Meniscus Recognition on Volumetric Glassware

Calibration Using Image Processing

Triya Haiyunnisa*, Hilman Syaeful Alam

Technical Implementation Unit for Instrumentation Development Indonesia Institute of Science

Bandung, Indonesia *[email protected]

Abstract— Volume instruments can be calibrated by filling or emptying volumetric instrument, the volumetric instrument using a reference volume measurement, i.e. by comparing two volumes. During volumetric calibration, meniscus’s reading affect experiment standard deviation directly. Error in meniscus recognition can be decreased by using webcam. The subtract between empty glassware and filled glassware could be analyzed of its pixel to recognize the meniscus of volumetric glassware. By taking some of the sample of volume, the regression of meniscus’s pixels could be determined. This regression equation is used to recognize the meniscus and as a feedback whether the desired volume is reached or not

Keywords—component; formatting; style; styling; insert (key words)

I.INTRODUCTION

Volume measurement is an important step in most industrial and analytical measurement operations. Laboratories must ensure that results obtained using these instruments are reliable. Volume instruments can be calibrated by filling or emptying volumetric instrument, the volumetric instrument using a reference volume measurement, i.e. by comparing two volumes. During volumetric calibration, meniscus reading affect experiment standard deviation directly. In old volumetric glassware method, reading of the meniscus performed by single operator. [2]

In this paper, the reading of meniscus is determined automatically by using webcam, which picture captured by webcam would processed into the reading of meniscus of glassware accurately. The reading of meniscus would be analyzed whether the reading of meniscus has shown the desired volume or not. If the desired volume has not reached, the glassware would be filled until the desired volume is reached.

II.VOLUMETRIC GLASSWARE CALIBRATION METHOD

The procedure of glassware calibration generally divided into 4 steps, i.e. preparation of measurement, measurement, calibration data recording, and analysis of measurement data [10] [4].

The preparations of measurement are preparing all the volumetric instrument (standard tools, measuring instruments, and calibration tools) and check the conditional volumetric

glassware physically, conditioning the Unit Under Test (UUT) by placing in calibration room for 1 night, clean all the volumetric instruments to be used, conditioning calibration room such as temperature and humidity of calibration room, and setting 0 on balance [9] [3].

Checking the conditional volumetric glassware physically is used to make sure that the scale of glassware could be read clearly, and no physically broken such as cracked nor leak [3].

Before being tested and used, the glassware must be cleaned. The liquids usually used for cleaning glassware are sodium dichromate sulphuric acid cleaning solution, nitric acid, fuming sulphuric acid, alcohol, and water [10] [7]. When the glassware clean, the walls will be uniformly wetted and the water will adhere to the glass surface in a continous film [9].

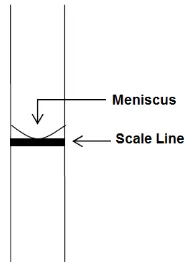

On the measurement step, the empty UUT e.g. glassware, are being weighed, and record the weigh. Fill the the UUT with distilled water carefully until reach the lowest point. Avoid air bubble stuck. Set the reading of meniscus until the line of measured point seems aligned with the lowest point of the meniscus [7]. Scheme of reading of meniscus:

Fig. 1. Setting of meniscus

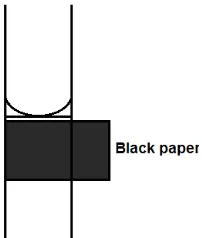

To read the meniscus, the lighting must be set so that the meniscus was dark and contrast with the background, which meniscus could be seen toward white-colored background and protected from unwanted light. This could be happened, if the volumetric glassware is surrounded by black - paper, where the distance is not more than 1 mm under scale line or boundary line capacity. The width of black - paper at least as 2015 International Conference on Automation, Cognitive Science, Optics, Micro Electro-Mechanical System, and

Information Technology (ICACOMIT), Bandung, Indonesia, October 29–30, 2015

same as diameter of volumetric glassware [10] [7]. The reading of meniscus by using black - paper could be illustrated in this Fig.2.

Fig. 2. The Reading of Meniscus by Using Black-Paper

Weigh the filled glassware and record. Repeat those steps for other measurement points and do all 3 times in every measurement point.

Calibration data retrieval is performed continuously from the lowest to the highest of the measuring point. After reach the highest measuring point, volumetric glassware then emptied and data collection starts again from the lowest measuring point. This process could be illustrated in fig 3.

Fig. 3. Illustration of Calibration data retrieval

After calibration data retrieval, analysis data is needed to determine the uncertainty of UUT. Parameters that can influence the quality of the result are weighing, water density, water temperature, ambient conditions, instrument characteristics, and operator. All those parameters are defined into mathematical equations to determine the uncertainty and sensitivity of each parameter.

Mathematic model of volume at temperature 200C [4]:

V = ∆R −ρu

ρm ρa−ρu [ − γ t − ]

Where

V

is volume at temperature 200C (liter), ∆R is mass of weighted water (kg), ρuis air density (kg/m3), ρm is weight density (kg/m3), ρa is distilled water density (kg/m3), γ is volume expansion coefficient of the material of the calibrated instrument (/0C), and t is temperature of distilled water (0C). This equation is calibrated system equation.Mathematic model of water density is a function of temperature using Tanaka Formula (Euramet cg-19:2011) [2]:

� = � [ − �+ �+�− ] g/ml (2)

Where is temperature (0C), � = − , º�, � =

, º�, � = , º� , � = , º�,

� = , �/��, and value of water density will convert into unit [kg/m3].

Distilled water mass is the difference between filled glass (IL) and empty glass (IE) [7].

∆R = IL− IE kg (3) Generally, the uncertainty of a measurement consists of several components which may be classified into two categories in accordance with the method used to estimate their numerical values i.e. type A and type B [2] [7].

Type A is evaluated by statistical analysis of series of Observations [2]. Measurement is repeated several times, and could be evaluated by calculated the standard deviation of measurement’s data divided by root of n values. The standard deviation is an estimate of the dispersion of the population from which the n values are taken [5] :

= √∑�= ��−�̅

− (4)

The uncertainty of repeatability of measurement

�=√ (5)

Type B is evaluated by other means other than statistical analysis of series of observations [5]. In this volumetric glassware calibration, parameters that influence the quality of the result which evaluated by using type B are mass of weighted water, air density, water density, density of reference mass, temperature, volume expansion coefficient of the material of the calibrated instrument, drift of standard instrument, and setting of meniscus [2].

Uncertainty of mass of weighted water affected by deviation standard of balance in maximum scale (� ) and Limit of Performance (LOP) of balance. This uncertainty could be defined as:

= √ � �

√ +

� �

√ (6)

The sensitivity coefficient of mass of weighted water density can be obtained by deriving volumetric calibration equation to mass.

� =���∆ = � −��

� � −�� [ − � − ] (7)

The uncertainty of air density is assumed as 10% of calibration room which is valued about 0.12 kg/m3.

= √. (8)

Sensitivity coefficient of air density could be determined by deriving volumetric calibration equation to air density

� =����

� = ∆

� −��

Uncertainty of water density sensitivity coefficients is considered equal for every point because water density doesn’t change in constant temperature.

= . (10)

Sensitivity coefficient of water density is obtained by deriving volumetric calibration equation to water density

� =���� = ∆ � −��

� � −�� [ − � − ] (11)

The uncertainty of volume expansion coefficient is assumed as 10% of coefficient of volume expansion coefficient of the material of the calibrated instrument.

Here are values of some volume expansion coefficient depend on material used for volumetric glassware, reference to ASTM E 542 document [10].

Material Volume Expansion

Coefficient

Coefficient sensitivity of volume expansion coefficient can be obtained by deriving volumetric calibration equation to volume expansion coefficient.

� =���� = ∆ � −��

� � −�� − (12)

The uncertainty of drift of standard tool is

�� � = ��√− (13)

In volumetric calibration, the largest error source is error on meniscus recognition. Based on EURAMET cg-19, the uncertainty of meniscus could be estimated as uncertainty of determining volume related to resolution of volumetric glassware’s lines scale ( �) [2]. Determination of uncertainty of meniscus recognition could be illustrated in this figure below.

Fig. 4. Concave Meniscus in a Graduated Volumetric Device [7]

By using triangular distribution, the uncertainty of meniscus recognition is

Object recognition has always been a challenging issue in image processing and computer vision [8] [15]. It is concerned with determining the identity of an object being observed in an image from a set of known tags [8]. For any object in an image, there are many 'features' which are interesting points on the object that can be extracted to provide a "feature" description of the object [13]. Humans can recognize any object in the real world easily without any efforts; on contrary machines by itself cannot recognize objects. Algorithmic descriptions of recognition task are implemented on machines; which is an intricate task. Thus object recognition techniques need to be developed which are less complex and efficient [8].

A. Difficulties in Object Recognition

There are some difficulties on recognize the object using image processing, i.e. lighting, positioning, and occlusion. The lightning conditions may differ during the course of the day. Also the weather conditions may affect the lighting in an image. In-door and outdoor images for same object can have varying lightning condition. Shadows in the image can affect the image light. Whatever the lightning may be the system must be able to recognize the object in any of the image [8].

Position in the image of the object can be changed. If template matching is used, the system must handle such images uniformly. The condition when object in an image is not completely visible is referred as occlusion [8].

Digital image processing (DIP) is to perform the operations on a digital image for a particular output and object recognition is one of the processes of image processing. DIP deals with the manipulation of the image with the help of computer [1].

Fig. 5. Digital Image Processing System

B. Meniscus recognition process

The meniscus recognition is found out by applying our proposed algorithm using MATLAB Simulator. A GUI (Graphical User Interface) is created to make the system user friendly [6].

Image input is a digital image that is taken by the camera and some operations are performed or we can say that the manipulation of an image is done which provides the output or processed image [1] [12]. The acquisition of an image is depends on the camera quality.

Input image might be analogue or digital; it has to be in digital form when given to the system. It is assumed that the image capturing device produces its output in RGB format [14]. In the first step, preprocessing is performed and the image is resized and transformed to grayscale image [11]. The image taken is in the empty condition and after filling condition. The process could be shown as figure below.

Fig. 6. Empty and Filling Glassware Captured

The subtract of those two images are subtracted. By subtracting the filled and empty volumetric glassware picture, the meniscus could be seen as a line. The line of meniscus could be analyzed its meniscus by plotting the pixels. The pixels of meniscus line is always shown the highest value of pixels. And the subtract of those 2 pictures can be shown below.

Fig. 7. Subtract between filling and empty glassware

After the operation performed on an image the processed image is the output. The output is also known as response. Object recognition, as its name is specifying, recognizing the object in digital images or videos. In this paper, by taking some of the sample of the volume given, we could determine the equation.

Fig. 8. Pixel of Subtract Picture

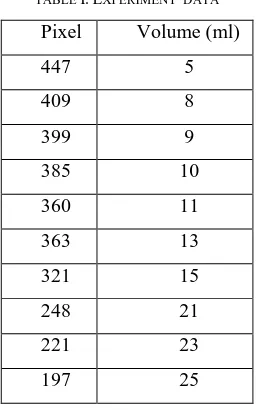

By taking some of the sample of volume, the regression of meniscus’s pixels could be determined. Here are the table of meniscus’s pixels depend on the filling volume.

TABLE I.EXPERIMENT DATA

Fig. 9. The linearity of Pixel’s Experiment Data

The regression equation is used to determine of the reading the meniscus by using webcam.

Volume = . − . Px (15)

IV. CONCLUSION

Acknowledgment

This research is used to change the calibration procedure of volumetric glassware in Bandung Technical Implementation Unit for Instrumentation Development, funded by Indonesian Institute of Sciences into an automatic system, where the filling procedure would fulfilled by micro pump into desired volume and controlled by camera on reading the meniscus until the desired volume is reached.

References

[1] Astha Gautam, Anjana Kumari, and Pankaj Singh, “The Concept of Object Recognition”, International Journal of Advanced Research in Computer Science and Software Engineering volume 5, Issue 3 (2015) [2] Guidelines on The Determination of Uncertainty in Gravimetric Volume

Calibration: EURAMET cg-19 verison 2.1, 2012

[3] ISO 384 : Laboratory Glassware – Principles of Design and Construction of Volumetric Glassware

[4] ISO 4787-1984: Laboratory Glassware – Volumetric Glassware – Methods for Use and Testing of Capacity

[5] ISO Guide to the Expression of Uncertainty in Measurement, 1995 [6] Joseph, Rohini Paul, Singh, C. Senthil, and M. Manikandan, “Brain

Tumor MRI Image Segmentation and Detection in Image Processing”,

International Journal of Research in Engineering and Technology Volume 3 (2014)

[7] KAN GLK – 06: Pedoman Kalibrasi Peralatan Volumetrik, Indonesia: KAN, 2007

[8] Khushboo Khurana, Reetu Awasthi, “Techniques for Object Recognition in Images and Multi-Object Detection” International Journal of Advanced Research in Computer Engineering & Technology (IJARCET)2013

[9] Lembeck, Josephine, “The Calibration of Small Volumetric Laboratory Glassware”, Washington DC: National Bureau of Standards, 1974 [10] Standard Practice for Calibration of Laboratory Volumetric Aparatus:

ASTM International E 542 – 01

[11] T.S., Surya, and M.S., Suchita, “Survey on Different Smoke Detection

Techniques Using Image Processing”, International Journal of Research in Computer and Communication Technology (2014)

[12] Tutorialspoint.com

[13] Y.Ramadevi, T.Sridevi, B.Poornima, and B.Kalyani, “Segmentation and

Object Recognition Using Edge Detection Techniques”

[14] Yadav, Gaurav, Gupta, Vikas, Gaur, Vinod, and Bhattacharya, Mahua,

“Optimized Flame Detection Using Image Processing Based Techniques”, Indian Journal of Computer Science and Engineering

Volume 3 (2012)

![Fig. 4. Concave Meniscus in a Graduated Volumetric Device [7]](https://thumb-ap.123doks.com/thumbv2/123dok/264330.506078/3.595.90.239.588.702/fig-concave-meniscus-graduated-volumetric-device.webp)