Thomas A. Edison: Managing Menlo Park, 1876-1882 By

Michael J. Gall

A Thesis submitted to the Graduate School-Monmouth University in partial fulfillment of the requirements

for the degree of Master of Arts

Graduate Program in History

i

Acknowledgments

ii

Table of Contents

Acknowledgement ...i

Table of Contents...ii

List of Figures, Tables, and Charts ...iii

Chapter 1. Introduction...1

Chapter 2. Growth of an Inventor and the Exposure to Artisan Traditions And Industrialization ...12

Chapter 3. Edison’s Menlo Park Laboratory: The Growth of the Facility ...31

Chapter 4. Artisan Management Strategies and the Craft of Invention...54

Chapter 5. Ind ustrial Management Strategies...79

iii

List of Figures, Tables, and Charts

Figures

Figure 1: Detail of Laboratory Facility, Post 1878 ...33

Figure 2: Second Floor Interior of Laboratory, February 22, 1880 ...34

Figure 3: Portrait of Chief Laboratory Assistant Charles Batchelor...36

Figure 4: Portrait of Machine Shop Foreman John Kruesi...38

Figure 5: Map Showing the Location of Edison’s Buildings at Menlo Park, N.J. ...41

Figure 6: Menlo Park Complex Original Site ...42

Figure 7: Sarah Jordan Boarding House ...47

Figure 8: 1879 Portrait of Thomas A. Edison...67

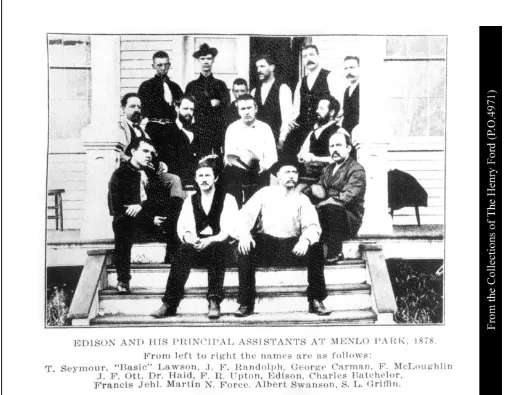

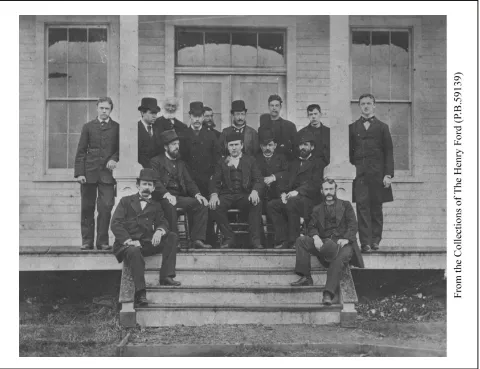

Figure 9: Edison and His Principal Assistants, 1878 ...68

Figure 10: Edison and Crew in Front of Laboratory, ca. 1880 ...69

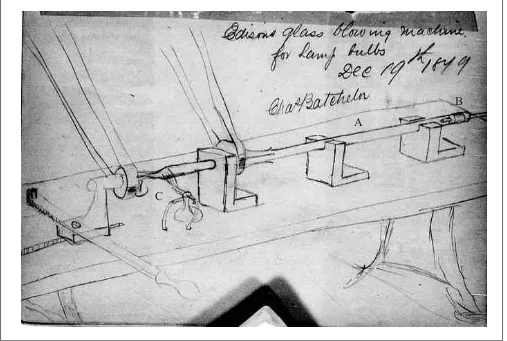

Figure 11: Charles Batchelor’s Conception for Semi-Automated Lamp Manufacture, December 19, 1879 ...92

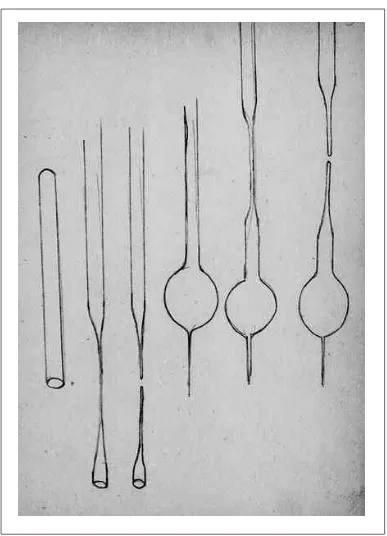

Figure 12: Drawing by Charles Batchelor of Proposed Stages of Bulb Manufacture ...94

Figure 13: John Kruesi’s Conception for Semi- Automated Lamp Manufacture May 20, 1880 ...95

Figure 14: Edison Lamp Works Glass Blowers ...97

Figure 15: Overview of the Vault’s Interior as it Currently Appears ...102

Charts Chart 1: Laboratory Facility Hierarchy Pre 1878 ...82

iv

List of Figures, Tables, and Charts

Charts Continued

Chart 3: Edison Lamp Works Hierarchy ...86

Tables

Chapter 1: Introduction

This thesis examines, as a case study, the evolution of Thomas Edison’s management strategy, from craft-based to industrially directed, at his Menlo Park laboratory facility and the associated Edison Lamp Works. Ultimately, this strategy influenced scientific research and development laboratories well into the twentieth century. During most of the nineteenth century, management of the invention process relied heavily, if not exclusively, on the use of artisan-based traditions. In fact, invention itself was an informally learned craft and coordination of the invention process required great skill, as the inventor simultaneously assumed the roles of scientist, experimenter, entrepreneur, and manager.

Laboratories, financed by inventors, were typically small, and inventors

was most evident at Thomas A. Edison’s invention and manufacturing facility in Menlo Park, New Jersey, which operated from1876 to 1882.

This thesis exa mines the evolution of management strategies as it occurred at Thomas Edison’s Menlo Park laboratory facility. This chapter presents a context to the change in management strategies inventors employed as a result of the growth and professionalization of the invention craft during the mid to late- nineteenth century. Chapter 2 describes Edison’s initial experience with craft-based work and

industrialization, and his early growth as an inventor before 1876. The growth of the Menlo Park facility, between 1876 and 1882, including the establishment of the Edison Lamp Works in Menlo Park, which was directly connected to and relied upon the lab facility for its operation, is outlined in Chapter 3. In these years, Edison developed industrial management tactics. Chapter 4 examines the craft traditions employed, primarily prior to late-1878, before the facility expanded. During this early period, the small operation of the facility enabled Edison to oversee the operation through a process of direct management.1 A small number of employees worked under his constant direction and oversight. To encourage the success of his laboratory and inventions, Edison relied upon craft traditions and artisan shop culture largely composed of worker semi-autonomy, apprenticeship, self-education, loyalty and camaraderie, industriousness, reciprocity, and bonds of mutuality.

Chapter 5 analyzes Edison’s selective implementation of industrial management strategies. By late 1878, the facility and workforce at Menlo Park had significantly increased in size. The expansion was a result of Edison’s efforts to invent an

incandescent lamp and an associated system of electrical generation and distribution. Edison’s goal was to patent an efficient and marketable incandescent lighting system capable of competing with the pre-existing gas and arc- lighting industries. The inventor proposed to market the new system by developing and installing central and isolated electrical power stations supported by a newly invented system of electrical generation and distribution. To produce lamps for this system, an incandescent lamp manufactory, was added to the Menlo Park complex in October 1880. The lamp manufactory, known as the Edison Lamp Works, relied heavily on the lab facility to test its lamps, invent cost-reducing production equipment and technology, and, initially, to provide payroll for its employees. In return, the lamp works was to provide the lab with funding for continued research and development on inventions that would further reduce the costs of

production. This cyclical relationship became a defining feature of modern industrial research and development laboratories. To effectively undertake the additional work and coordinate tasks, Edison systematically augmented the traditional pre-industrial

management style with limited aspects of modern industrial management tactics.

The Invention Process

In a process known as cooperative shop invention, inventors, during much of the nineteenth century, directly managed the processes of invention in small, make-shift laboratories.2 Working in cramped, rented spaces, in attic rooms, or in machine shops, inventors stocked their laboratories with an assortment of tools, spare parts, chemicals, and scientific books and apparatus. Inventors would commonly hire, contract, or solicit

the advice and talents of one or two machinists, mechanics, or skilled craftsmen. Skilled worker’s knowledge was essential for the development and refinement of efficient, operational, and patentable inventions. For example, during the development of his telegraph, Samuel Morse enlisted the help of mechanic Alfred Vail. For a short period in 1837, the two improved the telegraph from a cumbersome to a simple and efficient device at Vail’s father’s manufactory, the Speedwell Iron Works, in Morristown, New Jersey.3 Other inventors who followed this model included Alexander Graham Bell and Elihu Thompson.

The process of invention contained a number of steps. The first step was concept creation, whereby the inventor conceived a new system or mechanical device, typically as a significant improvement to an existing mechanism or technology. With luck and

entrepreneurial skill, the inventor was able to convince wealthy capitalists to finance the invention. Limited funding prohibited the inventor from hiring a large number of assistants. Employing his technical experience and scientific and mathematical

knowledge, the inventor constructed, experimented, and make necessary improvements to the experimental instrument or system.4 Less the lone inventor, the successful creation and redesign of an invention into a patent model entailed the cooperative efforts of one or two experimental assistants, machinists, and mechanics.5 Once the patent model was constructed and tested, the invention and a written detailed description of its operation and component parts, including schematics, were presented to the United States Patent Office for patent application and approval.

The successful implementation of the invention process relied not only on the knowledge, experience, and ingenuity of the inventor and his assistants, but also on the inventor’s entrepreneurial skills and ability to manage and coordinate inventive tasks; skills known collectively as the craft of invention.6 The craft of invention, principally established in the early to mid-1870s by inventors such as Thomas Edison, initially employed craft-based management strategies. In the laboratory, the inventor, who coordinated the operation through a process of direct management, assumed the role of the master artisan; his assistants became his apprentices. Inventors also heavily utilized aspects of artisan shop culture, including open and accessible dissemination of

knowledge among employees and peers, irregular work hours, opportunities for upward mobility, and the mastery of trade skills.7 Shop culture also consisted of a task-oriented and worker-controlled production pace, worker autonomy, close relationships between masters and their journeymen and apprentices, and bonds of mutuality. Inventors like Edison maintained these pre- industrial traditions to make the execution and coordination of the skill-based craft of invention most efficient.

Modification of the Invention Process

By the late-1870s and 1880s, inventors, such as Thomas Edison and Elihu Thomson, modified the traditional, strictly craft-based system of invention. Edison, at Menlo Park, selective ly adopted industrially-based management tactics without fully abandoning pre-existing management strategies.8 The combined use of pre-industrial and

6 W. Bernard Carlson, Innovation as a Social Process: Elihu Thomson and the Rise of General Electric,

1870-1900 (Cambridge 1991), 66.

7 Andre Millard, “Machine Shop Culture and Menlo Park,” in Working at Inventing: Thomas A. Edison and

modernized management practices resulted from limitatio ns placed on inventors’ ability to directly manage the invention process as their small laboratory facilities expanded into moderate-sized, multi-component complexes. At Menlo Park, the expanded required a higher number of assistants, enabling multiple projects to be conducted simultaneously. As the inventor’s direct control over employees, experiments, and related inventive tasks became more limited, successful coordination of the operation required a bureaucratic management structure and the employment of modernized managerial practices.

In this new structure, the inventor’s role became more focused on innovation conception, financial appropriation, and overall management. Increased experimental projects required a team approach for research and development of technology

innovation, whereby teams of assistants would experiment on and develop specific elements of the invention conceived by Edison. Teams were headed by a team leader or manager, who received from and provided continual project updates to Edison. The team research approach forced assistants to specialize in certain aspects of an invention’s development and operation.

Specialization provided workers with intimate knowledge of the science and technology surrounding only a particular component of an invention. Consequently, their knowledge of all aspects of the invention process was reduced. This limitation,

In addition to these modifications, Edison also realized that for the business of innovation to be profitable he needed to develop and patent inventions that he could manufacture, such as the incandescent lamp.9 Edison did this through the creation of his incandescent lamp manufactory, the Edison Lamp Works. Once established, Edison intended to use the manufactory to fund continued industry-based innovation by creating inventions that would reduce the costs of production. Ultimately, the establishment of a manufactory in association with an invention factory became a necessary component of the invention process.

The transformation or evolution of innovation management from strictly craft-based to both craft and industrially-craft-based was influenced by the inventor’s general awareness of industrialization and modern management tactics. Edison witnessed such industrial management strategie s during the mid-1860s while working as an itinerant telegrapher for Western Union Telegraph Company, a large national firm that sought to create a monopoly in the telegraph industry. Inventors also observed the rapid, but uneven, industrialization of artisan trades that occurred nationally.10 Throughout the nineteenth century, but with tremendous advances in the postbellum period,

industrialization reduced workers’ skills and wages, produced a division of labor, simplified and subdivided work tasks, employed greater mechanization, and created a

9 Andre Millard, Edison and the Business of Innovation (Baltimore and London, 1993), 42, 58.

10 Susan Hirsch, Roots of The American Working Class: The Industrialization of Crafts in Newark,

management hierarchy, a process known collectively as the “bastardization of craft.”11 Unlike other industrialists, the inventor/entrepreneur could not employ all the elements of modern industrialization in his laboratories. A wholehearted adoption of these elements would have rendered the inventor and his staff incapable of conducting the skill-based operation of invention. Choosing the most efficient aspects of each in the invention process enabled inventors like Edison to selectively blend craft and industrial practices.

Research and Research Goals

In order to create a detailed examination of Edison’s management strategy and the forces that influenced that strategy, this study focuses primarily on the years the Menlo Park lab facility was in operation, circa 1876-1882. This thesis is then a case study of a six-year period of the management practices at one of America’s first and most prolific scientific industrial research and development laboratories. Research for this study relied largely on primary sources. Unfortunately, during this study, the main repository of Edison-related records and documents, the Edison National Historic Site in West Orange, New Jersey, was closed. Consequently, research relied primarily on printed patent interference court records held at the National Archives, published documents in the

Thomas A. Edison Papers Microfilm Edition and The Papers of Thomas A. Edison, diaries, reminiscences, local accounts, labor statistics, and newspaper articles. Also consulted were workers’ time sheets, letters of correspondence, historic maps and images, and personal documents in the Edison Pioneers biography files and the William Hammer Collection at the Smithsonian Institution. Secondary sources were utilized to help focus the research topic and provide valuable insights into the context of nineteenth-century

11 Hirsch, Roots of The American Working Class, 22-24, 35; David Bensman, The Practice of Solidarity:

management strategies, invention operations, the social forces guiding innovation, and Thoma s Edison’s inventive career. Finally, archaeological data gathered from recent excavations at Menlo Park by Monmouth University, provided valuable, previously undocumented information about the infrastructure of secrecy and intellectual property protection at Menlo Park.

Historiography

The results of this study add to the historiography of Thomas A. Edison and the Menlo Park laboratory facility. Like most histories of the famous inventor, this study focuses on Thomas Edison, yet it is not intended as a biography or a history of

technology. Early Edison biographers, such as Frank Dyer, Thomas Martin and William Meadowcroft, Mary Nerney, and Francis Jones, present Edison, as suggested by the title of Nerney’s book, Thomas A. Edison: A Modern Olympian, as a sole inventor,

highlighting only his most impressive and famous inventions.12 These works utilize Edison’s own faded, distorted, and incomplete memories as the basis of their work. Between the 1950s and 1970s, biographers Matthew Josephson and Robert Conot were among the first to review the then unorganized multi- million-page document record generated by Edison, his laboratories and companies, and his workforce.13 Their works were the first to critically examine Edison and his career, identifying his weaknesses and strengths as an inventor and businessman, and the importance of his utilization of

cooperative shop practices to successfully conduct the invention process.

12 Nancy Nerney, Thomas A. Edison: A Modern Olympian (New York, 1934); Francis Arthur Jones, The

Life Story of Thomas Alva Edison (New York, 1907); Frank Dyer, et al., Edison: His Life and Inventions

Volume 1 (New York and London, 1929).

13 Robert Conot, A Streak of Luck (Toronto, New York, and London, 1979); Matthew Josephson, Edison: A

By the late 1980s, the three-part series, The Thomas A. Edison Papers: A Selective Microfilm Edition, was completed. This series contained thousands of chronologically sequenced primary documents, organized by subtopics, and enabled researchers to fill in gaps and correct misinformation presented by the preceding histories. Numerous Edison histories were produced after the publication of the microfilm edition. The first of these includes William Pretzer’s edited work, Working at Inventing, which provides a history of Edison’s creation of a new system of invention, which utilized a diverse social and technically-trained workforce and the use of corporate capitalism to fund technology innovation, influencing the management of later research and development facilities. In this work, historian Andre Millard, points out that Edison utilized artisan shop culture to conduct the invention process, a concept elaborated upon in this thesis.14 In Edison and the Business of Innovation, author Andre Millard, later challenges the myth, in part perpetuated by Edison himself, that the great inventor was not a keen businessman.15 Millard highlights Edison’s attention to detail and entrepreneurial skills as a manager of his laboratories and companies, focusing primarily on Edison’s years at his West Orange, New Jersey laboratory and associated manufactories after 1887. Millard points out that it was often the lack of sponsorship for technology innovation, rather than ill management, that forced the downfall of many Edison-owned companies. Finally, Paul Israel’s recent work outlines Edison’s development and career as an inventor, defining his importance and influence in the development of science and modern scientific innovation.

This study adds to the Edison historiography by examining Edison’s entrepreneurial and management skills, and the role of craft and industrially-based

Chapter 2: Growth of an Inventor and the Exposure to Craft Traditions and

Industrialization

Thomas Edison first experienced pre-industrial craft traditions and artisan shop cultures in the mid-1860s during his teenage years as an apprentice in the nascent field of telegraphy, and, later, in his work in machine shops. Like many apprentices, Edison soon became a journeyman in his trade. Working for a number of telegraph companies, he roamed the country as an itinerant telegrapher, learning and participating in the artisan shop culture of the telegraph operator. In the late-1860s and 1870s, as telegraphy underwent increased mechanization, task specialization, division of labor, reduction of trade skill and wages, and management bureaucratization, Edison was also exposed to industrially-based management strategies. His exposure to both artisan traditions and industrialization influenced his management strategy at Menlo Park.

Learning the Craft and Exposure to Industrial Management Tactics

Thomas Edison was born on February 11, 1847 in Milan, Ohio to Nancy and Samuel Edison. In 1854, his family moved to the growing town of Port Huron, Michigan, a stop on the Grand Trunk Railway. Typical of most rail lines, the railway contained telegraph lines along its right-of-way. First introduced commercially in 1844, telegraphy was still a new technology during his youth. Intrigued, Edison quickly took an interest in the work of telegraphers and the science and mechanics that governed the telegraph’s operation.1

As a boy, Edison’s formal education was limited, due to his family’s financial setbacks caused by the 1857 economic depression. Aware of the importance for an education, Edison’s mother, Nancy, continued her son’s tutelage through

instruction.2 Under his mother’s guidance, Edison read an array of literature, including Richard Parker’s Natural Philosophy, and Carl Fresenius’s System of Instruction in Qualitative Chemical Analysis.3 Natural Philosophy introduced Edison to telegraphy, as well as electricity, physics, and mechanics, and Fresenius’ work to chemical analysis. These works, part of the increasing popularization of science during the nineteenth century, sparked his interest in science and furthered his intellectual development.4

Inquisitive and curious like most boys, Edison was eager to put theory into

practice.5 He soon gained permission to set up his first laboratory in a baggage car at the nearby railroad stockyard. This situation, however, was short lived due to complications from spilled chemicals that engulfed the car in flames. Determined to continue, but banned from using the rail cars, young Edison moved his assortment of chemicals and scientific apparatus into the cellar of his home. Edison’s home laboratory was similar to that of the inventor Elihu Thomson, who also experimented with chemicals and electro-mechanis ms during his adolescence.6 Both labs were filled with a variety of chemicals and home-made mechanisms. Like many boys his age, Edison sought to create a space at home that was relatively free from adult supervision and control in order to freely explore the mysteries of science and unknown forces that governed the world in which he lived.7

2 Dyer, et al., Edison: His Life and Inventions, 1:26. 3

Dyer, et al., Edison: His Life and Inventions, 1:26-28, 37. 4

Hyman Kuritz, “The Popularization of Science in Nineteenth-Century America,” in History of Education Quarterly, Vol. 21, No. 3 (Autumn, 1981), 259-274.

5

According to social and gender historian E. Anthony Rotundo, applying knowledge in this way and learning from experience was part of boyhood culture during the nineteenth century. E. Anthony Rotundo,

American Manhood: Transformations in Masculinity from the Revolution to the Modern Era (New York, 1993), 44.

6 Carlson, Innovation as a Social Process, 34.

In 1862, Edison constructed a crude telegraph line between childhood friend James Clancy’s home and his own. Looking to improve his skills, that same year Edison informally began to learn the craft of the telegraph key from local telegraphers John Thomas and John Raper. Later that year, his formal introduction to the trade began with his apprenticeship under telegrapher James MacKenzie. During his apprenticeship, he tirelessly and industriously worked to become better acquainted with telegraph

technology and the telegraph trade. Eager to improve at manipulating the telegraph key, Edison claims to have worked eighteen hours daily under MacKenzie’s guidance to learn the Morse code and the skills needed to become a second class, or plug, operator.8 As an apprentice, Edison experienced the craft-based traditions and telegraph operators’ shop culture.9 Upon finishing his year- long apprenticeship, Edison, like most telegraph operators of his day, roamed the countryside, visiting new places in search of work.10

Being on the “tramp” or journeying in search of work to learn new skills and visit unseen places was part of every telegrapher’s life, as it was for most artisans of the day.11 As an itinerant telegrapher, Edison worked in a number of telegraph offices across the country, mainly for the Western Union Telegraph Company, as well as for smaller companies. Through constant practic e, experimenting, and observation, he increased his knowledge about the telegraph trade and eventually acquired the necessary skills to become a first class operator. Edison, however, was less interested in being an operator

Grove: Archaeological Excavations of the Boyhood Homesite of Thomas A. Edison in Port Huron, Michigan 1976-1994 (Rochester, 1994), 180.

8 Thomas Alva Edison, “Edison’s Autobiographical Notes,” in The Papers of Thomas A. Edison: The

Making of an Inventor, February 1847-June 1873, vol. 1, ed. Reese Jenkins, et al. (Baltimore, 1989), 631. 9 Dyer, et al., Edison: His Life and Inventions, Vol. 1, 49-50; Conot, A Streak of Luck, 19.

10 Israel, Edison: A Life of Invention, 20.

than he was in experimenting on and improving the machines and electrical instruments operators controlled and in inventing electro- mechanical devices.

Like many of his fellow operators, Edison “had the profoundest curiosity as to the underlying principles of electricity that made telegraphy possible.”12 Such curiosity was the foundation of a telegraph technical community, in which some telegraphers shared information regarding technological advances, science, and mechanical technology. They learned from reading scientific publications and trade journals, and, like the “fraternity of mechanicians ” found in the metal working trade, from constructing and examining each others’ innovative mechanical instruments.13 It was during his early years as a telegrapher that Edison was introduced to the necessary skills to become an inventor; skills the historian W. Bernard Carlson calls the “Craft of Invention.”14

Carlson explains that the craft or art of invention was a learned and intensive process that required an inventor to observe new scientific discoveries, to experiment, to turn concepts into working mechanisms, to patent the inventions, and to present his findings or results to the scientific community in published form.15 This craft required the inventor to not only master technical skills, but also learn entrepreneurship, attention to detail, and management skills. As such, the inventor assumed the role of scientist, inventor, manager, and entrepreneur. Typically, the inventor conceived an idea for a new mechanism or technology, acquired funding, hired skilled assistants, and managed

finances, tasks, and employees. The inventor was required to coordinate these elements to efficiently research, experiment, and develop an invention to create a patent model and

12 Dyer, et al., Edison: His Life and Inventions, Vol. 1, 100.

13 Anthony F. C. Wallace, “The Fraternity of Mechanicians,” in The Industrial Revolution in America, ed. Gary J. Kornblith (Boston and New York, 1998), 23-29.

patent application. Edison principally acquired the necessary skills for the craft of invention through a process of self-education and observation.

As an itinerant telegrapher, Edison, like many other journeyman telegraphers, spent his leisure and work hours tinkering with and experimenting on the telegraph to familiarize himself with the instrument’s mechanics and electrical operation. He realized that self- improvement, the cornerstone of the popularization of science, was necessary for advancement in scientific professions.16 Edison tirelessly absorbed scientific literature, visited libraries, purchased books, and experimented on electro- mechanical devices. Education and experiential knowledge were key to understanding the underlying principles of telegraphy and gaining insights to telegraph technology. Intent on making significant improvements upon the telegraph, Edison constantly made adjustments to the telegraph apparatus. These experiments included work on self-adjusting relays, modified repeaters, multiple telegraphy, systems of secret signaling, and fire-alarm and stock printing telegraphs.17

Reading about, experimenting with, and learning telegraph technology was part of the telegraph operators’ shop culture. So too was augmenting the routine of work, study, and experimentation with necessary periods of relaxation and fun. Edison and his fellow operators typically relieved the strenuous workday with long conversations, story-telling, and practical jokes. At work, Edison continuously found new ways to amuse his co-workers. One practical joke involved attaching batteries to a washbasin so that when touched, the unsuspecting party was briefly shocked.18

16 Kuritz, “The Popularization of Science in Nineteenth-Century America,” 264. 17 Israel, Edison: A Life of Invention, 35-49.

Humorous initiations, suffered by most telegraph operators, were also part of the work routine. For example, in April 1868, on his first day at work at the Boston Western Union office, he was told to take a lengthy press message for the Boston Herald from a New York operator. As Edison later told the story, the New York operator began sending the message with great speed, but he was able to keep up. Intent on making Edison break or interrupt the message, an action that first class operators discouraged, the New York operator began abbreviating and slurring his message. Knowing full well that he was at the receiving- end of a joke, Edison, keyed the New York operator, “You seem to be tired, suppose you send a little while with your other foot.”19 The room immediately filled with laughter and Edison passed the initiation. Initiations and shop practices like this bound operators into a community. Known as the “Knights of the Key,” the telegraphers took pride in their competence, skill, and command over the electro- mechanical devices needed to send and receive a coded language.

During periods of slow business, operators, like Edison, utilized their skill and limited autonomy to communicate over the telegraph with one another between distant locations. Operators told stories and jokes, shared personal information, offered advice to one another, and solidified friendships over the wire. Operators also became aware of changes occurring nationally within their trade, such as wage reductions, implementation of easily operated telegraphic machinery, the utilization of cheap female labor, and task specialization.

Prior to the mid-1860s, operators enjoyed relatively high wages due to the skill needed to accurately send and receive messages and tend the ir machines. The telegraph

19 Thomas A. Edison, “Edison’s Autobiographical Notes,” in The Papers of Thomas A. Edison: The Making

trade was craft-based, and telegraphers were responsible for conducting a multitude of tasks associated with telegraph communication. Telegraphers were expected to be knowledgeable in line and telegraph repair, battery recharge, and coded message communication.20 Operators also had to be versed in electrical science. However, telegraphy as a skilled, craft-based trade would begin to change as companies grew larger, bureaucratized, and became more competitive. Operators’ work also changed as their tasks became more specialized and deskilled due to the introduction of increased technological improvements to telegraphic machinery, such as automatic printing telegraphs.

By the late-1860s and 1870s, telegraph firms, such as Western Union Telegraph Company, had expanded and adopted industrial processes that resulted in the elimination of operators’ craft traditions from the workplace. Connected to the telegraph industry, during the 1870s after he became a professional inventor, Edison was aware of these changes. As the firms grew, they absorbed smaller companies and established control over vast regions of the country.21 The competition between the large firms necessitated cost cutting measures and the implementation of modernized managerial strategies. To reduce the skills required by telegraph operators, companies subdivided work tasks by creating new, more specialized, positions.22 Telegraph companies employed linesmen, battery operators, electricians, and mechanics. Operators were simply required to send and receive messages.

20 Israel, From Machine Shop to Industrial Laboratory, 64.

21 Vidkunn Ulriksson, The Telegraphers: Their Craft and Their Unions (Washington, D.C., 1953), 9-13; Israel, From Machine Shop to Industrial Laboratory, 54.

To gain greater control over the process and reduce production costs, large firms contracted inventors to create new telegraph devices. For example, duplex and diplex machines, introduced in 1872, allowed two messages to be sent or be received over a single line, thus reducing the cost of line installation and maintenance.23 Companies were determined to blanket the telegraph industry with corporate-owned patents. The goal sought by all companies was to retain the rights to key patents for which the industry depended, such as those for multiple telegraphy.24 Patent ownership enabled individual firms to dominate the industry.

Inventors were also hired to create telegraph machinery that required less skill to operate. For example, inventors constructed telegraphs that could accurately record messages on chemically treated paper, leaving black marks or perforations for the

message to be read and translated with ease. The new instruments enabled the companies to reduce operators’ wages and skills, as well as begin to hire women as a cheap

workforce. 25 Ultimately, workers were made expendable through the process of industrialization and the bastardization of craft.26

In response to the initial problem of wage reduction during the mid-1860s, as well as to gather as a fraternal organization united by the craft skills shared by operators, many telegraph operators united to form the National Telegraphic Union (NTU).27 In the fall of 1865, Edison, who wanted to retain high wages but welcomed the new strategy of

corporately sponsored innovation, became one of the founding members of the Cincinnati

23 Israel, From Machine Shop to Industrial Laboratory, Chapter 5; Leonard Reich, The Making of American

Industrial Research: Science and Business at GE and Bell, 1876-1926 (Cambridge, 1993), 4; Paul Israel, “Invention and Corporate Strategies,” in The Industrial Revolution in America, ed. Gary Kornblith (Boston and New York, 1998), 150-151.

24 Israel, “Invention and Corporate Strategies,” 150-151. 25 Gabler, The American Telegrapher, 51.

District of the NTU.28 Edison’s support of the union was based on his acknowledgement of the importance of skill, high wages, self- improvement, and occupational mobility as vehicles for success. Edison and other tradesmen agreed that these artisan traditions were necessary elements for the retention of the free labor ideology, as well as the pervading success ethic and concept of manhood, whereby male workers were determined through their own assiduousness, competence, skill, autonomy, and free labor to establish themselves as self- made men.29 In forming the NTU, operators joined together and encouraged strong trade community bonds, the retention of worker skills, and the promotion of self- improvement and self-education. In fact, the editors of The

Telegrapher, like Edison, acknowledged that one of the few ways operators could gain occupational mobility and success was by learning the technical aspects of their trade, as well as science and mechanics in order to improve telegraph technology through

invention.

Like a number of his fellow telegrapher operators, Edison hoped to succeed as an inventor by undertaking a process of self-education and self-discipline.30 Edison later wrote in 1882 that this process entailed reading, observation, experimentation, patience,

28 Jenkins, et al., in The Papers of Thomas A. Edison, vol. 1:xxxix, Doc. 168, n.1; Francis Jehl, Menlo Park

Reminiscences, vol. 1(Dearborn, 1937), 35. 29

Daniel Rodgers. The Work Ethic in Industrial America, 1850-1920 (Chicago and London, 1978), 30, 35; Brian Greenberg, Worker and Community: Response to Industrialization in a Nineteenth-Century American City, Albany, New York, 1850-1854 (Albany, 1985), 26-27; Gary Kornblith, “The Entrepreneurial Ethic,” in

Problems in American Civilization: The Industrial Revolution in America, ed. Gary Kornblith (Boston and New York, 1998), 71-79; John Cawelti, Apostles of the Self-Made Man: Changing Concepts of Success in America (Chicago and London, 1965), 5-6; Ava Baron, “Acquiring Manly Competence: The Demise of Apprenticeship and the Remasculinization of Printers’ Work,” in Mark Meanings for Manhood: Constructions of Masculinity in Victorian America, eds. C. Carnes and Clyde Griffen (Chicago and London, 1990), 153; Nick Salvatore, Eugene V. Debs: Citizen and Socialist (Urbana and Chicago: 1984), 23-24.

perseverance, enthusiasm, experience, imagination, and hard work.31 Engaging in these elements enabled Edison and other inventors to develop skills in the craft of invention. Beyond engrossing themselves in scientific literature and experimenting on new

telegraphic machinery, skills and knowledge were also acquired by immersing in the technical communities found in cities across the country. Cities such as New York and Boston had exceptional technically-oriented telegraph and machine trade communities, both of which aspiring inventors like Edison embraced. To develop their concepts into patentable inventions, operators with innovative mechanical concepts commonly consulted machinists and other telegraph operators for advice. However, most lacked financial support to see their concepts into patented, marketable inventions.

During the late 1860s, Edison worked in Boston, Massachusetts, and became acquainted with numerous telegraph companies and their associated machine shops. There, struggling to gain funding to invent his innovative concepts, Edison became aware of the necessity for financial support for his inventions. Edison understood, like most independent inventors, that investors would only provide financial support for the

creation of inventions for which there was or potentially could be a real market demand.32 Moreover, in the industrial arena, such as the telegraph industry, corporations selectively sponsored the invention of innovative technology geared toward reducing production and/or operating costs. With this knowledge, his growing skills in the craft of invention, and his insatiable urge to invent, Edison decided to become a professional inventor.

31 Thomas A. Edison, “How to Succeed as an Inventor,” in How to Succeed in Public Life: A Series of

Essays, ed. Lyman Abbott (New York, 1882), 94-104.

Entrepreneur and Inventor

On January 30, 1869, at almost 22 years old, Edison permanently ended his career as an itinerant telegraph operator to devote his full time and energy to inventing.33 Four months later, he moved to New York City, where he found the largest and most

technically oriented telegraph community in the nation. New York also offered Edison a supply of potential investors eager to increase their wealth, as well as telegraph

companies that sought to monopolize on inventors’ patents. During the late-1860s and 1870s, the telegraph industry experienced a significant rise in company-sponsorship of technological innovation for new telegraph instruments and systems.34 One such

company was Gold and Stock Telegraph Company (GSTC). In February 1871, GSTC, a leading private-line telegraph company, attempted to increase its patent ownership by enlisting Edison’s inventive talents. Gold and Stock Telegraph Company contracted Edison as a “Consulting Electrician and Mechanician.” 35 Under this contract, Edison was responsible for inventing new and efficient private-line telegraph apparatus, the patents for which were sold to and controlled by GSTC.

Edison included in the contract a provision that required GSTC to provide him with funds for a facility to invent a facsimile telegraph instrument. Edison historian Paul Israel notes that it was probably Edison who wished to include this provision on account of his former experience with manufacturing delays in Boston, where typical machine shop back orders delayed the construction of a patent model. Writing about this experience, Edison observed,

33 “Editorial Notice in the Telegrapher,” January 30, 1869, in The Papers of Thomas A. Edison, vol. 1, ed. Jenkins, et al., 111, Doc. 55.

What delays me here is awaiting the alteration of my instruments which on

account of the piling up of jobs at the instrument makers have been delayed and I will probably have to wait one week longer, and then if everything works as it has got to do for I’ll never say ‘fail’…36

Due to the rapidity of technological innovation in the telegraph industry, delays associated with invention and the patent process had to be minimized.

Funds provided in this contract enabled Edison to establish a machine shop initially for the sole purpose of inventing an efficient facsimile telegraph. On February 15, 1870, Edison established the Newark Telegraph Works, at 15 New Jersey Railroad Avenue in Newark, New Jersey with machinist, William Unger. By April, GSTC requested Edison to make improvements to and manufacture a gold stock report printing telegraph, for which it had recently acquired patent rights. The new facility allowed Edison to invent, experiment on, modify, and manufacture telegraph instruments at will. Edison now had a machine shop with which he could control output with relative

certainty. He was also able to utilize his machinists’ and mechanics’ craft and technical skills to assist in the invention process.

Few other inventors at this time, such as telegraph inventors Elisha Gray and Jesse Bunnell, were able to operate in their own machine shops by establishing business partnerships with machinists and mechanics.37 More commonly, inventors such as Alexander Graham Bell, Elihu Thomson and others during their early careers rented small spaces in machine shops. In these shops, the inventors paid one or two machinists to construct their inventions. By working directly with the machinists during this

process, inventors, including Edison, oversaw the creation, alteration, and modification of

36 Letter from Edison to E. Baker Welch, May 8, 1869, in The Papers of Thomas A. Edison, vol. 1, ed. Jenkins, et al., 121-123, Doc. 68.

their concepts into working patent models. Most inventors typically did not own their own shops, and, consequently, their experimental work was often delayed because of large customer orders that received priority. Edison, of course, no longer dealt with such delays. The Newark Telegraph Works was the first machine shop dedicated entirely to Edison for experimental work on and manufacture of stock printing telegraphs for GSTC.

Between 1870 and his departure from Newark in March 1876, Edison was a co-founder/owner of five different machine shops within the City of Newark. Some of these shops operated simultaneously, and all specialized in telegraph manufacture and

invention for different telegraph companies, includ ing GSTC, the Automatic Telegraph Company, the Western Union Telegraph Company, and the Atlantic and Pacific

Telegraph Company. In these shops, Edison developed the skills necessary for invention. Here, he acquired the skill and capability of simultaneously researching and developing multiple inventions, made possible through the employment of a coordinated, semi-bureaucratic management structure. Edison headed this loose hierarchy, based in a traditional cooperative artisan shop culture, where he was assisted by a small number of experimental assistants and a foreman, under whom worked machinists and mechanics.

Work on multiple inventions also necessitated long workdays of strenuous, tedious, and precise work. To ensure that he had ample time to conduct his work, Edison requested a clause in the lease for his machine shop, the American Telegraph Works, which conducted work for the Automatic Telegraph Company, that permitted the shop to “have the right to run nights.”38 Edison’s desire to work long days was typical of his personal and managerial style. In fact, Edison commonly worked sixteen to eighteen

hours daily in his shops, later stating that sleep caused a “loss of time, vitality, and

opportunities.”39 His views about rest and work were indicative of the pervading success ethic.40 For Edison and many other workers, particularly artisans, hard work helped build strong character, promoted one’s social status, and increased one’s chances of success through social and occupational mobility.41 Edison often pushed himself and his men to continue laboring once a task or invention was near completion or when a concept or mechanism was undergoing development. 42 During such times, it was necessary for the work momentum to remain static to encourage successful completion of steps within the invention process. To ensure that his assistants had full understanding of his inventive goals, Edison was continuously and fully engaged in the work with his men, toiling and getting dirty like an average employee. The inventor later commented, “I gave them a good training as to working hours and hustling.”43

After long work stints, Edison usually allowed his men time to rest, a tactic he had learned while an itinerant telegrapher and through his general awareness of task-orientated, pre- industrial modes of production. During this time, they socialized and indulged in alcohol and tobacco smoking for hours.44 In fact, Edison commonly joined his men during their leisure, chewing tobacco, drawing cartoons, and telling stories. In prosperous times, when he or the company earned profits, Edison displayed his

appreciation for his shop workers’ fine and hard work by providing them with a

39

Thomas A. Edison, The Diary and Sundry Observations of Thomas Alva Edison, ed. Dogbert D. Runes, (New York, 1948), 178; Conot, A Streak of Luck,48.

40 Rodgers. The Work Ethic in Industrial America, 7; Bensman, The Practice of Solidarity, 47-48; David Bensman, “Economics and Culture in the Gilded Age Hatting Industry,” in Small Business in American Life, ed. Stuart W. Bruchey (New York, 1980), 360.

41 Rotundo, American Manhood, 175. 42 Conot, A Streak of Luck, 49.

celebratory supper.45 For Edison, unlike most industrialists of his time, it was important to establish a feeling of camaraderie and promote a mutuality of interests with his

workers, a style of leadership that would carry through into his years at Menlo Park.46 By February 1872, in a partnership with machinist Joseph Murray, Edison established a telegraph instrument manufacturing shop called Murray & Co at 115 New Jersey Railroad Avenue in Newark to fulfill GSTC’s enormous orders.47 By mid-summer, this shop moved to 10-12 Ward Street in Newark and was renamed Edison & Murray.48 The new shop was large. An 1872 company inventory/balance sheet compiled by Charles Batchelor, Edison’s chief experimenter, indicates that the new shop contained $34,774.98 worth of equipment, tools, supplies, chemicals, and machinery.49 Certainly, Edison was making headway establishing himself as an inventor and manufacturer.

A variety of machinists, mechanics, and experimenters were employed by Edison & Murray, some of whom exhibited great skill and interest in electro- mechanical

instruments. These men would later follow Edison to Menlo Park. One of these

employees was Charles Batchelor, nicknamed “Batch” by Edison. Batchelor came to the United States in 1870 from England as a textile mechanic. In 1871 he served as a

precision machinist and mechanic in Edison’s Newark machine shop, the American Telegraph Works. Edison took notice of Batchelor’s mechanical skills and interest in electrical matters, and soon promoted him to the position of chief experimental assistant.

45

Conot, A Streak of Luck, 87; Dyer, et al., Edison: His Life and Inventions, vol. 1, 135.

46 Brian Greenberg notes, in Worker and Community, 30-31, that some industrialists, such as those in Albany during the mid -1850s, supported craft traditions by engaging in public outings, target shooting, and games to establish a sense of camaraderie with their employees.

47 R. G. Dun and Company Credit Report, March 6, 1872, in The Papers of Thomas A. Edison, vol. 1, ed. Jenkins, et al., 469, Doc. 252.

48 Jenkins, et al., in The Papers of Thomas A. Edison, vol. 1, ed. Jenkins, et al., 501, n. 1-2.

Edison paid Batchelor double what other workers in the Newark shop earned. Edison was also impressed by the mechanical skills of Charles Dean. Dean later worked at Menlo Park and conducted contract work for the precision- machined parts needed in the incandescent lamp experiments.

Additional machinists and mechanics from Newark who followed Edison to Menlo Park included Swiss machinist John Kruesi, later foreman of the Menlo Park machine shop, John Ott, Carl Herman, and James Bradley. Other workers included machinist Charles Wurth, Edison’s nephew Charles Edison, and ex-sailor turned

experimental assistant James Adams. Adams, like Batchelor, later proved instrumental in the development of new inventions both at the Ward Street shop and at Menlo Park. By 1875 Adams became one of Edison’s chief experimental assistants.50 The machine shop skills exhibited by these men were impressive, and Edison knew it. He utilized their skills and talents during the invention process, which was key to the success of his endeavors. At his Ward Street shop, Edison worked closely with the instrument makers, machinists, and mechanics. He learned from their skills and suggestions regarding modifications and alterations to improve the mechanical function of the instruments. His need for skilled artisans to assist in and make alterations to his work was crucial

throughout the inventive process, and he often rewarded those who assisted most for their valuable contributions.

For example, in recognition of their enormous intellectual and mechanical contribution in the development of his inventions, such as his electric pen and press machine, a duplication machine invented at his Newark, Ward Street shop for use by

50 Robert Rosenberg, et al.., in The Papers of Thomas A. Edison: From Workshop to Laboratory, June

stenographers, Edison rewarded his most valued machinists, mechanics, and experimental assistants with percentages of the royalties earned from the invention.51 In fact, in an oral agreement with Charles Batchelor, Edison gave the experimental assistant ten percent of the gross profits received from all inventions on which he was a mutual collaborator.52 In this way, Edison affirmed his bonds of mutual interest with his workers by

acknowledging and rewarding their hard work.53 Few contemporary employers

attempted to create such bonds. Those that did, however, viewed it as a way to obtain a loyal and industrious workforce.54

In autumn of 1875, Edison was contracted by Western Union as an experimenter in the new field of acoustic telegraphy, experiments for which he conducted at his Ward Street shop. In order to reduce expenses during the 1873 depression, as well as retain their dominance over the telegraph industry, Western Union needed to remain ahead of the competition with patent ownership of new, cutting-edge technologies. Through his contract negotiations with Western Union president William Orton, Edison demanded $200 weekly and $6,000 plus royalties for any successful patents that allowed the

simultaneous transmittal of five or more telegraph messages over a single wire.55 Edison continued experimentation in the field of acoustic telegraphy for the remainder of the year, at which point he made significant progress toward creating an acoustic telegraph instrument.

51 Thomas Edison Agreement with Charles Edison and W. H. Blennerhassett, October 1, 1875, in The Papers of Thomas A. Edison, vol. 2, ed. Rosenberg, et al., 584-586, Doc. 636; Thomas Edison Agreement with Charles Batchelor and James Adams, October 2, 1875, in The Papers of Thomas A. Edison, vol. 2, ed. Rosenberg, et al., 586, Doc. 637; “Edison’s Electric Pen and Duplicating Press Co., Charles Batchelor, and Thomas Edison,” 1876, in Thomas A. Edison Papers Microfilm Edition: Part 1, 1850-1878, ed. Reese Jenkins, et al. (Fredrick, 1985), microfilm 13: 934-938.

52 Conot, Streak of Luck, 103.

By late 1875 Edison became increasingly concerned with the long-term

expenditures of his Ward Street shop. Lease costs for his shop totaled at least $1,500 for the building rental.56 Moreover, the building could not be modified. Intent on saving money and to avoid paying rent, Edison decided to relocate his operation. In December 1875 Edison sent his father, Samuel, in search of a suitable location for his shop. After an exhaustive effort, Samuel and Thomas decided upon the small, rural hamlet of Menlo Park, New Jersey. Menlo Park was located immediately northeast of Metuchen and New Brunswick and a little over twenty miles southwest of New York City. This community offered Edison a quiet and secluded location to continue experimentation on acoustic telegraphy. Edison also chose Menlo Park because it was a stop on the Pennsylvania Railroad line. Proximity to the railroad provided him with quick and easy access to New York City, the nation’s financial and commercial center.

At the time Edison chose Menlo Park, the hamlet was the site of a failed real estate development. Established just one year prior by the Menlo Park Homestead Association, the community consisted of only a handful of homes and a few dirt roads.57 On December 29, 1875 Edison purchased seven property lots for $5,200 from Menlo Park Homestead Association Trustee George Goodyear.58 One of these lots, located on the edge of the community, was the display home/office for the Menlo Park Homestead Association. Edison chose the large three-story dwelling as his residence. Located just

56

Thomas Edison and William Unger Lease from William Kirk, May 1, 1871, in The Papers of Thomas A. Edison, vol. 1, ed. Jenkins, et al.,273, Doc. 157.

57 Thomas Archey, “Map of the Menlo Park Homestead Association on New Jersey Railroad.” Map filed at the Middlesex County Clerks Office, January 4, 1869: Map No. 77, File No. 77; Everts and Stewart,

Combination Atlas Map of Middlesex County New Jersey: Compiled, Drawn, and Published from Personal Examinations and Surveys (Philadelphia, 1876); Fredrick W. Beers, “Topographical Map of Middlesex County, New Jersey” (New York, 1872).

58 Deed recorded on December 29, 1875 in the Middlesex County Clerks Office in Book 157, Page 380; Deed, mortgage, bond, and agreement, Thomas A. Edison with George Goodyear, December 29, 1875, in

two blocks south of the future lab, the residence allowed Edison to easily travel to work at all hours of the day. The grand size of the home typified Edison’s newly earned status as a middle-class entrepreneur. Edison’s chief experimental assistant Charles Batchelor also displayed his newly acquired middle-class status by purchasing a property lot one block south of the lab and erecting a large home.59

The remaining six property lots would house the future laboratory. Edison hired his father, Samuel, a talented carpenter, to erect the lab. Situated on a hill crest

overlooking the surrounding quiet rural landscape, Samuel and a team of local workers constructed a long and narrow, two and one-half story, gable- front building with white clapboard siding. The laboratory’s façade resembled both a schoolhouse and a church, and was similar to that of early- nineteenth-century textile mills. The deceptive

appearance of this structure disguised the fact that it housed, on its first floor, a machine shop and office, and on its second floor, one of the largest private research and

experimental laboratories in the world. Edison now owned his own machine shop and laboratory, both strictly dedicated to inventing. This facility was to prove unique and become the frontrunner and model for industrial research and development into the twentieth century.

59 Letter from Charles Batchelor to Thomas Batchelor, February 8, 1876, in The Papers of Thomas A.

Chapter 3: Edison’s Menlo Park Laboratory: The Growth of the Facility

Edison moved into his Menlo Park laboratory in late March 1876. The facility remained in operation until October 1882. During those six years, the facility underwent three significant changes; the growth of the facility and workforce, a move to more focused experimental work, and the addition of the Edison Lamp Works, an incandescent lamp manufactory. The changes in the facility’s growth led Edison to revise his

approach to management from one based solely on craft-based traditions, to one that combined these traditions with an industrial management approach.

1876-1877

Edison’s Menlo Park laboratory facility was established to invent, develop, and patent commercially marketable electro- mechanical devices related to the telegraph industry. This facility was initially funded by Western Union Telegraph Company and GSTC. These two companies contracted with Edison to invent new telegraph

technology, the patents for which they purchased. For example, on January 29, 1877 Edison wrote to William Orton, President of Western Union, in request of a contract that would provide the inventor with $100 weekly for shop expenses, as well as royalties in exchange for the patent rights on all future inventions related to commercial telegraphy.1 Nearly two months later, Edison was granted the contract.2 In an effort to acknowledge the labor and skill required to develop an invention, Western Union agreed to provide Edison with additional compensation if the telegraph company later made improvements

1 Thomas Edison to William Orton, Draft, 29 January 1877, in The Papers of Thomas A. Edison: The Early

Years, April 1876-December 1877, vol. 3, ed. Robert Rosenberg, et al, (Baltimore and London, 1994), 238-239, Doc. 850.

to an invention he created.3 Such funding gave Edison advantages over many other contemporary inventors, most of whom conducted their experiments with a single

assistant in a small room or machine shop. Corporate financial support enabled Edison to expand his experimental facility and to hire highly skilled machinists and college trained, technically-oriented assistants.4

Financial support enabled Edison to create the largest private laboratory in the country, and in 1877, he described his facility:

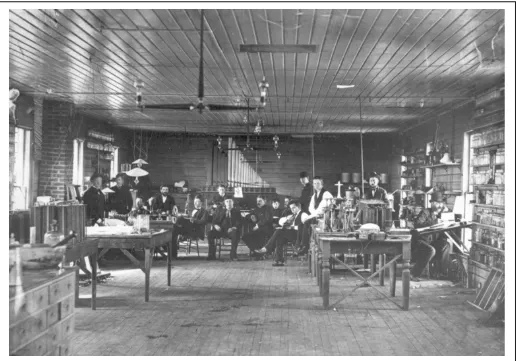

I have now thoroughly completed and stocked my laboratory at Menlo Park N.J. The first floor of the laboratory building was utilized as a machine shop and an office, the upper floor as the central experimenting room (Figure 1). Here, Edison experimented on and developed his innovative electro-mechanical devices. The experimenting room was brightly illuminated by a series of windows and gas, later incandescent, lamps. Shelves containing an assortment of chemicals bordered the room (Figure 2).

Edison’s initial workforce of craftsmen and experimental assistants was small. In 1876, he employed approximately ten individuals.6 Most of his Menlo Park employees had worked at his Newark Ward Street machine shop and laboratory. In particular, his chief experimental assistants, James Adams and Charles Batchelor, machine shop

3 Agreement with Western Union Telegraph Co., 22 March 1877, in The Papers of Thomas A. Edison, vol. 3, ed. Rosenberg, et al,275-280, Doc. 876.

4 Israel, Edison: A Life of Invention, 155.

5 Thomas Edison to William Orton, Draft, 29 January 1877, in The Papers of Thomas A. Edison, vol. 3, ed. Rosenberg, et al,238-239, Doc. 850.

foreman, Charles Wurth, who quite later in April 1877, and machinist Ezra Gilliland, followed Edison to the new facility (Figure 3).7 Others whom Edison hired included assistants Anthony Bronk and James Gilliland, Ezra’s brother, machinist Alfred

Swanson, and local carpenters, Martin Force and Milo and Smith Acker. With help from these men, Edison began experimenting.

Between March 1876 and December 1877, Edison and his team developed and experimented on a number of innovative mechanical, electrical, and acoustic instruments, including an acoustic telegraph, the phonograph, and improvements on his electric pen and duplicating press. Because of his recent work with and knowledge of acoustic

telegraphy, Edison also embarked in the related, nascent field of telephony, and improved upon Alexander Graham Bell’s recently invented, but inefficient, telephone transmitter.

Developing a new telephone transmitter, Edison and his team tested materials such as plumbago and carbon to amplify and better regulate electrical resistance of the signal transmitted through the telephone line. Carbon produced the best results creating a marked improvement of vocal transmission. Realizing the profits that could be gained, Edison began manufacturing small carbon buttons in his carbon production shed. Located near the rear of the laboratory, this shed was filled with numerous kerosene lamps. To acquire sufficient carbon deposits, lamp wicks were turned high, creating a sooty film on the interior of the lamp chimneys. One or two helpers working in this shed scraped the film from the chimneys and gently rolled it into small buttons. The carbon buttons were then sold to Western Union for use in telephone transmitters.8

7 Jenkins, et al, The Papers of Thomas A. Edison, vol. 3, ed. Rosenberg, et al., 287.

Edison next attempted to create an apparatus for the telephone that would allow one to record and repeat verbal conversations, in order to replace printing telegraphs. On July 18, 1877, the concept of the phonograph was born which could do just that. Edison and his workforce spent the next eighteen months assiduously laboring to develop and improve his phonograph. In December 1877, John Kruesi, Edison’s new machine shop foreman, had constructed an early working model of the phonograph (Figure 4).9 Within weeks, Edison displayed this instrument to Western Union officials and journalists. They were astonished. Never before had the human voice been repeated by a machine.

1878 and 1879

By early 1878 Edison and his phonograph had become instant sensations. Reports about his new invention quickly flooded newspapers.10 The novelty and originality of the instrument made Edison and his laboratory famous. The public marveled at the unknown forces behind its operation and traveled to the laboratory in swarms to obtain a glimpse of the famous speaking machine. Edison and his laboratory became the center of attention for reporters for the next few years. Newspaper journalists began to write about Edison and his talents in mythical proportions, dubbing him the “Wizard of Menlo Park.” His facility, which produced new inventions at a factory- like pace, was called the “invention factory.” Hereafter, this conjurer of unknown forces and his staff were plagued by crowds of journalists eager to get the scoop on his next big invention.

Edison’s fame from his phonograph invention provided him with new opportunities. He was now a popular figure. The publicity he received from press

9 John Kruesi became foreman between January and April 1877.

Figure4:PortraitofmachineshopforemanJohnKruesi.

reports made him a desired employer to work for. Skilled workers and young boys eager to learn mechanical and electrical knowledge from one of the world’s most famous inventors bombarded Edison with letters of application. His popularity enabled him to choose the most qualified men to serve as assistants and excite the interest of potential financiers and investors, including J. P. Morgan, affiliates of Drexel, Morgan and Company, and William Orton, President of Western Union.

By autumn of 1878, major changes had occurred at the laboratory facility. Edison’s efforts to make the phonograph commercially marketable continued,

significantly reducing his work in telegraphy. Edison, also took on a new project that September, the invention of an efficient incandescent lamp and the development of an associated system of electrical generation and distribution. This project required enormous effort, time, money, manpower, and intelligence. It also necessitated an expansion of the facility and workforce, as well as the creation of new departments to conduct the work.11

To finance the incandescent lighting project, on October 16, 1878 Edison and twelve other investors, including affiliates of Western Union and Drexel, Morgan and Company, incorporated the Edison Electric Light Company. This company was

established to “own, manufacture, operate and license the use of various apparatus used in producing light, heat or power by electricity.”12 The new company provided Edison with $30,000 investment capital to devote toward the invention of a marketable

incandescent lamp that could compete with gas and arc lighting. Technology historian

11 Thomas Edison, Legal Testimony and Statement, Sawyer and Man versus Edison (1881), in Thomas A.

Edison Papers, Part I, ed. Jenkins, et al., microfilm, 2:73.

12 Incorporation and Association Papers: The Edison Electric Light Company, 16 October 1878, in Thomas

Thomas Hughes indicates that the Edison Electric Light Company was largely formed as a means to provide funding for Edison’s inventive activities in the field of incandescent lighting.13 For the next two years, Edison and his team worked towards the development of an efficient incandescent lamp.

Once Edison began the new project, his workforce and the laboratory experienced enormous growth (Figures 5 and 6; see Figure 2). After one year, the number of employees at the facility increased from eighteen to forty-two.14 To

accommodate the now larger workforce and the increased inventive activity, and to better manage, coordinate, and subdivide work tasks, Edison had to expand the facility. By the end of Autumn, 1878, the lab’s first floor now included rooms for chemistry,

photometering, a galvanometer, telephone development, and a furnace. To staff these new departments, Edison hired a barrage of skilled and semi-skilled workers, including chemists, mathematicians, physicists, engineers, and a number of technically oriented assistants. Many of these employees were university educated and had received degrees from such colleges as Bowdoin College, Rutgers University, Princeton University, Stevens Institute of Technology, Columbia College, and various American and foreign polytechnic institutions. Many new employees were also artisans who learned their trade skills from master artisans.

In November 1878 Edison used funds from Edison Electric Light Company to move the machine shop from the first floor of the laboratory into a new brick building

13 Thomas P. Hughes, “Edison and Electric Light,” in Donald MacKenzie and Judy Wajcman, ed., The

erected immediately behind the lab. The shop, run by shop foreman, John Kruesi and later by foreman Thomas Logan, measured approximately 135 feet long by 25 feet wide and contained an office for the foreman, a workroom, and engine and boiler rooms.15 An electric dynamo generating room was added later. A series of windows along the north and south walls of the shop let in sufficient light to illuminate the building. The shop floor was filled with an array of lathes, milling, and grinding machines, powered by a steam engine, and operated by machinists, tool makers, and mechanics.

Edison’s machine shop was utilized exclusively for the fabrication and

modification of parts and tools specifically designed for his inventions and patent models. The work conducted in the shop was of a generalized nature, different from the

specialized machine shops, like the telegraph machine shops, where many inventors conducted their work.16 Experimental machine work necessitated greater skill and competency. The machinists in Edison’s shop were continuously required to create a variety of new parts and tools from sketches, an essential aspect of the invention process, provided to them by Edison and his experimental assistants.17 Typically, Edison, his chief assistant, Batchelor, and other assistants provided the machine shop staff with written, drawn, or verbal instructions for new devices, tools, or

adjustments/improvements for machined objects. The shop staff produced the requested objects and offered advice on mechanical improvements. The machinists’ goal was to create working patent models of the inventions. Due to the variation in and generalized nature of the work and their close association with the experiments, many of the shop

15 Israel, Edison: A Life of Invention, 177; Charles Clarke to Francis Jehl, 10 November 1928, Edison Pioneers Biography Files, Box 27-4, Henry Ford Museum and Greenfield Village, Dearborn, Michigan. 16 Brook Hindle, Emulations and Invention (New York: New York University Press, 1981), 98; Carlson,