size of the specimens based onHamdan

(2004). The antishrink efficiency tests procedure was prepared

afterKollman et al. (1975). Water absorption and dimensional

stability (linear expansion, thickness swelling and antishrink efficiency) of the specimens were calculated from the follow-ing equations:

Water absorption (%)= W2−W1

W1 ×100

whereW1= weight before soaking, g;W2= weight after

soak-ing, g.

Thickness swelling and linear expansion (%)

= D1−D2

D2 ×100

whereD1= initial thickness or linear expansion, mm;D2= final

thickness or linear expansion, mm.

Antishrink efficiency= St−Su

Su ×100

St= treated volumetric swelling coefficient;Su= untreated

vol-umetric swelling coefficient.

where S= V2−V1

V1 ×100

S= volumetric swelling coefficient; V2= wood volume after

wetting with water; V1= wood volume before wetting with

water.

2.2. Evaluation of mechanical properties

The specimens for static bending test were prepared in

accor-dance with the method developed byGhanaharan et al. (1994)

whereas samples for compression parallel to grain were

pre-pared using the method described byJanssen (1981). A total

of 120 specimens were used for the determination of static bending and compression parallel to the grain. The tests were performed using an Instron testing machine with a capacity

of 100 kN in a controlled room temperature of 20±2◦C and

65±3% RH.

3.

Statistical analysis

The changes in dimensional stability of phenolic-treated and control strips were discussed using column graph. Stan-dard error was used as an indicator for significant difference between the variables. For mechanical properties, the statis-tical analysis was carried out using the statisstatis-tical analysis software (SAS). A least significant difference (LSD) method was used to identify the dominant factor and its

interac-tion that affect the means atp≤0.05. This method ranks the

Fig. 1 – Water absorption percentage after 24-h soaking for control and phenolic-treated bamboo strip.

Note: Means followed with the same lettersa,bwere not

significantly different (p≤0.05). Vertical bar represent

standard error.

when the strength properties were adjusted for moisture con-tent and specific gravity (SG) at the time of test.

4.

Results and discussion

4.1. Physical properties

The extent and magnitude of water absorption and dimen-sional stability, i.e., thickness swelling, linear expansion perpendicular to grain and antishrink efficiency (ASE), of the

samples, are shown inFigs. 1, 2, 3 and 4, respectively. Results

indicate that phenolic-treated bamboo strips exhibited lower water absorption and improved the dimensional stability, which lesser extent of thickness swelling and linear expansion compared to those of control samples. Water absorption after 24-h water soaking for phenolic-treated (5-min pressing) and control samples was 33.25 and 51.32%, respectively. Samples pressed for 17-min showed an improvement of 135% water absorption.

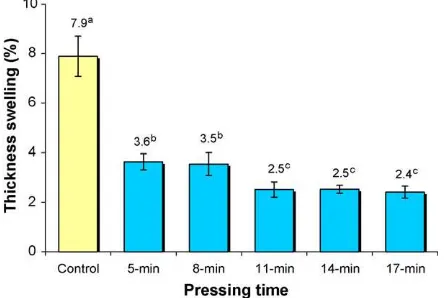

Fig. 2 – Thickness swelling percentage after 24-h soaking for control and phenolic-treated bamboo strip.

Note: Means followed with the same lettersa,bwere not

significantly different (p≤0.05). Vertical bar represent

standard error.

Fig. 3 – Linear expansion perpendicular to the grain percentage after 24-h soaking for control and phenolic-treated bamboo strip.

Note: Means followed with the same lettersa,bwere not

significantly different (p≤0.05). Vertical bar represent

standard error.

Fig. 4 – Antishrink efficiency after 24-h soaking for phenolic-treated strips.

Note: Means followed with the same lettersa,bwere not

significantly different (p≤0.05). Vertical bar represent

standard error.

In the thickness swelling study, after 5-min press (3.64%), phenolic-treated strips showed less swelling than control samples (7.89%), upon soaking for 24 h. The thickness swelling after 8, 11, 14 and 17-min were 3.55, 2.52, 2.53, and 2.41%, respectively. Linear expansion of bamboo strips for phenolic-treated and control samples were evaluated. In gen-eral, phenolic-treated strips showed less linear expansion than control samples. The linear expansion value of 5.34% was obtained from control samples compared to 1.93% for phenolic-treated (after 5-min pressing). Water absorption, thickness swelling and linear expansion were reduced when the pressing time of phenolic-treated strips was extended.

The standard error and LSD for the physical properties

of phenolic-treated strips and control (4-year-old culms ofG.

scortechinii) are also presented inFigs. 1–3. The variability of

physical properties was significant between phenolic-treated

and control strips. A significant difference (p≤0.05) was

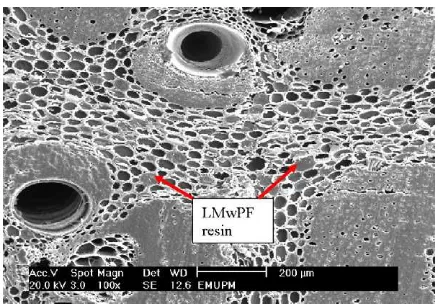

Fig. 5 – LMwPF resins were found in parenchyma (100×).

control samples. No significant difference (p≤0.05) was found

within all treated samples for linear expansion, whereas

significant differences (p≤0.05) in water absorption and

thick-ness swelling were observed after 11-min pressing time. This explained that the physical properties of bamboo strips decrease when pressing time extended. However, the proper-ties decreased gradually after 11-min pressing time.

The antishrink efficiency (ASE) of phenolic-treated strips

was increased when pressing time extended (Fig. 4). The

high-est values (75%) were reached after 17 min of pressing time. This proved that pressing time influences the curing time of

LMwPF resin. According toCollins (1996)during hot pressing

these methylol groups were converted into more methylene bridges between phenolic rings resulting in the formation of a very highly cross-linked thermoset polymer. On the other hand, high ASE that might be due to the availability of treated strips reduced the holding capacity of water molecules in

parenchyma cells. According toAbd. Latif and Mohd. Tamizi

(1992), parenchyma cells serve as sites for water storage in bamboo. The higher content of parenchyma cells in the

bam-boo increases the water holding capacity of the bambam-boo (Liese

and Grover, 1961).

Improvement of dimensional stability is due to penetra-tion of LMwPF resin into bamboo strips. After being pressed at

140◦C, the resins are cured and thus they prevent absorption

of phenolic-treated strips and the samples became dimen-sionally stable. However, pressing time does not affect the improvement of dimensional stability after 11-min pressing

time.Furuno et al. (2004)in agreement withDeka and Saikia

(2000)concluded that good dimensional stability may be due to the bulking effect where the resin occupied the lumen either in granules or in patches when cured. This suggests that the low molecular weight resins were deposited exten-sively into the wood cell walls and thus were effective in reducing the swelling of wood specimens during water immer-sion. It has been assumed that the deposition of polymer within the wood cell walls resulted improvement in

dimen-sional stability as well as high decay resistance (Imamura et

al., 1998).

Scanning electron micrograph (SEM) was used to observe the penetration of LMwPF in bamboo strips. The resins were

recognized in parenchyma (Figs. 5 and 6), such as resin

gran-ules and patch which forms various shapes and sizes. Based

onFuruno et al. (2004)using LMwPF resin, it is assumed that the fraction of higher molecular weight resin remained on the inner walls as granular forms. Only the part of the resin which penetrated into the bamboo strips contributed to the enhance-ment of dimensional stability and mechanical properties of the samples.

4.2. Mechanical properties

Table 1shows the mean values of mechanical properties of

G. scortechiniiafter being impregnated and pressed under

var-ious pressing times. The modulus of rupture (MOR), modulus of elasticity (MOE) and compressive stress were studied. The treatment was significantly reduced moisture content at about 4.8% in average compared to control strips. A slight increment in the SG of phenolic-treated strips was observed at 0.8 as compared to 0.75 for control samples. This result is consid-ered good since there was only a small increase in weight. The

finding (SG) was in good agreement withZaidon et al. (1990)

andShams et al. (2004)but differed to that found byDeka et al. (2003), who treatedBambusa tuldaRoxb. with a thermosetting resin and found that the SG remained unchanged.

The strength properties of control samples were slightly lower than phenolic-treated after 5-min pressing time. The

MOR values were 177 N mm−2and 205 N mm−2, respectively.

The highest values of MOR, MOE and compression parallel

to grain (224 N mm−2; 21,719 N mm−2 and 94 N mm−2) were

achieved after 17-min pressing. The strength properties were significantly improved of 26, 21 and 22% for MOR, MOE and compression parallel to gain, respectively.

The results of statistical analysis (LSD and ANCOVA) are

shown inTable 1. The mean values were analysed with LSD

and found that the MOR values were significantly different at

p≤0.05 when comparing control and phenolic-treated strips.

However, in MOE and compression to the grain values, a

sig-nificant difference (p≤0.05) was found after 17-min pressing

time.

When the mechanical properties values were adjusted which the MC and SG used as factor. The results indicate that pressing time had a significant effect on MOR and MOE. However, in compression parallel to grain no significant

dif-ference atp≤0.05 (which is in contrast to the case of MOR

and MOE) was found between control and phenolic-treated

T

bamboo strips. The results suggest that the pressing time only affects the MOR and MOE not compression parallel to grain of bamboo strips. However, generally there is no significant effect within the pressing time observed.

In general, the results were also consistent with the fact that impregnation with LMwPF resin improves the strength properties of lignocelluloses material. The MOR, MOE and compression values of treated samples were higher than control strips, which may be attributed to the present of LMwPF resin in bamboo strips. It also could be explained that, during pressing, the resins were polymerized and cured (seeFigs. 5 and 6). Therefore, when pressure and heat were applied, the strips became densified while the resin

polymer-ized.Rowell (1991)noted that the resin usually starts as a

low molecular weight pre-polymer and builds the degree of

polymerization in the curing process. According toDeka and

Saikia (2000), MOR and MOE values were increased due to the fact that the bulked volumes of the treated samples remained the same after curing. They also found that MOR and MOE of wood which treated with PF increased the values at about 21

and 12%, respectively. In other study byShams et al. (2004),

they note that the mechanical properties of treated samples increased when the pressure increased.

5.

Conclusion

The treatment of bamboo strips with LMwPF resin followed

by pressing at 140◦C improved the dimensional stability and

strength properties of the strips. The treatment improved water absorption, thickness swelling and linear expansion perpendicular to grain after 24 h of cold water soaking. The values for MOR, MOE and compression parallel to grain of phenolic-treated strips were increased when the pressing time increases. The highest strength properties were attained at 17 min of pressing time.

Acknowledgements

The author acknowledges the Forest Research Institute Malaysia (FRIM), Ministry of Science Technology and Innova-tion (MOSTI) and Universiti Putra Malaysia (UPM) for funding this project. The resins provided by Malaysian Adhesive Chemical (MAC) are gratefully acknowledged. The results are part of the PhD project of U.M.K. Anwar.

r e f e r e n c e s

Abd. Latif, M., Liese, W., 1995. Utilization of bamboos. In Abd. Razak, O., Abd. Latif, M., Liese, W., Norini. H. (Eds.), Planting and Utilization of Bamboo in Peninsular Malaysia. Forest Research Institute Malaysia Research Phamplet no. 11, pp. 50–110.

Abd. Latif, M., Mohd. Tamizi, M., 1992. Variation in anatomical properties of three Malaysian bamboo from natural stands. J. Trop. For. Prod. 5 (1), 90–96.

Anonymous, 1999. General bonding requirements for urea formaldehyde and phenol formaldehyde (MR) and phenol formaldehyde (WBP) resin adhesives. Malaysian Adhesives and Chemicals Sdn. Bhd., pp. 1–4.

Anwar, U.M.K., Zaidon, A., Paridah, M.T., Razak, W., 2004. The potential of utilising bamboo culm (Gigantochloa scortechinii) in the production of structural plywood. INBAR. J. Bamboo Rattan 3 (4), 393–400.

Anwar, U.M.K., Zaidon, A., Hamdan, H., Mohd. Tamizi, M., 2005.

Physical and mechanical properties ofGigantochloa scortechinii

Bamboo Splits and Strips. J. Trop. For. Sci. 17 (1), 413–418. Collins, P.J., 1996. Current research activities on wood adhesives

at CSIRO. Proceedings of the 25th Forest Research Conference, CSIRO Division of Forestry and Forest Products, Clayton, Victoria, Australia, vol. 1, November 18–21, 1996, pp. 1–8. Deka, M., Saikia, C.N., 2000. Chemical modification of wood with

thermosetting resin: effect on dimensional stability and strength property. Bioresour. Technol. 73, 179–181 (Short communication).

Deka, M., Das, P., Saikia, C.N., 2003. Studies on dimensional stability, thermal degradation and termite resistant properties

of bamboo (Bambusa tuldaRoxb.) treated with thermosetting

resins. Bamboo Rattan 2 (1), 29–41.

Furuno, T., Imamura, Y., Kajita, H., 2004. The modification of wood by treatment with low molecular weight

phenol-formaldehyde resin: a properties enhancement with neutralized phenolic-resin and resin penetration into wood cell walls. Wood Sci. Technol. 37, 349–361.

Ghanaharan, R., Janssen, J.J.A., Oscar, A., 1994. Bending strength of Guadua Bamboo comparisons of different testing procedures. INBAR Working Paper no. 3, pp. 1–24.

Gindl, W., Zargar-Yaghubi, F., Wimmer, R., 2003. Impregnation of softwood cell walls with melamine-formaldehyde resin. Bioresour. Technol. 87, 325–330.

Hamdan, H., 2004.Characterizing the mechanical properties and

behavior ofGigantochloa scortechiniifor structural application.

PhD University of Wales, U.K.

Imamura, Y., Yalinkilic, M.K., Kajita, H., Furuno, T., 1998. Properties enhancement of wood by treatment with neutralized phenolic-resin. In: Proceedings of the Fourth Pacific Rim Bio-based Composites Symposium, November 2–5, Bogor, Indonesia.

Janssen, J.J.A., 1981. The relationship between mechanical properties and the biological and chemical composition of bamboo. Bamboo production and utilization. In: Higuchi, T. (Ed.), Proceedings of XVIII IUFRO World Congress, Kyoto, 1981. Kyoto University, Kyoto, Japan, pp. 27–32.

Kollman, F.E.P., Kuenzi, E.W., Stamm, A.J., 1975. Principles of Wood Sciences and Technology. Part 2. Wood Based Materials. Spriger-Verlag, Berlin/Heidelberg/New York.

Liese, W., Grover, P.N., 1961. Untersuchungen ¨uber den Wassergehalt von indischen Bambushalmen. Ber. Deut. Bot. Gesellschaft 74, 105–117.

Mahlberg, R., Paajanen, L., Nurmi, A., Kivist ¨o, A., Koskela, K., Rowel, R.M., 2001. Effect of chemical modification of wood on the mechanical and adhesion properties of wood

fiber/polypropylene fiber and polypropylene/veneer composites. Holz als Roh-und Werk stoff 59, 319–326. Mansur, A., 2000. Analysis of Calcutta bamboo for structural

composites materials. Ph.D. Virginia Tech. Virginia Polytechnic Institute and State University.

Rowell, R.M., 1991. Chemical modification of wood. In: Hon, D.N.S., Shiraishi, N. (Eds.), Handbook on Wood and Cellulosic Material. Marcel Dekker, Inc., New York, pp. 703–756, Chapter 15.

Shams, M.I., Yano, H., Endou, K., 2004. Compressive deformation of wood impregnated with low molecular weight phenol formaldehyde (PF) resin I: effects of pressing pressure and pressure holding. Wood Sci. 50, 337–342.