PRESENTASI TEKNIK

FLEXIBLE PACKAGING

MATERI

Proses produksi “flexible packaging”

Pre press

Printing

Extrusion dan Dry Lamination

Metalizing

Material untuk flexible packaging :

printing/main substrate, Barrier dan heat sealing

Material yang umum digunakan dan cara

pembuatannya

PROSES PRODUKSI KEMASAN

LENTUR

DESIGN

Koreksi teks, layout, gambar / slide, ukuran

FINAL ART WORK (F/A)

Persetujuan pemesan PEMBUATAN SILINDER Proof print SILINDER POLOS CETAK MZ

DL / EXT

DL / EXT

BAG MAKING

SLITTING

GUDANG / EKSPEDISI

MZ = Metalizing DL = Dry Laminating

EXT = Extrusion Coating /

Laminating MATERIAL CETAK (FILM),

TINTA

FILMLESS ENGRAVING

SLIDE + F/A

COMPUTER

SCAN

INPUT DESIGN TANPA SLIDE

KOREKSI / MANIPULASI

ANALOG DIGITAL (PIXEL)

SOFTWARE : PHOTOSHOP ILLUSTRATOR FREEHAND CORELDRAW PAGEMAKER

OUTPUT

(DISKET/OPTICAL DISC)

CYLINDER ENGRAVER

INTERFACE

PROSES PEMAHATAN SILINDER

OLEH INTAN

CELL ALREDY CUT

CYLINDER

CELL WALL

CUTTING TOOL

CUTTING TOOL MOTION

CYLINDER MOTION

CELL TO BE CUT

UKURAN-UKURAN SEL

UNTUK ELECTRONIC ENGRAVING

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

Path of Engraving Tool Tip100 % Cells

SCREEN ANGEL YANG DIBUAT DENGAN

ELECTRONIC ENGRAVING

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

Elongated.

60 Deg Cells

Compressed.

30 Deg Cells

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

Normal.

FILMLESS

CYLINDER MAKING

Aplikasi Software di Macintosh

Aplikasi Software di PC

Freehand 7.0

Freehand 5.0

Illustrator 6.0

Photoshop 3.05

Photoshop 4.0

Corel Draw 6.0

Quark X Press 3.1

Page Maker 5.0

Corel Draw

Media Transfer di Macintosh

Media Transfer di PC

Optical 3.5” 230 MB

Optical 3.5” 230 MB

Optical 5.25” 1.3 GB

Floppy disk 3.5” 1.4 MB

CATATAN

1. Barcode cukup disebutkan nomor barcode serta

Code

: EAN/UPC/ITF

Magnification

: 80% - 200%

Clear Area Height

: …mm

2. Teks Mandarin, Arab, Jepang atau teks asing lainnya harus sbb :

a. Software Free Hand, Illustrator, atau Corel Draw dilakukan

convert to path

b. Hindarkan software Quark X Press dan Page Maker

3. Resolusi Image sebaiknya 300 dpi (tidak terinterpolasi)

Color

: CMYK atau RGB

Hindarkan Bitmap dan Indexed Color

Format File : EPS, TIFF minimal JPEG

Khusus PC compressed format : AJR

4. Media Transfer Format :

MAC

Macintosh

PROSES PRA CETAK

PEMROSESAN GAMBAR

PEMROSESAN CYLINDER

FILM LESS FILM

COMPUTER AIDED DESIGN OPTICAL DISK

KOREKSI/MODIFIKASI PENGATURAN LAYOUT

PRINT OUT COMPUTER

ELECTROMECHANICAL ENGRAVING REFLECTION COPY CHROME PLATING POLISH/CLEANING PROOF CYLINDER CETAK DIRECT ETCHING DESIGN KASAR ORIGINAL ARTWORK FINAL ARTWORK LAYOUT FILM/COLOR SEPARATION MOUNTING BLUE PRINT/CHROMALIN/ PROOF OFFSET

BASE : , CIRCUM BUBUT (Fe) PLATING Ni 1-2

Cu 200

POLISH/CLEANING

PHOTO SENSITIVE AGENT COATING

LETTER PRESS

IMPRESSION

CYLINDER

PAPER

IMAGE

CARRIER

INK

ROLLERS

PLATE

OFFSET

INK TRAY

INKING

SYSTEM

PLATE

CYLINDER

WATER PAN

DAMPENING SYSTEM

RUBBER BLANKET

CYLINDER

SABLON

SUBSTRATE

SCREENED

IMAGE

FRAME

OPEN

SCREEN

STENCIL

SQUEEGE

FLEXOGRAFI

INK PAN

FOUNTAIN

ROLL

ANILOX

ROLL

PLATE

CYLINDER

IMPRESSION

CYLINDER

GRAVURE

DOCTOR

BLADE

GRAVURE

CYLINDER

IMPRESSION

CYLINDER

PAPER/

FILM

MESIN GRAVURE

UNWINDER SCANNING HEAD BAK TINTA

HEATER

COOLING ROLL

POSITION

COMPENSATION ROLL

+

RUBBER PRESS

TINTA DOCTOR

BLADE

PAPER

PROSES LAMINATING

Second Material

Coating

Rewinder

Combining

Roller

Drying Process

First Material

Doctor Blade

TANDEM LAMINATOR PROCESS & PACKAGING MATERIALS & DESIGN FOR SPICES

SPIC

E

Device Unwinder AC 1 Extruder 1 Sandwich Unwinder 1

A C B

Film &

Materials Ony/print Adhesive LDPE Alumuniumfoil Property &

Function Good impactstrenght Good toughness Good heat resistance Improving Bonding strenght Adhesion Good processability Gas barrier Moisture proof Good stiffnes Shielding light Good display effect

AC2 Extruder2 Sandwich

Unwinder2 Rewinder C D

Vacuum

Metallizing

Machine

Unwind

Rewind

Spreader Rollers

Load Cell Rollers

Wire Feed System

Closed-Loop Control for

Closed-Loop Control for

Wire & Power

Wire & Power

Optical Density

Calculate Wire

Speed

Calculate

Power

Thyristor &

Transformer

Speed Wire

V & I

TYPICAL METALLIZED FILM

STRUCTURE

1

2

3

4

5

1. Metal Layer, Alum., 500 Ang, 0,05 Micron, 0,2 Gauge

2. Corona or Flame Treatment

3. Copolymer Bonding Layer

4. Core Layer of Homopolymer OPP, 18 - 20 Micron, 70 - 80 Gauge

MATERIAL UNTUK FLEXIBLE

PACKAGING

1. Material untuk printing / main subtrate

2. Material untuk barrier

3. Material untuk heat seal

•

Untuk proses cetak diperlukan material dengan

sifat - sifat :

- Mudah menyerap / menerima tinta

- Permukaan cukup halus dan rata

- Tahan terhadap perlakuan pada mesin cetak

• Contoh material untuk printing :

Kertas, Cellophane, NY, PET, OPP

SIFAT PELINDUNG (BARRIER)

MATERIAL PLASTIK

Semua material, kecuali kaca dan metal, bisa dilalui (“permeable”) oleh

uap air, udara dan gas-gas lainnya

Karena metal foil tidak transparan dan kaca tidak flexible untuk “flexible

packaging” umumnya digunakan bahan plastik (polymer)

Pengaruh uap air dan oksigen terhadap makanan :

- Potato Chips

- Makanan berlemak

- Kopi bubuk

Uap air

Uap air

Uap air

melempem

bau tengik

MEKANISME PERMEASI GAS

MELALUI FILM TIPIS

Tahap I

: Gas melarut dalam film

Tahap II

: Gas terdifusi melalui film

KONDISI TES YANG UMUM

DIGUNAKAN

1. Jungle room

: 100

0F (38

0C), 90% RH

2. Moist room

: 85

0F (29

0C), 81% RH

3. Dry room

: 125

0F (52

0C), 12% RH

4. Cold room

: 35

0F - 45

0F (1,7

0C - 7,2

0C), 80%

5. General room

: 0

0F (9

0C - 18

0C), Ambient RH

6. Controlled lab

: 72

0F (22

0C), 50% RH

Contoh-contoh Spesifikasi

Flexible Packaging

NO ITEM KOMPOSISI

1. CANDY INNER HALLS PET 12/PR/CPP25 2. CANDY INNER TANGO PET 12/PR/VMCPP25 3. CANDY INNER FOX PVC TWIST 25

4. CANDY INNER SWISSEL PVC TWIST 25 (AL7/WAX/PAPER 25) 5. CANDY OUTER HALLS OPP 20/PR/DL/VMCPP25

6. CANDY OUTER TANGO OPP 20/PR/DL/CPP25

7. CANDY OUTER FOX PET 12/PR/PE15/AL7/DL/CPP25 8. CANDY OUTER SWISSEL OPP 20/PR/PP40

9. OUTER COFFEE O 100 SACHET OPP 25/PR/DL/LLDPE 80 10. OUTER MAX TEA TARIKK 30 PSC OPP 20/PR/PP20/CPP40

11. INCO CAFÉ PET PVDC 14/PR/DL/LLDPE 75 12. OUTER CAPPUCINO 50 SACHET OPP 25/PR/DL/CPP 45

13. OUTER INDOCAFE ORIGINAL BLEND OPP 20/PR/PP 20/CPP 40 14. OUTER INDOCAFE 30 SACHET OPP 20/PR/PP 20/CPP 40 15. OUTER COFFEMIX 45 SACHET OPP 25/PR/DL/CPP 45

16. ALU FOIL COFFEMIX 20 GR OPP 20/PR/PE 15/AL 7/PE 40 17. ALU FOIL MAX TEA LEMON TEA OPP 20/PR/PE 15/AL 7/PE 40

USAGE AND FILM COMPOSITION (1)

Usage Content Composition Laminating Method

Cookie PT/PE MST/PE OPP/PE PE extrusion lamination Candy PET/PE ONY/PE KOP/PE Dry lamination

Marine Product KPET/PE KONY/PE * solvent type

Potato Chip * solvent-free type

Frozen Food

Spaghetti PT/PE/CPP OPP/PE/CPP PE extrusion lamination PET/PE/CPP KOP/PE/CPP (CPP is seated fillm) Tea PT/PE/AL/PE OPP/PE/AL/PE PE extrusion lamination Flour PET/AL/PE

Coffee PT/PR/PAPER/PE/AL/PE Potato Chip MST/PE/PAPER/PE/AL/PE Powdered milk OPP/PE/PAPER/PE/AL/PE Dry Foods Powdered Juice PET/PE/PAPER/PE/AL/PE OPP/PE/VM-PET/PE/CPP

Nodle PT/CPP MST/CPP OPP/CPP Dry lamination Cookie PET/CPP ONY/CPP KOP/CPP * solvent type

Candy KPET/CPP KONY/CPP OPP/VMCPP * Solvent – free type Spaghetti

USAGE AND FILM COMPOSITION (2)

Usage Content Composition Laminating Method

Flour *1 *2 * 1 * 2 Dry lamination Powdered milk OPP/EVAL/PE OPP/EVAL/PE * Solvent type

Dry Foods Powdered juice PE Extrusion lamination

*1 : Dry lamination * Solvent type

* 2 : PE Extrusion lamination jam KPT/PE OPP/PE PET/PE Dry lamination

Liquid soup ONY/PE KONY/PE KPET/PE * Solvent type Liquid

Foods

Mayonnaise PT/PE/OPP/PE PET/VM-PET/PE PE Extrusion lamination

*1 *2 *1 *2 *1 : Dry Lamination OPP/KPT/PE OPP/EVAL/PE * Solvent type

OPP/PET/PE PET/EVAL/PE * 2 : PE Extrusion lamination ONY/PE KONY/PE KPET/PE Dry lamination

Oil Foods Sausage KPT/PE OPP/PE * Solvent type Hamburger OPP/KPT/PE PET/AL/PE PE Extrusion lamination

OPP/PVDC/PE PET/PVDC/PE

Curry ONY/PE PET/PE ONY/CPP Dry lamination Retort

Foods

Meat souce PET/CPP PET/ONY/CPP * Solvent

Hamburger PET/AL/PE PET/AL/CPP

Rice PET/AL/ONY/PE PET/AL/ONY/CPP

PE means PE, EVA, ionomer resin, PE (20 )/PE (20~50), PE (20 )/EVA(20~50 ) and PE (20 ) /ionomer resin (20~50)

PENENTUAN SPESIFIKASI KEMASAN

LENTUR

Tujuan

: menentukan kombinasi material yang cocok dengan

suatu produk tertentu

Spesifikasi Kemasan Lentur ditentukan oleh:

Jenis Isi

Mesin Pengisi

Berat Isi

“Shelf Life” (masa sampai kadaluarsa)

Harga Jual

Peredaran, Distribusi, dan Cara Penjualan

Keinginan Khusus :

- mudah disobek

1. JENIS ISI

ISI

MAKANAN

BUKAN MAKANAN

SEGAR

DIPROSES/

DIAWETKAN

AWET/ TAHAN

LAMA

MUDAH RUSAK

1. K.L. YG BERISI UDARA

2. K.L. YG BERISI GAS N

(GAS FLUSHED)

3. VAKUM

4. BOIL/REBUS

5. RETORT

6. DIBEKUKAN

7. ASEPTIK

8. DIBERI ZAT DEOXIDANT

9. BIASA

1. PENGARUH CAHAYA-A1

2. PENGARUH OKSIGEN-PET

3. PENGARUH UAP AIR-OPP

4. AROMA MUDAH HILANG-A1

5. ISI BEREAKSI THD K.L.

2. MESIN PENGISI

MESIN

PENGISI

DENGAN

MESIN

DENGAN

TANGAN

1. VERTIKAL

3. CUP

2. HORIZONTAL

1.1. POWDER

1.2. CAIRAN

PADAT

2.1. KECEPATAN TINGGI

2.2. KECEPATAN SEDANG

3.1. CUP SEALER SEDERHANA

3.2. CUP SEALER +

Mesin Packaging Tipe VFFS

1. Gravity feeding

2. Mempunyai produk dalam bentuk yang

kecil, tidak mempunyai ukuran regular

3. Struktur film yang dilaminasi diperlukan

secara khusus

SKEMA VFFS

TOTAL END SEAL (TES)**

FILL SPACE LENGTH (FSL)** PRODUCTCIRCUMFERENCE (C)*

TOTAL CRIMP LENGTH (TCL)*

FILL SPACE LENGTH (FSL)*

FILL SPACE WIDTH (FSW)** SIDE SEAL

WIDTH (SSW)**

NOTE :

* WIDTH = C + OVERLAP * CUTOFF = FS + TCL

** WIDTH = FSW + 2 x SSW

Mesin Packaging Tipe HFFS

1. Produk mempunyai dimensi yang terukur

2. Produk dapat dimasukkan ke dalam kemasan

tanpa menggunakan gravitasi

3. Pemotongan film dalam lembaran tunggal

terjadi pada saat pembentukan kemasan

SKEMA HFFS

3.BERAT ISI

1. UKURAN KECIL ( < 50 g )

4. SHELF LIFE

1. KEMASAN TUNGGAL

2. ADA KEMASAN LUAR :

- KEMASAN LUAR KARTON

SHELF LIFE TESTING MELBA TOAST

COND. @ 85

0F, 81% RH

6.0 5.0 4.0 3.0 2.0 1.0

0

10

20

BI

CO

R

90

O

P4

00

S

BIC

OR

38

0 A

B

25

0

PV

D

C

CO

AT

ED

C

EL

LO

PH

A

N

E

% WEITGHT GAIN

SHELF LIFE TESTING MELBA TOAST

COND. @ 100

0F, 90% RH

9.0 8.0 7.0 6.0 5.0 4.0 3.0 2.0 1.0

0

5

10

15

CONDITIONING TIME (DAYS)

BIC

OR

90

OP

400

S A

ND

38

0 A

B

25

0

PV

D

C

C

O

AT

ED

C

EL

LO

5. DISTRIBUSI + CARA

PENJUALAN

1. DALAM KOTA

2. LUAR PULAU

3. EXPORT

6. HARGA JUAL

1. MURAH

7. KEINGINAN KHUSUS

1. MUDAH DISOBEK

MATERIAL UNTUK HEAT SEALING

Heat sealing adalah proses penyatuan (“welding”) 2 polymer termo

plastik dengan menggunakan panas dan tekanan

Ada dua macam bentuk material untuk heat sealing :

Film

: PE, LLDPE, CPP

Coating

: Acrylic, PVDC, NC

Cara heat seal ada 3 :

1. Conduction Sealing

BAHAN KEMASAN PLASTIK YANG

UMUM DIGUNAKAN

SYMBOL

POLYMER

APPLICATION

LDPE (PE)

Low Density Polyethylene

General PurposePackaging

LLDPE

Linear Low Density Poly Ethylene

High Strength PE

EVA

Ethylene Vynil Acetate

Low Temperature Sealant

EAA

Ethylene Acrylid Acid

Hot Tack

HDPE

High Density Poly Ethylene

Moisture Barrier, Stiffness

CPP

Casted Poly Propylene

Moisture Barrier, Sealant

OPP

Oriented Poly Propylene

Printing, Moisture Barrier

PET

Poly Ethylene Terephtalate

Printing, Gas Barrier

JENIS-JENIS DAN SIFAT MATERIAL YANG UMUM

DIGUNAKAN

FUNGSI

NO MATERIAL GRADE Print Barrier H2O Barrier O2 Heat Seal KETERANGAN PENGGUNAAN

1 KERTAS LITHO 0 - - X MUDAH DISOBEK LAMINASI DGN PE, UNTUK

HVS 0 - X KEMASAN YANG MUDAH

KRAFT 0 - - X DIBUKA

COATED 0 0 - - X

2 ALUMINIUM FOIL SOFT TEMPER X 0 0 0 0 0 0 0 0 X UMUMNYA DIBERI MAKANAN, OBAT, DLL HARD TEMPER 0 0 0 0 0 0 0 0 0 0 0 COATING OBAT (PRESS THROUGH

PACK), TUTUP MENTEGA

3 CELLOPHANE PT 0 - 0 X MUDAH DISOBEK OBAT DAN KEMASAN

MSAT 0 0 0 0 0 0 LAIN YG HARUS DIBUKA

4 PVC PLAIN 0 0 0 X BISA DIPLINTIR (TWIST) UNTUK PERMEN

COATED 0 0 0 0

5 PE LDPE - 0 - 0 0 0 FUNGSI UTAMA HAMPIR SEMUA KEMASAN

MDPE - 0 - 0 0 0 ADALAH UNTUK HEAT MENGGUNAKAN LDPE

HDPE 0 0 - 0 0 0 SEAL ATAU LLDPE UNTUK HEAT

LLDPE - 0 - 0 0 0 SEAL. MDPE DAN HDPE

JARANG DIGUNAKAN

CATATAN :

0

= BAIK

0000

= BAIK SEKALI

-

= KURANG

JENIS-JENIS DAN SIFAT MATERIAL YANG UMUM

DIGUNAKAN (Lanjutan)

FUNGSI

NO MATERIAL GRADE Print Barrier H2O Barrier O2 Heat Seal KETERANGAN PENGGUNAAN

6 NYLON ONY 0 - 0 0 X TAHAN TERHADAP TERUTAMA DIGUNAKAN PVDC COATED 0 0 0 0 0 0 - TUSUKAN UTK CAIRAN &VACUUM

NON-ALUMINIUM FOIL 7 PET PET 0 0 - 0 X BAIK SEKALI UNTUK UNTUK KEMASAN YANG

PVDC COATED 0 0 0 0 X PRINTING DIJALANKAN PADA MESIN METALLIZED - 0 0 0 X PACKAGING KECEPATAN

TINGGI

8 OPP PLAIN FILM 0 0 0 - X DIBANDINGKAN DGN MATERIAL ALTERNATIF COATED 0 0 0 0 0 0 0 PET, OPP KURANG UNTUK PET

CO-EXTRUDED 0 0 0 - 0 TAHAN TERHADAP PEARLIZED 0 0 - 0 PANAS

METALLIZED 0 0 0 0 0 0 0 X

9 CPP PLAIN - 0 - 0 0 0 DIBANDINGKAN DGN COCOK UTK MESIN METALLIZED - 0 0 0 0 0 0 0 0 0 LLDPE, CPP LEBIH KECEPATAN TINGGI

MUDAH DIPOTONG (MISALNYA UTK PERMEN (PUTUS) DI MESIN DAN PILLOW PACK), BISA TITIK LELEH LEBIH TAHAN LEBIH DARI 120'C TINGGI (UTK STERILISASI DGN

CARA "RETORT")

10 COPOLYMER EVA X 0 - 0 0 0 0 DIBANDINGKAN DGN PE, MATERIAL ALTERNATIF EVA X 0 - 0 0 0 0 SIFAT HEAT SEAL LEBIH (LEBIH BAIK) DARIPADA

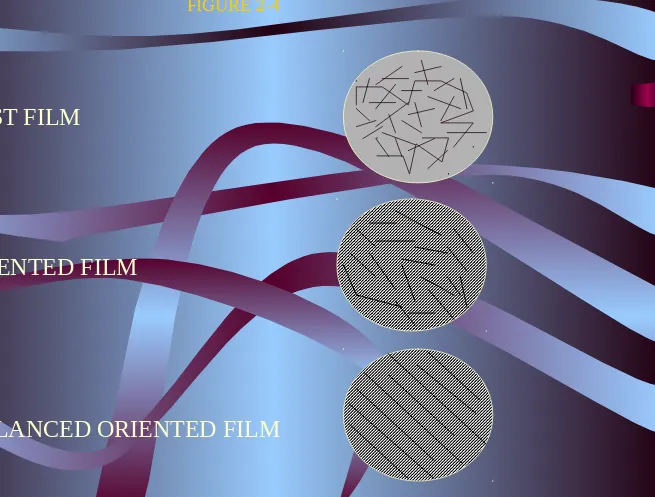

FIGURE 2-4

CAST FILM

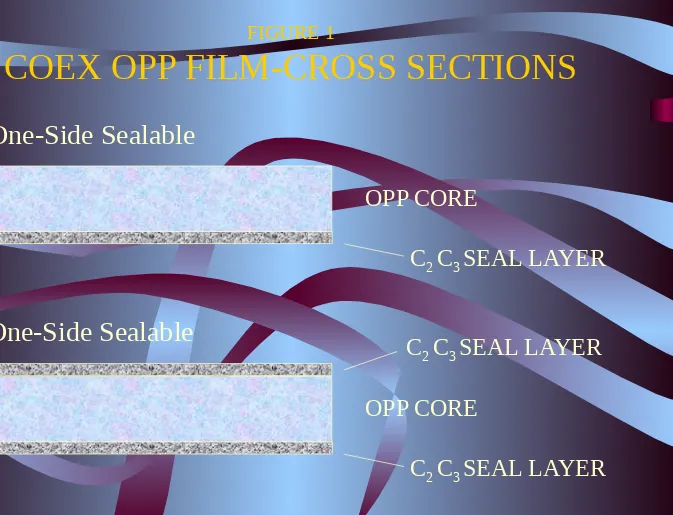

FIGURE 1

COEX OPP FILM-CROSS SECTIONS

One-Side Sealable

OPP CORE

C

2C

3SEAL LAYER

OPP CORE

C

2C

3SEAL LAYER

One-Side Sealable

C

Unoriented Polypropylene Film

Production Process

Extruder

Melt Extrusion Casting

Chill Roll Winder

OPP PRODUCT

Slitting Packaging

Finishing Section Polypropylene Resins

Oriented Polypropylene Film

Production Process

OPP PRODUCT

Extruder

Oven Winder

Slitting Packaging

Extrusion Casting Machine

Direction Orientation Orientation Transverse

Direction

Winding Finishing Section Polypropylene Resins

T Die Heater Roll

Tenter

Plain Cellulose Film Production Process

Coagulation

Sheet

Product

Roll

Product Liquid Caustic Soda

Carbon Disulfide and liquid Caustic Soda Pul Feeder

Pulp

Casting Machine Drying Winder

Slurry

Aging

Sulfide Dissolving

Post Treatment Decomposition and Regeneration

Raw Material Section Films Making Section

Slitting Packaging

Moisture-proof Cellulose Film

Production Process

Resin, Plasticizer, Organic Solvent and Wax

Lacquer

Cotter Winder

To Finishing section

Base Cellulose Film

Humidity Control Drying

Coating Tower

EXTRUDER

Die

2 ( or more ) water cooled Highly polished chill roll

Wind up

( Usually twin stasion ) Rubber

Nip ( or pinch ) rolls

Treater bar

Trimmer (slitter )

Rubber ( or pinch ) roll Stainless steel

Idler roll

Stainless steel nip ( or pinch ) roll ( driven )i

PRODUCT LIST

PT. NESTLE INDONESIA

NO PRODUK

STRUKTUR MATERIAL

1. FOX’S INNER PET 12/PR/DL/VMCPP25

2. FOX’S FRUIT&MINT 150 gr PET 12/PR/DL/AL 7/PE 18/LLDPE 25 3. POLO SPEARMINT 5 PACK PET 12/PR/DL/CPP 30

4. COFFEEMATE 450 gr PET 12/PR/DL/AL 7/DL/LLDPE 45 5. ALUFOIL-NESTEA BAG 1000 gr PET 12/PR/PE 15/AL 7/P0E 25 6. ALUFOIL BAG – FOX’S FRUIT &

MINT 150 x 3 gr

PET 12/PR/PE 15/AL 7/PE 25

7. ALUFOIL-FOX TROPICAL FRUIT 100gr PET 12/PR/PE 15/AL 7/PE 25 8. POUCH MILO CM 750 gr PET 12/PR/PE 15/AL 7/PE 30 9. SACHET CERELAC RICE & NESTUM

RICE

PET 12/PR/DL/AL 7/DL/LLDPE 55

10. MAGGI NOODLE WRAP. OPP 20/PR/PE 18 11. SEASONING BEEF & CHICKEN MBI

50 gr.

OPP 20/PR/DL/VMCPP 25

12. RICE FLAKE FOIL PORRIDGE NBI 50 gr

OPP 20/PR/DL/VMCPP 25