EDISI 2022

visiON

To be a Leading Company engaged in the business of providing Engineering, Production, Installation (EPI)

in Concrete Industry in Southeast Asia miSsiON

1. Providing competitive products and services, and meeting customer expectations.

2. Providing more value through business

processes that meet and fulfill the requirements and expectations of stakeholders.

3. Carrying out appropriate management and technology systems to improve the efficiency, consistency of quality, occupational safety and health with environmentally conscious.

4. Growing and developing together with working partners in a sound and sustainable manner.

5. Developing competence and welfare of

employees.

Business activities in precast concrete products were initiated by PT Wijaya Karya since 1978. The robust economic growth and developments in Indonesia at that time accelerated the growth of precast concrete products business. To anticipate it, PT Wijaya Karya continued to expand its business operations by setting up new plants/

factories and creating variety of the products.

In order to enhance its operations and professionalism, PT Wijaya Karya Beton Tbk. (Wika Beton) was established as a subsidiary company of PT Wijaya Karya on March 11, 1997.

As the Market Leader in the industry in Indonesia, Wika Beton is supported by its operation network which consists of 10 (ten) plants/

factories, and several sales offices scattered throughout Indonesia.

The operation network is created to ensure the customers’ satisfaction.

To keep up with the industry’s needs and customers’ satisfaction, Wika Beton run its operation in accordance with the current requirement such as ISO 9001:2015, occupational safety and health, etc.

PRECAST CONCRETE PRODUCTS

Precast concrete products are commonly used in the construction nowadays. Almost all of the structures require it.

It is simply because the use of precast concrete has lot of advantages.

It is fast. The components of the structures, which is made of precast concrete, can be simultaneously manufactured with the other construction activities. Hence, it saves time.

It is economical and durable. Initially, we use timber or steel in some of the structures. The use of timber will need more frequent replacement, as it is not strong and does not last long. Steel is becoming expensive. Moreover those materials require maintenance, whereas concrete is maintenance free.

Flexibility in shape. The shape can be produced in accordance to the requirement.

Quality assured. The production are centralized in one place and can be easily controlled.

Wika PC Spun Pile is produced by the process of spinning. The high level of concrete compactness as a result of centrifugal force causes Wika PC Spun Pile to have high durability and permeability to with stand certain environment condition.

PC Spun Pile is designed to bear various types of structures. It is used among others on high-rise buildings, industrial buildings, marine structures, bridges, etc.

PC Spun Square Piles is a hollow square pile which is produced by the process of spinning. The pile can be used for deep foundation of structures, such as high-rise buildings, industrial buildings, bridge, marine structures, etc. It has many advantages compared with normal square piles.

The bearing capacity is relatively equal to the normal square pile although it requires less usage of material. It is lighter so that it can reduce transportation cost.

The latest product innovation is the post tension segmental spun pile product. The pile consists of several segments that are assembled into one pile with post tension technology. The advantages of using post tension spun pile is to meet the needs of the pole with a large diameter (up to 2 m) and length adjust to the needs without using connection.

Usually used as foundation on the dock structure.

These products are used as the components of fly over or bridge structures. Initially the beams were produced only in ”I” shape. Presently, we produce box girders, U-girders, etc. and also produce voided slab, concrete diaphragm, half slab as complement of the structures.

Based on the process of stressing, girder are produce in two methods pretension and posttension, subject to the conditions and requirements.

The pretensioned girders is a monolithic girder which is economical as it does not require additional prestressing accessories and prestressing process at the construction site.

Post-tensioned girder is produced in segments and normally assembled and post tensioned at site. The segmental girder is required when the weight and size of girder does not enable it to be lifted and transported.

Prestressed Concrete Sheet Pile was initially produced in flat shape.

PC Corrugated Sheet Pile is subsequently produced to get a better performance for certain conditions.

PC sheet pile is normally used as permanent structures of retaining walls like quay walls, revetments, jetties, break waters, reclamation walls, training dykes, foot protection, dolphins, dock walls, cut off walls, river embankments, water control gates, etc.

The preference of using concrete sheet pile is for the convenience and the low cost in its construction/installation work.

The application of precast concrete products in marine structures has an additional advantages. Not only do we have faster and more economical construction work, it also make the job easier. The construction work will be more complicated if there is still cast in site concrete work.

Concrete Piles, Sheet Piles, Girders, Slabs, etc. are required for structures like wharf/jetty, bridge, break water, etc.

Railway sleeper produced by Wika Beton is monoblock pretensioned concrete sleeper using the single line production system. The production method developed by Wika Beton is flexible and suitable for the conditions in Indonesia.

The other products related to railway are catenary poles, slab for railway bridge, ballast protection wall, railway crossing, etc.

The Prestressed Spun Concrete Pole (PC Pole) produced using the centrifugal method constitutes the last generation of the electrical pole development in Indonesia. From wooden pole, steel pole and square concrete pole, prestressed spun concrete pole were subsequently introduced. This type of concrete pole is produced in various types for low-voltage, medium-voltage and high voltage electrical distribution networks. To facilitate handling in remote areas, Wika Poles are also produced in segments.

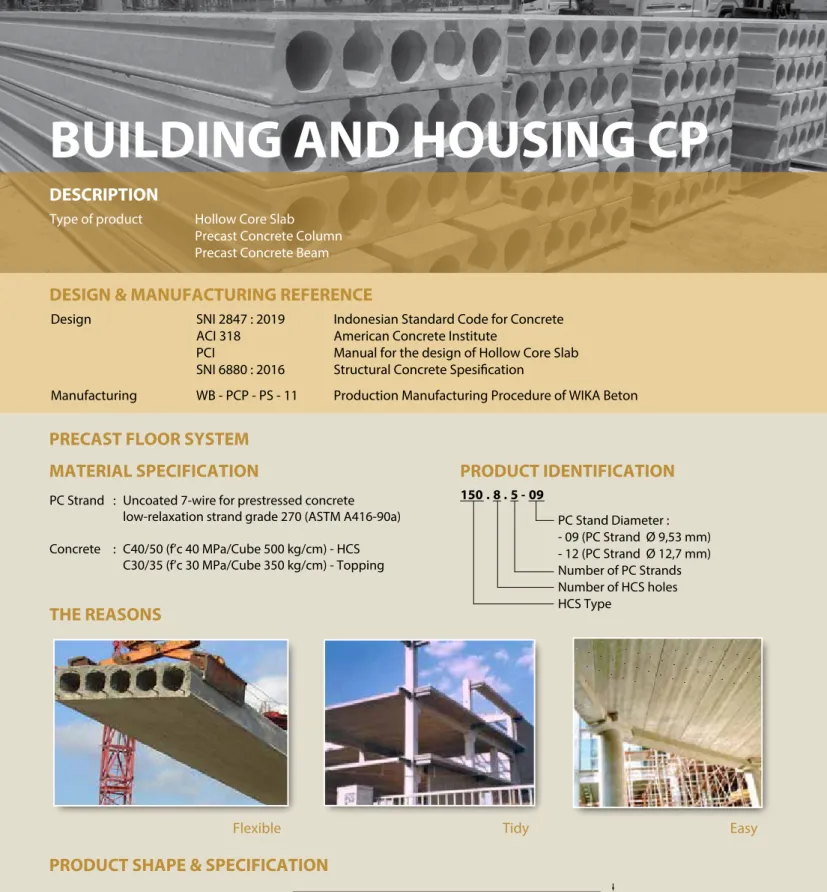

Wika Beton also produce other type of standard products as well as custom-made products as required by our customer. Some of the products are :

- Pipe Rack for oil company.

- Water Storage and Water Cooling Tower for power plant.

- Building and Housing Components.

- Fences.

- Underground Utility Ducting, etc.

The main product of this structures is concrete pipe, which consists of low pressure pipes and pressure pipes. The low pressure pipe is used as sewerage, water distribution, etc.

The pressure pipe is produced using vibro pressed centrifugal system to get high density concrete with low permeability and low shrinkage.

It is used as raw water transmission pipes as part of water treatment plant which requires very high resistance to the water pressure.

PILES

BRIDGE CONCRETE PRODUCTS

RETAINING WALL CONCRETE

PRODUCTS OTHER PRECAST CONCRETE

PRODUCTS

PRESTRESSED SPUN CONCRETE POLES

HYDRO STRUCTURE CONCRETE PRODUCTS

MARINE STRUCTURE CONCRETE PRODUCTS

RAILWAY CONCRETE PRODUCTS

PC POLES

DESCRIPTION

Type of Poles

DPC Poles Prestress Concrete Poles for Electrical Distribution Line TPC Poles Prestress Concrete Poles for Telecommunication Line

SDPC Poles Segmental Prestress Concrete Poles for Electrical Distribution Line STPC Poles Segmental Prestress Concrete Poles for Telecommunication Line System of Joints Bolt and nuts for SDPC Poles

Welding at steel joint plate for STPC Poles

DESIGN & MANUFACTURING REFERENCE

Design SNI 6880 : 2016 Structural Concrete Specification

SPLN D3.019 - 2:2021 Prestressed Concrete Poles for Distribution Line SPLN 121 : 1996 Prestressed Concrete Poles for Transmision Line

STEL-2001 Ver.2 Telecommunication Specification - Prestressed Concrete Spun Poles SNI 2847 : 2019 Indonesian Concrete Code for Concrete

Manufacturing WB - PCP - PS - 05 Production Manufacturing Procedure

PRODUCT SHAPE & SPECIFICATION | PC POLES

POLE LENGTH

TOP DIAMETER BOTTOM

DIAMETER

PRESTRESSING STEEL SPIRAL

Concrete Compressive Strength fc' = 42 MPa

Electrical Distribution Line PC Poles DPC

DPC DPC

DPC DPC

9 11 12

13 14

200 350 200 350 200 350 500 350 500 350 500

157 190 190 190 190 190 190 190 190 190 190

277 310 337 337 350 350 350 363 363 377 377

580 710 1.050 1.050 1.230 1.230 1.230 1.410 1.410 1.670 1.670

TPC TPC

7 9

150 150

124 124

202 224

300 430 Telecommunication Line PC Poles

SDPC SDPC SDPC

7 9 11

100 100 200 200

124 157 157 190

202 277 277 337

300 580 580 1.050 Segmental Electrical Distribution Line PC Poles Class Length

(m)

Horizontal Load (daN)

Weight (kg/pcs) Type

Top (mm)

Bottom (mm) Outside Diameter

PRODUCT APPLICATION

January - 2022

PC POLES

Concrete Compressive Strength fc' = 50 MPa

Segmental Electrical Transmission Line PC Poles Class Length

(m)

Horizontal Load (daN)

Weight (kg/pcs) Type

Top (mm)

Bottom (mm)

Outside Diameter

TRANSMISSION PC POLES APPLICATION

POLES FOUNDATION TYPE

POLES INSTALLATION METHOD

Installation by Lifting Crane Installation by Box Equipment Embeded foundation Base Plate foundation STPC

STPC

STPC

STPC

STPC

STPC

STPC

STPC 17

18

19

22

23

25

27

30

800 1.000 1.200 800 1.000 1.200 800 1.000 1.200 800 1.000 1.200 800 1.000 1.200 800 1.000 1.200 800 1.000 1.200 800 1.000 1.200

245 290 290 245 290 290 245 290 290 245 290 290 245 290 290 245 290 290 245 290 290 245 290 290

500 545 545 515 560 560 530 575 575 575 620 620 590 635 635 620 665 665 650 695 695 695 740 740

3.030 3.650 3.650 3.320 3.990 3.990 3.630 4.350 4.350 4.650 5.510 5.510 5.010 5.930 5.930 5.820 7.040 7.040 6.670 7.800 7.800 8.100 9.400 9.400

ITEM REFERENCE DESCRIPTION SPECIFICATION Aggregate ASTM C33/C33M-18 Standar Specification for Concrete

Aggregates Cement SNI 2049 : 2015

SNI 7064 : 2014 Portland Cement

Portland Cement Composite Standard Product Type I Special Order : Type II or V Admixture ASTM C494/C494M-19 Standar Specification for Chemmical

Admixture for Concrete Type F : High Range Water Reducing Admixture

PC Strand ASTM A416/A416M-21

SNI 1154 : 2016 Standar Specification for Steel Strand Uncoated Seven-Wire for Prestressed Concrete

Grade 270 (Low Relaxation Type) KBjP-P7 RB

PC Wire JIS G 3536 : 2014 SNI 1155 : 2016

Uncoated Stress-Relieved Steel Wires and Strand for Prestressed Concrete

SWPD 1 (Deformed Wire Type) KBjP-N

PC Bar JIS G 3137 : 2008

SNI 7701 : 2016 Small Size-Deformed Steel Bar for

Prestressed Concrete Grade D - Class 1 - SBPD 1275/1420 KBjP-Q N1

Rebar SNI 2052 : 2017 Reinforcement Steel for Concrete Steel Class : BjTS 420 A/B (Deformed) Steel Class : BjTP 280 (Round) Spiral Wire

Note : *) Chapter 4 Structural design requirement for piles with no seismic loading (In case pile is consider to seismic loading, piles detail should re-design refer to ACI 543R chapter 5

JIS G 3532 : 2011 Low Carbon Steel Wire SWM-P (Round Type)

Cold-reduced steel wire for the reinforcement of concrete and manufacture of welded fabric Joint Plate JIS G 3101 : 2015 Rolled Steel for General Structure SS400 (Tensile Strength 400 N/mm2)

Applicable steel product for steel plates and sheets, steel strip in coin, sections, flats and bars

Welding ANSI / AWS D1.1 : 2015 Structural Welding Code Steel AWS A5.1/E6013

NIKKO STEEL RB 26/ RD 260, LION 26 or equivalent Concrete SNI 2834 : 2000

SNI 2493 : 2011 Concrete Mix Design

Making and Curing Concrete Sample

PC PILES

DESCRIPTION

Type of PC Poles Prestress Concrete Pretension Spun Piles

Prestress Concrete Post-Tension Spun Piles (Cylinder Piles) Prestress Concrete Square Piles

Prestress Concrete Triangular Piles Prestress Concrete Spun Square Piles System of Joints Welding at steel joint plate

Type of Shoe Concrete Pencil Shoe (Standard) for PC Spun Piles, Spun Square Piles & Square Piles Mamira Shoe (Special Order) for PC Spun Piles

Method of Driving Dynamic Pile Driving : Diesel Hammer and Hydraulic Hammer Static Pile Driving : Hydraulic Static Pile Driver (Jacking Pile) Inner Borring System

MATERIAL SPECIFICATION

August - 2022

DESIGN AND MANUFACTURING REFERENCE

Design SNI 6880 : 2016 Structural Concrete Specification

ACI 543R* Design, Manufactured and Installation of Concrete Piles PCI 7

thEdition Precast and Prestressed Concrete

SNI 2847 : 2019 Indonesian Concrete Code for Concrete Manufacturing WB - PCP - PS - 05 Production Manufacturing Procedure

WB - PCP - PS - 06 Production Manufacturing Procedure for Cylinder Piles WB - PCP - PS - 08 Production Manufacturing Procedure for Square Piles

PC PILES

PILE SHAPE | PRESTRESSED CONCRETE PRETENSION SPUN PILES

PILE LENGTH SIZE

JOINT PLATE

WITHOUT JOINT PLATE (UPPER PILE) JOINT PLATE

MIDDLE / UPPER PILE

PILE LENGTH SIZE

JOINT PLATE

WITHOUT JOINT PLATE FOR SINGLE PILE PENCIL SHOE

BOTTOM / SINGLE PILE

PRESTRESSING STEEL SPIRAL

SIZE

WALL (t) PILE SECTION

SPECIFICATION | PRESTRESSED CONCRETE PRETENSION SPUN PILES

Concrete Compressive Strength fc' = 52 MPa Size

(mm)

Thickness Wall

(t)

Cross Section

(cm2)

Section inertia (cm4)

WeightUnit (kg/m)

Class

Bending Moment Crack*

(kN.m) Break (kN.m)

Allowable Compression

(kN)

Decompression Tension

(kN)

Handling with

“C Hook” at pile edge (m)

Length of Pile (m) Single/Double***

Unit Conversion 1 Ton = 9,806 kN

300

350

400

450

500

600

800

1.000**

1.200**

60

65

75

80

90

100

120

140

150

452

582

766

930

1.159

1.571

2.564

3.782

4.948

34.608

62.163

106.489

166.570

255.324

510.509

1.527.870

3.589.571

6.958.137 113

145

191

232

290

393

641

946

1.237 A2 A3 B C A1 A3 B C A2 A3 B C A1 A2 A3 B C A1 A2 A3 B C A1 A2 A3 B C A1 A2 A3 B C A1 A2 A3 B C A1 A2 A3 B C

24,5 29,4 34,3 39,2 34,3 41,2 49,0 58,8 53,9 63,7 73,5 88,3 73,5 83,4 98,1 107,9 122,6 103,0 122,6 137,3 147,1 166,7 166,7 186,3 215,7 245,2 284,4 392,2 451,1 500,1 539,3 637,4 735,5 804,1 912,0 1.029,6 1.176,7 1.176,7 1.274,8 1.421,9 1.667,0 1.961,2

36,8 44,1 61,8 78,4 51,5 61,8 88,3 117,7 80,9 95,6 132,4 176,5 110,3 125,0 147,1 194,2 245,2 154,4 183,9 205,9 264,8 333,4 154,4 183,9 205,9 264,8 333,4 588,4 676,6 750,2 970,8 1.274,8 1.103,2 1.206,1 1.367,9 1.853,3 2.353,4 1.765,1 1.912,2 2.132,8 3.000,6 3.922,4

714 696 664 637 916 898 865 828 1.210 1.192 1.126 1.088 1.490 1.453 1.418 1.385 1.315 1.843 1.806 1.754 1.738 1.648 2.506 2.487 2.415 2.329 2.239 4.065 3.976 3.920 3.798 3.629 5.990 5.901 5.774 5.626 5.420 7.824 7.648 7.511 7.365 7.042

221 288 409 513 294 361 484 626 369 437 683 833 374 511 641 764 1.034 520 656 849 910 1.253 671 741 1.008 1.328 1.678 1.188 1.513 1.721 2.180 2.836 1.782 2.109 2.579 3.133 3.927 2.375 3.021 3.529 4.079 5.325

10 11 12 14 11 12 13 15 11 12 14 16 11 13 14 15 17 12 13 15 15 18 13 14 16 18 19 16 18 19 21 23 18 20 21 23 25 21 22 24 25 29

11 / 16 12 / 17 14 / 19 15 / 20 12 / 17 13 / 18 14 / 20 16 / 21 13 / 18 13 / 19 16 / 21 17 / 23 13 / 18 14 / 19 15 / 21 16 / 22 18 / 24 14 / 19 15 / 21 16 / 22 17 / 23 19 / 25 15 / 21 16 / 21 17/ 23 19 / 25 21 / 28 18 / 24 20 / 26 20 / 27 22 / 29 24 / 30 21 / 27 22 / 29 23 / 30 25 / 30 27 / 30 23 / 29 25 / 30 26 / 30 27 / 30 30 / 30 Note : *) Crack Moment Based on JIS A 5335-1987 (Prestressed Spun Concrete Piles)

** ) Type of Shoe for Bottom Pile is Mamira Shoe

***) Number of Pile Lifting Position on Handling Process for Pile Driving Case 1 = Single Lifting Point Position : Minimum 1 m from end of Pile

Case 2 = Double Lifting Point Position (Using Pulley) : First Point Minimum 1,5 m from end of Pile

Second Point Minimum 1/3 L from end of Pile

PILE SHAPE | PRESTRESSED CONCRETE POST-TENSION SPUN PILES (CYLINDER PILES)

PILE SECTION PILE SEGMENT

POST-TENSION HOLE Ø 35 MM

WALL (t) SIZE

LONGITUDINAL REBAR

SPIRAL WIRE

SIZE

SEGMENT LENGTH

SPECIFICATION | PRESTRESSD CONCRETE POST-TENSION SPUN PILES (CYLINDER PILES)

Concrete Compressive Strength fc' = 52 MPa

PRODUCTION, PILE ASSEMBLING AND DISTRIBUTION PROCESS

Post-tensioning

Stockyard Facility Cylinder Pile Distribution

(mm)Size

Thickness Wall(t)

Cross Section

(cm2)

Section inertia (cm4)

Unit Weight

(kg/m) Class Allowable

Compression (kN)

Length of Pile (m) Single/Double*

(kN.m) (kN.m) Bending Moment Crack* Ultimate 800

1.000

1.200

1.500

1.800

2.000 120

140

150

170

200

200

2.564

3.782

4.948

7.103

10.053

11.309

1.527.870

3.589.517

6.958.136

15.962.533

32.672.563

46.369.907

641

946

1.237

1.776

2.513

2.827 A B C D A B C D A B C D A B C A B C A B C

392 539 637 735 735 1.030 1.177 1.324 1.177 1.667 1.961 2.059 2.157 2.942 3.334 3.628 4.609 5.099 4.707 5.786 6.570

637 784 1.177 1.275 1.079 1.716 2.157 2.402 1.373 2.648 3.040 3.138 2.599 4.315 5.099 4.168 6.374 7.551 5.246 7.747 9.463

4.020 3.824 3.628 3.481 5.884 5.491 5.393 5.197 7.845 7.305 6.962 6.864 11.179 10.590 10.198 15.984 15.493 14.905 17.945 17.357 16.866

24 / 36 24 / 36 30 / 42 30 / 42 24 / 36 30 / 42 30 / 48 36 / 48 30 / 48 36 / 48 42 / 54 42 / 60 36 / 48 36 / 54 42 / 60 36 / 48 36 / 54 42 / 60 35 / 55 40 / 60 45 / 65 Unit Conversion 1 Ton = 9,806 kN

Note : *) Number of Pile Lifting Position on Handling Process for Pile Driving Case 1 = Single Lifting Point Position : Minimum 1/8 L from end of Pile

Case 2 = Double Lifting Point Position (Using Pulley) : First Point Minimum 2 m from end of Pile

Second Point Minimum 1/3 L from end of Pile

SIZE

JOINT PLATE (MIDDLE PILE)

WITHOUT JOINT PLATE (UPPER PILE) MIDDLE / UPPER PILE JOINT PLATE

PILE LENGTH SIZE

JOINT PLATE (BOTTOM PILE)

WITHOUT JOINT PLATE (SINGLE PILE) BOTTOM / SINGLE PILE PENCIL SHOE

PILE SECTION PRESTRESSING STEEL

SPIRAL

SIZE

SPECIFICATION | PRESTRESSED CONCRETE SQUARE PILES

Concrete Compressive Strength fc' = 42 MPa Unit Conversion 1 Ton = 9,806 kN

Note : *) Length of Pile may exceed usual standard whenever lifted in certain position

SPECIFICATION | TYPICAL SPLICE

PILE SHAPE | PRESTRESSED CONCRETE SQUARE PILES

Size (mm)

Cross Section

(cm2)

Unit Weight

(kg/m) Class

Bending Moment Crack

(kN.m)

Ultimate (kN.m)

Allowable Compression

(kN)

Decompression Tension

(kN)

Length of Pile*

(m) Compatible

to Body Mcrack Optional Splice Class

200 x 200 250 x 250

300 x 300

350 x 350

400 x 400

450 x 450

500 x 500 400 625

900

1.225

1.600

2.025

2.500

100 156

225

306

400

506

625 A A B C A B C D A B C D A B C D A B C D A B C D

15,2 22,5 24,7 27,3 35,7 39,0 43,9 48,2 52,3 59,5 65,0 71,6 77,4 85,4 93,3 115,9 109,5 118,7 127,6 144,9 148,7 158,8 168,8 178,7

26,0 33,9 42,5 50,9 50,9 61,1 73,3 91,6 64,4 85,5 106,9 128,3 97,7 122,1 146,6 219,9 137,4 164,8 192,4 247,3 183,2 213,6 244,3 274,8

481 798 781 764 1.163 1.145 1.124 1.094 1.608 1.576 1.544 1.513 2.098 2.065 2.033 1.942 2.657 2.624 2.592 2.529 3.286 3.253 3.220 3.188

269 276 341 405 347 414 492 607 379 499 619 735 504 626 745 1.094 631 753 874 1.111 758 882 1.002 1.123

6 - 9 6 - 10 6 - 11 6 - 11 6 - 11 6 - 11 6 - 12 6 - 12 6 - 11 6 - 12 6 - 12 6 - 13 6 - 12 6 - 12 6 - 13 6 - 14 6 - 12 6 - 13 6 - 13 6 - 14 6 - 13 6 - 13 6 - 14 6 - 14

I III

II I IV III II I III

II I I IV III II I III III II I III

II I I

II IV - II V IV/V

- III/IV/V

IV - IV III/IV

V IV/V III/IV/V II/III/IV/V

IV IV III/IV II/III/IV

IV III/IV II/III/IV II/III/IV

Size (mm)

Bending Moment

Class Tension

Crack

(kN.m) Ultimate

(kN.m) Allowable (kN) Ultimate

(kN.m) 200 x 200

250 x 250

300 x 300

350 x 350

400 x 400

450 x 450

500 x 500 I II I II III IV I II III IV V I II III IV I II III IV V I II III IV I II III IV

15,3 7,5 31,1 29,3 22,9 12,6 58,4 44,4 42,0 38,8 22,9 75,2 66,8 56,0 32,4 119,6 110,6 92,3 84,1 38,9 154,9 138,0 127,7 64,2 193,4 161,9 148,5 74,1

20,7 10,0 42,0 39,5 31,1 17,1 78,9 60,0 56,7 52,5 31,0 101,5 90,1 75,6 43,6 161,5 149,3 124,6 113,6 52,6 209,2 186,3 172,3 86,7 261,1 218,6 200,3 100,1

410 160 541 406 406 240 820 615 541 406 240 820 820 541 271 1.157 867 820 615 271 1.446 1.157 867 410 1.163 1.157 867 410

461 180 609 457 457 270 923 692 609 457 270 923 923 609 305 1.301 976 923 692 305 1.626 1.301 976 461 1.308 1.300 976 461

Upper Pile 300x300 Class A Mom. Crack = 35,7 kN.m Mom. Ultimate = 50,9 kN.m Decomp. Tension = 347 kN

Splice : Class IV

Mom. Ultimate = 38,8 kN.m Tens. Allowable = 406 kN Splice of PC Piles having equivalent performance to the crack bending moment of the main body.

Application of optional splices should be approved by structure designer.

Bottom Pile 300x300 Class A Mom. Crack = 35,7 kN.m Mom. Ultimate = 50,9 kN.m Decomp. Tension = 347 kN

Upper Pile 300x300 Class A Mom. Crack = 35,7 kN.m Mom. Ultimate = 50,9 kN.m Decomp. Tension = 347 kN

Splice : Class V

Mom. Ultimate = 22,9 kN.m Tens. Allowable = 240 kN

Bottom Pile 300x300 Class A Mom. Crack = 35,7 kN.m Mom. Ultimate = 50,9 kN.m Decomp. Tension = 347 kN

EXAMPLES OF SPLICE SELECTION

Case 1 : Compatible to Body Moment Crack

Case 2 : Optional Splice

Piles Foundation for Power Plant or Industrial Factory

Piles for Marine Structurer Piles Foundation for Building Piles Foundation for Bridges

PRODUCT APPLICATION

Size (mm) 280 320

318,7 422,6

9.080 16.189

79,7 105,7

A B A B

6,5 8,8 8,7 11,8

9,0 17,4 10,9 21,1

414 387 559 531

269 276 341 405

6 - 8 6 - 9 6 - 8 6 - 9 Cross

Section (cm2)

Section inertia (cm4)

Unit Weight

(kg/m) Class

Bending Moment Crack

(kN.m) Ultimate (kN.m)

Allowable Compression

(kN)

Decompression Tension

(kN)

Length of Pile*

(m) Unit Conversion 1 Ton = 9,806 kN

PILE SHAPE | PRESTRESSED CONCRETE TRIANGULAR PILES

PILE LENGTH SIZE

JOINT PLATE (MIDDLE PILES)

WITHOUT JOINT PLATE (UPPER PILES) MIDDLE / UPPER PILES JOINT PLATE

PILE LENGTH SIZE

JOINT PLATE (BOTTOM PILES)

WITHOUT JOINT PLATE (SINGLE PILES) BOTTOM / SINGLE PILES PENCIL SHOE

PRESTRESSING STEEL SPIRAL

SIZE

WALL (t)

PILE SECTION

PILE SHAPE | PRESTRESSED CONCRETE SPUN SQUARE PILES

PILE LENGTH SIZE

JOINT PLATE (MIDDLE PILE)

WITHOUT JOINT PLATE (UPPER PILE) MIDDLE / UPPER PILE JOINT PLATE

PILE LENGTH SIZE

BOTTOM / SINGLE PILE

PRESTRESSING STEEL

SPIRAL

SIZE SIZE JOINT PLATE (MIDDLE PILE)

WITHOUT JOINT PLATE (UPPER PILE)

PILE SECTION

SPECIFICATION | PRESTRESSED CONCRETE SQUARE PILES

Concrete Compressive Strength fc' = 42 MPa

SPECIFICATION | PRESTRESSED CONCRETE SQUARE PILES

Concrete Compressive Strength fc' = 52 MPa Unit Conversion 1 Ton = 9,806 kN

Size (mm) 400 x 400

450 x 450 75

80

1.109

1.365

194.159

307.000

63,7 78,4 98,1 107,9 83,4 107,9 127,5 132,4 1.132,6

373 425 717 899 375 519 658 793 1.118

6 - 13 6 - 14 6 - 15 6 - 16 6 - 13 6 - 15 6 - 16 6 - 16 6 - 16 98,1

117,7 176,5 215,7 122,6 166,7 204,9 235,3 304,0

1.791 1.771 1.698 1.662 2.226 2.186 2.148 2.111 2.041 277

341 A2 A3 B C A1 A2 A3 B C Thickness

Wall (t)

Cross Section

(cm2)

Section inertia (cm4)

Unit Weight

(kg/m) Class

Bending Moment

Note : *) Length of Pile may exceed usual standard whenever lifted in certain position Crack

(kN.m)

Ultimate (kN.m)

Allowable Compression

(kN)

Decompression Tension

(kN)

Length of Pile*

(m)

INTERACTION DIAGRAM

INTERACTION DIAGRAM OF PC SPUN PILE

DIAMETER 300 INTERACTION DIAGRAM OF PC SPUN PILE

DIAMETER 350

AXIAL LOAD (kN)

MOMENT (kN-M)

AXIAL LOAD (kN)

MOMENT (kN-M)

INTERACTION DIAGRAM OF PC SPUN PILE DIAMETER 450

AXIAL LOAD (kN)

MOMENT (kN-M) INTERACTION DIAGRAM OF PC SPUN PILE

DIAMETER 400

AXIAL LOAD (kN)

MOMENT (kN-M)

INTERACTION DIAGRAM OF PC SPUN PILE DIAMETER 600

AXIAL LOAD (kN)

MOMENT (kN-M) INTERACTION DIAGRAM OF PC SPUN PILE

DIAMETER 500

AXIAL LOAD (kN)

MOMENT (kN-M)

INTERACTION DIAGRAM OF PC SPUN PILE DIAMETER 1000

AXIAL LOAD (kN)

MOMENT (kN-M)

INTERACTION DIAGRAM OF PC SPUN PILE DIAMETER 1200

AXIAL LOAD (kN)

MOMENT (kN-M) INTERACTION DIAGRAM OF PC SPUN PILE

DIAMETER 800

AXIAL LOAD (kN)

MOMENT (kN-M)

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

INTERACTION DIAGRAM

INTERACTION DIAGRAM OF PC SPUN PILE

DIAMETER 300 INTERACTION DIAGRAM OF PC SPUN PILE

DIAMETER 350

AXIAL LOAD (kN)

MOMENT (kN-M)

AXIAL LOAD (kN)

MOMENT (kN-M)

INTERACTION DIAGRAM OF PC SPUN PILE DIAMETER 450

AXIAL LOAD (kN)

MOMENT (kN-M) INTERACTION DIAGRAM OF PC SPUN PILE

DIAMETER 400

AXIAL LOAD (kN)

MOMENT (kN-M)

INTERACTION DIAGRAM OF PC SPUN PILE DIAMETER 600

AXIAL LOAD (kN)

MOMENT (kN-M) INTERACTION DIAGRAM OF PC SPUN PILE

DIAMETER 500

AXIAL LOAD (kN)

MOMENT (kN-M)

INTERACTION DIAGRAM OF PC SPUN PILE DIAMETER 1000

AXIAL LOAD (kN)

MOMENT (kN-M)

INTERACTION DIAGRAM OF PC SPUN PILE DIAMETER 1200

AXIAL LOAD (kN)

MOMENT (kN-M) INTERACTION DIAGRAM OF PC SPUN PILE

DIAMETER 800

AXIAL LOAD (kN)

MOMENT (kN-M)

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

Diagram Interaction of crack load Diagram Interaction of nominal load

RAILWAY CONCRETE PRODUCT

DESCRIPTION

Type of Railway Product PC Sleepers Prestress Concrete Sleepers for Mainlane & Depo PC Bearers Prestress Concrete Bearers for Turnout & Scissors PC Catenary Poles Prestress Concrete Catenary Poles for Electrical Line

DESIGN & MANUFACTURING REFERENCE

Design PD No.10 Perumka Indonesian Railways Design Reference

AREMA Chapter 30 - 2009 American Railway Engineering and Maintenance of Way Association BS EN 13230 : 2016 (series) Railway Application - Track - Concrete Sleepers and Bearers

SNI 8828 : 2019 SNI Bantalan Beton dan Sistem Penambat untuk Jalan Rel AS 1085 : 2003 (series) Australian Standard

TB/T 3080 - 2030 Technical Concrete Sleeper Railway Industry Standards GOST 10629 - 1988 Prestressed Concrete Sleepers for Railway Wide 1.520 mm JIS A 5373 : 2010 Precast Prestressed Concrete Products

SNI 6880 : 2016 Structural Concrete Spesification

PRODUCT SHAPE | PC SLEEPERS

2440

330

195 220

SLEEPER S-35 BALLASTED

180

180

SPECIFICATION | PC SLEEPERS

Note : *) Type of Rail is available for R-33, R-38, R-40, R-42, R-50, R-54 & R-60

**) Type of fastening is available for Pindad E-Clip, Pandrol E-Clip, Vossloch Clip, DE-Clip or others adjustable to customer requirement Track

Gauge */**

(mm) N-1067 N-1067 S-1435 S-1435 S-1435

Ballasted Ballastless

Ballasted Ballastless Ballasted/Ballastless

180 180 250 120 300

150 150 200 100 50

2.000 2.000 2.440 2.150 2.600

52 52 62 52 62

190 250 300 270 328 Track Type Design Axle Load

(kN)

Design Speed (km/hour)

Sleeper Length (mm)

Compresive Strength

(MPa)

Sleeper Weight (kg)

April - 2022

Manufacturing WB - PCP - PS - 10 Production Manufacturing Procedure

2000

250

190

150

210

SLEEPER N-67 BALLASTED

SLEEPER N-67

BALLASTLESS SLEEPER S-35

BALLASTLESS 150

2000

240

205 185

214

2150

271

241 140

197

RAIL W AY CP

PRESTRESSING STEEL SPIRAL

WALL (t)

PRODUCT SHAPE | PC BEARER FOR SWITCHES AND CROSSINGS SPECIFICATION | PC CATENARY POLES

Concrete Compressive Strength fc' = 52 MPa

Type C-50 C-65 C-75 C-110 C-150

350 350 350 400 450

5,00 6,50 7,50 11,00 15,00

10,00 13,00 15,00 22,00 30,00

11 - 14 11 - 14 11 - 14 11 - 14 11 - 14 70

70 70 75 80

616 616 616 766 930

64.115 64.115 64.115 106.489 166.570

154 154 154 191 232 Outside

Diameter

(mm) Crack

(ton.m) Ultimate (ton.m) Thickness

Wall (mm)

Cross Section

(cm2)

Section Inertia (cm4)

Unit Weight (kg/m)

Length of Pile

(m) Bending Moment

TURNOUT ARRANGEMENT LENGTH

TOP DEPTH

BOTTOM

SPECIFICATION | PC BEARER FOR SWITCHES AND CROSSINGS

Concrete Compressive Strength fc' = 62 MPa

Type N1067

S1435 154 Variable 220 300 260

Length Depth Bottom Top Unit Weight

(kg/m)

Dimension (mm)

Note :

1. Type, quantity and dimension of PC Bearer for Switches and Crossing per arrangement is adjustable to customer requirement 2. Type of fastening is adjustable to customer requirement

PRODUCT SHAPE | PC CATENARY POLES

PRODUCT APPLICATION

Railway Sleepers Railway Catenary Poles Railway Turnout Railway Bridges

BRIDGE CONCRETE PRODUCT

DESCRIPTION

Type of PC Girder PC U Girder PC I Girder

PC Voided Slab PC Segmental Box Girder Type of Precast Bridge Floor PC Double Tee PC / RC Full Depth Slab

PC Channel Girder Prestress System Post-Tension or Pretension

DESIGN AND MANUFACTURING REFERENCE

Design SNI 6880 : 2016 Structural Concrete Specification

SNI T - 12 - 2004 Indonesian Concrete Code : Bridge Concrete Design SNI 1725 : 2016 Indonesian Concrete Code : Design Load for Bridge PCI 7

thEdition Precast and Prestressed Concrete

AASHTO - LRFD Bridge Design Specifications 2017 Manufacturing WB - PCP - PS - 07 Production Manufacturing Procedure

WB - PCP - PS - 08 Production Precast Product Procedure

GIRDER SHAPE & DIMENSION | PC U GIRDER

SPECIFICATION | POST-TENSION PC U GIRDER

Note : Based on bridge load refer to SNI 1725 : 2016 and assume bridge section parameter : 250 mm for CIP Slab, 70 mm concrete deck slab and 50 mm (+50 mm / -0 mm) asphaltic layer

August - 2022 PC U H-120 cm

Spacing/fc'Beam (cm/MPa)

Beam Support Reaction (kN) Span

(m) 13 1415 1617 18 1920 21 2223 2425 26 2728 29 3031 3233 34 3536 37 3839 4041 42 4344 45 4647 4849 50

310/45 310/45 310/45 310/45 310/45 310/45 310/45 310/45 310/45 270/45

412 442472 506539 569 599629 660 612

495 504513 520526 532 537542 546 496

1.436 1.494 1.549 1.607 1.663 1.713 1.763 1.811 1.859 1.702 VDL VLL Vult

PC U H-140 cm Spacing/fc'Beam

(cm/MPa)

Beam Support Reaction (kN)

310/45 310/45 310/45 310/45 310/45 310/45 310/45 310/50 310/50 310/50 310/50 270/50

599 630662 694 725757 788820 858 890921 988

532 537542 546 550554 557561 575 589603 562

1.749 1.800 1.850 1.900 1.949 1.997 2.045 2.095 2.170 2.237 2.304 2.304 VDL VLL Vult

PC U H-165 cm Spacing/fc'Beam

(cm/MPa)

Beam Support Reaction (kN)

310/45 310/45 310/45 310/45 310/45 310/50 310/50 270/50

849881 913945 997 1.009 1.041 988

587590 592603 617 631638 561

2.172 2.219 2.266 2.328 2.395 2.463 2.518 2.304 VDL VLL Vult

PC U H-185 cm Spacing/fc'Beam

(cm/MPa)

Beam Support Reaction (kN)

310/50 310/50 310/50 310/50 310/50 310/60 310/60 270/60 270/60

1.124 1.163 1.197 1.231 1.264 1.297 1.331 1.260 1.290

645652 659 666673 680686 604 610

2.634 2.698 2.754 2.811 2.867 2.924 2.981 2.730 2.781 VDL VLL Vult

PC U H-210 cm Spacing/fc'Beam

(cm/MPa)

Beam Support Reaction (kN)

310/60 310/60 310/60 310/60 270/60

1.481 1.518 1.552 1.587 1.505

701 708715 722635

3.194 3.253 3.311 3.370 3.095 VDL VLL Vult

PC U H-230 cm Spacing/fc'Beam

(cm/MPa)

Beam Support Reaction (kN)

310/60 310/60 310/60 310/60 310/70 270/70 270/70

1.703 1.740 1.777 1.814 1.851 1.830 1.866

729 736 743750 757665 671

3.526 3.586 3.647 3.707 3.768 3.564 3.621 VDL VLL Vult

A

H

300 300

H

(cm) A

(cm) Area

(cm2) Inertia

(cm4) 120140

165 185210 230

172172 190 190190 208

9.178 10.366 11.878 13.066 14.678 15.936

12.633.291 19.634.469 31.358.776 43.340.406 62.328.088 80.742.448

BRIDGE CP

GIRDER SHAPE & DIMENSION | PC I GIRDER

210 80

70 20

PC I H-210

Area : 7.495 cm2 Inertia : 41.087.033 cm4 170

80

70 20

PC I H-170

Area : 6.695 cm2 Inertia : 23.641.085 cm4 160

55

65 18

PC I H-160

Area : 4.773 cm2 Inertia : 14.611.104 cm4 125

35

65 17

PC I H-125

Area : 3.167 cm2 Inertia : 5.496.255 cm4 35

90

65 17

PC I H-90

Area : 2.572 cm2 Inertia : 2.266.607 cm4

SPECIFICATION | POST-TENSION PC I GIRDER

Note : Based on bridge load refer to SNI 1725 : 2016 and assume bridge section parameter : 250 mm for CIP Slab, 70 mm concrete deck slab and 50 mm (+50 mm / -0 mm) asphaltic layer

*) H-210 Dapped End with additional web thickness 50 mm and RIB Span

(m) 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45*

46*

47*

48*

49*

50*

185/45 185/45 185/45 185/45 185/45 185/45 140/45

146 160 175 189 203 218 190

316 327 337 345 351 357 303

761 800 835 868 899 928 793 PC I H-90 cm

Beam Support Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

185/45 185/45 185/45 185/45 185/45 185/45 140/45 140/50

249 264 279 294 309 324 280 292

362 367 371 374 378 380 321 323

976 1.004 1.031 1.057 1.082 1.107 940 960 PC I H-125 cm

Beam Support Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

185/45 185/45 185/45 185/45 185/45 185/45 185/45 185/45 140/45 140/45

393 410 427 444 460 477 494 511 452 466

383 386 388 390 392 393 395 397 333 334

1.197 1.223 1.249 1.274 1.300 1.325 1.350 1.374 1.178 1.199 PC I H-160 cm

Beam Support Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

185/45 185/45 185/45 185/45 185/45 185/45 185/45 185/45 185/50 140/45 140/45 140/50

587 606 628 647 666 684 703 722 741 655 671 687

398 399 401 402 403 404 405 406 410 341 342 343

1.469 1.496 1.526 1.553 1.579 1.605 1.630 1.656 1.687 1.447 1.469 1.490 PC I H-170 cm

Beam Support Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

185/45 185/45 185/45 185/45 185/45 185/45 185/45 185/45 185/50 185/50 185/60 185/60 185/60 140/60 140/60 140/60

735 754 774 794 814 833 858 878 897 917 996 1.017 1.038 929 946 966

404 405 406 410 414 418 422 427 431 435 439 443 447 346 347 348

1.665 1.692 1.719 1.751 1.784 1.817 1.855 1.888 1.921 1.954 2.092 2.127 2.162 1.824 1.848 1.876 PC I H-210 cm

Beam Support Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

GIRDER SHAPE & DIMENSION | PC VOIDED SLAB

PC VS-74/97 Area : 5.032 cm2 Inertia : 2.977.551 cm4 PC VS-57/97

Area : 4.397 cm2 Inertia : 1.411.372 cm4

PC VS-62/97 Area : 4.420 cm2 Inertia : 1.785.520 cm4

PC VS-66/97 Area : 4.784 cm2 Inertia : 2.170.299 cm4

SPECIFICATION | POST-TENSION VOIDED SLAB

Note : Based on bridge load refert to SNI 1725 : 2016 and assume bridge cross section parameter only 50 mm asphaltic layer without over topping CIP Slab

SPECIFICATION | POST-TENSION VOIDED SLAB WITH OVERTOPPING

30 39

74

97 30

33

66

97 30

31

62

97 25

28,5

57 97

PC VS-57+18/97

Area : 5.766 cm2 Inertia : 2.855.560 cm4

PC VS-62+18/97

Area : 5.815 cm2 Inertia : 3.435.186 cm4

PC VS-66+18/97

Area : 6.201 cm2 Inertia : 4.020.154 cm4

PC VS-74+18/97

Area : 6.492 cm2 Inertia : 5.300.499 cm4

18

30 39

74

97 30

33

66

97 25

28,5

57

18 18

97

30 31

62 97

18

Span (m)

6 7 8 9 10 11 12 13 14 15 16

PC VS 57/97 PC VS 62/97 PC VS 66/97 PC VS 74/97

97/50 97/50 97/50 97/50 97/50 97/50

39 45 51 57 63 69

195 209 219 228 234 239

400 433 459 482 501 518 Beam Support

Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

97/50 97/50 97/50 97/50 97/50 97/50 97/50

39 45 52 58 64 70 76

195 209 219 228 234 239 244

401 434 460 483 502 520 535 Beam Support

Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50

42 49 55 62 69 75 82 89

195 209 219 228 234 239 244 248

404 438 465 488 508 526 542 557 Beam Support

Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50

44 51 58 65 72 79 86 93 103 110 117

195 209 219 228 234 239 244 248 251 254 256

407 441 468 492 512 531 547 563 580 594 607 Beam Support

Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

Span (m)

6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

PC VS 57/97 PC VS 62/97 PC VS 66/97 PC VS 74/97

97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/60 97/70

61 71 81 91 101 111 121 131 143 152 162

111 119 125 130 134 137 139 141 143 145 146

279 306 329 350 369 388 405 421 440 455 470 Beam Support

Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/60 97/70

62 72 82 92 102 112 122 132 144 154 164 174

111 119 125 130 134 137 139 141 143 145 146 147

280 307 330 351 371 389 406 423 442 457 473 487 Beam Support

Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/60 97/70 97/70 97/70

65 75 86 96 107 117 128 138 151 161 172 182 193 203

111 119 125 130 134 137 139 141 143 145 146 147 148 149

283 311 335 356 376 395 413 430 450 466 482 497 512 528 Beam Support

Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/50 97/60 97/70 97/70 97/70 97/70

67 78 89 100 110 121 132 143 156 167 177 188 199 210 221 231

111 119 125 130 134 137 139 141 143 145 146 147 148 149 150 151

286 314 338 360 381 400 418 436 456 472 489 505 520 536 551 566 Beam Support

Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

SEGMENT SHAPE & DIMENSION | PC BOX GIRDER SPAN UP TO 50 m (HIGHWAY & LIGHT RAIL TRAIN)

Height Width of slab Thickness of slab Web

Thickness Note

Top Bottom Top Bottom

2.600 mm 10.300 mm 4.000 mm 300 mm 277 mm Span by Span

External Stressing Span 40-50 m 225 mm

2.500 - 3.484 mm 13.000 mm 5.000 mm 250 - 443 mm 450 mm Balance Cantilever External Stressing Span 50-100 m 225 mm

2.400 mm 10.300 mm 4.300 mm 250 mm 300 mm Span by Span

External Stressing Span 30-40 m (Train) 300 mm

SPAN UP TO 100 m (HIGHWAY & LIGHT RAIL TRAIN)

SPAN UP TO 40 m (RAILWAY BRIDGE - RM1921 LOAD)

2.600

10.300

4.000 225

277

200

13.000

5.000 2.500 - 3.483

250

2791

443 R500

450 450

2.400

10.300

4.300 250

250

300 300

GIRDER SHAPE & SPECIFICATION | PC BULB TEE GIRDER

DIMENSION | PC BOX GIRDER

PC Bulb Tee H-230 Area : 13.677,5 cm2 Inertia : 104.700.913,6 cm4 230

240

25

120

Note : Based on bridge load refer to SNI 1725 : 2016 and assume bridge section parameter using 150 mm topping slab and 50 mm asphaltic layer

Span(m)

Bulb Tee Beam Weight (ton/pcs) Spacing/fc'

(cm/MPa)

Beam Support

VDL VLL Vult

Reaction (kN)

250/70 250/70 250/70 250/70 250/70 250/70

238 241 245 248 255 255

1.727 1.755 1.782 1.810 1.838 1.865

648 653 659 664 669 675

3.358 3.403 3.448 3.492 3.537 3.582 55

56 57 58 59 60

SLAB SHAPE & DIMENSION | PC DOUBLE TEE FOR TRUSS BRIDGE FLOOR

2100 560

200 310 50

400 100 1.100 100 400

PC DT H-56 for Class A bridge Area : 4.976 cm2 Inertia : 758.607,78 cm4

PC DT H-56 for Class B bridge Area : 4.075,97 cm2 Inertia : 702.011,25 cm4 PC DOUBLE TEE FOR TRUSS BRIDGE FLOOR

Patent Number : ID P0026747 Certified by The Ministry of Law and Human Right

Republic of Indonesia

Note :

CLASS A : 7 meter width of traffic lane with additional 1 meter kerb in each side of bridge CLASS B : 6 meter width of traffic lane with additional 0,5 meter kerb in each side of bridge

SLAB SHAPE & SPECIFICATION | FULL DEPTH SLAB FOR CONCRETE/STEEL BRIDGE FLOOR

FULL DEPTH SLAB FOR BRIDGE

SLAB LENGTH (WIDTH OF BRIDGE)

ROADWAY SLAB SLAB BEAM CONNECTION

SLAB WIDTH

CONCRETE / STEEL GIRDER SLAB THICKNESS

SLAB BEAM CONNECTION HOLE

PRODUCT APPLICATION

PC I or PC U Girder for Bridges Box Girder Bridges Double Tee Slab for Bridge Floor Full Depth Slab for Bridge Floor

150 150

1.650 560

200 310 50

175100 1.100 100175

150 150

DOUBLE TEE LATERAL STRESSING SYSTEM STRUCTURAL JOINT

STEEL TRUST BEAM 560

GIRDER SHAPE & DIMENSION | PC CHANNEL GIRDER

SPECIFICATION | PRETENSION CHANNEL GIRDER

CG 60 x 120

Area : 4.329 cm2 Inertia : 1.293.103 cm4

CG 70 x 120

Area : 4.806 cm2 Inertia : 2.023.171 cm4

CG 80 x 120

Area : 5.274 cm2 Inertia : 2.968.087 cm4

CG 90 x 120

Area : 5.728 cm2 Inertia : 4.142.306,02 cm4 1.200

580 50

50

20 20

240 240

PROJECT REFERENCE

Project Simpang Susun Semanggi (Box Girder)

Project Simpang Susun Semanggi

(Box Girder) Project Jalan Layang Kereta Api

(Box Girder) Project MRT Jakarta

(Box Girder) Span

(m)

6,6 7,6 8,69,6 10,6 11,6 12,613,6 14,6 15,6 16,617,6 18,6 19,6 20,621,6

CG 60 x 120 CG 70 x 120 CG 80 x 120 CG 90 x 120

120/50 120/50 120/50 120/50 120/50 120/50 120/50 120/60

44 50 5764 71 78 8791

220 231 237242 245 247 248249

455 483 504522 536 549 564571 Beam Support

Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

120/50 120/50 120/50 120/50 120/50 120/50 120/50 120/50 120/50 120/60 120/60

47 55 6269 77 84 9299 107 114 121

224 235 242246 249 252 253254 254 254 254

467 496 518536 552 565 578589 600 610 620 Beam Support

Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

120/50 120/50 120/50 120/50 120/50 120/50 120/50 120/50 120/50 120/50 120/50 120/60 120/60

51 59 6775 83 91 10799 115 123 131138 146

228 239 246250 254 256 257258 258 259 258258 258

478 508 531550 566 580 593606 617 628 639649 659 Beam Support

Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa)

120/50 120/50 120/50 120/50 120/50 120/50 120/50 120/50 120/50 120/50 120/50 120/50 120/60 120/60 120/70 120/70

54 63 7180 88 97 105114 122 131 140148 156 165 173182

174 170 166254 257 259 261262 262 262 262262 262 262 262262

384 388 393563 580 595 608621 633 645 656667 678 689 700712 Beam Support

Reaction (kN) VDL VLL Vult

Beam Spacing/fc'

(cm/MPa) 1.170

15 15 15 1.170 15 15 1.170 15 15 1.170 15

50 150400

600 50 150500 50 150600 50 150700

1.200

580 50

50

25 25

235 235

1.200

580 50

50

30 30

230 230

1.200

580 50

50

35 35

225 225

700 800 900