Initial low oxygen stress controls superficial scald of apples

Zhenyong Wang, David R. Dilley *

Department of Horticulture,Michigan State Uni6ersity,East Lansing,MI48824,USA

Received 31 January 1999; accepted 13 December 1999

Abstract

The effectiveness of initial low oxygen stress (ILOS) to control apple scald without postharvest application of scald inhibitors and fungicides was investigated. Scald susceptible (‘Granny Smith’, ‘Law Rome’, ‘Red Delicious’) and not susceptible (‘Idared’) fruits were harvested preclimacterically and treated at 1°C with (1) ILOS pretreatment or (2) no pretreatment as control. Fruit were then stored at 0.5 – 1°C in 3% O2 with 0% CO2, 1.5% O2 with 3% CO2, or

0.7 – 0.8% O2with 3% CO2in flow-through controlled atmosphere (CA) or in air. ILOS of 0.5 and 0.25% O2for 2

weeks resulted in excellent control of scald when fruits were subsequently held in CA (3% O2, 0% CO2). Initial

treatment with 0.25% O2for 2 weeks, and when this treatment was supplemented with an additional 2 weeks of low

O2stress after 2 months of storage, were more effective treatment regimens for scald control than all other treatments.

ILOS followed by CA storage at 1.5% O2gave complete control of scald. A commercial test of initial low O2stress

confirmed its efficacy for controlling scald in several cultivars of apples. The production ofa-farnesene and its volatile

oxidation product 6-methyl-5-hepten-2-one (MHO) was inhibited by initial low O2stress treatments and 1.5% O2CA.

The 0.25% O2initial stress treatment caused stronger inhibition ofa-farnesene and MHO production than 0.5% O2

initial stress treatment. The accumulation of MHO was related to scald development of apples. © 2000 Elsevier Science B.V. All rights reserved.

Keywords:Apple; Superficial scald; Initial low O2 stress; Volatiles;a-Farnesene; 6-Methyl-5-hepten-2-one

www.elsevier.com/locate/postharvbio

1. Introduction

Superficial scald of apples is a physiological disorder which, following long-term storage, has the potential to destroy the market value and utility of millions of tons of fresh apples annually (Wang and Dilley, 1999). The disorder is

pre-vented commercially by postharvest drench treat-ment with diphenylamine (DPA) (Smock, 1957). This drench treatment must include a fungicide to prevent decay development. Numerous countries have banned the use of DPA or importation of DPA-treated fruits, which mandates development of alternative methods to control scald.

It has been proposed that apple fruit may pos-sess at harvest or may acquire after harvest resis-tance to scald (Gallerani et al., 1990; Barden and Bramlage, 1994a,b). It is speculated that the skin browning associated with the disorder results

* Corresponding author. Tel.:+1-517-3553286 or +1-517-3557483; fax: +1-517-3530890.

E-mail addresses: [email protected] (Z. Wang), [email protected] (D.R. Dilley)

from autooxidative processes that disrupt cell membranes and are brought about by depletion of endogenous antioxidants such as ascorbic acid or a-tocopherol during low temperature storage (Meir and Bramlage, 1988). Free-radicals such as hydroxyl (OH), hydroperoxyl (HO2) and

super-oxide (O2−) can attack and destroy lipid and

protein macro molecular structures essential for cellular function (Anet, 1969; Halliwell and Gut-teridge, 1989; Stadtman, 1993) and subsequently lead to scald symptom development. Extensive investigations in Australia (Anet and Coggiola, 1974 and references cited therein) indicated that scald results from the autoxidation of a volatile sesquiterpene hydrocarbon a-farnesene (2,6,10-trimethyl-2,6,9,11-dodecatetraene) in the fruit skin (Meigh and Filmer, 1969). Based on in vitro studies, oxidation of a-farnesene was hypothe-sized to yield conjugated triene hydroperoxide free-radicals which injure the hypodermal cells and give rise to the symptoms of scald (Anet, 1969, 1972). However, Rowan et al. (1995) found that in vivo only trace amounts of these were detectable; the major oxidation products that ac-cumulated in apple peel were two 2,7,8,11-tetraen-6-ol (conjugated trienol) isomers.

Scald development in ‘Granny Smith’, a culti-var very susceptible to scald, was correlated to the oxidation of a-farnesene to conjugated triene hy-droperoxides (Huelin and Coggiola, 1970; Filmer and Meigh, 1971). Song and Beaudry (1996) found that 6-methyl-5-hepten-2-one (MHO), a volatile product of a-farnesene oxidation, caused a scald-like disorder when applied to peel tissue of susceptible apple fruit. Scald can be induced by the conjugated triene (CT) products of a -far-nesene oxidation, and the concentration and time of appearance of these products is related to the severity of the disorder (Anet, 1972). The scald inhibitor chemicals DPA and ethoxyquin are ef-fective inhibitors of lipid peroxidation, and ethanol vapor which controls scald (Scott et al., 1995a; Wang and Dilley, 1996, 1997; Wang et al., 1997; Ghahramani and Scott, 1998a) is a free-rad-ical scavenger (Halliwell and Gutteridge, 1989). Little et al. (1982) reported that scald of ‘Granny Smith’ apples was largely controlled by an initial low O2 stress followed by CA storage. Low O2

could exert its action partly by increasing endoge-nous ethanol production (Wang et al., 1997; Ghahramani and Scott, 1998b). We have tested the concept that initial low O2 stress prior to CA

storage controls scald by inducing production of ethanol and inhibiting a-farnesene synthesis and its oxidation to yield MHO. Initial low O2 stress

treatments were investigated to determine effec-tive treatment regimens and to gain insight into the mechanism of scald control.

2. Materials and methods

2.1. Initial low oxygen stress followed by CA storage

2.1.1. Plant materials and ILOS treatments

Preclimacteric ‘Law Rome’ apples were ob-tained from the Michigan State University, Clarksville Horticultural Experiment Station (MSU CHES) and ‘Granny Smith’ apples were obtained from a grower in southwest Michigan, about 2 weeks prior to the onset of autocatalytic ethylene production. Forty to 60 fruit were placed in 20-l CA chambers in each of three replicates for each cultivar and storage period evaluation. Two levels of initial low O2 stress were employed: 0.5

and 0.25% O2 for 2 weeks at 1°C. The control

fruit did not receive low O2 stress. The low O2

stress atmospheres were generated with an air separator (Permea™, Model 5, Permea, St Louis, MO) and distributed through a capillary flow board system for maintaining controlled atmo-spheres in a flow-through system. After the low O2stress, the fruit were stored in dynamic (slowly

ventilated) CA under 3 or 1.5% O2 at 1°C, using

a flow rate of 0.18 void volume exchanges per h. Some fruit so treated were again subjected to the same low O2 stress treatments after 2 months in

CA. Other groups of fruit were stored in air or in 3 or 1.5% O2 CA without prior low O2 stress.

2.1.2. Scald index measurement

of fruit surface area affected, where no scald=0,

B25%=1, 25 – 50%=2, and \50%=3. The scald index was normalized to 100 by multiplying the values by 100/3.

2.1.3. Analysis of 6olatiles

To determine the effects of ILOS on ripening, scald development, and production ofa-farnesene and its oxidation product MHO, fruit were re-moved from storage at appropriate intervals and transferred to 20°C in air. Solid phase microex-traction/gas chromatography/mass spectrometry (SPME/GC/MS) was employed to identify and quantify the volatiles including a-farnesene and MHO as described by Song et al. (1997). Five to eight fruit from each treatment were enclosed in 4-l glass jars at 20°C for 1.5 h. The headspace was sampled by SPME equilibrating for 4 min to absorb volatiles and analyzed as described previ-ously. At the same time intervals, samples (14 mg) of epicuticular wax were removed from the ‘Granny Smith’ fruit and placed in glass vials (2 ml) for 3 h at 20°C to determine the amount of a-farnesene and MHO partitioned in the

epicutic-ular wax by SPME/GC/MS as described previously.

2.2. Continuous low O2 stress

‘Granny Smith’ apples as used for the ILOS studies were employed. Fruit were placed in 10-l glass desiccators at 1°C and ventilated with 0.13, 0.25, 0.4, 0.5, 0.75, 1.0, 1.25 or 1.5% O2 or with

air (20.7% O2). The low O2 atmospheres were

made and distributed as described above. The ventilation rate through the chambers was 54 ml min−1(approximately 0.6 void volume exchanges

per h). Volatiles analyses commenced 1 week after the low O2 levels were established and continued

at weekly intervals throughout the 8-month stor-age period. The volatiles profile of more than 60 compounds produced by intact fruit in a flow through system at 1°C and while in various stor-age atmospheres was obtained. Fruit were exam-ined for scald and other physiological disorders after removal from storage and again after 7 days at 20°C.

2.3. Initial low O2 stress trials under commercial conditions

Apples were obtained in 1997 from six Michi-gan orchards. Fruit were stored in four 42 m3CA

storage rooms at CHES. ‘Red Delicious’ strains were ‘Red Chief’, ‘Starkrimson’, ‘NuRed’, ‘Ace’ and ‘Super Spur’. ‘Rome’ strains were ‘Law Rome’ and ‘Galia Beauty’. ‘Winesap’ strains were ‘Stayman’ and ‘Turley’. All fruit were harvested preclimacteric and loaded into the rooms between 6 and 13 October. Each of the four rooms con-tained 126 bins (about 0.63 m3

per bin). The rooms were loaded with an identical stacking pattern and sealed on 13 October and brought to 2.3% O2 by 18 October. Dry lime was employed

to scrub carbon dioxide. A nitrogen generator (Permea™ experimental prototype, 1987) was used for initial O2 pull-down and as needed to

maintain O2levels. CA room c1 was maintained

at 0.7% O2 with 0.5% carbon dioxide throughout

the storage period at 0.1°C. CA room c2 was maintained at 1.5% O2 with 0.5% carbon dioxide

throughout the storage period at 0.1°C. Fruit in CA room c3 had ILOS at 0.5590.19% for 18 days from 20 October to 6 November and be-tween 24 October and 4 November (12 days) the O2level was 0.4890.11%. Fruit in CA room c4

had ILOS at 0.6190.21% for 18 days beginning on 20 October and between 27 October and 7 November (12 days) the O2 level was 0.519

0.13%. For CA rooms 3 and 4, the carbon dioxide level was 0.5%. At the end of the ILOS, the temperature was raised in CA rooms 3 and 4 from 0.1 to 2°C for 3 days then returned to 0.1°C and the O2level was raised to 1.5% for the duration of

the storage period. The rooms were opened after about 8 months in CA. Three 40-fruit samples were obtained from each lot and examined for scald, internal disorders and flavor immediately after storage and again after a week at 20°C.

3. Results

3.1. Initial low oxygen stress

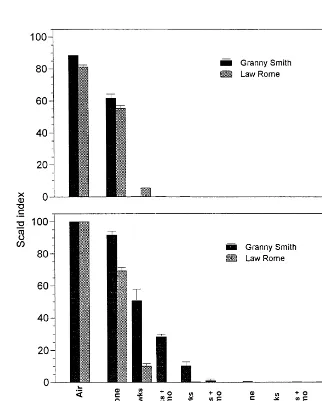

oxy-gen level of ILOS progressively diminished the incidence and severity of scald in ‘Granny Smith’ and ‘Law Rome’ fruit subsequently stored in CA at 3% O2 without CO2; whereas fruit provided

ILOS and stored at 1.5% O2 with CO2 did not

develop a significant level of scald (Fig. 1A,B). These results confirmed our studies in 1996/97 in which ‘Granny Smith’, ‘Law Rome’ and ‘Red Delicious’ apples stored in air at 1°C without

ILOS developed severe scald and those held in CA storage at 3% O2 exhibited only partial

con-trol. ILOS at 0.5% O2 for 1 or 2 weeks with

subsequent storage in CA at 3% O2largely

attenu-ated scald and 2 weeks at 0.5% O2 was more

effective than 1 week (Wang et al., 1997). In the 1996/97 tests, CA storage of ILOS-treated fruit at 1.5% O2 completely controlled internal browning

in both cultivars, whereas CA storage at 3% O2

did not. Internal browning incidence (probably senescence-related) in ‘Granny Smith’ fruit was 74 and 49% for fruit stored in air and 3% O2,

respec-tively, and this was reduced by about one-half by ILOS followed by CA at 3% O2and was not seen

in fruit from 1.5% O2with or without ILOS. Also

core browning (a slight discoloration of tissue immediately adjacent to the seed cavity that is related to immaturity at harvest) was seen in ‘Law Rome’ subjected to the greatest degree of O2

stress and only when stored at 1.5% O2CA (57%).

Slight core browning in ‘Granny Smith’ was not related to CA treatments. The incidence of decay was most prevalent in the air control fruit for both cultivars (11 and 15%, respectively) and was reduced to about 2% by ILOS treatments.

ILOS treatments resulted in high retention of flesh firmness of both cultivars when followed by CA at 1.5% O2. Initial flesh firmness was 82 and

89 N for ‘Granny Smith’ and ‘Law Rome’ respec-tively, and for ILOS followed by CA at 1.5% O2

was 76 and 80 N and for 3% O2was 70 and 65 N,

respectively.

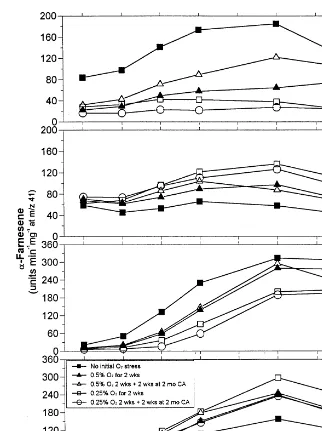

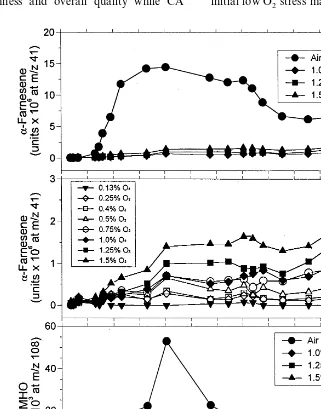

‘Granny Smith’ apples without ILOS produced more a-farnesene after 8 months of storage in 1.5% O2 CA than those with ILOS treatments

(Fig. 2) and also accumulated morea-farnesene in the epicuticular wax (Wang, 1998). Control fruit stored in 3% O2produced lower amounts ofa

-far-nesene than ILOS treated fruit (Fig. 2). Apples with ILOS at 0.25% O2 produced about one-half

as much a-farnesene than those with 0.5% ILOS treatment after 5 and 8 months in 1.5% O2

stor-age. Fruit receiving 0.25% O2 ILOS treatments

produced about one-half as mucha-farnesene and MHO as those with 0.5% O2 stress for all CA

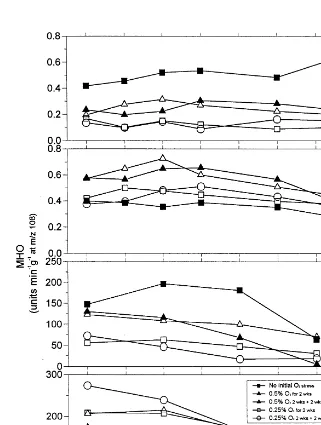

storage conditions for both ‘Granny Smith’ and ‘Law Rome’ cultivars in air at 20°C after 5 months of storage (Wang, 1998). In contrast, after 8 months of storage, the potential of fruit to produce MHO with 0.25% O2 initial stress

treat-ments had increased for 3% O2, but not 1.5% O2

storage (Fig. 3). This indicates that the a -far-nesene production of apples was inhibited by ILOS treatments and also that ILOS at 0.25% O2

and/or 1.5% O2CA more strongly inhibiteda

-far-nesene production than storage without ILOS and/or CA at the 3% O2 level. Fruit given the

combination of 0.25% O2ILOS treatment and CA

at 1.5% O2 had an approximately threefold lower

content of MHO than did 0.5% O2ILOS and CA

at 3% the O2 level.

3.2. Continuous low or ultra low oxygen stress

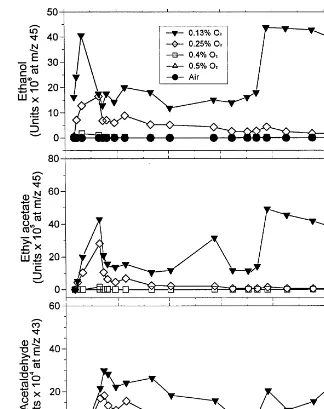

Ethanol, ethyl acetate and acetaldehyde were detected during storage only at O2 levels below

0.5% O2(Fig. 4A – C). The results for fruit held at

0.75, 1.0, 1.25 and 1.5% O2were similar to values

for fruit held in air and are omitted from Fig. 4. Very small amounts of ethanol and ethyl acetate were detected within the first 2 or 3 weeks of storage as measured in the atmosphere exiting the fruit chambers. Ethanol production by fruit held below 0.5% O2 was observed within 1 week after

commencing the low O2 regimens. At 0.13% O2,

ethanol production rose to a peak after 2 weeks and then declined to a steady-state value followed by an increase after 150 days. Fruit held at 0.25% O2produced ethanol at a lower level than those at

0.13% and the peak occurred at 21 days followed by a gradual decline for the remainder of the storage period (Fig. 4A). A similar pattern was seen for fruit held at 0.4% O2 but the level of

ethanol production was much lower and declined to non-detectable levels after a month of storage. The pattern of ethyl acetate production was simi-lar to that of ethanol (Fig. 4B), but production commenced slightly later. Acetaldehyde began to progressively accumulate after 4 weeks at 0.4% O2

and below but the rise was not detectable until production of ethanol and ethyl acetate reached their maximum values (Fig. 4C). Acetaldehyde production at 0.13 and 0.25% O2remained at high

values for several weeks before gradually declin-ing. Near the end of the storage period, acetalde-hyde again accumulated in fruit kept in 0.13% O2

and followed that of ethanol and ethyl acetate. a-Farnesene was produced in copious amounts by fruit in air after 3 weeks and production was generally progressively lower as the O2 level

stor-Fig. 2. Effect of initial low oxygen stress ona-farnesene levels in the headspace of ‘Granny Smith’ (A, B) and ‘Law Rome’ (C, D) apples stored in 1.5% (A, C) and 3% (B, D) O2 CA for 8 months at 0.5°C.

age period (Fig. 5C). MHO was not detected at O2 levels below 1.25% and was generally

de-tectable only at 1.5% O2 or above. The

relation-ship observed between the levels of O2 favoring

ethanol production and reduced levels of MHO suggest that ethanol metabolism may be directly related to keeping MHO at low levels.

Alterna-tively, MHO production may involve an oxidative enzyme with a fairly low affinity for molecular O2.

The mechanism for scald control by ILOS re-mains to be resolved. Scald developed on the air-stored fruit after 4 months of storage and on the 1.5% O2 stored fruit after 10 months of

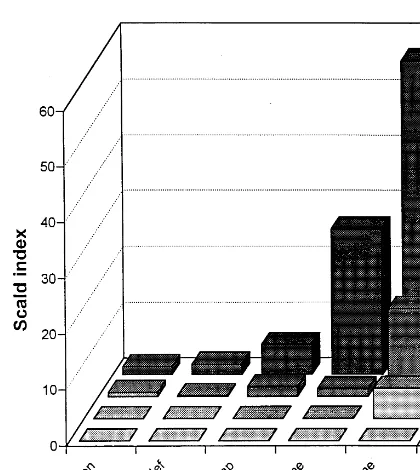

3.3. Initial low O2 stress under commercial conditions

No internal disorders or off-flavors were de-tected in fruit from any of the storage regimens. Upon removal from storage, scald was evident in fruit from the continuous 1.5% O2CA but not on

fruit from the other storage regimens; scald

inten-sified after a week at 20°C. Fruit from ultra low CA (0.7% O2throughout) were scald-free (Fig. 6).

Some ‘Red Delicious’ and ‘Law Rome’ fruit had pigment purpling on removal from 0.7% O2

stor-age but this largely cleared after a few days in air at 20°C. All cultivars from CA room c2 (1.5% O2throughout) exhibited scald of varying degrees

with an overall scald index average of 0.52. Fruit

Fig. 4. Change in production rates of ethanol (A), ethyl acetate (B) and acetaldehyde (C) in ‘Granny Smith’ apples at low levels of oxygen and in air storage at 0.5°C.

from CA room 3 and 4 (ILOS for 18 days at 0.55 and 0.61% O2, respectively) had very low scald

index values of 0.09 and 0.03. ‘Galia Beauty Rome’ was the only cultivar with appreciable scald (data not shown). These fruit were very immature at harvest.

4. Discussion

4.1. Initial low oxygen stress controls scald

al., 1982; Van der Merwe et al., 1997; Wang et al., 1997; Ghahramani and Scott, 1998b) although other investigators find that ILOS is sometimes ineffective (Truter et al., 1994). The level and duration of ILOS as well as the temperature and the subsequent O2 regimens during CA may be

important factors determining the efficacy of ILOS. The treatment regimen of ILOS prior to 1.5% O2CA storage resulted in excellent retention

of fruit firmness and overall quality while CA

storage at 3% O2 following low O2stress did not.

The decline in the incidence of scald as the degree of initial low O2stress increased is consistent with

scald reduction obtained following ethanol vapor treatment and suggests that the effects may be related to some aspect of ethanol metabolism.

That apples produce ethanol when the O2level

is below the extinction point of alcohol fermenta-tion (ca 1%) suggests that a storage regimen of initial low O2stress may induce apples to produce

Fig. 6. Effects of initial low oxygen stress and oxygen levels in CA storage (1.5% O2+0.5% CO2) at the MSU CHES facility on controlling scald of apples stored for 8 months at 0.1°C plus 7 days at 20°C in air. Treatment designation: A, 1.5% O2 CA as control; B, 0.55% O2initial stress for 18 days then 1.5% O2 CA; C, 0.61% O2initial stress for 18 days then 1.5% O2 CA; D, 0.7% ultra-low O2 CA continuously. Scald index (0, none; 1, slight; 2, moderate; 3, severe) was normalized to 100 by multiplying the values by 100/3.

ILOS treatment may be a consequence of the ethanol produced and/or metabolism induced to reduce the concentration of some metabolites or ameliorate their actions. CA storage following ILOS, at O2levels known to reduce scald, may be

expected to further attenuate scald incidence and severity.

4.2. a-Farnesene and MHO production

Our results support the concept thata-farnesene and its oxidation breakdown product MHO are related to the scald disorder (Huelin and Coggiola, 1970; Filmer and Meigh, 1971; Anet, 1972; Rowan et al., 1995; Song and Beaudry, 1996; Mir et al., 1999). O2 levels below 1.25% completely arrested

MHO production (Fig. 5) anda-farnesene produc-tion decreased as O2levels declined from 1.5 down

to 0.13%. The data indicate thata-farnesene is not the limiting factor but rather its metabolism lead-ing to MHO production and/or metabolism may be. Mir et al. (1999) observed a burst in the rate of MHO production that was associated with scald development in ‘Cortland’ apples.

For non-ILOS fruit, morea-farnesene accumu-lated in the epicuticular wax of ‘Granny Smith’ apple fruit following removal from 1.5% O2 than

in the wax of fruit from 3% O2storage while ‘Law

Rome’ fruit with ILOS treatment produced more a-farnesene after 8 months of storage at both 1.5 and 3% O2 than ‘Granny Smith’ fruit. MHO

production by intact fruit and its accumulation in the cuticle of ‘Granny Smith’ apples were markedly lower after 8 months in CA storage following ILOS at 0.25% O2for 2 weeks (Fig. 3). High MHO

production/accumulation values were strongly positively related to the scald index. A putative role of MHO in scald development must be early during storage as fruit stored hypobarically within 2 months of being harvested do not scald whereas those stored with longer delays do scald (Wang and Dilley, 2000). MHO production of fruit begins within the first 2 months when fruit are stored in air.

4.3. Implications of these results

In our flow-through CA experiments, we used ethanol and be an effective means to control scald

even after the O2level is raised above the extinction

point during subsequent storage. Apples receiving continuous 0.25% O2 stress produced ethanol (as

measured in the atmosphere exiting slowly venti-lated chambers of fruit) soon after the O2level was

reduced below the extinction point as would be expected (Fig. 4). The internal ethanol level, al-though not measured in this experiment, would rise in advance of ethanol being detected in the gas atmosphere surrounding the fruits. Moreover, ini-tial ethanol vapor treatment reduced scald (Scott et al., 1995a; Wang et al., 1997) in apples subse-quently stored at reduced O2 levels and this was

gas mixtures at a flow rate that is just sufficient to remove CO2 produced in respiration and provide

a constant CO2and O2level. This amount of fresh

atmosphere flushing is apparently sufficient to remove the trace amounts of scald-related volatile substances that may partition into the epicuticular wax (Matich et al., 1998). Such substances may include a-farnesene and 6-methyl-5-hepten-2-one derived from the biological oxidation of a -far-nesene (Filmer and Meigh, 1971; Spicer et al., 1993). Ventilation would not be expected to favor loss of conjugated trienols derived from a -far-nesene (Whitaker et al., 1997). In theory, removal of volatiles by use of a scrubber is feasible. How-ever, the ability of mineral oil impregnated wraps (Brooks et al., 1919) and vegetable oil coatings (Scott et al., 1995b) to reduce scald is thought to be a consequence of volatiles partitioning into them. Our data are consistent with our observation that fruit do not scald during 8-month storage when flow-through CA is employed at 1.5% O2

with 3% CO2. Moreover, scald is largely controlled

in commercial storage at 1.5% O2 with 3% CO2

employing air separators to remove CO2 by

flush-ing (Dilley, 1990).

ILOS of ca 0.25 – 0.5% O2 for 14 days at 0°C

followed by warming to 2°C for 3 days can effec-tively control scald of apples not treated with DPA when fruit are subsequently stored at 1.5% O2 at

0°C employing a static CA regimen. CA storage at 0.7% O2completely controlled scald (Fig. 6)

confi-rming the results of Lau (1990). However, fruit of some cultivars exhibited symptoms of anaerobic fermentation damage.

Since initial low O2 stress followed by CA at

1.5% O2 controlled scald effectively and

main-tained it at commercially acceptable levels, this CA storage regimen may provide a safe and effective means to store apples not treated with DPA. Avoiding DPA drenching would also avoid the use of postharvest fungicides, which is an issue of growing concern. Our present results support the concept that the beneficial effects of ILOS may be related to ethanol metabolism in some manner. A similar conclusion was recently reported by Ghahramani and Scott (1998b) who suggested that control of scald by ILOS may be due to increased production of ethanol and consequent reduction in

a-farnesene and conjugated triene accumulation. The residual effect of ethanol vapor treatment in reducing scald of apples subsequently stored in air (Wang and Dilley, 1996) suggests that ethanol may act apart from the effect of low O2 alone.

4.4. Alternati6e strategies

Strategies to control scald may depend on culti-var and the duration of the storage period. For fruit which are to be marketed after only 6 months in CA, using a N2 generating system to maintain

1.5% O2 with 3% CO2 has provided satisfactory

control of scald. Fruit for long-term CA for 7 or more months may require a more rigorous strat-egy. This may include ILOS at 0.25 – 0.5% O2levels

for 2 weeks prior to CA at 1.5% O2and 3% CO2.

CA at 1 – 1.5% O2 and using atmosphere flushing

to control the CO2 level at 1 – 2% may provide

adequate scald control for mature fruits not yet producing significant levels of ethylene. A commer-cial test of the initial low O2stress regimen

confi-rmed the efficacy of ILOS for controlling scald. Moreover, the fruit retained excellent firmness and flavor attributes not achieved by continuous CA storage at 0.7% O2which also controlled scald. The

ILOS regimen employed is compatible and achiev-able with current CA technologies and CA O2

monitors/controllers available to establish and maintain controlled atmospheres for storing apples without using postharvest-applied scald inhibitor/ fungicide drenches to the fruit.

Acknowledgements

We gratefully acknowledge the Michigan Apple Research Committee, the Washington State Tree Fruit Research Commission and the Michigan Agricultural Experiment Station for financial sup-port. We also thank the staff at the MSU CHES and Toni Warner and Tom J. McCully for techni-cal assistance.

References

Anet, E.F.L.J., 1972. Superficial scald, a functional disorder of stored apples: IX. Effect of maturity and ventilation. J. Sci. Food Agric. 23, 763 – 769.

Anet, E.F.L.J., Coggiola, I.M., 1974. Superficial scald, a func-tional disorder of stored apples: X. Control ofa-farnesene autoxidation. J. Sci. Food Agric. 25, 293 – 298.

Barden, C.L., Bramlage, W.J., 1994a. Relationships of antiox-idants in apple peel to changes in a-farnesene and conju-gated trienes during storage, and to superficial scald development after storage. Postharvest Biol. Technol. 4, 23 – 33.

Barden, C.L., Bramlage, W.J., 1994b. Accumulation of antiox-idants in apple peel as related to preharvest factors and superficial scald susceptibility of the fruit. J. Am. Soc. Hortic. Sci. 119, 264 – 269.

Brooks, C., Cooley, I.S., Fisher, D.F., 1919. Nature and control of apple scald. J. Agric. Res. 18, 211 – 240. Dilley, D.R., 1990. Application of air separator technology for

the control of superficial scald of apples not treated with scald inhibiting chemicals. In: Proceedings of the 23rd International Horticultural Congress, Florence, Italy, Au-gust 27 – September 1, 1990, pp. 656.

Filmer, A.A.E., Meigh, D.F., 1971. Natural skin coating of the apple and its influence on scald in storage. IV. — Oxidation products ofa-farnesene. J. Sci. Food Agric. 22, 188 – 190.

Gallerani, G., Pratella, G.C., Budini, R.A., 1990. The distribu-tion and role of natural antioxidant substances in apple fruit affected by superficial scald. Adv. Hortic. Sci. 4, 144 – 146.

Ghahramani, F., Scott, K.J., 1998a. The action of ethanol in controlling superficial scald of apples. Aust. J. Agric. Res. 49, 199 – 205.

Ghahramani, F., Scott, K.J., 1998b. Oxygen stress of ‘Granny Smith’ apples in relation to superficial scald, ethanol, a-far-nesene and conjugated trienes. Aust. J. Agric. Res. 49, 207 – 210.

Halliwell, B., Gutteridge, I.C., 1989. Free Radicals in Biology and Medicine. Clarendon, Oxford, p. 543.

Huelin, F.E., Coggiola, I.M., 1970. Superficial scald, a func-tional disorder of stored apples: V. Oxidation of a -far-nesene and its inhibition by diphenylamine. J. Sci. Food. Agric. 21, 44 – 48.

Lau, O.L., 1990. Efficacy of diphenylamine, ultra-low oxygen, and ethylene scrubbing on scald control in ‘Delicious’ apples. J. Am. Soc. Hortic. Sci. 115, 959 – 961.

Little, C.R., Faragher, J.D., Taylor, H.S., 1982. Effects of initial low oxygen stress treatments in low oxygen modified atmosphere storage of ‘Granny Smith’ apples. J. Am. Soc. Hortic. Sci. 107, 320 – 323.

Matich, A.J., Banks, N.H., Rowan, D.D., 1998. Modification ofa-farnesene levels in cool-stored ‘Granny Smith’ apples by ventilation. Postharvest Biol. Technol. 14, 159 – 170. Meigh, D.F., Filmer, A.A.E., 1969. The natural skin coating

of the apple and its influence on scald in storage: III. a-farnesene. J. Sci. Food Agric. 20, 139 – 143.

Meir, S., Bramlage, W.J., 1988. Antioxidant activity in ‘Cort-land’ apple peel and susceptibility to superficial scald after storage. J. Am. Soc. Hortic. Sci. 113, 412 – 418.

Mir, N., Perez, R., Beaudry, R.M., 1999. A poststorage burst of 6-methyl-5-hepten-2-one (MHO) may be related to su-perficial scald development in ‘Cortland’ apples. J. Am. Soc. Hortic. Sci. 124, 173 – 176.

Rowan, D.D., Allen, J.M., Fielder, S., Spicer, J.A., Brimble, M.A., 1995. Identification of conjugated triene oxidation products of a-farnesene in apple skin. J. Agric. Food Chem. 43, 2040 – 2045.

Scott, K.J., Yuen, C.M.C., Ghahramani, F., 1995a. Ethanol vapor — a new anti-scald treatment for apples. Posthar-vest Biol. Technol. 6, 201 – 208.

Scott, K.J., Yuen, C.M.C., Kim, G.H., 1995b. Reduction of superficial scald of apples with vegetable oils. Postharvest Biol. Technol. 6, 219 – 223.

Smock, R.M., 1957. A comparison of treatments for control of the apple scald disease. Proc. Am. Soc. Hortic. Sci. 69, 91 – 100.

Song, J., Beaudry, R.M., 1996. Rethinking apple scald: new hypothesis on the causal reason for development of scald in apples. HortScience 31, 605.

Song, J., Gardner, B.D., Holland, J.F., Beaudry, R.M., 1997. Rapid analysis of volatile flavor compounds in apple fruit using SPME and GC/Time-of-Flight Mass Spectrometry. J. Agric. Food Chem. 45, 1801 – 1807.

Spicer, J.A., Brimble, M.A., Rowan, D.D., 1993. Oxidation of a-farnesene. Aust. J. Chem. 46, 1929 – 1939.

Stadtman, E.R., 1993. Oxidation of free amino acids and amino acid residues in proteins by radiolysis and by metal-catalyzed reactions. Annu. Rev. Biochem. 62, 797 – 821. Truter, A.B., Combrink, J.C., Burger, S.A., 1994. Control of

superficial scald in ‘Granny Smith’ apples by ultra-low and stress levels of oxygen as an alternative to diphenylamine. J. Hortic. Sci. 69, 581 – 587.

Van der Merwe, J.A., Combrink, J.C., Truter, A.B., Calitz, F.J., 1997. Effect of initial low oxygen stress treatment and CA storage at increased carbon dioxide levels on post-stor-age quality of South African-grown ‘Granny Smith’ and ‘Topred’ apples. In: Mitchman, E.J. (Ed.), Apples and Pears. Proc. 7th Int. Nat. CA Res. Conf., 2: 79-84. Wang, Z., 1998. Alternative strategies to control scald of

apples and some biochemical bases. Ph.D. Thesis, Michi-gan State University, East Lansing.

Wang, Z., Dilley, D.R., 1996. Ethanol vapor treatment: A new alternative approach to control superficial scald of apples. Proc. Mich. State Hortic. Soc. 126, 35 – 40.

Wang, Z., Dilley, D.R., 1997. The relationship ofa-farnesene production and its oxidation product 6-methyl-5-hepten-2-one to superficial scald of ‘Granny Smith’, ‘Law Rome’, ‘Red Delicious’ and ‘Idared’ apples during controlled at-mosphere and air storage. In: Mitchman, E.J. (Ed.), Ap-ples and Pears. Proc. 7th Int. Nat. CA Res. Conf., 2: 98 – 104.

Wang, Z., Dilley, D.R., 2000. Hypobaric storage reveals the nature of low temperature induction of superficial scald of apples. Postharvest Biol. Technol. 18, 191 – 199.

Wang, Z., McCully, T.J., Dilley, D.R., 1997. The effect of ultra low oxygen storage, initial oxygen stress and ethanol vapor treatments on controlling superficial scald of

‘Granny Smith’, ‘Law Rome’, ‘Red Delicious’ and ‘Idared’ apples. In: Mitchman, E.J. (Ed.), Apples and Pears. Proc. 7th Int. Nat. CA Res. Conf., 2: 105 – 111.

Whitaker, B.D., Solomos, T., Harrison, D.J., 1997. Quantifi-cation ofa-farnesene and its conjugated trienol oxidation products from apple peel by C18-HPLC with UV detection. J. Agric. Food Chem. 45, 760 – 765.