In an effort to minimize the costs of facilities in the process industries, this practice has been established based on the technical requirements in the existing standards of major industrial users, contractors or standards organizations. Although this practice is expected to cover the majority of the requirements of most users, individual applications may involve requirements that will be added to this practice and that will take precedence over this practice. Determinations as to fitness for purpose and particular matters or the application of the Practice to particular project or technical situations should not be made solely on the basis of the information contained in these materials.

The use of trade names from time to time should not be construed as an expression of preference, but rather should be recognized as normal usage in commerce. Any practices or guidelines are intended to be consistent with applicable laws and regulations, including OSHA requirements. To the extent these practices or guidelines would conflict with OSHA or other applicable laws or regulations, such laws or regulations must be followed.

Consult an appropriate professional before applying or acting on any material contained in or suggested by the Practice. Process Industry Practices (PIP), Construction Industry Institute, The University of Texas at Austin, 3925 West Braker Lane (R4500), Austin, Texas 78759.

Introduction

Purpose

Scope

Process Industry Practices

Industry Guides and Standards

Definitions

Roadway Classifications

General

Primary Roadways

Secondary Roadways

Tertiary Roadways

Construction and Heavy Haul

General Design Considerations 7

- Access to Public Roadways

- Materials

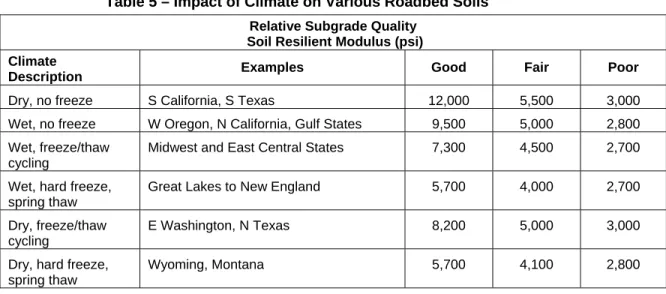

- Climate

- Traffic Loading

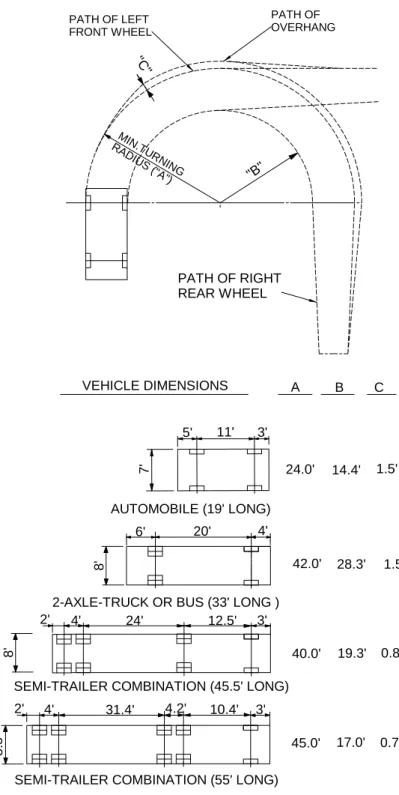

Controlled and adequate access to local streets and highways during major construction projects requires early team planning and may require investment in new road access. Property owners receive compensation for confiscated property; property owners can donate land for a priority route if they can benefit from the road project or from new or The connection from a public access point to the plant boundary can vary from a parking lot driveway to a multi-lane road with a length measured in miles.

If more than one entity is involved, it can be challenging to resolve multiple requests.

Layout and Traffic Control

- General

- Traffic Flow

- Plant Roadway

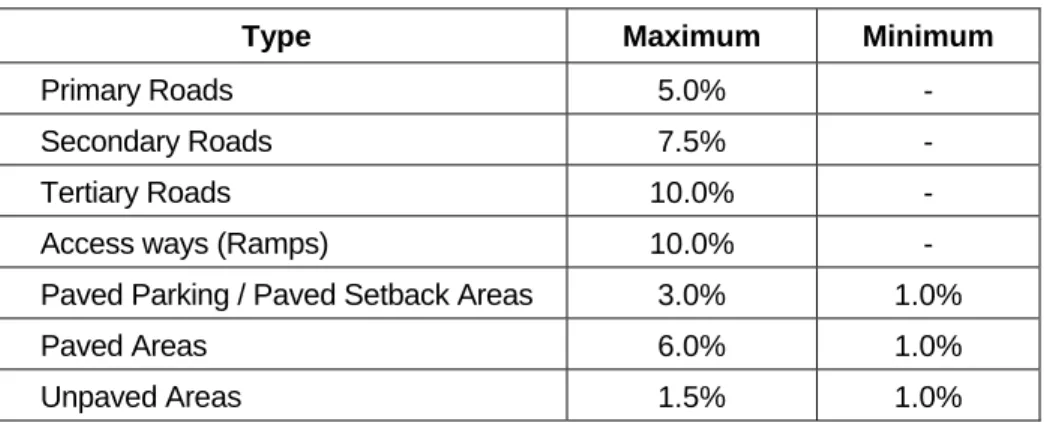

- Vertical Alignment

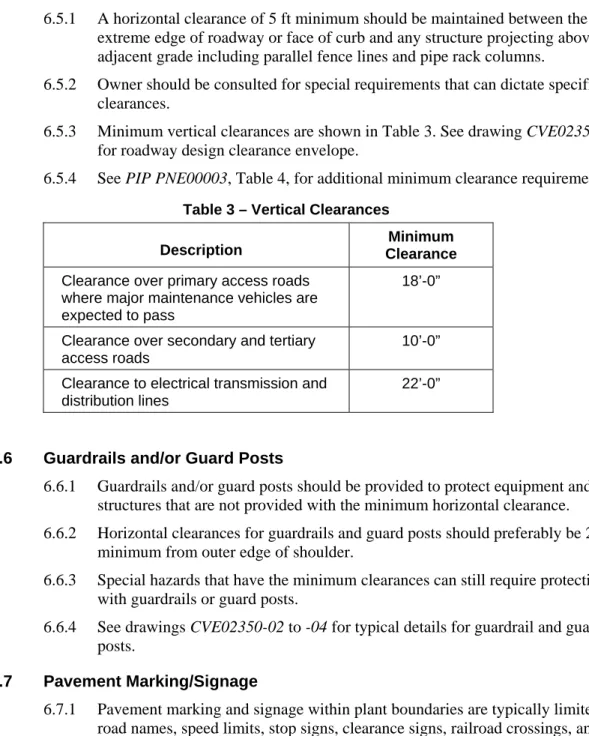

- Horizontal and Vertical

- Guardrails and/or Guard Posts

- Pavement Marking/Signage

Each curve type has three subsets, depending on the signs and relative magnitudes of the tangent gradient lines. The typical sign convention is positive for numbers increasing forward and negative for numbers decreasing forward. The minimum recommended curve length for a 5% grade change is 35 ft for a crest curve and 85 ft for a sag curve.

These lengths include factors for eye level and the object viewed that would allow 115 feet of stopping distance.

Paving/Roadway Design

- Paving System Selection

- Flexible Pavement

- Rigid Paving

- Alternative Surface Treatment for

- Paving Over Low-Strength Soils

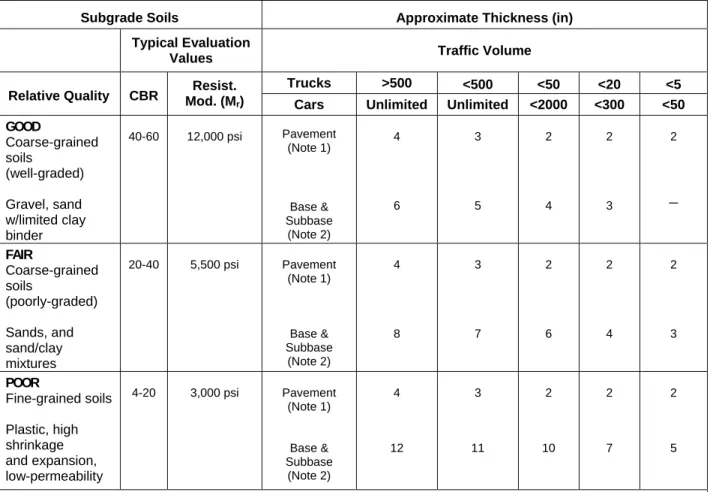

May be produced in stationary plants with careful control of the production process or mixed in place. Thickness requirements for asphalt pavements depend primarily on the strength requirements of the finished subgrade. Because the stability of the subsoil is closely related to its density and moisture content, subsoil tests must be carried out as close as possible to expected conditions.

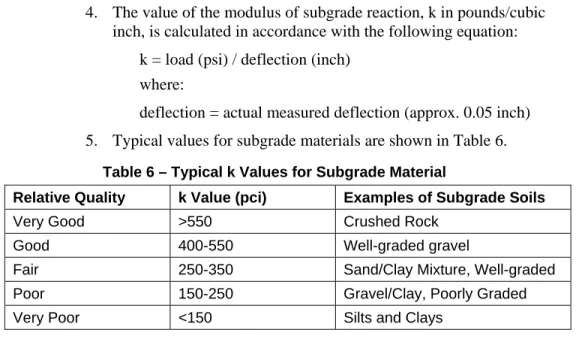

Due to the typical nature and intended use of a specific pavement and the available knowledge and experience with the local subgrade materials, pavement design can often be accomplished with confidence without a site-specific evaluation of the subgrade. If tests are required to assess the strength of the subgrade, the following tests can be used to determine the strength of the base and foundation on site: Results from one of the four test methods cannot be converted to equivalent values from another method.

The test procedure involves loading a 6- to 30-inch diameter test plate on top of the surface of the material. The deflection and recoil are measured at the plate and at distances up to 1.5 times the diameter from the edge of the plate. A resistance value test determines the thickness of a pavement structure required to prevent plastic deformation of the soil under imposed wheel loads.

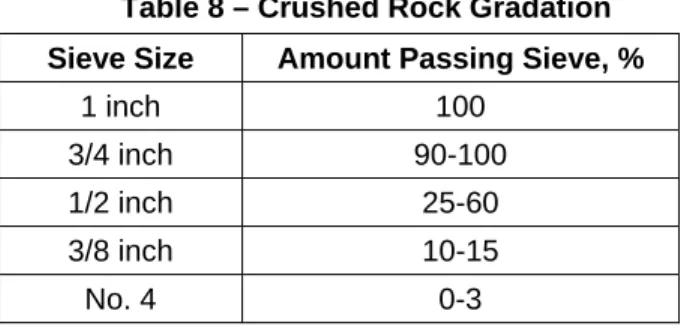

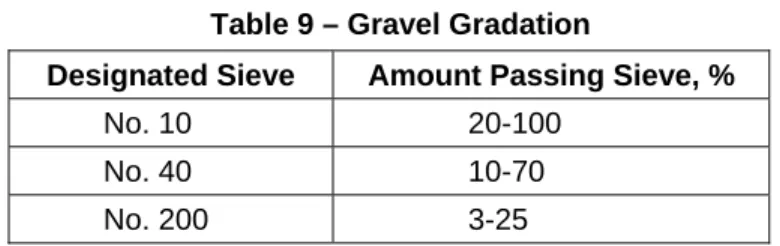

Subbase, and top 6 inches of subgrade shall be compacted to a dry density not less than 90% of the maximum dry density (Modified Proctor). Maximum size of stone should not be greater than one third of the lesser thickness of the base course or the sub-base course. Maximum size of stone should not be greater than one third of the thickness of the base layer.

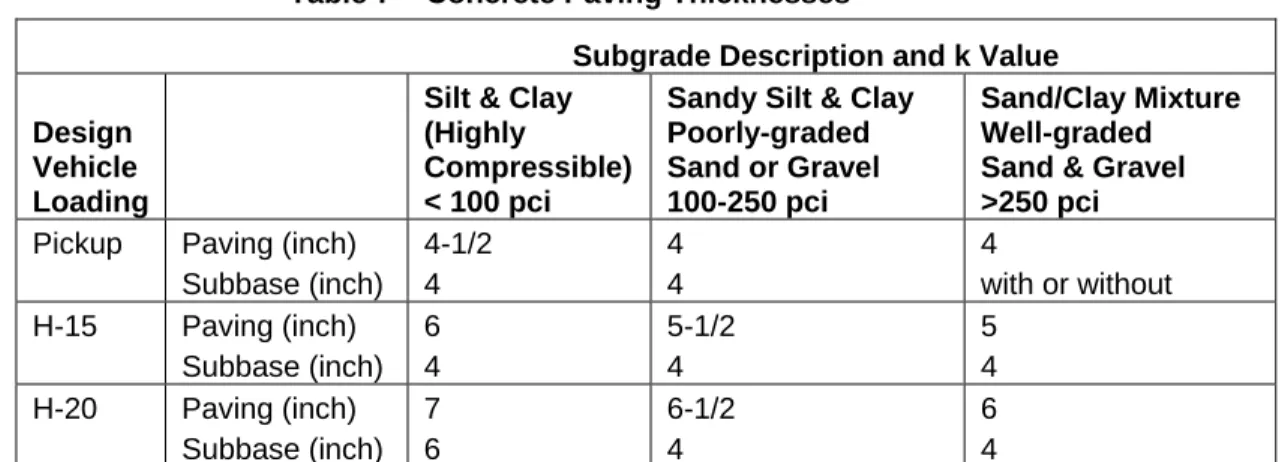

A pressure distributor should be used to spray approximately 0.2 to 0.5 gal/sq ydon of low viscosity asphalt onto the prepared subgrade surface. Due to the rigidity of the concrete slab, the concentrated wheel loads are distributed over a large supporting area of the base. 2 The module is intended for measuring the temporary (elastic) properties of the base and not the long-term load-bearing properties of the soil.

The lock prevents lateral movement of the unit and improves the distribution of the load to the substrate. Allows lateral water flow within the plane of the geotextile material and dissipates excess pore water pressure.

Drainage Considerations

- Roadway Drainage

- Culverts

- Ditches

- Curbs, Gutters and Inlets

- Headwalls

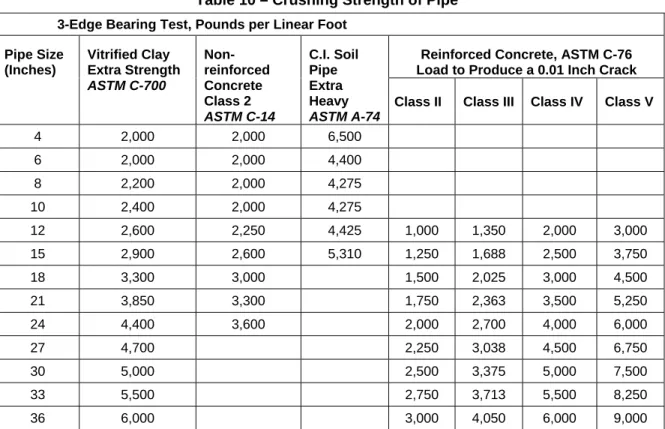

- Pipe Crushing Strength

- Pipe Loading

Concrete culverts can be made of either precast or cast-in-place reinforced concrete, depending on the size and complexity of the culvert design. Inverts of corrugated metal culverts are typically paved to extend the life of the culvert by protecting the invert from corrosion and abrasion. Unless the width of the trench is specified and controlled during construction, calculating soil loads from Anson Marston's formulas is impractical.

Pipes larger than 12 inches to 36 inches are assumed to have a channel width 2 feet greater than the outside diameter of the pipe. The width of the pipe bed and the quality of contact between the pipe and the bed after contact affect the distribution of vertical forces. The magnitude of the lateral pressure acting against the sides of a pipe and the area of the pipe over which the lateral pressure acts.

Crossings

Railroad Crossings

A factor of safety cannot be calculated by laws and equations, but depends entirely on engineering judgment and experience. Typically, rigid pipes should be designed with a higher factor of safety than flexible pipes because flexible pipes can deflect more before failure.

Pipeline Crossings

Typical Details