PROGRAM ARDUINO

int rain_pin = A0;

int ldr_pin = A1;

int rain_sensor = 0;

int ldr_sensor = 0;

int In1 = 2;

int In2 = 3;

int pwmpin = 5;

int limit_keluar = 6;

int limit_masuk = 7;

int limit_out;

int limit_in;

void setup() {

// put your setup code here, to run once:

Serial.begin(9600);

pinMode(In1, OUTPUT);

pinMode(In2, OUTPUT);

pinMode(pwmpin, OUTPUT);

pinMode(limit_keluar, INPUT_PULLUP);

pinMode(limit_masuk, INPUT_PULLUP);

}

void loop() {

// put your main code here, to run repeatedly:

rain_sensor = analogRead(rain_pin);

ldr_sensor = analogRead(ldr_pin);

// Serial.print(rain_sensor);

// Serial.print(" , ");

// Serial.println(ldr_sensor);

if(rain_sensor<800 || ldr_sensor<200){

simpan();

}

else{

jemur();

}

// jemur();

// simpan();

}

{

do{

digitalWrite(In1, LOW);

digitalWrite(In2, HIGH);

analogWrite(pwmpin, 255);

limit_out = digitalRead(limit_keluar);

}

while(limit_out == HIGH);

digitalWrite(In1, LOW);

digitalWrite(In2, LOW);

analogWrite(pwmpin, 0);

Serial.println("jemur");

}

void simpan()

{

do{

digitalWrite(In1, HIGH);

digitalWrite(In2, LOW);

analogWrite(pwmpin, 255);

limit_in = digitalRead(limit_masuk);

}

Arduino Nano 3.0 (ATmega328):

schematic

,

Eagle files

.

Arduino Nano 2.3

(ATmega168): manual(pdf), Eagle files.

Note:

since the free version of

Eagle does not handle more than 2 layers, and this version of the Nano is 4 layers, it is

published here unrouted, so users can open and use it in the free version of Eagle.

Microcontroller Atmel ATmega168 or ATmega328

Operating Voltage (logic

level) 5 V

Input Voltage

(recommended) 7-12 V

Input Voltage (limits) 6-20 V

Digital I/O Pins 14 (of which 6 provide PWM output)

Analog Input Pins 8

DC Current per I/O Pin 40 mA

Flash Memory 16 KB (ATmega168) or 32 KB (ATmega328) of which 2 KB used by

bootloader

SRAM 1 KB (ATmega168) or 2 KB (ATmega328)

EEPROM 512 bytes (ATmega168) or 1 KB (ATmega328)

Clock Speed 16 MHz

The Arduino Nano can be powered via the Mini-B USB connection, 6-20V unregulated external power supply (pin 30), or 5V regulated external power supply (pin 27). The power source is automatically selected to the highest voltage source.

The FTDI FT232RL chip on the Nano is only powered if the board is being powered over USB. As a result, when running on external (non-USB) power, the 3.3V output (which is supplied by the FTDI chip) is not available and the RX and TX LEDs will flicker if digital pins 0 or 1 are high.

The ATmega168 has 16 KB of flash memory for storing code (of which 2 KB is used for the bootloader); the ATmega328 has 32 KB, (also with 2 KB used for the bootloader). The ATmega168 has 1 KB of SRAM and 512 bytes of EEPROM (which can be read and written with the EEPROM library); the ATmega328 has 2 KB of SRAM and 1 KB of EEPROM.

Each of the 14 digital pins on the Nano can be used as an input or output, using pinMode(), digitalWrite(), and digitalRead()functions. They operate at 5 volts. Each pin can provide or receive a maximum of 40 mA and has an internal pull-up resistor (disconnected by default) of 20-50 kOhms. In addition, some pins have specialized functions:

Serial: 0 (RX) and 1 (TX). Used to receive (RX) and transmit (TX) TTL serial data. These pins are connected to the corresponding pins of the FTDI USB-to-TTL Serialchip.

External Interrupts: 2 and 3. These pins can be configured to trigger an interrupt on a low value, a rising or falling edge, or a change in value. See theattachInterrupt()function fordetails.

PWM: 3, 5, 6, 9, 10, and 11. Provide 8-bit PWM output with theanalogWrite()function.

SPI: 10 (SS), 11 (MOSI), 12 (MISO), 13 (SCK). These pins support SPI communication, which, althoughprovidedbytheunderlyinghardware,isnotcurrentlyincludedintheArduinolanguage.

LED: 13. There is a built-in LED connected to digital pin 13. When the pin is HIGH value, the LED is on, when the pin is LOW, it'soff.

The Nano has 8 analog inputs, each of which provide 10 bits of resolution (i.e. 1024 different values). By default they measure from ground to 5 volts, though is it possible to change the upper end of their range using the analogReference()function. Additionally, some pins have specialized functionality:

I2C: 4 (SDA) and 5 (SCL). Support I2C (TWI) communication using theWire library(documentation on the Wiringwebsite).

There are a couple of other pins on the board:

AREF. Reference voltage for the analog inputs. Used withanalogReference().

Reset. Bring this line LOW to reset the microcontroller. Typically used to add a reset button to shields which block the one on theboard.

The Arduino Nano has a number of facilities for communicating with a computer, another Arduino, or other microcontrollers. The ATmega168 and ATmega328 provide UART TTL (5V) serial communication, which is available on digital pins 0 (RX) and 1 (TX). An FTDI FT232RL on the board channels this serial

communication over USB and the FTDI drivers(included with the Arduino software) provide a virtual com port to software on the computer. The Arduino software includes a serial monitor which allows simple textual data to be sent to and from the Arduino board. The RX and TX LEDs on the board will flash when data is being transmitted via the FTDI chip and USB connection to the computer (but not for serial communication on pins 0 and 1).

A SoftwareSerial libraryallows for serial communication on any of the Nano's digital pins.

The ATmega168 and ATmega328 also support I2C (TWI) and SPI communication. The Arduino software includes a Wire library to simplify use of the I2C bus; see the documentationfor details. To use the SPI communication, please see the ATmega168 or ATmega328 datasheet.

The Arduino Nano can be programmed with the Arduino software (download). Select "ArduinoDiecimila, Duemilanove, or Nano w/ ATmega168" or "ArduinoDuemilanove or Nano w/ ATmega328" from the Tools > Board menu (according to the microcontroller on your board). For details, see the referenceand tutorials.

The ATmega168 or ATmega328 on the Arduino Nano comes preburned with a bootloaderthat allows you to upload new code to it without the use of an external hardware programmer. It communicates using the original STK500 protocol (reference, C header files).

You can also bypass the bootloader and program the microcontroller through the ICSP (In-Circuit Serial Programming) header; see these instructionsfor details.

Rather then requiring a physical press of the reset button before an upload, the Arduino Nano is designed in a way that allows it to be reset by software running on a connected computer. One of the hardware flow control lines (DTR) of the FT232RL is connected to the reset line of the ATmega168 or ATmega328 via a 100 nanofarad capacitor. When this line is asserted (taken low), the reset line drops long enough to reset the chip. The Arduino software uses this capability to allow you to upload code by simply pressing the upload button in the Arduino environment. This means that the bootloader can have a shorter timeout, as the lowering of DTR can be well-coordinated with the start of theupload.

This setup has other implications. When the Nano is connected to either a computer running Mac OS X or Linux, it resets each time a connection is made to it from software (via USB). For the following half-second or so, the bootloader is running on the Nano. While it is programmed to ignore malformed data (i.e. anything besides an upload of new code), it will intercept the first few bytes of data sent to the board after a

connection is opened. If a sketch running on the board receives one-time configuration or other data when it first starts, make sure that the software with which it communicates waits a second after opening the

Arduino can sense the environment by receiving input from a variety of sensors and can affect its surroundings by controlling lights, motors, and other actuators. The microcontroller on the board is programmed using the Arduino programming language(based on Wiring) and the Arduino development environment (based on Processing). Arduino projects can be stand-alone or they can communicate with software on running on a computer (e.g. Flash, Processing, MaxMSP).

Arduino is a cross-platoform program. You’ll have to follow different instructions for your personal OS. Check on the Arduino sitefor the latest instructions. http://arduino.cc/en/Guide/HomePage

Once you have downloaded/unzipped the arduino IDE, you’ll need to install the FTDI Drivers to let your PC talk to the board. First Plug the Arduino to your PC via USB cable.

Now you’re actually ready to “burn” your first program on the arduino board. To select “blink led”, the physical translation of the well known programming “hello world”, select

File>Sketchbook>

Arduino-0017>Examples>

Digital>Blink

Once you have your skecth you’ll

see something very close to the

screenshot on the right.

In

Tools>Board

select Arduino NANO

and with the AtMEGA you’re using

(probably 328)

Now you have to go to

Tools>SerialPort

1. Warranties

1.1 The producer warrants that its products will conform to the Specifications. This warranty lasts for one (1) years from the date of the sale. The producer shall not be liable for any defects that are caused by neglect, misuse or mistreatment by the Customer, including improper installation or testing, or for any products that have been altered or modified in any way by a Customer. Moreover, The producer shall not be liable for any defects that result from Customer's design, specifications or instructions for suc h products. Testing and other quality control techniques are used to the extent the producer deemsnecessary.

1.2 If any products fail to conform to the warranty set forth above, the producer's sole liability shall be to replace such products. The producer's liability shall be limited to products that are determined by the producer not to conform to such warranty. If the producer elects to replace such products, the producer shall have a reasonable time to replacements. Replaced products shall be warranted for a new full warrantyperiod.

1.3 EXCEPT AS SET FORTH ABOVE, PRODUCTS ARE PROVIDED "AS IS" AND "WITH ALL FAULTS." THE PRODUCER DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, REGARDING PRODUCTS, INCLUDING BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULARPURPOSE

1.4 Customer agrees that prior to using any systems that include the producer products, Customer will test such systems and the functionality of the products as used in such systems. The producer may provide technic al, applications or design advice, quality characterization, reliability data or other services. Customer acknowledges and agrees that providing these services shall not expand or otherwise alter the producer's warranties, as set forth above, and no additional obligations or liabilities shall arise from the producer providing suchservices.

1.5 The Arduinoproducts are not authorized for use in safety-critical applications where a failure of the product would reasonably be expected to cause severe personal injury or death. Safety-Critical Applications include, without limitation, life support devices and systems, equipment or systems for the operation of nuclear facilities and weapons systems. Arduinoproducts are neither designed nor intended for use in military or aerospace applications or environments and for automotive applications or environment. Customer acknowledges and agrees that any such use of Arduinoproducts which is solely at the Customer's risk, and that Customer is solely responsible for compliance with all legal and regulatory requirements in connection with suchuse.

1.6 Customer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements concerning its products and any use of Arduinoproducts in Customer's applications, notwithstanding any applications- related information or support that may be provided by theproducer.

2. Indemnification

The Customer acknowledges and agrees to defend, indemnify and hold harmless the producer from and against any and all third-party losses, damages, liabilities and expenses it incurs to the extent directly caused by: (i) an actual breach by a Customer of the representation and warranties made under this terms and conditions or (ii) the gross negligence or willful misconduct by the Customer.

3. Consequential Damages Waiver

In no event the producer shall be liable to the Customer or any third parties for any special, collateral, indirect, punitive, incidental,

consequential or exemplary damages in connection with or arising out of the products provided hereunder, regardless of whether the producer has been advised of the possibility of such damages. This section will survive the termination of the warranty period.

4. Changes tospecifications

Data pack F Issued March 1997 232-3816

DataSheet

Light dependent resistors

NORP12

RS

stock number 651-507

NSL19-M51

RS

stock number 596-141

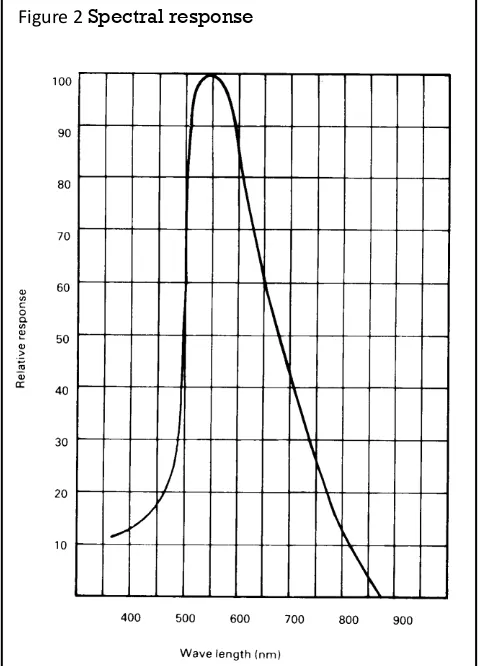

Two cadmium sulphide (cdS) photoconductive cells withspectralresponsessimilartothatofthehuman

eye.Thecellresistancefallswithincreasinglightinten- sity.Applicationsincludesmokedetection,automatic lightingcontrol,batchcountingandburglaralarmsys- tems.

Guide to source illuminations

Lightsource Illumination(Lux)

Moonlight 0.1

60W bulbat1m

501WMESbulbat0

.1m 100

Fluorescentlighting 500

Brightsunlight 30,000

Light memory characteristics

Lightdependentresistorshaveaparticularpropertyin thattheyrememberthelightingconditionsinwhich theyhavebeenstored.Thismemoryeffectcanbe minimisedbystoringtheLDRsinlightpriortouse. Lightstoragereducesequilibriumtimetoreach steady resistancevalues.

NORP12

(RS stock no. 651-507)Absolute maximum ratings Voltage,acordcpeak 320VC urrent 75mAP owerdissipationat30°C 250mW Operating temperature range-60°C to +75°C

Electrical characteristics

TA = 25°C. 2854°K tungsten light source

Parameter Conditions Min. Typ. Max. Units

Cell resistance 1000 lux

10 lux - - 400 9 - - k

Dark resistance - 1.0 - - M

Dark capacitance - - 3.5 - pF

Rise time 1 1000 lux

10 lux - - 2.8 18 - - ms ms

Fall time 2 1000 lux

10 lux - - 48 120 - - ms ms 1. Dark to 110%RL

2. To 10 ×RL

RL = photocell resistance under given illumination.

Features

● Wide spectralresponse

● Lowcost

● Wideambienttemperaturerange. Circuit symbol

232-3816

*1Ftc=10.764 lumens

2

Figure 1 Power dissipation derating Figure 3 Resistance as a function of illumination

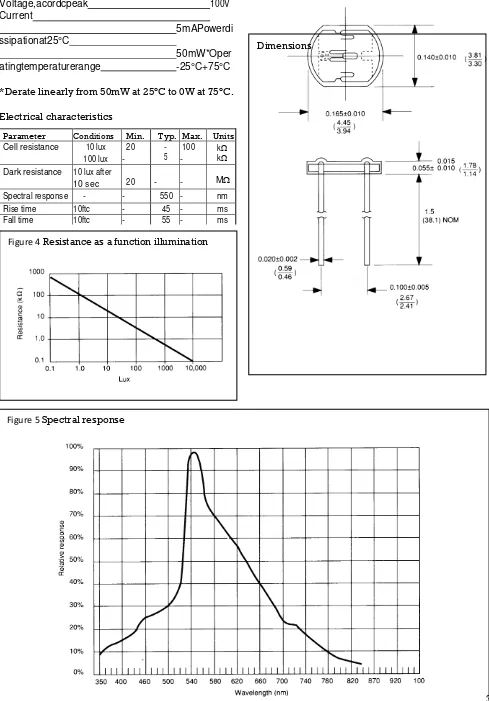

Absolute maximum ratings

Voltage,acordcpeak 100V

Current

5mAPowerdi ssipationat25°C

50mW*Oper

atingtemperaturerange -25°C+75°C

*Derate linearly from 50mW at 25°C to 0W at 75°C.

Electrical characteristics

232-3816

3

Figure 4 Resistance as a function illumination

Dimensions

Figure 5 Spectral response

Parameter Conditions Min. Typ. Max. Units

Cell resistance 10 lux

100 lux 20 -

- 5

100 -

k k Dark resistance 10 lux after

10 sec 20 - - M

Spectral response - - 550 - nm

Rise time 10ftc - 45 - ms

232-3816

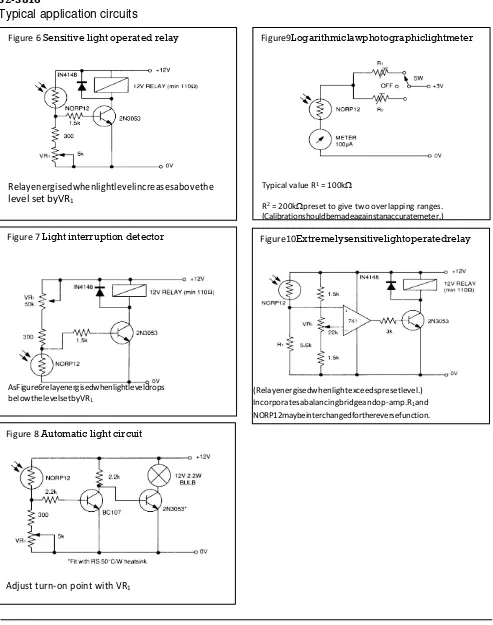

Typical application circuits

TheinformationprovidedinRStechnicalliteratureisbelievedtobeaccurateandreliable;however,RSComponentsassumesnoresponsibilityforinaccuracies

oromissions,orfortheuseofthisinformation,andalluseofsuchinformationshallbeentirelyattheuser’sownrisk.NoresponsibilityisassumedbyRSComponentsforanyinfringementsofpaten tsorotherrightsofthirdpartieswhichmayresultfromitsuse. SpecificationsshowninRSComponentstechnicalliteraturearesubjecttochangewithoutnotice.

RSComponents,POBox99,Corby,Northants,NN179RS Telephone: 01536201234

AnElectrocomponentsCompany © RS Components1997

Figure 6 Sensitive light operated relay

Relayenergisedwhenlightlevelincreasesabovethe level set byVR1

Figure9Logarithmiclawphotographiclightmeter

Typical value R1 = 100k

R2 = 200kpreset to give two overlapping ranges.

(Calibrationshouldbemadeagainstanaccuratemeter.)

Figure 7 Light interruption detector

AsFigure6relayenergisedwhenlightleveldrops belowthelevelsetbyVR1

Figure 8 Automatic light circuit

Adjust turn-on point with VR1

Figure10Extremelysensitivelightoperatedrelay

(Relayenergisedwhenlightexceedspresetlevel.) Incorporatesabalancingbridgeandop-amp.R1and

T

T

h

h

i

i

c

c

k

k

F

F

i

i

l

l

m

m

T

T

e

e

c

c

h

h

n

n

o

o

l

l

o

o

g

g

y

y

–

–

S

S

e

e

n

n

s

s

o

o

r

r

A

A

p

p

p

p

l

l

i

i

c

c

a

a

t

t

i

i

o

o

n

n

s

s

telecontrolli S.r.l. Web Site: www.telecontrolli.com

1 of 6

RAINSENSOR

In this document we would describe an easy interface to use the Telecontrolli capacitive rain sensor.

Telecontrolli rain sensor is made of thick- film technology.

It is made up of three parts:

Capacitivesensor

Heatergenerator

Temperature sensor

On the top side you can find the capacitive sensor. This side part is exposed to the natural agents (rain) while on the bottom side there are the heater generator, the temperature sensor and the connection interface (sixpads). Each function of the rain sensor has stand-alone connections compared to the other in the same mode; so the user has more flexibility in the design of hardwareinterface.

The capacitive sensor has a rain sensitive area, which in dry conditions assumes the nominal value. Moreover in presence of the rain, the capacitance goes to high values compared to dry conditions and the ratio changing is over 300%.

In the table_1 is explained how the capacitance changes in the ratio of percentage of the sensitive area when covered byrain.

Sensitive area

Capacitanc

e

Ratio

Capacitanc

e

% Dry

%

water

pF

%

100

0

100

0

75

25

176

76

50

50

232

232

0

100

≥359

≥359

T

T

h

h

i

i

c

c

k

k

F

F

i

i

l

l

m

m

T

T

e

e

c

c

h

h

n

n

o

o

l

l

o

o

g

g

y

y

–

–

S

S

e

e

n

n

s

s

o

o

r

r

A

A

p

p

p

p

l

l

i

i

c

c

a

a

t

t

i

i

o

o

n

n

s

s

telecontrolli S.r.l. Web Site: www.telecontrolli.com

2 of 6

RAINSENSOR

To read the changing of sensor capacitance, we may adopt two strategies:

Frequency measurements (countermode)

Pulse measurements (timermode)

The simplest hardware which satisfies both strategies is a low cost microcontroller and few other parts. In the diagrams_1 are showed the two hardware strategies for the capacitive sensor interface.

diagrams_1

On the bottom side of “rain sensor” you have one temperature sensor like NTC by Epcosp/nB57620C0102Kwith a nominal resistance value of 1000 Ohm @ 25°C.

This sensor may be used to monitor the environment temperature and to control the heather generator to avoid frost and dump.

+5V

C2

R8

TCrainsensor U2A

SENS2 uC_counter 6 4 5 +5V R9

TC rain sensor SENS3

1 uC_COMP

T

T

h

h

i

i

c

c

k

k

F

F

i

i

l

l

m

m

T

T

e

e

c

c

h

h

n

n

o

o

l

l

o

o

g

g

y

y

–

–

S

S

e

e

n

n

s

s

o

o

r

r

A

A

p

p

p

p

l

l

i

i

c

c

a

a

t

t

i

i

o

o

n

n

s

s

telecontrolli S.r.l. Web Site: www.telecontrolli.com

3 of 6

RAINSENSOR

In the table_2 is reported the Epcos R/T characteristic (resistance/temperature).

T ( °C )

Rnom

( Ohm )

Rmin

( Ohm

)

Rmax

( Ohm )

-5

3564

3068

4061

0

2832

2457

3206

5

2267

1983

2552

10

1829

1611

2046

15

1486

1318

1653

20

1215

1086

1344

25

1000

900,0

1100

30

828,2

740,2

916,1

35

689,9

612,8

767,0

40

577,8

510,2

645,5

45

486,6

427,1

546,1

50

411,8

359,4

464,3

55

350,2

303,9

396,5

60

299,2

258,2

340,2

65

256,7

220,4

293,1

70

221,2

188,9

253,5

75

191,4

162,6

220,1

80

166,2

140,5

191,9

85

144,8

121,9

167,8

T

T

h

h

i

i

c

c

k

k

F

F

i

i

l

l

m

m

T

T

e

e

c

c

h

h

n

n

o

o

l

l

o

o

g

g

y

y

–

–

S

S

e

e

n

n

s

s

o

o

r

r

A

A

p

p

p

p

l

l

i

i

c

c

a

a

t

t

i

i

o

o

n

n

s

s

telecontrolli S.r.l. Web Site: www.telecontrolli.com

4 of 6

RAINSENSOR

In the diagram_2 is showed a simple method for the NTC conditioning.

diagram_2

To drive the heather you need only one low cost NPN transistor with Ic ≤ 500mA / VCE ≥ 25V for 12V standard

bus voltage.

The nominal resistance is 42 Ω and in this condition the current is I= 0.285A. It produces a power of P=3.43W. In

the table_3 is reported the time that occurs to the heather to rise different temperatures of rain sensor. The test has been done on a capacitive sensor with a dry surface.

∆

t ( sec

)

°C

Sensor

Substrat

e

R_NTC

( Ohm )

∆

t ( sec

)

°C

Sensor

Substrat

e

R_NTC

( Ohm )

0

27

930

90

76.

5

188

15

41

550

105

78

175

30

54

360

120

79

169

45

62

280

135

81.

5

163

60

68.5

238

150

82.

5

160

75

73.5

206

165

83.

5

156

T

T

h

h

i

i

c

c

k

k

F

F

i

i

l

l

m

m

T

T

e

e

c

c

h

h

n

n

o

o

l

l

o

o

g

g

y

y

–

–

S

S

e

e

n

n

s

s

o

o

r

r

A

A

p

p

p

p

l

l

i

i

c

c

a

a

t

t

i

i

o

o

n

n

s

s

telecontrolli S.r.l. Web Site: www.telecontrolli.com

5 of 6

RAINSENSOR

table_3

To estimate the time/power (Joule) that needs to evaporate some grams of water it is possible to use the approximative formula:

Time ( sec ) = grams_of_ humidity * 663

Conclusion

The use of the Telecontrolli rain sensor is the simplest way to design your own applications.

telecontrolli S.r.l. Web Site: www.telecontrolli.com

6 of 6 C1

R1

R2 R3

TC rain sensor

SENS1 R4

8

7

U1

VCC

PCI NT/RESET/ ADC0/PB5 1

PCI NT3/CLKI/ADC3/PB3 2

6 +5V 12 V 4 CN1 5

R5 +5V 12 V

Q1 R6 R7 D1 CN2 1 2

RAINSENSOR

+5V +5V

IndiceRevisioni :

Disegnato

A. Cennerazzo

Title RAI N SENSORI NTERF ACE

Si ze A4

Docume nt Number

440016223

Rev Draf t

Date: Mo nday , Nov e mber 03,2008 Sheet 1 of 1